The global RS232 cable market continues to demonstrate steady resilience despite the rise of newer communication protocols, driven by legacy system integration in industrial automation, healthcare, and telecommunications. According to a 2023 report by Mordor Intelligence, the global serial communication market—encompassing RS232 technologies—is projected to grow at a CAGR of approximately 4.2% from 2023 to 2028. This sustained demand stems from the need for reliable, low-latency point-to-point connections in mission-critical environments. As industries across North America, Asia-Pacific, and Europe maintain vast inventories of RS232-dependent equipment, the requirement for high-quality, durable cables remains strong. This ongoing reliance has fostered a competitive manufacturing landscape, with key players focusing on signal integrity, EMI shielding, and ruggedized designs. Based on market presence, product performance, and customer reviews, the following nine manufacturers have emerged as leaders in RS232C cable production, meeting the stringent demands of modern industrial ecosystems.

Top 9 Cable Rs232C Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 SH

Domain Est. 2014

Website: deshide.com

Key Highlights: SH-RS232M USB-C to RS232 DB9 Serial Cable with FTDI Chip for Windows Linux Mac. USB-C to DB9 Serial:Designed for devices that do not have a USB-A port.Missing: rs232c manufacturer…

#2 Fundamentals of RS

Domain Est. 1990

Website: analog.com

Key Highlights: RS-232 is a complete standard. This means that the standard sets out to ensure compatibility between the host and peripheral systems….

#3 Serial communication Basic Knowledge

Domain Est. 1992

Website: contec.com

Key Highlights: Connection method. In RS-232C, the connectors and signal assignments have been standardized, so many standard-compliant cables are available commercially….

#4 5000 Series USB

Domain Est. 1995

#5 RS

Domain Est. 1997

Website: belden.com

Key Highlights: Commonly used in applications like POS and computer communications, RS-232 & RS-423 Cables offer proven reliability and performance backed by a 10-year, ……

#6 RS232 Serial Cables

Domain Est. 2000

#7 Serial Cables, RS 232 & DB9 Cable Connectors

Domain Est. 2001

Website: my.rs-online.com

Key Highlights: 7-day delivery · 10-day returnsWe offer all sorts of serial cables including db9 connector or RS 232 cable. You can simply browse through the products that we have in our store….

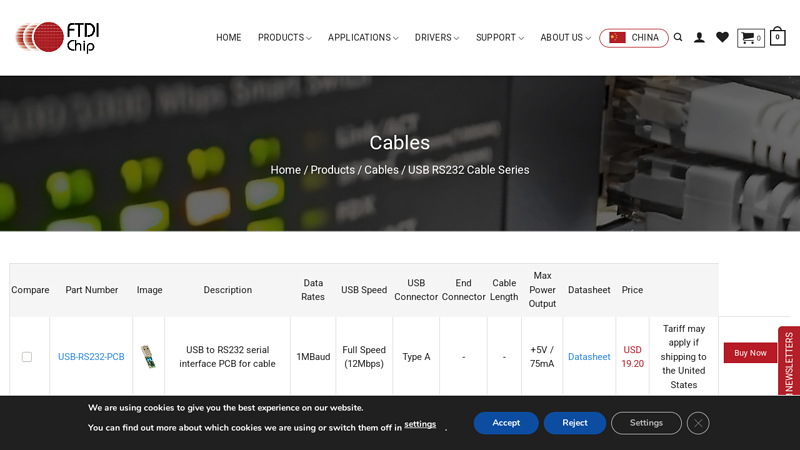

#8 USB RS232 Cable Series

Domain Est. 2001

Website: ftdichip.com

Key Highlights: USB to UART cable with RS232 level UART signals. 1MBaud, Full Speed (12Mbps), Type A, Wire ended, 1.8m, -, Datasheet, USD25.80, Tariff may apply if shipping ……

#9 MISUMI RS232C Cables

Domain Est. 2007

Website: us.misumi-ec.com

Key Highlights: Shop MISUMI RS232C Cables at MISUMI. MISUMI offers FREE CAD download, short lead times and competitive pricing. Quote and order online today!…

Expert Sourcing Insights for Cable Rs232C

H2: 2026 Market Trends for RS232C Cables

As of 2026, the market for RS232C cables—despite being a legacy serial communication standard—continues to demonstrate resilience in specific industrial, medical, and infrastructure sectors. While largely superseded by USB, Ethernet, and wireless technologies in consumer electronics, RS232C cables maintain a niche presence due to their reliability, simplicity, and compatibility with long-standing systems. The following trends define the RS232C cable market in 2026:

1. Sustained Demand in Industrial Automation and Legacy Systems

Many manufacturing plants, utility grids, and transportation systems still rely on RS232C for communication between programmable logic controllers (PLCs), Human-Machine Interfaces (HMIs), and older machinery. The high cost and operational risks associated with overhauling these systems ensure continued demand for RS232C cables, particularly in regions with aging infrastructure such as North America and parts of Europe.

2. Integration with Modern Adapters and Converters

A significant trend in 2026 is the increased use of RS232-to-USB, RS232-to-Ethernet, and RS232-to-wireless (e.g., Wi-Fi/Bluetooth) converters. These hybrid solutions allow legacy RS232C devices to interface with modern computing platforms, extending the life of older equipment. The market for such adapter-equipped RS232C cables is growing, especially in sectors like healthcare and building automation.

3. Growth in Niche and Specialized Applications

RS232C remains prevalent in specialized fields including aerospace, defense, and scientific instrumentation, where deterministic communication and noise immunity are critical. In 2026, demand is bolstered by military modernization projects and the need for secure, point-to-point communication in sensitive environments where newer protocols may introduce vulnerabilities.

4. Regional Market Disparities

Developed markets show declining organic growth for pure RS232C cables, but replacement and maintenance demand remains steady. In contrast, emerging economies—particularly in Southeast Asia, Africa, and parts of Latin America—are seeing moderate growth as industrialization brings older equipment into use or necessitates retrofitting with compatible communication cables.

5. Focus on Ruggedized and High-Reliability Versions

Manufacturers are differentiating their RS232C cable offerings by emphasizing durability, shielding, and compliance with industrial standards (e.g., IP ratings, RoHS, REACH). In 2026, there is increased demand for cables with enhanced EMI protection and extended temperature ranges, especially in harsh environments like oil & gas, mining, and outdoor telecommunications.

6. Decline in Consumer and IT Segments

The consumer electronics and general IT sectors have almost entirely phased out native RS232C ports. This has reduced the volume market, pushing suppliers to focus on B2B and OEM channels rather than retail. As a result, the RS232C cable market is increasingly specialized and less price-sensitive.

7. Environmental and Regulatory Pressures

Environmental regulations continue to influence material choices in cable manufacturing. In 2026, there is a noticeable shift toward halogen-free, recyclable insulation materials in RS232C cables, driven by EU directives and corporate sustainability goals.

Conclusion

While the RS232C cable market is mature and shrinking in broad consumer applications, it remains viable and stable within industrial and technical niches. The 2026 landscape is characterized by adaptation—through converters, rugged designs, and integration strategies—ensuring that RS232C technology persists as a reliable backbone in critical systems worldwide. Suppliers who focus on reliability, compatibility, and specialized applications are best positioned to succeed in this evolving market.

Common Pitfalls When Sourcing RS232C Cables (Quality and IP Considerations)

Sourcing RS232C cables may seem straightforward, but several critical pitfalls related to quality and IP (Ingress Protection) ratings can compromise performance, reliability, and safety—especially in industrial or harsh environments. Being aware of these issues helps ensure long-term functionality and compliance.

Poor Cable Quality and Material Standards

One of the most common issues is selecting RS232C cables made from substandard materials. Low-quality conductors, inadequate shielding, and thin insulation can lead to signal degradation, electromagnetic interference (EMI), and premature failure. Cables lacking proper shielding (e.g., foil or braided shields) are especially vulnerable in electrically noisy environments. Additionally, non-compliant or counterfeit cables may not meet TIA/EIA-232 standards, resulting in unreliable data transmission and compatibility problems with connected devices.

Incorrect or Missing IP Rating for Environmental Conditions

Another major pitfall is ignoring the Ingress Protection (IP) rating when deploying RS232C cables in demanding environments. Cables not rated for dust or moisture (e.g., lacking IP65, IP67, or higher) can fail in outdoor, industrial, or washdown settings. For example, using a standard PVC-jacketed cable in a high-humidity or wet area may lead to corrosion of connectors and internal conductors. Always verify that the cable and its connectors meet the required IP rating for the specific application to ensure durability and safety.

Neglecting Mechanical Durability and Flex Life

RS232C cables used in moving machinery or automated systems are subject to constant flexing and mechanical stress. Sourcing cables without sufficient mechanical robustness—such as those lacking strain relief or flexible jacketing—can result in broken conductors or intermittent connections. Industrial-grade cables with reinforced jackets and high flex-life ratings are essential in dynamic environments but are often overlooked in cost-driven procurement decisions.

Inadequate Connector Quality and Plating

The quality of connectors (e.g., DB9 or DB25) is often underestimated. Poorly constructed connectors with thin plating (e.g., nickel instead of gold) on contacts increase resistance and are prone to oxidation, leading to signal loss or intermittent communication. Additionally, connectors without proper locking mechanisms may disconnect due to vibration, especially in transportation or industrial machinery.

Lack of Compliance and Certification

Finally, sourcing cables without proper certifications (such as CE, RoHS, or UL) poses risks related to safety, environmental standards, and legal compliance. Non-certified cables may not undergo rigorous testing for fire resistance, halogen content, or electrical performance, increasing the risk of system failure or non-compliance with industry regulations.

Avoiding these pitfalls requires careful evaluation of material quality, environmental suitability (including IP rating), mechanical resilience, connector specifications, and regulatory compliance during the sourcing process.

Logistics & Compliance Guide for RS232C Cables

This guide outlines the essential logistics considerations and compliance requirements for the transportation, handling, and use of RS232C cables in commercial and industrial applications.

Regulatory Compliance

RS232C cables must meet several international and regional regulatory standards to ensure safety, performance, and environmental responsibility. Key compliance areas include:

- Electromagnetic Compatibility (EMC): RS232C cables must comply with EMC directives such as the EU’s 2014/30/EU to minimize electromagnetic interference. Shielded variants are often required in industrial settings.

- RoHS (Restriction of Hazardous Substances): Compliance with EU Directive 2011/65/EU is mandatory, restricting the use of lead, mercury, cadmium, and other hazardous materials in cable components.

- REACH (Registration, Evaluation, Authorization, and Restriction of Chemicals): Ensure all cable materials are registered and compliant under EU Regulation (EC) No 1907/2006.

- Fire Safety Standards: Cables may need to meet flame retardancy standards such as UL 2556 or IEC 60332, especially for use in enclosed or populated environments.

- Country-Specific Certifications: Depending on the destination, cables may require additional certifications such as UL (USA), CSA (Canada), PSE (Japan), or CCC (China).

Packaging and Labeling Requirements

Proper packaging and labeling are critical for protection during transit and regulatory compliance:

- Packaging: Use anti-static bags or moisture-resistant packaging for bulk shipments. Coiled cables should be secured to prevent tangling or physical damage.

- Labeling: Each package must include:

- Product name and model number (e.g., RS232C Serial Cable)

- Length and connector types (e.g., DB9 to DB9, male/female)

- Manufacturer or supplier information

- Compliance markings (e.g., CE, RoHS, REACH)

- Batch/lot number and manufacturing date

- Barcodes and SKUs: Include scannable barcodes for inventory tracking and supply chain integration.

Storage and Handling Protocols

To maintain cable integrity before deployment:

- Environmental Conditions: Store in a dry, temperature-controlled environment (10°C to 30°C recommended). Avoid exposure to direct sunlight, moisture, and corrosive chemicals.

- Coiling Method: Use figure-eight or over-under coiling to prevent kinking and internal wire damage.

- Stacking Limits: Adhere to manufacturer stacking guidelines to avoid crushing lower layers in bulk storage.

- ESD Precautions: Handle in electrostatic discharge (ESD)-protected areas when intended for sensitive electronic environments.

Transportation and Shipping

Ensure safe and compliant shipment across domestic and international channels:

- Mode of Transport: RS232C cables can be shipped via air, sea, or ground. No hazardous material classification is typically required.

- Export Documentation: For international shipments, include a commercial invoice, packing list, and bill of lading or air waybill. Indicate HS Code 8544.42 (electric conductors for a voltage ≤1,000 V).

- Customs Clearance: Verify destination country import regulations; some may require conformity assessment or local agent representation.

- Insurance: Recommend shipping insurance for high-value or bulk consignments.

End-of-Life and Recycling

Support environmental sustainability through responsible disposal:

- WEEE Compliance (EU): As electronic components, RS232C cables fall under the Waste Electrical and Electronic Equipment Directive (2012/19/EU). Provide take-back or recycling information to end users.

- Recycling Instructions: Encourage users to recycle cables through certified e-waste facilities. Copper and plastic components are recyclable.

- Landfill Restrictions: Prohibited in many jurisdictions; emphasize proper disposal methods in user documentation.

Documentation and Record Keeping

Maintain accurate records for audits and traceability:

- Retain copies of compliance certificates (RoHS, REACH, CE, etc.)

- Keep shipping logs, batch records, and supplier declarations

- Update compliance status as regulations evolve (e.g., RoHS recasts)

By adhering to this guide, organizations can ensure the safe, legal, and efficient handling of RS232C cables throughout their lifecycle—from manufacturing to end-of-use.

Conclusion for Sourcing RS-232C Cables:

In sourcing RS-232C cables, it is essential to prioritize compatibility, build quality, and supplier reliability. Despite being a legacy interface, RS-232C remains in use across industrial, medical, and telecommunication systems where stable serial communication is required. When selecting these cables, key considerations include correct pin configurations (e.g., DB9 or DB25 connectors), shielding for noise resistance, cable length (within RS-232 limitations), and adherence to TIA/EIA-232 standards.

Sourcing from reputable suppliers ensures compliance with technical specifications and reduces the risk of communication failures or signal degradation. Additionally, evaluating factors such as environmental durability, availability of custom lengths or connectors, and warranty support enhances long-term reliability. Although newer communication protocols have largely superseded RS-232, maintaining a reliable supply chain for these cables supports continuity in legacy systems and critical infrastructure.

In summary, a strategic sourcing approach—balancing technical accuracy, quality assurance, and supplier credibility—ensures dependable performance and operational continuity when utilizing RS-232C cables in modern and legacy applications.