The global power connectors market is experiencing robust growth, driven by rising demand across automotive, industrial, and renewable energy sectors. According to Grand View Research, the global power connectors market was valued at USD 11.9 billion in 2022 and is expected to expand at a compound annual growth rate (CAGR) of 5.8% from 2023 to 2030. This growth is fueled by increasing electrification, advancements in electric vehicles (EVs), and the expansion of smart infrastructure. Within this landscape, C20 power connectors—widely used in high-power applications such as data centers, industrial machinery, and power distribution units—are gaining prominence due to their standardized design and high-current handling capabilities. As demand intensifies, a select group of manufacturers are leading innovation, quality, and global supply. Below is a data-driven overview of the top 8 C20 power connector manufacturers shaping the industry’s future.

Top 8 C20 Power Connector Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 China C20 Power Connector Manufacturers and Factory, Suppliers

Domain Est. 2021

Website: anen-connector.com

Key Highlights: C20 Power Connector – Manufacturers, Suppliers, Factory from China · Combination of Power connector PA75 · Module Power Connector DJL37 · Module Power Connector ……

#2 IEC 60320 C20 Power Cords / Electrical Power Cables

Domain Est. 1994

Website: newark.com

Key Highlights: Free delivery over $150 · 60-day returnsBuy IEC 60320 C20 Power Cords / Electrical Power Cables. Newark Electronics offers fast quotes, same day dispatch, fast delivery, ……

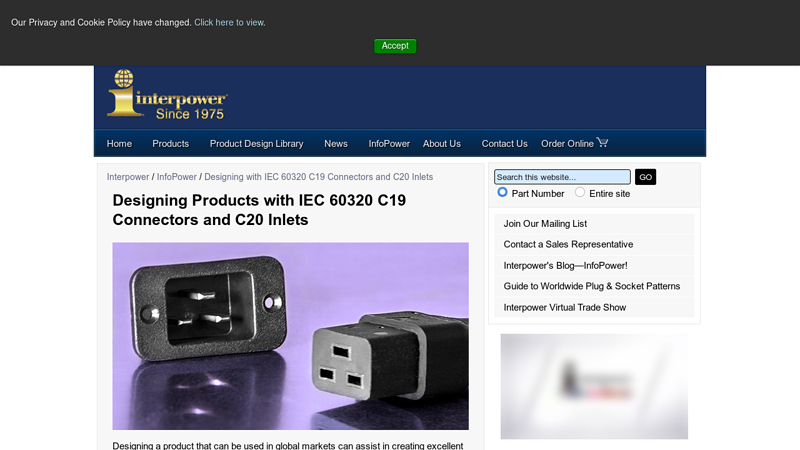

#3 Designing Products with IEC 60320 C19 Connectors and C20 Inlets

Domain Est. 1996

Website: interpower.com

Key Highlights: Two of the most commonly used IEC 60320 connectors and inlets at Interpower are the C19 and C20. The mounting style for the C19 connector is cable-mount….

#4 IEC C20 PDU Input Power Cords

Domain Est. 1996

Website: chatsworth.com

Key Highlights: Discover reliable IEC C20 input power cords with C20 plug for eConnect PDUs. Ensure secure power connections in data centers. Shop now at Chatsworth.com….

#5 C20 to C21 Power Cord, Heavy Duty, 20A, 2.5 ft, Red

Domain Est. 1996

Website: tripplite.eaton.com

Key Highlights: C20 to C21 20A heavy-duty cable connects high-output devices with C19/C22 power connectors commonly found on high-powered IT equipment. Recommended for powering ……

#6 C20 to C19 Black Cords

Domain Est. 1996

Website: stayonline.com

Key Highlights: 4-day delivery 30-day returnsIdeal for bridging power between C19 PDU and rack mounted equipment. Available in ratings of either 16A or 20A, these cords offer versatility and relia…

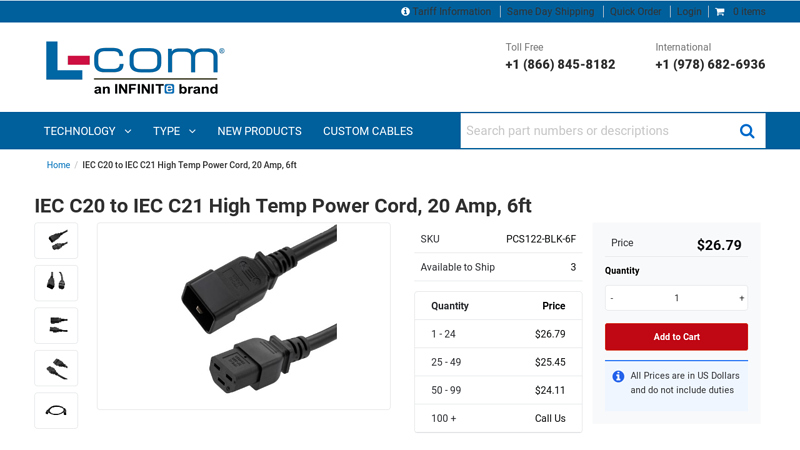

#7 IEC C20 to IEC C21 High Temp Power Cord, 20 Amp, 6ft

Domain Est. 1996

Website: l-com.com

Key Highlights: The PCS122-BLK-6F high-temperature power cord from L-com comes with a C20 male connector on one end and a C21 female connector on the other end….

#8 IEC C20 Power Cord

Domain Est. 2013

Website: cableleader.com

Key Highlights: 5-day delivery 30-day returnsOur C19/C20 power cables are heavy-duty, perfect for data centers, servers, PDUs, and UPS systems. Available in 12AWG and 14AWG, 250V rated….

Expert Sourcing Insights for C20 Power Connector

H2: 2026 Market Trends for C20 Power Connectors

The C20 power connector market in 2026 is poised for steady growth and strategic evolution, driven by increasing power demands in data centers, advancements in high-performance computing, and a growing emphasis on energy efficiency and reliability. As a high-current variant within the IEC 60320 connector family (rated for 16A at 250V AC, typically used with C19 inlets), the C20 connector serves critical applications where standard connectors like the C14 fall short. Key trends shaping the market include:

-

Data Center Expansion and Hyperscale Demand: The continued proliferation of cloud computing, artificial intelligence (AI), and large language models (LLMs) is driving the construction and upgrading of hyperscale data centers. These facilities house high-density server racks, AI accelerators (GPUs, TPUs), and high-performance storage systems that require significantly more power than traditional IT equipment. C20/C19 connectors are the standard solution for powering 1U/2U servers, blade server chassis, PDUs (Power Distribution Units), and high-wattage switches/routers in these environments. The relentless growth in data processing needs ensures sustained demand for C20 connectors through 2026.

-

Rising Power Density in IT Equipment: Server and networking hardware manufacturers are packing more computational power into smaller form factors. This trend directly increases the power draw per rack unit. Equipment exceeding the 10A/12A limit of the standard C14/C13 connection often necessitates the use of C20/C19 connectors. As processors, memory, and accelerators become more power-hungry, the adoption of C20 connectors is expected to extend beyond just the highest-end servers to a broader range of mid-to-high-tier enterprise equipment.

-

Focus on Efficiency and Reliability: Data center operators prioritize uptime and energy efficiency (PUE). C20 connectors, being designed for higher currents with robust contacts and secure latching mechanisms (often requiring a latch or screw for disconnection), offer superior reliability compared to lower-rated connectors operating near their limits. This reduces the risk of arcing, overheating, and connection failures, contributing to overall system stability. The market will likely see continued innovation in materials (e.g., improved contact alloys) and design (e.g., enhanced strain relief, better heat dissipation) to further boost reliability and efficiency.

-

Growth in High-Performance Computing (HPC) and AI Infrastructure: Beyond general data centers, specialized HPC clusters and dedicated AI training/inference infrastructure represent a significant growth vector. These systems, often utilizing dense GPU/TPU arrays, are major consumers of power. The C20/C19 interface is fundamental for powering individual server nodes and related infrastructure within these high-power racks, making it a critical component in the AI hardware ecosystem.

-

Supply Chain Resilience and Component Sourcing: The post-pandemic era has heightened awareness of supply chain vulnerabilities. Manufacturers of C20 connectors and the equipment using them are likely to focus on securing reliable sources for critical materials (copper, specific plastics) and diversifying manufacturing geographically to mitigate risks. This could lead to increased investment in regional production or nearshoring strategies by major connector suppliers.

-

Competition and Innovation Pressure: While the C20/C19 standard is well-established, competition among connector manufacturers (e.g., Amphenol, TE Connectivity, Molex, LEMO, Hubbell) remains intense. Innovation will focus on:

- Higher Performance: Developing connectors capable of handling even higher currents or improved thermal management within the same form factor for future-proofing.

- Smaller Footprints/High-Density Designs: Creating C20 variants or integrated solutions that allow for higher port density on PDUs and equipment inlets, maximizing rack space.

- Enhanced Features: Integrating monitoring capabilities (e.g., current sensing) or improved safety features (e.g., visual indicators, fool-proof mating).

- Sustainability: Using more recyclable materials and designing for easier disassembly and end-of-life recycling.

-

Regional Market Dynamics: Growth will be strongest in regions experiencing rapid data center build-out, particularly North America (driven by major cloud providers), parts of Europe (due to digital sovereignty initiatives), and Southeast Asia. Emerging markets may see slower adoption initially, focusing on standard C13/C14 applications, but the long-term trend will pull demand for higher-capacity connectors as their digital infrastructure matures.

In summary, the 2026 C20 power connector market is fundamentally tied to the trajectory of high-power IT infrastructure. Driven by insatiable demand from data centers, HPC, and AI, the market will experience steady growth. Key trends emphasize reliability, efficiency, supply chain security, and incremental innovation to meet the escalating power demands of modern computing. While facing no imminent technological replacement for its core application, competition will push manufacturers to enhance performance, density, and sustainability.

Common Pitfalls When Sourcing C20 Power Connectors (Quality and IP)

Sourcing C20 power connectors—commonly used in high-power IT and medical equipment—requires careful attention to both quality and intellectual property (IP) concerns. Overlooking these factors can lead to product failures, safety hazards, compliance issues, and legal risks. Below are key pitfalls to avoid:

Poor Manufacturing Quality and Material Selection

Low-cost C20 connectors may use substandard materials such as inferior-grade thermoplastics or inadequate contact plating (e.g., insufficient nickel or tin layers). This can result in poor thermal performance, reduced current-carrying capacity, and increased risk of overheating or arcing. Always verify that connectors meet IEC 60320 standards and request material certifications from suppliers.

Inadequate Temperature and Current Ratings

Some suppliers may misrepresent or exaggerate the temperature rating (e.g., claiming 120°C when the actual rating is lower) or current handling capability (typically rated for 16A or 20A at 250V). Using under-rated connectors in high-load applications can lead to connector degradation, melting, or fire hazards. Confirm ratings with test reports and ensure compliance with UL, CSA, or VDE certifications.

Counterfeit or Non-Compliant Components

The market includes counterfeit connectors that mimic reputable brands but fail to meet safety and performance standards. These parts often lack proper certification marks or have inconsistent labeling. Always source from authorized distributors or verified manufacturers and validate certifications through official databases.

Lack of IP Protection and Design Infringement

C20 connectors, especially those with proprietary locking mechanisms or enhanced shielding, may be protected by patents or design rights. Using clones or reverse-engineered versions without proper licensing exposes your company to IP litigation. Conduct due diligence to ensure your chosen connector does not infringe on existing patents, particularly if integrating into commercial products.

Insufficient Environmental Protection (IP Rating Misinterpretation)

While C20 connectors are typically used in controlled environments, some applications require environmental resistance. Be cautious of suppliers claiming IP ratings (e.g., IP54) without third-party validation. Standard C20 connectors are not inherently sealed; any claimed ingress protection must be verified through documented testing, especially if used in non-ideal conditions.

Inconsistent Interoperability and Mating Cycles

Poorly manufactured connectors may not mate reliably with standard C19 inlets or fail prematurely after repeated connect/disconnect cycles. This impacts serviceability and system uptime. Request data on mating cycle durability (typically rated for 1,000+ cycles) and conduct sample testing before full-scale integration.

Supply Chain Transparency and Traceability Gaps

Opaque supply chains can introduce inconsistent quality and hidden risks. Suppliers may source from multiple unverified subcontractors, making traceability difficult during audits or field failures. Insist on full traceability documentation, including mold lot numbers and manufacturing locations, to ensure consistency and support quality investigations.

Logistics & Compliance Guide for C20 Power Connector

This guide outlines key logistics considerations and compliance requirements for the C20 power connector, a high-current IEC 60320 component commonly used in servers, data centers, and high-power IT equipment.

Regulatory Compliance

IEC Standards

The C20 connector must comply with IEC 60320-1 and IEC 60320-2-2 standards, which define dimensional compatibility, temperature ratings (typically rated up to 70°C or 105°C), and electrical performance (rated for 16A or 20A at up to 250V AC). Ensure all manufactured or imported units are tested and certified to these specifications.

Regional Certification Requirements

- North America: Products incorporating C20 connectors must meet UL 60320-1 (UL 498 in some cases) and be listed by a Nationally Recognized Testing Laboratory (NRTL) such as UL, ETL, or CSA.

- European Union: CE marking is required under the Low Voltage Directive (LVD) and the Electromagnetic Compatibility (EMC) Directive. Compliance with RoHS and REACH regulations is mandatory.

- United Kingdom: UKCA marking is required post-Brexit, with adherence to UK versions of LVD, EMC, RoHS, and REACH.

- China: CCC (China Compulsory Certification) may be required for final equipment, though components like C20 connectors may be covered under the end-product certification.

- Other Regions: Check local requirements in markets such as South Korea (KC Mark), Japan (PSE), and Australia/New Zealand (RCM).

Environmental & Material Compliance

RoHS and REACH

Ensure the C20 connector is free from restricted substances per EU RoHS (e.g., lead, cadmium, mercury, certain flame retardants). Full material disclosure (FMD) and SVHC (Substances of Very High Concern) screening under REACH must be documented.

Conflict Minerals

If supplying to U.S. markets, compliance with the Dodd-Frank Act Section 1502 may require reporting on the use of conflict minerals (tin, tantalum, tungsten, gold) in connector components.

Packaging & Shipping

Packaging Standards

Use anti-static, ESD-safe packaging for C20 connectors to prevent damage during transit, especially for bulk shipments. Packaging must protect against moisture, vibration, and physical impact. Label packages with ESD warning symbols and handling instructions.

Shipping Documentation

Include detailed commercial invoices, packing lists, and certification documentation (e.g., test reports, RoHS compliance, IEC certification) with each shipment. Clearly specify product codes, quantities, and HS codes (e.g., 8536.69 for electrical connectors) to facilitate customs clearance.

Import & Customs Considerations

Tariff Classification

Classify C20 connectors under the appropriate Harmonized System (HS) code. In most jurisdictions, this falls under 8536.69 (“Electrical apparatus for switching or protecting electrical circuits…”). Verify local tariff codes to ensure accurate duty assessment.

Duty and Tax Implications

Be aware of duty rates, VAT, or GST applicable in the destination country. Leverage free trade agreements if applicable (e.g., USMCA, EU-South Korea FTA) to reduce tariffs. Maintain records for audit purposes.

Storage & Handling

Environmental Conditions

Store C20 connectors in a dry, temperature-controlled environment (typically 15–30°C, 30–60% RH) to prevent material degradation or corrosion. Avoid exposure to direct sunlight or chemicals.

Shelf Life & Inventory Rotation

Monitor inventory using FIFO (First In, First Out) principles. While connectors have a long shelf life, inspect older stock for signs of material aging or packaging damage before deployment.

End-of-Life & Recycling

WEEE Compliance

In the EU and other regulated markets, ensure C20 connectors are designed for recyclability and marked with the “crossed-out wheeled bin” symbol if part of EEE (Electrical and Electronic Equipment). Support WEEE take-back programs as required.

Recycling Instructions

Provide end-of-life handling guidance to customers, recommending separation of metal (copper contacts) and thermoplastic (housing) components for proper recycling.

Supplier & Supply Chain Management

Qualification & Audits

Source C20 connectors only from qualified suppliers with documented quality management systems (e.g., ISO 9001). Conduct regular audits to verify compliance with environmental, safety, and performance standards.

Traceability

Maintain full traceability of batches, including lot numbers, manufacturing dates, and test certifications. This is critical for recalls or compliance investigations.

This guide ensures safe, compliant, and efficient logistics handling of C20 power connectors across global supply chains. Always consult local regulations and industry standards for specific project requirements.

Conclusion for Sourcing C20 Power Connectors

In conclusion, sourcing C20 power connectors requires careful consideration of electrical specifications, quality standards, application requirements, and supplier reliability. As high-current connectors commonly used in servers, data centers, and high-power medical or industrial equipment, C20 connectors must meet IEC 60320 standards and be rated for temperatures up to 120°C or 105°C, depending on the use case. Key factors in the sourcing process include material quality (such as thermoset or high-temperature thermoplastics), contact resistance, current rating (typically up to 16A or 20A), and compatibility with mating C19 inlets.

Sourcing from reputable manufacturers or authorized distributors ensures compliance with safety certifications (e.g., UL, CE, CSA), reduces the risk of counterfeit components, and supports long-term reliability. Additionally, evaluating total cost—including volume pricing, lead times, and logistics—helps optimize procurement without compromising performance. For mission-critical applications, investing in high-quality, correctly rated C20 connectors is essential to ensure safety, efficiency, and system uptime.

Ultimately, a strategic sourcing approach that balances technical requirements, supplier credibility, and cost-effectiveness will ensure the successful integration of C20 power connectors into high-power electrical systems.