The global cabinet and locker wood products market has experienced steady growth over the past decade, driven by rising demand in residential, commercial, and institutional construction sectors. According to Grand View Research, the global wood-based panel market—encompassing plywood, MDF, particleboard, and engineered wood used in cabinets and lockers—was valued at USD 138.6 billion in 2022 and is projected to expand at a CAGR of 6.4% from 2023 to 2030. This growth is fueled by increasing urbanization, growth in modular furniture adoption, and a surge in do-it-yourself (DIY) home improvement projects, particularly in emerging economies. Additionally, sustainability trends have prompted manufacturers to innovate with eco-friendly composites and FSC-certified materials, reshaping competitive dynamics across the supply chain. In this evolving landscape, a select group of manufacturers have emerged as leaders, combining scale, quality, and technological advancement to meet rising global demand. The following list highlights the top 10 cabinet and locker wood manufacturers, selected based on production capacity, market reach, innovation in engineered wood solutions, and adherence to environmental standards.

Top 10 Cabinet Locker Wood Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 Lockers Cabinets Shelving Manufacturer

Domain Est. 2008

Website: hometeamlockers.net

Key Highlights: List Industries Inc. manufactures lockers, kd and welded cabinets, portable traffic gates, and industrial shelving systems that are perfect no matter where you ……

#2 CompX Security Products

Domain Est. 1998

Website: compx.com

Key Highlights: CompX is a domestic cabinet lock manufacturer with facilities in South Carolina, Illinois and California. As industry leading producers of cabinet locks….

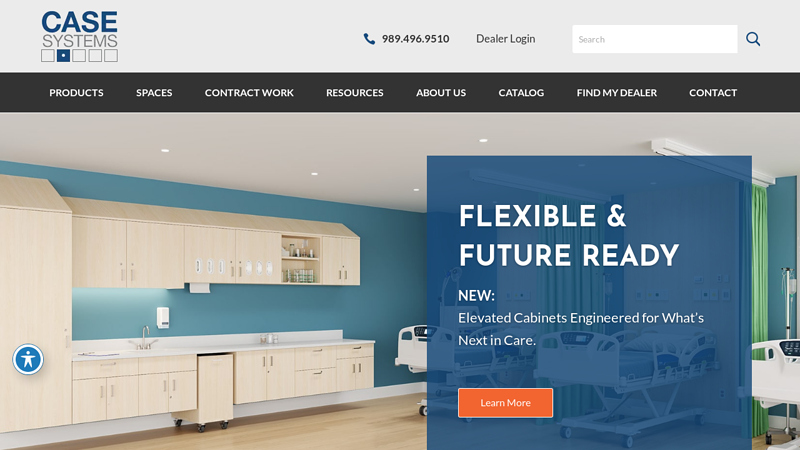

#3 Case Systems

Domain Est. 1996

Website: casesystems.com

Key Highlights: Casework that fits your work your way. Design your space with flexible and elegant commercial cabinet and storage solutions….

#4 Lockers For Sale

Domain Est. 1997

Website: lockers.com

Key Highlights: $600 delivery · 15-day returnsLockers.com is your source for metal lockers, wood lockers, plastic lockers, school lockers and gym lockers. Order factory direct from the industry l…

#5 List Industries

Domain Est. 1997

Website: listindustries.com

Key Highlights: LOCKERS, CABINETS, SHELVING … We have the perfect storage solution for your space. No matter your environment – school, office, gym, arena, indoor, or outdoor – ……

#6 Cabinets

Domain Est. 1997

Website: edsal.com

Key Highlights: Ready-to-Assemble Storage Cabinets, Heavy Duty Welded Steel Flammable Safety Cabinets, Heavy Duty Welded Steel Flammable Safety Cabinets….

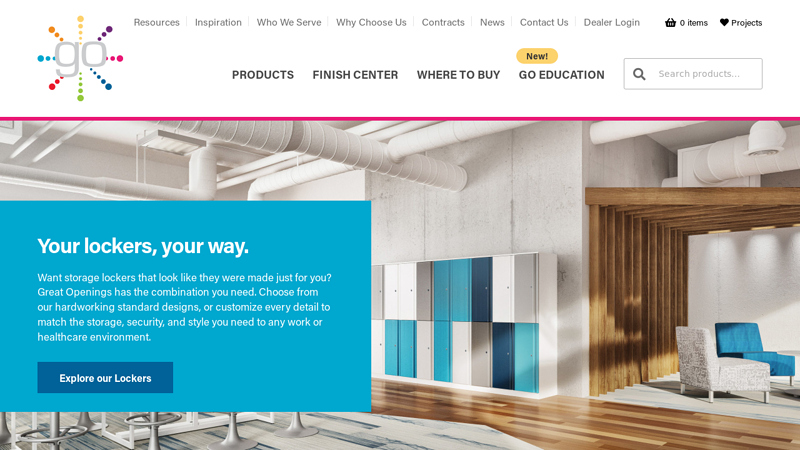

#7 Great Openings

Domain Est. 1997

Website: greatopenings.com

Key Highlights: Great Openings creates high-quality furniture and innovative storage components that make office organization easy for everyone. From lockers to desking….

#8 Art Metal Products

Domain Est. 2000

Website: artmetalproducts.com

Key Highlights: LOCKERS, CABINETS, SHELVING. We have the perfect storage solution for your space. No matter your environment – school, office, gym, arena, indoor or outdoor, we ……

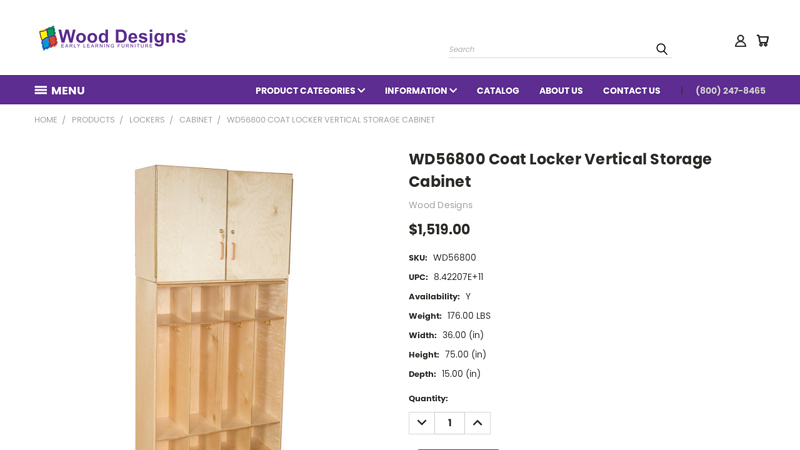

#9 WD56800 Coat Locker Vertical Storage Cabinet

Domain Est. 2004

Website: wooddesigns.com

Key Highlights: In stock $5 deliveryGREENGUARD Gold certified. Vertical storage unit with locker base. (4) Locker sections with cubby storage above and blow. The locking top cabinet offers ……

#10 Commercial Club, Resort Wood Cabinet Lockers

Domain Est. 2006

Website: pohlcustomcabinets.com

Key Highlights: Commercial custom wood lockers set up for digilock security, hardwood doors in shaker and raised panels, composite toekick and/or composite doors….

Expert Sourcing Insights for Cabinet Locker Wood

2026 Market Trends for Cabinet Locker Wood

Rising Demand for Sustainable and Eco-Friendly Materials

In 2026, the cabinet and locker wood market is witnessing a significant shift toward sustainability. Consumers and commercial developers are increasingly prioritizing environmentally responsible products. This trend is driving demand for cabinet locker wood sourced from certified forests (such as FSC or PEFC) and manufactured with low-VOC (volatile organic compounds) finishes. Bamboo, reclaimed wood, and rapidly renewable timber species are gaining traction as alternatives to traditional hardwoods. Manufacturers are responding by emphasizing carbon footprint transparency and adopting circular production practices, including recycling wood waste and optimizing supply chain logistics.

Growth in Customization and Smart Storage Solutions

The demand for personalized cabinetry continues to rise, particularly in residential kitchens, bathrooms, and home offices. In 2026, consumers are seeking cabinet locker systems that offer modular designs, adjustable shelving, soft-close mechanisms, and integrated lighting. Moreover, the integration of smart technology—such as touchless opening systems, embedded sensors for humidity and temperature control, and app-connected storage management—is becoming more common. This trend is especially prominent in urban housing and luxury builds, where space optimization and convenience are key.

Influence of Minimalist and Scandinavian Design Aesthetics

Minimalism remains a dominant design trend shaping the cabinet locker wood market. Light-toned wood finishes—such as white oak, ash, and beech—are preferred for their clean, airy appeal. Flat-panel and handleless cabinet designs are increasingly popular, aligning with contemporary interior styles that emphasize simplicity and functionality. Scandinavian influences continue to drive demand for natural textures, organic shapes, and multifunctional furniture that blends seamlessly into compact living spaces.

Supply Chain Resilience and Regional Manufacturing Shifts

Ongoing global supply chain volatility has prompted a strategic shift toward regional and local wood sourcing and manufacturing. In 2026, many cabinet producers are reshoring operations or partnering with nearby suppliers to reduce lead times and mitigate risks from geopolitical disruptions. This trend supports faster delivery, lower transportation emissions, and greater responsiveness to market demands. Additionally, digital inventory management and AI-driven demand forecasting are being adopted to improve supply chain efficiency.

Technological Advancements in Wood Processing and Finishing

Innovation in wood processing technologies is enhancing the durability, aesthetics, and performance of cabinet locker wood. Techniques such as thermal modification, acetylation, and UV-cured coatings are improving moisture resistance and dimensional stability—critical for humid environments like kitchens and bathrooms. Digital wood grain printing and CNC precision cutting enable high customization without sacrificing cost-efficiency. These advancements allow manufacturers to offer premium-quality products at competitive price points.

Expansion in Commercial and Institutional Applications

Beyond residential use, the cabinet locker wood market is growing in commercial sectors such as healthcare, education, and hospitality. Institutions are investing in durable, hygienic wood-based lockers and storage units that combine aesthetic appeal with long-term performance. Antimicrobial wood coatings and easy-to-clean surfaces are being developed to meet health and safety standards. This expansion is fueled by renovation projects and new constructions aiming for biophilic design, which incorporates natural materials to enhance occupant well-being.

Conclusion

The 2026 cabinet locker wood market is characterized by a convergence of sustainability, technology, and design innovation. As consumer preferences evolve and environmental regulations tighten, manufacturers and designers must adapt by offering eco-conscious, customizable, and technologically enhanced wood solutions. Regional production, smart integration, and minimalist aesthetics are set to define the future of the industry, positioning wood as a timeless yet modern material in functional storage design.

Common Pitfalls When Sourcing Cabinet Locker Wood (Quality and IP)

Sourcing wood for cabinet and locker manufacturing involves more than just finding affordable material—it requires careful attention to quality consistency and intellectual property (IP) compliance. Overlooking these aspects can lead to production delays, customer dissatisfaction, legal risks, and reputational damage. Below are key pitfalls to avoid:

Poor or Inconsistent Wood Quality

One of the most frequent issues is receiving wood that fails to meet specified standards in terms of grain consistency, moisture content, durability, or freedom from defects like knots, warping, or discoloration. Inconsistent quality can result in mismatched finishes, structural weaknesses, and increased waste during manufacturing. Always verify supplier certifications (e.g., FSC, PEFC), request sample batches, and establish clear quality benchmarks in contracts.

Lack of Traceability and Certification

Without proper documentation, it’s difficult to verify the wood’s origin and sustainability credentials. Using uncertified or illegally sourced timber exposes your business to regulatory penalties and reputational harm, especially under laws like the U.S. Lacey Act or the EU Timber Regulation. Ensure suppliers provide full chain-of-custody documentation and adhere to environmental and ethical sourcing standards.

Misrepresentation of Wood Species

Some suppliers may mislabel or substitute lower-grade or non-compliant wood species to cut costs. For example, passing off rubberwood as oak or using non-durable species for moisture-prone applications can compromise product integrity. Confirm species authenticity through lab testing or trusted grading reports, and specify exact species in procurement agreements.

Intellectual Property (IP) Infringement Risks

Using wood finishes, patterns, or engineered wood products that incorporate patented textures, laminates, or designs without proper licensing can lead to IP violations. This is particularly relevant when sourcing decorative veneers or branded composite materials (e.g., certain high-pressure laminates). Always verify that suppliers have rights to the materials they provide and include IP indemnity clauses in contracts.

Overlooking Moisture Content and Stability

Wood with improper moisture content can expand, contract, or warp after fabrication, leading to misaligned doors, gaps, or joint failures. Especially in humid or variable climates, using wood not acclimated to the right moisture levels compromises long-term performance. Require moisture content reports (typically 6–8% for indoor cabinetry) and store materials properly upon delivery.

Dependence on Unverified Suppliers

Sourcing from suppliers without thorough due diligence increases the risk of fraud, inconsistent supply, and substandard materials. Conduct on-site audits, check references, and consider third-party inspections—especially when dealing with international vendors. Building long-term relationships with reputable suppliers reduces exposure to quality and compliance issues.

Failure to Address Customization and Compatibility

Custom stains, cuts, or engineered wood configurations may require specific handling or adhesives. Using incompatible materials or processes can void warranties or lead to delamination and finish failure. Ensure technical specifications are clearly communicated and validated before production begins.

By proactively addressing these pitfalls, manufacturers can ensure high-quality, compliant, and legally sound wood sourcing for durable and market-ready cabinet and locker products.

Logistics & Compliance Guide for Cabinet Locker Wood

Overview

This guide outlines the essential logistics and compliance considerations for the handling, transportation, and regulatory adherence related to cabinet locker wood products. These guidelines ensure safe, efficient operations while meeting international and local standards.

Material Specifications

- Wood Type: Solid hardwood or engineered wood (e.g., plywood, MDF)

- Finish: Varnished, laminated, or painted surfaces

- Dimensions: Standard locker units range from 300mm to 900mm in width and 1800mm to 2000mm in height

- Packaging: Wrapped in protective plastic film, secured on wooden pallets, and corner-protected with cardboard or foam

Packaging & Handling Requirements

- Secure Stacking: Limit stacking height to 2 meters to prevent crushing or warping

- Moisture Protection: Use moisture-resistant wrapping; avoid direct exposure to rain or humidity

- Labeling: Clearly mark packages with handling symbols (e.g., “Fragile,” “This Side Up,” “Do Not Stack”)

- Load Securing: Use stretch wrap, straps, or shrink film to stabilize pallets during transit

Transportation Guidelines

- Mode of Transport: Suitable for road, sea, and air freight; sea freight recommended for bulk shipments

- Container Requirements: Use dry, ventilated containers; avoid condensation buildup

- Temperature & Humidity Control: Maintain ambient temperature (10–25°C) and relative humidity (40–60%) to prevent warping or cracking

- Documentation: Include commercial invoice, packing list, bill of lading, and certificate of origin

International Compliance Standards

- ISPM 15 (International Standards for Phytosanitary Measures No. 15):

- Wooden packaging materials (e.g., pallets, crates) must be heat-treated and stamped with the official ISPM 15 mark

-

Non-compliance may result in shipment rejection or fumigation fees at destination

-

REACH & RoHS Compliance (EU):

- Ensure finishes, adhesives, and coatings are free from restricted substances (e.g., formaldehyde, lead, phthalates)

-

Provide Safety Data Sheets (SDS) upon request

-

CARB Phase 2 (California Air Resources Board):

-

Formaldehyde emissions from composite wood products (e.g., MDF, particleboard) must meet ≤ 0.05 ppm

-

FSC or PEFC Certification (Optional but Recommended):

- Demonstrates responsible forest sourcing; required by some eco-conscious buyers

Customs & Import Regulations

- HS Code Classification:

- Typical code: 9403.60 (Wooden office or store furniture) – verify based on final product use

- Duties & Tariffs: Vary by destination country; consult local customs authority

- Import Documentation: May require test reports, compliance certificates, or import licenses

Environmental & Safety Considerations

- Waste Management: Recycle packaging materials (plastic, cardboard, wood); dispose of damaged wood per local regulations

- Worker Safety: Use PPE (gloves, safety glasses) during handling to prevent splinters or injuries

- Fire Safety: Store away from open flames; wood products are combustible

Quality Control & Inspection

- Pre-Shipment Inspection: Check for damages, discoloration, or dimensional inaccuracies

- Moisture Content Testing: Ensure wood moisture level is between 8–12% to prevent post-delivery warping

- Documentation Verification: Confirm all compliance certificates and shipping papers are complete and accurate

Storage Recommendations

- Indoor Storage: Required; keep in dry, well-ventilated area off the ground

- Stacking: Max 3 layers high; use dunnage between layers if necessary

- Duration: Avoid long-term storage (>6 months) without climate monitoring

Conclusion

Adhering to this logistics and compliance guide ensures the safe delivery and regulatory acceptance of cabinet locker wood products across global markets. Regular audits and supplier verification are recommended to maintain standards and customer trust.

In conclusion, sourcing wood for cabinet lockers requires careful consideration of several key factors including durability, aesthetics, cost, sustainability, and availability. Hardwoods such as oak, maple, and birch are popular choices due to their strength and attractive grain patterns, while engineered woods like plywood and MDF offer cost-effective and stable alternatives, especially for painted finishes. It is essential to ensure that the wood meets quality standards and is sourced responsibly, ideally from certified sustainable forests (e.g., FSC or PEFC), to support environmental stewardship. Additionally, local sourcing can reduce lead times and transportation costs while supporting regional economies. Ultimately, the right choice of wood will balance performance, visual appeal, and sustainability, contributing to the long-term functionality and value of the cabinet lockers.