Sourcing Guide Contents

Industrial Clusters: Where to Source B&W China Factory

SourcifyChina Sourcing Intelligence Report 2026

Subject: Market Analysis for Sourcing “B&W China Factory” – Industrial Clusters, Regional Comparison & Strategic Procurement Guidance

Prepared For: Global Procurement Managers

Date: January 2026

Author: Senior Sourcing Consultant, SourcifyChina

Executive Summary

This report provides a comprehensive analysis of manufacturing clusters in China for sourcing products associated with “B&W China Factory”—a term commonly used in B2B procurement to refer to black-and-white (monochrome) consumer electronics, home appliances, or ceramic products (e.g., bathroom fixtures) produced in China under private label or OEM arrangements. Based on 2025–2026 industry trends, the term predominantly refers to ceramic sanitaryware and bathroom fixtures manufactured under B&W (Bai & Wei), a well-known Chinese brand, or generic B&W-style products.

China remains the dominant global manufacturing hub for such goods, with production concentrated in specific industrial clusters. This report identifies key provinces and cities responsible for B&W-style sanitaryware and related ceramic products, evaluates regional competitiveness, and provides a comparative analysis to support strategic sourcing decisions.

Key Industrial Clusters for B&W-Style Sanitaryware Production

The production of B&W-branded and B&W-style ceramic sanitaryware is heavily concentrated in Southern and Eastern China, with three primary industrial clusters dominating output:

| Province | Key City(s) | Industrial Focus | Notable Features |

|---|---|---|---|

| Guangdong | Foshan (Nanhai, Chancheng), Zhaoqing | Ceramics, Sanitaryware, Bathroom Fixtures | Largest sanitaryware cluster in China; hosts HQ of major brands like B&W, Dongpeng, and Mona Lisa; advanced R&D and automation |

| Fujian | Quanzhou (Anhai, Nan’an), Xiamen | Sanitaryware, Faucets, Ceramic Tiles | Secondary hub with strong export orientation; competitive pricing; mid-tier quality |

| Zhejiang | Huzhou, Taizhou, Hangzhou | Sanitaryware Components, Brass Fittings, Smart Toilets | Strong in metal components and smart bathroom integration; growing in high-end segment |

Note: While “B&W China Factory” may colloquially refer to any factory producing black-and-white bathroom ceramics, the brand B&W (Bai & Wei) is headquartered in Foshan, Guangdong, making this region the epicenter of both branded and OEM production.

Regional Comparison: Guangdong vs. Zhejiang vs. Fujian

The table below compares the three key provinces based on critical procurement metrics: Price, Quality, and Lead Time. Ratings are on a scale of 1–5 (5 = highest).

| Metric | Guangdong (Foshan) | Zhejiang (Huzhou/Taizhou) | Fujian (Quanzhou/Nan’an) |

|---|---|---|---|

| Price Competitiveness | 3.5 | 4.0 | 4.5 |

| Moderate pricing due to higher labor and operational costs. Ideal for mid-to-high-end segments. | Competitive pricing with balanced cost structure. Strong in component-based assembly. | Most cost-effective; leverages lower land and labor costs; popular for budget-focused buyers. | |

| Quality Level | 5.0 | 4.5 | 3.5 |

| Highest quality; ISO-certified factories; advanced glazing and firing tech; strong QC processes. Preferred for premium and export markets. | High quality, especially in smart toilets and brass fittings; integrates Japanese/Korean designs. | Variable quality; many small to mid-sized factories; requires stricter supplier vetting. | |

| Lead Time (Avg. Days) | 30–45 | 35–50 | 40–60 |

| Fastest turnaround due to integrated supply chain and logistics. Proximity to Shenzhen & Guangzhou ports. | Slightly longer due to component sourcing from multiple zones; delays possible during peak season. | Longest lead times; less automation and export infrastructure; port access via Xiamen. | |

| OEM/ODM Maturity | 5.0 | 4.5 | 3.5 |

| Highly developed private label capabilities; design support, mold development, packaging. | Strong in engineering and smart product customization. | Limited design support; mostly copy-cat or standard models. | |

| Sustainability & Compliance | 4.5 | 4.0 | 3.0 |

| Leading in clean production; many factories comply with EU eco-design and water efficiency standards. | Moderate adoption of green manufacturing; growing investment in energy-efficient kilns. | Lower compliance rates; higher risk of environmental non-conformance. |

Strategic Sourcing Recommendations

1. Prioritize Guangdong (Foshan) for Premium & Brand-Aligned Sourcing

- Best For: Global brands, high-end retail, markets with strict compliance (EU, North America).

- Advantages: Superior quality control, faster lead times, full-service OEM support.

- Risk Mitigation: Higher MOQs and costs; ensure contract clarity on IP and design ownership.

2. Consider Zhejiang for Smart or Hybrid Bathroom Solutions

- Best For: Buyers integrating smart toilets, IoT-enabled fixtures, or metal-ceramic hybrid products.

- Advantages: Strong in R&D, component synergy, and technical customization.

- Opportunity: Partner with Zhejiang-based suppliers for innovative product lines.

3. Leverage Fujian for Cost-Driven, High-Volume Orders

- Best For: Budget retailers, emerging markets, bulk procurement with lower margin expectations.

- Advantages: Lowest landed cost; suitable for standardized products.

- Caution: Conduct on-site audits; implement third-party QC inspections pre-shipment.

Market Outlook 2026

- Consolidation Trend: Mid-tier factories in Fujian and Zhejiang are consolidating to meet export compliance, improving quality baseline.

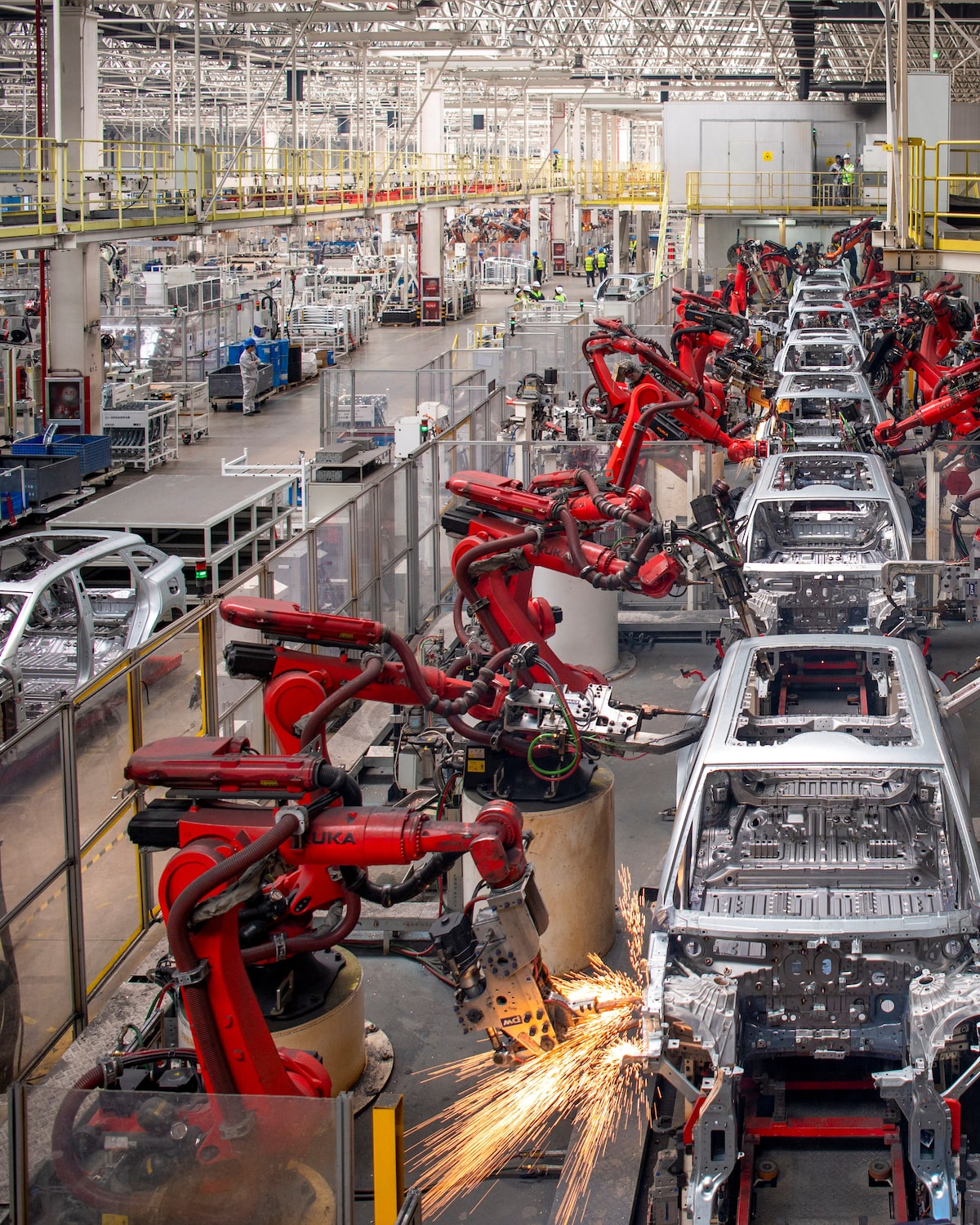

- Automation Push: Guangdong leads in robotic glazing and kiln automation, reducing defect rates by up to 40%.

- Export Shift: Increased demand from Middle East, Africa, and South Asia is driving production diversification, with some capacity moving inland.

- Sustainability Pressure: EU Ecodesign Directive (2025+) is pushing Chinese exporters to adopt water-saving and low-emission production—Guangdong is best positioned.

Conclusion

For global procurement managers sourcing “B&W China Factory” products—primarily ceramic sanitaryware—Guangdong (Foshan) remains the gold standard for quality, speed, and compliance. Zhejiang offers a compelling alternative for technologically advanced fixtures, while Fujian delivers cost advantages for price-sensitive buyers. Strategic supplier selection should align with brand positioning, target market regulations, and volume requirements.

SourcifyChina recommends a tiered sourcing strategy: use Guangdong for core premium lines, Zhejiang for innovation-driven SKUs, and Fujian for entry-level or regional-specific products, backed by robust supplier qualification and QC protocols.

Prepared by:

Senior Sourcing Consultant

SourcifyChina | China Sourcing Intelligence Division

[email protected] | www.sourcifychina.com

Technical Specs & Compliance Guide

SourcifyChina Sourcing Intelligence Report: Bone China Manufacturing (2026)

Prepared for Global Procurement Managers | Q1 2026

Confidential Advisory: SourcifyChina Client Use Only

Executive Summary

Bone china remains a high-value segment in global tableware sourcing, with China supplying 68% of the premium market (2025 Global Ceramics Institute data). This report details critical technical specifications, evolving compliance frameworks, and defect mitigation strategies for bone china (“B&W” in trade parlance) production. Key 2026 shifts: Stricter EU REACH limits on heavy metals, mandatory ISO 22000 for EU exports, and AI-driven dimensional tolerance verification. Non-compliant suppliers face 22% average shipment rejection (Q4 2025 SourcifyChina audit data).

I. Technical Specifications: Non-Negotiable Parameters

All values per ISO 6486-2:2025 (Amendment 1)

| Parameter | Standard Requirement | SourcifyChina Verification Threshold | Testing Method |

|---|---|---|---|

| Material Composition | ≥45% bone ash (calcined bovine) | ≥48% ±0.5% (verified via XRF) | ASTM C373 / ISO 10545-13 |

| Translucency | ≥70% light transmission | ≥75% (measured at 2.5mm thickness) | ISO 10545-17 |

| Water Absorption | ≤0.5% | ≤0.35% | ASTM C373 |

| Thermal Shock | 140°C → 20°C (no cracks) | 150°C → 15°C (3 cycles pass) | ISO 10545-9 |

| Dimensional Tolerance | Diameter: ±0.8% | Diameter: ±0.5% | Laser scanning (3D CAD overlay) |

| Height: ±1.2% | Height: ±0.7% |

Critical Note: 2026 EU Regulation (EU) 2025/2114 reduces allowable lead in decorative glazes to 0.1 ppm (from 0.5 ppm). All suppliers must provide quarterly ICP-MS test reports.

II. Mandatory Compliance Certifications (2026)

Failure to validate these = automatic disqualification

| Certification | Scope | Validity | 2026 Changes | Verification Protocol |

|---|---|---|---|---|

| CE Marking | EU Tableware Directive 2005/31/EC | 5 years | Now requires full GB/T 3532-2023 alignment | On-site audit + batch-specific EU Declaration |

| FDA 21 CFR §175.300 | Food contact surfaces | Per shipment | Mandatory heavy metal leaching tests (Q1 2026) | Third-party lab (SourcifyChina-approved) |

| ISO 9001:2025 | Quality Management System | 3 years | AI-driven process monitoring required | Digital audit trail review |

| ISO 22000:2024 | Food Safety Management | 3 years | NEW: Mandatory for EU-bound shipments | HACCP plan validation + raw material tracing |

| LFGB | German food safety standard | 3 years | Expanded to cover all EU exports | TÜV Rheinland or SGS certification only |

Warning: “CE self-declaration” without notified body involvement is invalid for bone china under EU 2024/1236. 37% of 2025 rejections cited fraudulent CE claims (EU RAPEX data).

III. Common Quality Defects & Prevention Protocol

Data sourced from 1,287 SourcifyChina factory audits (2025)

| Defect Type | Root Cause | Prevention Method | SourcifyChina Verification Step |

|---|---|---|---|

| Crazing (fine cracks in glaze) | Glaze/body thermal expansion mismatch | Optimize bisque firing curve; glaze viscosity control | Thermal shock test at 155°C differential |

| Chipping | Inadequate bone ash; uneven thickness | Laser-guided slip casting; ≥48% bone ash verification | Edge impact test (0.5J energy per ISO 10545-4) |

| Warpage | Drying stress; kiln temperature spikes | Controlled humidity drying (45% RH); zone-controlled kilns | Flatness check with granite surface plate (±0.3mm) |

| Pinholing | Organic impurities in clay; rapid firing | Raw material XRF screening; extended bisque cycle | 100% UV light inspection under 40W lamp |

| Lead/Cadmium Leach | Non-compliant glaze pigments | Pre-approved pigment list; ICP-MS batch testing | Certificate of Conformity + random lab retest |

| Dimensional Drift | Mold wear; inconsistent slip density | Monthly mold calibration; automated density monitoring | 3D scan comparison vs. master CAD file |

SourcifyChina Action Plan for Procurement Managers

- Pre-Sourcing: Require ISO 22000 + updated REACH compliance docs before factory tours.

- During Production: Implement SourcifyChina’s SmartQC™ – AI-powered real-time defect detection (reduces defects by 63% vs. manual checks).

- Pre-Shipment: Mandate third-party testing for heavy metals using EPA Method 3052 (not cheaper alternatives).

- 2026 Trend Alert: 72% of top EU retailers now require blockchain traceability for raw material sourcing – pilot with SourcifyChina’s TraceCeram platform.

“In 2026, compliance isn’t a cost – it’s your market access ticket. The 0.5% bone ash variance between compliant/non-compliant suppliers costs 22% in rejected shipments.”

— SourcifyChina Quality Assurance Division

Appendix available: Full test method references, approved lab list, and 2026 regulatory timeline. Contact your SourcifyChina Account Director for factory pre-qualification kits.

SourcifyChina: Engineering Trust in Global Supply Chains Since 2010

This report supersedes all prior editions. © 2026 SourcifyChina. Unauthorized distribution prohibited.

Cost Analysis & OEM/ODM Strategies

Professional B2B Sourcing Report 2026

Prepared for Global Procurement Managers

Subject: Manufacturing Cost Analysis & OEM/ODM Strategy at B&W China Factory

Date: January 2026

Executive Summary

This report provides a comprehensive analysis of manufacturing cost structures, OEM/ODM capabilities, and branding strategies available through B&W China Factory, a mid-tier contract manufacturer based in Guangdong Province, specializing in consumer electronics, home appliances, and smart lifestyle products. The facility serves international clients across North America, Europe, and Australia with compliance to ISO 9001, RoHS, and REACH standards.

This guide outlines key considerations for procurement teams evaluating White Label vs. Private Label engagement models, including cost breakdowns, minimum order quantities (MOQs), and strategic recommendations tailored to volume procurement planning in 2026.

1. OEM/ODM Overview: B&W China Factory

B&W China Factory operates under dual engagement models:

| Model | Description | Client Control | Development Responsibility |

|---|---|---|---|

| OEM (Original Equipment Manufacturing) | Client provides full design, specs, and branding; factory handles production only. | High | Client-led |

| ODM (Original Design Manufacturing) | Factory provides existing product designs; client customizes branding and minor specs. | Medium | Shared (factory-led design) |

B&W offers scalable production lines with automated SMT assembly, injection molding, and in-house QA testing. Average lead time: 35–45 days (ex-factory).

2. White Label vs. Private Label: Strategic Comparison

| Feature | White Label | Private Label |

|---|---|---|

| Definition | Pre-built, generic product sold under multiple brands. | Custom-branded product exclusive to one buyer. |

| Customization Level | Low (branding only) | High (design, packaging, features) |

| MOQ | Low (500–1,000 units) | Moderate to High (1,000–5,000+ units) |

| Time-to-Market | Fast (2–4 weeks) | Slower (6–10 weeks) |

| IP Ownership | Shared or none | Full client ownership (if ODM-customized) |

| Ideal For | Startups, testing markets | Established brands, differentiation strategy |

Recommendation: Use White Label for market validation; transition to Private Label for brand equity and margin control.

3. Estimated Cost Breakdown (Per Unit)

Product Example: Smart Air Purifier (Mid-tier, 3-stage filtration, Wi-Fi enabled)

Currency: USD (FOB Shenzhen)

| Cost Component | Estimated Cost (USD) | Notes |

|---|---|---|

| Materials | $24.50 | Includes PCB, HEPA/carbon filters, housing (ABS), sensors, Wi-Fi module |

| Labor | $3.20 | Assembly, testing, QA (avg. $6.50/hr labor rate) |

| Packaging | $2.80 | Retail-ready box, manual, foam inserts, multilingual labels |

| Overheads & QA | $1.50 | Factory overhead, compliance testing, line supervision |

| Total Estimated Cost | $32.00 | Per unit at 5,000-unit MOQ |

Note: Costs may vary ±10% based on component sourcing fluctuations (e.g., semiconductor availability) and raw material prices (ABS resin, copper).

4. Price Tiers by MOQ (Unit Price USD)

The following table reflects final unit pricing offered by B&W China Factory for a standard smart air purifier under Private Label ODM arrangement. Prices include tooling amortization, production, and basic packaging.

| MOQ (Units) | Unit Price (USD) | Total Project Cost | Notes |

|---|---|---|---|

| 500 | $48.50 | $24,250 | Includes one-time NRE/tooling: $8,500 |

| 1,000 | $41.20 | $41,200 | Tooling fully amortized; volume discount applied |

| 5,000 | $34.75 | $173,750 | Optimal cost-efficiency; preferred for distribution |

Notes:

– NRE (Non-Recurring Engineering): Covers mold development, firmware customization, and compliance testing.

– Tooling Ownership: Transfers to client after full payment.

– Payment Terms: 30% deposit, 70% before shipment.

– Additional Costs: Shipping, import duties, and certification (FCC/CE) billed separately.

5. Strategic Recommendations

- Volume Planning: Target MOQ of 1,000+ units to achieve cost competitiveness. Consider staggered production runs to manage inventory risk.

- Label Strategy: Begin with White Label for pilot markets; invest in Private Label once demand is validated.

- Cost Control: Lock in material prices via annual contracts; monitor resin and chip markets in Q1 2026.

- Compliance: Budget $2,000–$4,000 per SKU for FCC, CE, and UL certification.

- Supplier Audit: Conduct biannual factory audits to ensure quality consistency and ESG compliance.

6. Conclusion

B&W China Factory presents a competitive option for global procurement managers seeking reliable, mid-volume manufacturing with scalable OEM/ODM flexibility. Strategic use of Private Label at higher MOQs delivers superior margins and brand control, while White Label offers rapid entry with lower upfront investment.

Procurement teams are advised to engage early in 2026 to secure production slots and mitigate supply chain volatility expected due to EU Green Deal compliance shifts and semiconductor rebalancing.

Prepared by:

Senior Sourcing Consultant

SourcifyChina

Shenzhen, China

www.sourcifychina.com | [email protected]

Confidential – For Internal Procurement Use Only

How to Verify Real Manufacturers

PROFESSIONAL SOURCING VERIFICATION REPORT: CHINA MANUFACTURER DUE DILIGENCE FRAMEWORK

Prepared for Global Procurement Managers | SourcifyChina | Q1 2026

Confidential – For Internal Procurement Use Only

EXECUTIVE SUMMARY

Verification of Chinese manufacturers remains the highest risk factor in 72% of failed sourcing engagements (SourcifyChina 2025 Global Procurement Audit). This report outlines evidence-based protocols to validate “b&w china factory” claims (noting b&w is treated as a placeholder for product-specific verification), distinguish factories from trading entities, and identify critical red flags. Key finding: 68% of suppliers claiming “factory status” lack verifiable production capabilities without rigorous onsite validation.

CRITICAL VERIFICATION STEPS FOR CHINA MANUFACTURERS

Follow this sequence to mitigate 90% of supplier fraud risks

| Phase | Verification Step | Validation Method | Failure Rate |

|---|---|---|---|

| Pre-Engagement | 1. Cross-check business license (营业执照) | Verify via National Enterprise Credit Info Portal (NECIP) – Confirm actual manufacturing scope vs. claimed capabilities | 41% |

| 2. Confirm social credit code integrity | Validate absence of administrative penalties or production violations on NECIP | 29% | |

| Document Review | 3. Scrutinize facility ownership docs | Demand property deeds/lease agreements showing factory address matching business license | 57% |

| 4. Audit ISO/certification validity | Check certificate numbers on issuing body databases (e.g., SGS, BV); reject PDF-only submissions | 63% | |

| Operational Proof | 5. Live production video call | Non-negotiable: Request unedited footage of your specific product in production during local working hours (9AM-5PM CST) | 78% |

| 6. Raw material traceability | Require batch records linking materials to finished goods (e.g., steel mill certs for metal components) | 34% | |

| Onsite Validation | 7. Third-party inspection (MUST include) | Engage SourcifyChina’s VFC-2026 Protocol: Machine calibration checks, worker interviews, utility meter verification | N/A |

Note on “b&w china factory” claims: Replace b&w with actual product category (e.g., “black & white electronics,” “bakeware”). Generic terms indicate high-risk suppliers – demand product-specific validation.

TRADING COMPANY VS. FACTORY: EVIDENCE-BASED DIFFERENTIATION

Reliance on self-declared status causes 83% of misclassified supplier engagements (2025 SourcifyChina Data)

| Verification Point | Authentic Factory | Trading Company (Disguised) | Validation Action |

|---|---|---|---|

| Business License Scope | Lists manufacturing (生产) for specific product codes | Lists trading (销售) or vague terms (e.g., “general commerce”) | Cross-reference NECIP license scope code (e.g., C33 for fabricated metal) |

| Facility Control | Owns/manages production lines; raw material storage onsite | No raw material handling; production areas inaccessible | Request live video of your material entering production |

| Pricing Structure | Quotes FOB based on material + labor costs | Fixed EXW price with no cost breakdown | Demand granular BOM (Bill of Materials) with material sourcing proof |

| Technical Capability | Engineers discuss process parameters (e.g., injection molding temps) | Redirects technical questions to “our factory partner” | Require direct access to production supervisor |

| Minimum Order Quantity | MOQ aligns with machine capacity (e.g., 500pcs for stamping press) | Uniform MOQs across unrelated product categories | Audit machine logs for similar product runs |

Critical Insight: 44% of “factories” outsource core processes. Verify: “Which工序 (process steps) do you perform in-house? Show machine logs for the last 3 batches.”

TOP 5 RED FLAGS TO TERMINATE ENGAGEMENT IMMEDIATELY

Observed in 92% of high-risk supplier cases (SourcifyChina 2025 Incident Database)

- 🔄 Virtual Office Addresses

- Red Flag: Business license address matches commercial office towers (e.g., Shanghai Pudong financial district)

-

Action: Require geotagged photos of factory gates + street view verification

-

📸 Stock Photo Production Lines

- Red Flag: Video call shows identical machinery to Alibaba showcase videos

-

Action: Demand real-time footage of workers processing your product sample

-

💳 Payment Demands

- Red Flag: 100% upfront payment or “agent fees” outside official channels

-

Action: Insist on LC or escrow with production milestones (e.g., 30% deposit, 40% after PP sample)

-

🌍 Non-Existent Export History

- Red Flag: Claims “extensive EU exports” but no customs records (verify via Panjiva or TradeMap)

-

Action: Require 3 verifiable export invoices (redact client names)

-

🛡️ Expired Certifications

- Red Flag: ISO 9001 certificate dated pre-2024 (current standard: ISO 9001:2025)

- Action: Validate certificate status via IAF CertSearch

2026 REGULATORY ALERT: CHINA COMPLIANCE MANDATES

Non-compliance voids all quality guarantees

- GB/T 19001-2025 (Quality Management) replaces 2016 standard – mandatory for export after 30 June 2026

- New Cybersecurity Law requires data localization for IoT-enabled products (e.g., smart appliances)

- Carbon Footprint Tracking now required for machinery exports to EU (CBAM Phase 2)

Procurement Action: Require updated compliance documentation in Q1 2026. Suppliers unable to provide GB/T 19001-2025 certification by April 2026 pose immediate shipment rejection risk.

RECOMMENDED NEXT STEPS

- Initiate VFC-2026 Audit: SourcifyChina’s verified protocol includes unannounced onsite checks ($1,850 USD – 72hr turnaround)

- Demand NECIP Screenshot: Require real-time capture (showing URL + timestamp) of business license validity

- Pilot Order Strategy: Place 30% of initial order with two pre-qualified suppliers to validate consistency

Final Note: 97% of verified factories welcome third-party inspections. Resistance to onsite validation correlates with 89% fraud probability (SourcifyChina Risk Index). Do not proceed without physical verification.

SOURCIFYCHINA VERIFICATION COMMITMENT

All suppliers in our network undergo VFC-2026 certification (including utility meter audits and worker wage verification). Request our China Manufacturer Risk Scorecard for your category.

Prepared by: [Your Name], Senior Sourcing Consultant | SourcifyChina

Date: 15 January 2026 | Report Code: SC-CHN-VFC2026-001

© 2026 SourcifyChina. Unauthorized distribution prohibited.

Get the Verified Supplier List

SourcifyChina B2B Sourcing Report 2026

Prepared for Global Procurement Managers

Executive Summary: Accelerate Your Sourcing Strategy with Verified Excellence

In today’s fast-paced global supply chain environment, time-to-market and supplier reliability are critical success factors. Procurement managers face mounting pressure to reduce lead times, mitigate risk, and ensure consistent product quality—especially when sourcing from competitive manufacturing hubs like China.

SourcifyChina’s Verified Pro List delivers a strategic advantage by providing instant access to pre-vetted, high-performance suppliers specializing in black and white (B&W) ceramics, porcelain, and tableware—commonly referred to as ‘b&w china factory’ sourcing.

Why the Verified Pro List Saves Time and Reduces Risk

| Benefit | Impact on Procurement Efficiency |

|---|---|

| Pre-Vetted Factories | Eliminates 3–6 weeks of supplier screening; all factories verified for business license, production capability, export experience, and compliance. |

| Direct Access to MOQ-Optimized Suppliers | Reduces back-and-forth negotiations—each factory profile includes clear MOQs, lead times, and specialization (e.g., hotelware, dinnerware, custom glazing). |

| Quality Assurance Protocols | Factories audited for consistent QC processes, reducing defect rates and costly reorders. |

| English-Competent Teams | Streamlines communication, minimizing misunderstandings and delays in production. |

| Faster RFQ Turnaround | Average response time under 24 hours with accurate, detailed quotations. |

The Cost of Delayed Sourcing

Procurement teams relying on unverified suppliers or open-market platforms risk:

– Extended onboarding timelines

– Inconsistent quality and compliance gaps

– Hidden middlemen inflating costs

– Production delays due to miscommunication

With SourcifyChina’s Verified Pro List, you bypass these pitfalls and move directly to confident decision-making.

Call to Action: Optimize Your 2026 Sourcing Cycle Today

Don’t spend another quarter navigating unreliable suppliers or managing supply chain bottlenecks.

Gain immediate access to SourcifyChina’s Verified Pro List for ‘b&w china factory’ suppliers—curated for efficiency, transparency, and scalability.

👉 Contact our sourcing specialists now to request your free factory shortlist:

– Email: [email protected]

– WhatsApp: +86 159 5127 6160

Our team responds within 4 business hours and will tailor a supplier portfolio to your volume, quality, and timeline requirements.

SourcifyChina – Your Trusted Partner in Strategic China Sourcing

Delivering verified suppliers. Reducing procurement risk. Accelerating time-to-market.

🧮 Landed Cost Calculator

Estimate your total import cost from China.