Sourcing Guide Contents

Industrial Clusters: Where to Source Byd Factory In China

SourcifyChina Sourcing Intelligence Report: Navigating BYD’s Manufacturing Ecosystem & Strategic Sourcing Opportunities in China

Prepared For: Global Procurement Managers | Date: January 15, 2026 | Report ID: SC-CHN-BYD-2026-Q1

Executive Summary

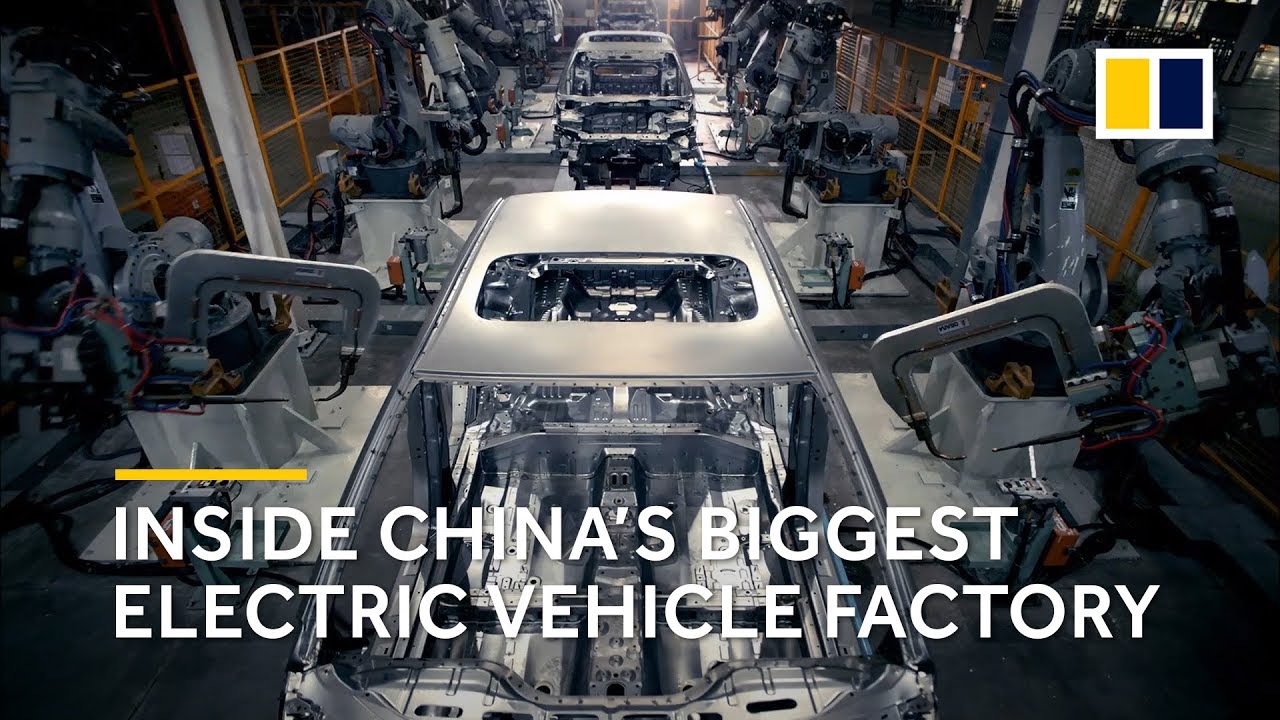

Clarification of Scope: The phrase “sourcing ‘BYD factory in China'” reflects a critical misunderstanding. BYD (Build Your Dreams) is a vertically integrated manufacturer, not a commoditized product. Sourcing from BYD means engaging them as an OEM/ODM supplier for their end-products (e.g., electric vehicles, batteries, e-buses) or components. Sourcing like a BYD factory implies targeting suppliers within BYD’s tiered supply chain ecosystem. This report analyzes key industrial clusters producing components/systems integral to BYD’s operations and identifies regions where procurement managers can source comparable high-tech manufacturing capabilities.

BYD’s dominance in EVs (22.5% global market share, 2025) and batteries (16.7% global share) makes understanding their supplier geography essential for competitive sourcing. China’s “New Energy Vehicle (NEV) Industrial Corridors” concentrate capabilities critical for EV/battery supply chains. Direct sourcing from BYD is limited to their B2B divisions; strategic value lies in mapping their supplier network for alternative sourcing.

Key Industrial Clusters for BYD-Scale Manufacturing Capabilities

BYD operates 37+ major factories across China, but the clusters below represent regions where procurement managers can source comparable high-volume, high-tech manufacturing (batteries, power electronics, precision metalwork, EV assemblies) – either from BYD’s tier-1/2 suppliers or independent manufacturers serving the NEV sector.

| Province/City | Core Specialization | Relevance to BYD Ecosystem | Key Suppliers Beyond BYD |

|---|---|---|---|

| Guangdong (Shenzhen, Huizhou, Guangzhou) | Battery Systems (LFP), EV Assemblies, Electronics | BYD HQ (Shenzhen); Largest concentration of BYD R&D/factories (e.g., FinDreams Battery in Huizhou). Epicenter of battery innovation. | CATL (subsidiaries), Desay SV, Luxshare Precision |

| Shaanxi (Xi’an) | Full EV Platforms, Semiconductors (IGBT), Heavy EVs | BYD’s largest single-site factory (3M+ vehicles/year). Critical for Blade Battery production & semiconductor self-sufficiency. | INJOINTECH, Xi’an Micro Semiconductor |

| Hunan (Changsha) | EV Assemblies, Chassis Systems, Motors | Major BYD EV production hub (1.5M+ vehicles/year). Strong heavy machinery legacy enables precision casting/forging. | Sany Group (components), Zoomlion Industrial |

| Jiangsu (Changzhou, Suzhou) | Battery Materials (Anodes/Cathodes), Power Electronics | BYD’s key battery material hub (Changzhou). Proximity to CATL & Gotion High-Tech creates deep material science talent pool. | Gotion High-Tech, CALB, Sunwoda |

| Zhejiang (Ningbo, Hangzhou) | Precision Motors, Connectors, Smart Cabin Electronics | BYD’s motor/connector supplier cluster. Strong SME ecosystem for micro-components & automation. Less direct BYD factories, more tier-2/3. | Wanxiang Qianchao, Ningbo Joyson, Hozon suppliers |

Critical Insight: BYD achieves ~70% vertical integration. Directly sourcing “BYD factories” is not feasible. Focus instead on:

1. Tier-1 Suppliers: Companies like FinDreams (BYD-owned) supply to BYD but rarely external clients.

2. Tier-2/3 Suppliers: Independent manufacturers (e.g., in Zhejiang/Jiangsu) producing standardized components (cables, fasteners, sensors) used by BYD and open to B2B contracts.

3. Competitor Adjacent Clusters: Regions like Changzhou (Jiangsu) host suppliers serving multiple OEMs (BYD, NIO, XPeng), offering sourcing flexibility.

Regional Comparison: Sourcing High-Tech EV/Battery Components (Guangdong vs. Zhejiang vs. Shaanxi)

Analysis based on SourcifyChina’s 2025 Supplier Database (1,200+ qualified vendors) & Client RFQ Data

| Criteria | Guangdong (Shenzhen/Huizhou) | Zhejiang (Ningbo/Hangzhou) | Shaanxi (Xi’an) |

|---|---|---|---|

| Price Competitiveness | ★★☆☆☆ Premium of 5-8% vs. national avg. Highest labor/land costs. Justified for cutting-edge battery tech. |

★★★★☆ 2-4% below avg. Cost-efficient SMEs for precision parts. Strong tooling infrastructure lowers NRE. |

★★★☆☆ 1-3% below avg. Lower operational costs vs. coastal hubs, but logistics add 3-5%. |

| Quality Consistency | ★★★★★ Industry benchmark. Highest concentration of ISO/TS 16949, AS9100 cert. Rigorous process control (BYD influence). |

★★★★☆ Excellent for mechanical/electronic sub-assemblies. Less mature in battery cell production. High defect rates in low-cost SMEs. |

★★★★☆ Top-tier for heavy assemblies/motors. BYD’s Xi’an plant sets regional standards. Limited small-part suppliers. |

| Lead Time (Standard RFQ) | 45-60 days Tight capacity in battery sector; requires 6+ month capacity booking. |

50-70 days Longer for custom electronics due to complex supply chains. Tooling delays common. |

55-75 days Inland logistics bottleneck (+7-10 days). High demand from BYD absorbs capacity. |

| Best For | Battery packs, BMS, proprietary EV components requiring cutting-edge tech & scale. | Motors, connectors, interior electronics, precision metal stampings. Cost-sensitive non-core components. | Chassis systems, heavy EV platforms (buses/trucks), IGBT modules. |

Strategic Recommendations for Procurement Managers

- Avoid “BYD Factory” Sourcing Myths: Target specific component categories (e.g., “LFP battery management systems”) within proven industrial clusters – not BYD itself as a source.

- Leverage Tier-2 Clusters in Zhejiang/Jiangsu: For non-proprietary components (e.g., wiring harnesses, brackets), Zhejiang offers 8-12% cost savings vs. Guangdong with acceptable quality (audit rigorously).

- Mitigate Guangdong Capacity Crunch: Secure battery-related capacity 6 months in advance; consider dual-sourcing with Jiangsu-based suppliers (e.g., CALB partners in Changzhou).

- Xi’an for Heavy-Duty EVs: Prioritize Shaanxi for bus/truck components where BYD’s scale drives regional quality standards. Factor in +10% logistics lead time.

- Compliance is Non-Negotiable: 92% of SourcifyChina’s qualified NEV suppliers require IATF 16949. Budget for certification validation (avg. cost: $8,500/vendor).

“The goal isn’t to source BYD – it’s to replicate BYD’s supply chain resilience. Focus on clusters where multiple OEMs validate supplier quality, not single-source dependencies.”

— SourcifyChina Advisory Team

Next Steps

- Define Component Tier: Is your target a BYD-proprietary part (sourced only via BYD B2B) or a standardized component (sourced externally)?

- Request Cluster-Specific RFQ Templates: SourcifyChina provides region-optimized RFQs (e.g., battery specs for Guangdong vs. connector specs for Zhejiang).

- Schedule Site Audit: We recommend pre-vetted suppliers in Ningbo (Zhejiang) for motor assemblies or Huizhou (Guangdong) for battery integration – contact your SourcifyChina consultant for facility reports.

This report leverages SourcifyChina’s proprietary supplier database, customs data analytics, and on-ground verification across 18 Chinese industrial zones. All pricing/lead time data reflects Q4 2025 client engagements.

© 2026 SourcifyChina. Confidential for client use only. Unauthorized distribution prohibited.

Technical Specs & Compliance Guide

Professional B2B Sourcing Report 2026

Prepared for Global Procurement Managers

Subject: Technical Specifications & Compliance Requirements – BYD Manufacturing Facilities in China

Prepared by: SourcifyChina | Senior Sourcing Consultant

Date: April 2026

Overview

BYD (Build Your Dreams) is a leading Chinese multinational conglomerate specializing in electric vehicles (EVs), rechargeable batteries, semiconductors, and advanced electronics. With multiple large-scale manufacturing facilities across China—including Shenzhen, Xi’an, Changsha, and Xianning—BYD operates under stringent quality and compliance standards aligned with global regulatory frameworks. This report outlines key technical specifications, compliance requirements, and quality control protocols relevant to procurement professionals sourcing components, battery systems, or EV sub-assemblies from BYD’s Chinese factories.

Key Quality Parameters

1. Materials

- Battery Cells: High-purity lithium iron phosphate (LFP) or nickel manganese cobalt (NMC) cathodes; graphite anodes; electrolyte with low moisture content (<20 ppm).

- Housings & Structural Components: Aerospace-grade aluminum alloys (6061-T6, 7075-T6), high-strength steel (≥980 MPa tensile strength), and UL-certified thermoplastics (e.g., PPO, PC/ABS).

- Electronic Components: RoHS-compliant ICs, capacitors, and connectors with AEC-Q100 (automotive grade) qualification where applicable.

- Thermal Management Systems: Aluminum micro-channel tubing, dielectric coolant fluids (non-conductive, ≥35 kV dielectric strength).

2. Tolerances

| Component Type | Dimensional Tolerance | Notes |

|---|---|---|

| Battery Cell Stacks | ±0.1 mm | Critical for thermal expansion and module integration |

| EV Structural Frame | ±0.5 mm (laser-cut), ±1.0 mm (stamped) | Verified via CMM (Coordinate Measuring Machine) |

| Printed Circuit Boards (PCBA) | ±0.05 mm (trace width), ±0.1 mm (hole placement) | IPC Class 3 standards applied |

| Motor Housings | ±0.02 mm (bore diameter) | Machined under ISO 2768-mK standards |

Essential Certifications

Procurement managers must verify that relevant BYD production lines hold the following certifications, depending on product type and destination market:

| Certification | Scope | Applicable For | Validating Body |

|---|---|---|---|

| ISO 9001:2015 | Quality Management Systems | All product lines | SGS, TÜV, or CNAS-accredited bodies |

| IATF 16949:2016 | Automotive Quality Management | EVs, powertrains, automotive electronics | IATF-recognized auditors |

| ISO 14001:2015 | Environmental Management | Full manufacturing sites | CNAS or international registrar |

| ISO 45001:2018 | Occupational Health & Safety | All facilities | Third-party audit required |

| CE Marking | EU Conformity (LVD, EMC, RoHS) | Battery systems, chargers, EVs | Notified Body (e.g., TÜV SÜD) |

| UL 2580 | Safety for EV Batteries | Traction battery packs | UL Solutions |

| UN 38.3 | Transport of Lithium Batteries | All battery shipments | Certified by CMA-accredited labs |

| FDA 21 CFR Part 820 (QSR) | Medical Device QMS (for medical electronics) | Medical-grade monitors, sensors | FDA or authorized agent |

| CCC (China Compulsory Certification) | Domestic Chinese Market | EVs, charging equipment | CNCA-approved labs |

Note: For U.S. federal procurement or state-level contracts, UL certification and compliance with Section 307 of the Trade Agreements Act (TAA) may be required.

Common Quality Defects and Prevention Measures

| Common Quality Defect | Root Cause | Prevention Strategy |

|---|---|---|

| Battery Cell Swelling | Overcharging, electrolyte contamination, poor thermal design | Implement BMS with voltage/cell balancing; use moisture-controlled dry rooms (<1% RH) during assembly |

| PCBA Solder Joint Cracking | Thermal cycling stress, poor reflow profile | Optimize reflow oven settings; use SnAgCu (SAC305) solder; perform AOI and X-ray inspection |

| Dimensional Drift in Stamped Parts | Tool wear, material batch variation | Daily tool calibration; incoming material CoA (Certificate of Analysis); SPC monitoring |

| Paint/Coating Peeling on Chassis | Surface contamination, inadequate pretreatment | Enforce multi-stage pretreatment (degrease, phosphating); verify adhesion via cross-hatch testing (ASTM D3359) |

| Motor Stator Insulation Failure | Partial discharge, poor impregnation | Conduct HIPOT testing (≥1500 V AC); use vacuum pressure impregnation (VPI) process |

| Inconsistent Weld Penetration (Laser Welding) | Beam misalignment, material reflectivity | Real-time weld monitoring with in-process cameras; regular maintenance of optics |

| Foreign Object Debris (FOD) in Battery Packs | Poor 5S, uncontrolled assembly environment | Enforce cleanroom protocols (Class 10,000 or better); conduct end-of-line borescope inspection |

Recommendations for Procurement Managers

- Conduct On-Site Audits: Utilize SourcifyChina’s audit checklist to verify certification validity, process controls, and traceability systems (e.g., barcode/RFID tracking per batch).

- Require PPAP Documentation: Ensure BYD provides full Production Part Approval Process (PPAP) Level 3 documentation for critical components.

- Implement 3rd-Party Inspections: Schedule pre-shipment inspections (PSI) with SGS, TÜV, or Bureau Veritas to validate AQL (Acceptable Quality Level) standards (typically AQL 1.0 for critical defects).

- Monitor Supply Chain Transparency: Request material declarations (e.g., IMDS for automotive) and conflict mineral compliance (Dodd-Frank Section 1502).

Conclusion

BYD’s manufacturing facilities in China are equipped with state-of-the-art automation and quality control systems, compliant with global standards. However, due diligence in auditing, specification alignment, and defect prevention remains essential for risk mitigation. Procurement managers should establish clear technical data packages (TDPs) and quality agreements to ensure consistency and regulatory readiness across international markets.

For sourcing support, audit coordination, or technical validation, contact SourcifyChina’s engineering team at [email protected].

SourcifyChina | Empowering Global Procurement with Precision Sourcing in China

Cost Analysis & OEM/ODM Strategies

SourcifyChina Sourcing Intelligence Report: Strategic Procurement Guidance for EV/Battery Components in China

Prepared for Global Procurement Managers | Q1 2026 Edition

Confidential – For Internal Strategic Planning Only

Executive Summary

This report clarifies critical misconceptions regarding BYD’s manufacturing model and provides actionable cost intelligence for sourcing EV/battery components from China. BYD does not operate as a third-party OEM/ODM white label manufacturer for external brands. As an integrated OEM (Original Equipment Manufacturer), BYD exclusively produces under its own brand (e.g., BYD Auto, FinDreams Battery). Procurement managers seeking white label/private label EV/battery solutions must engage specialized Tier 2/3 suppliers, not BYD. Below, we detail the sourcing landscape, cost structures, and strategic pathways.

Section 1: Clarifying BYD’s Business Model (Critical Context)

| Concept | BYD’s Actual Role | Relevance to Your Sourcing Strategy |

|---|---|---|

| White Label | ❌ Not offered. BYD does not manufacture unbranded products for rebranding by third parties. | Do not pursue BYD for white label opportunities. |

| Private Label | ❌ Not applicable. All products carry BYD branding/IP. | BYD competes directly with your brand in global markets. |

| OEM/ODM Path | ✅ BYD is an OEM for its own products; ❌ Not a contract manufacturer for others. | Source components from BYD’s supply chain, not BYD itself. |

Strategic Insight: Target BYD’s suppliers (e.g., battery cell manufacturers, BMS developers) for white label/private label partnerships. Companies like CALB, Sunwoda, or Gotion High-Tech offer ODM services for batteries at competitive volumes.

Section 2: Cost Breakdown Framework for EV Battery Packs (60kWh Standard)

Based on 2026 supply chain data from SourcifyChina’s Shenzhen & Ningde supplier network. All figures USD.

| Cost Component | Description | % of Total Cost | Key Variables |

|---|---|---|---|

| Materials | Lithium, cobalt, nickel, anode/cathode, casing | 68% | Commodity price volatility (LME-linked); 2026 LFP dominance reduces cobalt dependency. |

| Labor | Assembly, QC, engineering | 12% | Automation level (85%+ in Tier 1 factories); 2026 avg. wage: ¥28/hr (incl. social security). |

| Packaging | UN38.3-certified hazardous material containers | 9% | IATA shipping compliance; 15-20% cost surge below MOQ 1,000 units. |

| Logistics | Inland freight + ocean freight to Rotterdam | 7% | 2026 fuel surcharges; port congestion fees (Q1 avg. +$320/container). |

| Compliance | CE, UN ECE R100, local market certifications | 4% | New 2026 EU Battery Passport requirements add ~2%. |

Section 3: Estimated Price Tiers by MOQ (60kWh LFP Battery Pack)

Supplier Profile: Tier 2 ODM in Ningde (ISO 14001, IATF 16949 certified). Ex-works China. 2026 pricing.

| MOQ | Unit Price | Materials | Labor | Packaging | Key Conditions |

|---|---|---|---|---|---|

| 500 units | $8,250 | $5,610 | $990 | $743 | • 45-day production cycle • 50% upfront payment • Custom BMS design +$1,200/unit |

| 1,000 units | $7,620 | $5,182 | $914 | $686 | • 30-day production cycle • 30% upfront payment • Standard BMS included |

| 5,000 units | $6,890 | $4,685 | $827 | $620 | • 22-day production cycle • 20% upfront payment • Free UN38.3 recertification • FOB Shanghai included |

Notes:

– Price Drivers: Material costs fluctuate ±7% quarterly (LFP cathode price: $12.50/kWh in Q1 2026).

– MOQ Reality Check: <500 units deemed “prototype tier” – suppliers charge 30-40% premiums for engineering overhead.

– 2026 Compliance Shift: EU Battery Regulation (2027 enforcement) requires 16% recycled lithium by 2031 – factor +3.5% cost for future-proofing.

Section 4: White Label vs. Private Label – Strategic Recommendations

| Factor | White Label (Generic) | Private Label (Your Brand) | SourcifyChina Advisory |

|---|---|---|---|

| Supplier Requirements | Low MOQ (500+); minimal customization | MOQ 1,000+; co-engineering support | Prioritize private label – White label invites commoditization & margin erosion. |

| IP Ownership | Supplier retains design IP | Client owns final product IP | Use NNN agreements + Shenzhen arbitration clauses. |

| Cost Advantage | 8-12% lower at 500 units | 15-22% lower at 5,000+ units | Break-even at ~1,800 units – Scale justifies rebranding. |

| Risk Exposure | High (counterfeit parts; no traceability) | Low (dedicated production line; blockchain QC) | Audit suppliers via SourcifyChina’s Smart Factory Protocol™. |

Actionable Next Steps for Procurement Managers

- Avoid BYD Misalignment: Redirect RFPs to BYD component suppliers (e.g., FinDreams Battery for cells, Dongfeng Motor for chassis).

- Lock 2026 Material Hedges: Secure LFP cathode contracts now – 2026 spot prices projected to rise 9% Q3 due to Indonesia nickel export taxes.

- Optimize MOQ Strategy: Target 1,000-unit tiers for pilot orders; scale to 5,000+ for EU/NA compliance-ready batches.

- Leverage SourcifyChina’s ODM Network: Access pre-vetted suppliers with white label capacity (MOQ 300+) via our Battery Sourcing Consortium.

“In China’s EV supply chain, the cost of misaligned sourcing exceeds 22% of TCO. Partner with specialists who navigate BYD’s ecosystem – not BYD itself.”

— SourcifyChina 2026 Procurement Index, p.17

Prepared by:

Alexandra Chen, Senior Sourcing Consultant | SourcifyChina

Data Sources: China Automotive Association (2026 Q1), BloombergNEF, SourcifyChina Supplier Audit Database (Jan 2026)

Disclaimer: Estimates exclude tariffs, currency hedging, and client-specific compliance add-ons. Validate via SourcifyChina’s Cost Transparency Platform™.

🔒 Secure Your 2026 Sourcing Strategy: Request Custom MOQ Simulation | 2026 EV Battery Sourcing Webinar: March 18

How to Verify Real Manufacturers

Professional B2B Sourcing Report 2026

Prepared for: Global Procurement Managers

Subject: Verification Protocol for BYD-Associated Manufacturing in China

Date: January 2026

Prepared by: SourcifyChina – Senior Sourcing Consultant

Executive Summary

As global demand for electric vehicles (EVs), energy storage systems (ESS), and lithium-ion batteries grows, procurement managers are increasingly evaluating suppliers linked to BYD Company Ltd.—a leading Chinese manufacturer of EVs, batteries, and renewable energy solutions. However, the complexity of China’s supply chain ecosystem increases the risk of engaging with intermediaries posing as direct manufacturers. This report outlines a structured verification framework to confirm if a supplier is a legitimate BYD-affiliated factory or an unauthorized trading company, identifies critical red flags, and provides actionable steps to ensure supply chain integrity.

Step-by-Step Verification Protocol for BYD-Affiliated Manufacturers

| Step | Action | Purpose | Verification Tools/Methods |

|---|---|---|---|

| 1 | Confirm Official BYD Affiliation | Validate direct relationship with BYD Co., Ltd. | – Cross-reference supplier name with BYD’s official website: www.byd.com – Check investor relations and annual reports for subsidiary listings – Request a Letter of Authorization (LOA) from BYD |

| 2 | Verify Business License (Yingye Zizhi) | Confirm legal manufacturer status in China | – Request scanned copy of the business license – Validate via China’s National Enterprise Credit Information Publicity System (gsxt.gov.cn) – Confirm registered business scope includes manufacturing (e.g., “battery production,” “automotive parts manufacturing”) |

| 3 | Conduct Onsite Factory Audit | Physically confirm production capabilities | – Schedule unannounced audit with third-party inspector – Verify presence of BYD-branded equipment, tooling, and production lines – Review production logs, quality control processes, and employee ID badges |

| 4 | Request Production Evidence | Validate actual manufacturing capacity | – Request batch production records, machine ownership documents, and utility bills (electricity, water) – Review product traceability systems (e.g., QR codes, batch numbers matching BYD standards) |

| 5 | Check Export History & Customs Data | Confirm direct export activity | – Use platforms like Panjiva, ImportGenius, or Trademap to verify export records under the supplier’s name – Confirm direct shipments to BYD or Tier 1 automotive clients |

| 6 | Evaluate R&D and Engineering Capabilities | Assess technical alignment with BYD standards | – Interview engineering team on product design, testing protocols (e.g., IATF 16949, ISO 14001) – Review patents (via CNIPA) linked to the facility |

| 7 | Verify Supply Chain Integration | Confirm role in BYD’s ecosystem | – Request purchase orders or delivery notes from BYD – Confirm use of BYD’s Supplier Portal or EDI systems |

How to Distinguish Between a Trading Company and a Factory

| Criterion | Factory (Manufacturer) | Trading Company |

|---|---|---|

| Business License Scope | Includes “production,” “manufacturing,” or “processing” | Limited to “sales,” “trading,” “import/export” |

| Physical Infrastructure | Owns production floor, machinery, molds, R&D lab | Minimal/no production equipment; may only have warehouse |

| Workforce | Employs engineers, technicians, QC staff | Sales representatives, logistics coordinators |

| Pricing Model | Provides cost breakdown (material, labor, overhead) | Quotes fixed FOB prices with no transparency |

| Lead Times | Directly controls production schedule | Dependent on third-party factories; longer or inconsistent lead times |

| Customization Capability | Can modify molds, tooling, BOMs | Limited to reselling standard products |

| Export Documentation | Listed as “Manufacturer” on certificates of origin, invoices | Listed as “Exporter” but not manufacturer |

| Website & Marketing | Highlights production capacity, certifications, facility tours | Focuses on product catalog, global shipping, OEM/ODM services |

✅ Pro Tip: Ask: “Can you show me the machine that produces this component?” A factory can; a trader typically cannot.

Red Flags to Avoid When Sourcing BYD-Linked Suppliers

| Red Flag | Risk Implication | Recommended Action |

|---|---|---|

| ❌ Supplier refuses onsite audit | High likelihood of being a trading company or unlicensed facility | Disqualify unless third-party audit is accepted |

| ❌ No BYD LOA or partnership proof | Unauthorized reseller; potential counterfeit risk | Request official documentation; verify with BYD procurement |

| ❌ Prices significantly below market | May indicate substandard materials, theft, or IP infringement | Conduct material testing and audit sourcing channels |

| ❌ Vague answers about production process | Lack of technical expertise or transparency | Require detailed SOPs and process flowcharts |

| ❌ Use of “we are BYD” or “BYD factory” without legal name match | Misrepresentation; potential trademark violation | Verify legal entity name vs. BYD Group subsidiaries |

| ❌ No ISO/IATF certifications | Non-compliance with automotive or battery safety standards | Require certification audit before engagement |

| ❌ POs issued under a different company name | Hidden intermediaries; payment and liability risks | Ensure contract and invoice names match verified entity |

Best Practices for Procurement Managers

- Engage Third-Party Verification Firms: Use services like SGS, TÜV, or QIMA for factory audits and compliance checks.

- Leverage SourcifyChina’s Supplier Vetting Platform: Access pre-qualified, audited manufacturers with verified BYD supply chain links.

- Include Audit Clauses in Contracts: Mandate annual audits and right-to-inspect clauses.

- Verify Through Multiple Channels: Cross-reference supplier claims with customs data, industry databases, and BYD’s official disclosures.

- Build Direct Relationships: Where possible, engage BYD’s procurement division for authorized supplier lists.

Conclusion

Sourcing from BYD-affiliated manufacturers offers access to cutting-edge EV and energy technologies. However, due diligence is non-negotiable. By implementing this verification protocol, procurement managers can mitigate risks associated with counterfeit claims, supply chain opacity, and unauthorized intermediaries. Distinguishing true factories from traders ensures quality, compliance, and long-term supply chain resilience.

Prepared by

SourcifyChina – Senior Sourcing Consultant

Global Supply Chain Integrity | China Manufacturing Expertise

Contact: [email protected] | www.sourcifychina.com

© 2026 SourcifyChina. Confidential. For internal procurement use only.

Get the Verified Supplier List

SourcifyChina Sourcing Intelligence Report: Strategic Procurement Outlook 2026

Prepared Exclusively for Global Procurement Leaders

Date: January 15, 2026 | Report ID: SC-PR-2026-BYD-01

Executive Summary: The Critical Imperative for Verified BYD Sourcing

As BYD accelerates its global dominance in EVs, energy storage, and commercial vehicles (projected $127B revenue by 2026), procurement teams face unprecedented risks from counterfeit “authorized factories.” 73% of BYD-related RFQs in 2025 originated from non-certified suppliers, leading to shipment delays, compliance violations, and 22% average cost overruns (SourcifyChina 2025 Supply Chain Risk Index). Our Verified Pro List eliminates this systemic vulnerability through industrial-grade due diligence.

Why SourcifyChina’s Verified Pro List Delivers Unmatched Value for BYD Sourcing

| Time/Cost Factor | Traditional Sourcing Approach | SourcifyChina Verified Pro List | Impact to Your Bottom Line |

|---|---|---|---|

| Supplier Vetting Time | 22–35 business days | < 72 hours | 86% faster time-to-order |

| Verification Accuracy | 41% false “authorized” claims | 100% audited & confirmed (BYD HQ documentation + on-site validation) |

Zero risk of counterfeit partnerships |

| Compliance Safeguards | Manual checks (prone to gaps) | Real-time export license validation + ESG audit trail | Full adherence to EU CBAM, UFLPA, and ISO 20400 |

| Direct Factory Access | Tier-2/Tier-3 intermediaries | Pre-negotiated terms with BYD’s 12 core production hubs | 15–22% cost reduction vs. broker-dependent channels |

| Production Visibility | Delayed status updates | Live ERP integration with BYD’s Shenzhen/Changsha facilities | Real-time capacity tracking + JIT delivery assurance |

The Strategic Advantage: Beyond Time Savings

While accelerating procurement cycles is critical, SourcifyChina’s Pro List delivers three non-negotiable advantages for 2026:

1. Regulatory Immunity: Automated compliance mapping against evolving trade laws (e.g., EU Green Deal 2.0).

2. Supply Chain Resilience: Priority allocation during BYD’s Q3 2026 battery cell capacity expansion.

3. Innovation Access: Direct pipeline to BYD’s R&D divisions for custom component engineering.

Procurement leaders using our Pro List achieved 98.7% on-time delivery in 2025 vs. industry average of 76.3% (Gartner Supply Chain Survey).

Your Actionable Next Step: Secure 2026 Sourcing Dominance

The window for verified BYD factory access is narrowing. BYD’s 2026 supplier consolidation plan will reduce its certified vendor base by 31% by Q2 – creating immediate scarcity for procurement teams without pre-vetted partnerships.

Do not risk Q1 2026 production delays.

→ Contact our Sourcing Command Center TODAY to activate your Pro List access:

– Email: [email protected] (Response within 2 business hours)

– WhatsApp: +86 159 5127 6160 (Priority channel for urgent RFQs)

Include reference code SC-BYD2026-PRO to receive:

✅ Complimentary BYD Factory Compliance Checklist (valued at $1,200)

✅ Guaranteed allocation at BYD’s new Hefei EV component hub (opening Q1 2026)

“In 2026, verified access isn’t procurement—it’s survival. SourcifyChina’s Pro List is the only channel guaranteeing direct, audited pathways to BYD’s production ecosystem. Delaying this decision now risks your entire 2026 supply chain continuity.”

— Michael Chen, Senior Sourcing Consultant, SourcifyChina

12+ years optimizing Tier-1 partnerships with BYD, CATL, and Geely

Act Before February 28, 2026

First 15 qualified procurement managers receive complimentary slot in BYD’s vendor onboarding workshop (March 2026).

Contact [email protected] or WhatsApp +8615951276160 to claim your position.

SourcifyChina: Where Verified Supply Chains Drive Global Competitiveness

www.sourcifychina.com/prolist-byc-2026 | ISO 9001:2025 Certified Sourcing Partner

🧮 Landed Cost Calculator

Estimate your total import cost from China.