The global demand for buttons continues to grow steadily, fueled by expansion in the fashion, apparel, and textile industries. According to a report by Mordor Intelligence, the global textile accessories market—which includes buttons—was valued at USD 87.6 billion in 2023 and is projected to grow at a CAGR of 5.2% from 2024 to 2029. This upward trajectory reflects increasing consumer demand for high-quality, sustainable, and custom-designed fasteners across both mass-market and premium clothing segments. As brands seek reliable supply chains and cost-effective sourcing solutions, partnering with established wholesale button manufacturers has become critical. Based on production capacity, global reach, material innovation, and customer reviews, here are the top 10 button wholesale manufacturers shaping the industry today.

Top 10 Buttons Wholesale Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 BUTTONS & NOVELTIES

Domain Est. 1995

Website: fashiondex.com

Key Highlights: International producer of buttons. Over 50,000 types of buttons in novelties, basic and fashion styles. All price range. Samples available. Cater to all markets ……

#2 USA Buttons

Domain Est. 1997

Website: usabuttons.com

Key Highlights: We have button parts for most industry standard sizes and most button machines in the industry including Badge-a-minit size button parts. FIND BUTTON PARTS NOW ……

#3 Buttonology Inc. – Premium Italian-Made Buttons in NYC

Domain Est. 2007

Website: buttonologyinc.com

Key Highlights: Buttonology Inc. takes pride in offering a premium selection of Italian-made buttons. Available for both individual and wholesale purchases….

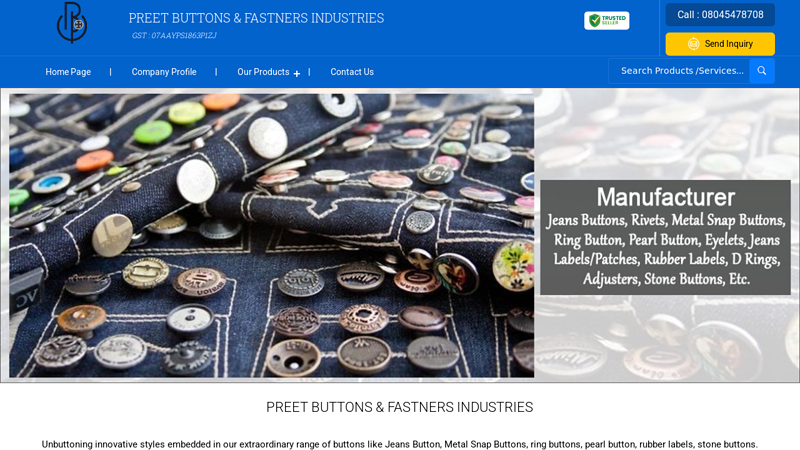

#4 Jeans Button Manufacturer,Metal Snap Buttons Supplier,Wholesaler …

Domain Est. 2007

Website: preetbuttons.com

Key Highlights: We are engaged in manufacturing a fabulous range of products including Jeans Button, Metal Snap Buttons, Ring Buttons, Pearl Snap Button, Rubber labels and ……

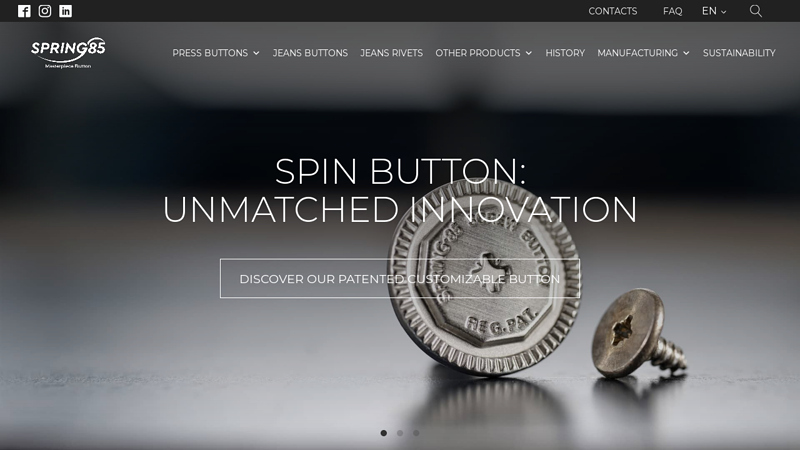

#5 Jeans Buttons and Rivets Manufacturer

Domain Est. 2016 | Founded: 1985

Website: spring85buttons.com

Key Highlights: Jeans buttons and rivets manufacturers for the fashion industry since 1985: specialists for clothing buttons, rivets and closures for jeans, leather, ……

#6 Wholesale Clothing Buttons for Sewing and Apparel Manufacturers

Domain Est. 2022

Website: sterlingbuttons.com

Key Highlights: Sterling Buttons has a deep inventory of vintage and modern clothing buttons available for bulk or wholesale orders. We can also custom manufacture and ……

#7 Wholesale pins and buttons for your store

Domain Est. 1998

#8 Speedy Buttons

Domain Est. 2003

Website: speedybuttons.com

Key Highlights: At Speedy Buttons, we are dedicated to providing top-quality, custom-made pin-back buttons and promotional products with unparalleled speed and exceptional ……

#9 The Button Company

Domain Est. 2007

Website: thebuttoncompany.net

Key Highlights: Welcome to The Button Company ( Wholesale Supplier of Unique Buttons) Shop Heirloom Buttons, Shop Plastic/Poly Buttons, Shop Shell Buttons, Shop Metal Buttons….

#10 Buttons Galore Wholesale

Domain Est. 2012

Website: buttonsgalorewholesale.com

Key Highlights: We’re a family-owned company with over 25 years in the craft industry, fueled by a deep passion for creativity and quality. What started as a small idea has ……

Expert Sourcing Insights for Buttons Wholesale

2026 Market Trends for Buttons Wholesale

The buttons wholesale industry is poised for notable shifts by 2026, driven by evolving consumer preferences, sustainability imperatives, and technological advancements. Here are the key trends expected to shape the market:

Growing Demand for Sustainable and Eco-Friendly Materials

Environmental consciousness will continue to influence purchasing decisions across the fashion and manufacturing sectors. By 2026, wholesale buyers will increasingly prioritize buttons made from biodegradable, recycled, or renewable materials such as wood, corozo (vegetable ivory), recycled plastics, and organic cotton. Suppliers who can verify eco-certifications and transparent supply chains will gain a competitive edge, as brands seek to meet corporate sustainability goals and consumer expectations.

Rise of Customization and Personalization

The demand for unique, branded, or limited-edition buttons will accelerate. Fashion brands, independent designers, and craft markets are leveraging custom buttons to differentiate products and enhance brand identity. Digital printing, laser engraving, and on-demand manufacturing will enable wholesalers to offer low-minimum custom orders, catering to small-batch producers and fast-fashion cycles without excess inventory.

Expansion of E-Commerce and Direct-to-Manufacturer Platforms

Online wholesale marketplaces and B2B e-commerce platforms will dominate distribution channels by 2026. Wholesalers investing in user-friendly digital catalogs, AI-powered product recommendations, and seamless ordering systems will capture larger market share. Integration with inventory and ERP systems will allow for real-time stock updates and faster fulfillment, meeting the growing need for supply chain agility.

Influence of Circular Fashion and Repair Culture

As the fashion industry embraces circular economy models, there will be increased demand for replacement buttons and repair kits. Wholesalers may see growth in supplying standardized or heritage-style buttons to support garment repair, upcycling, and resale markets. Collaborations with repair services and sustainability-focused brands will open new revenue streams.

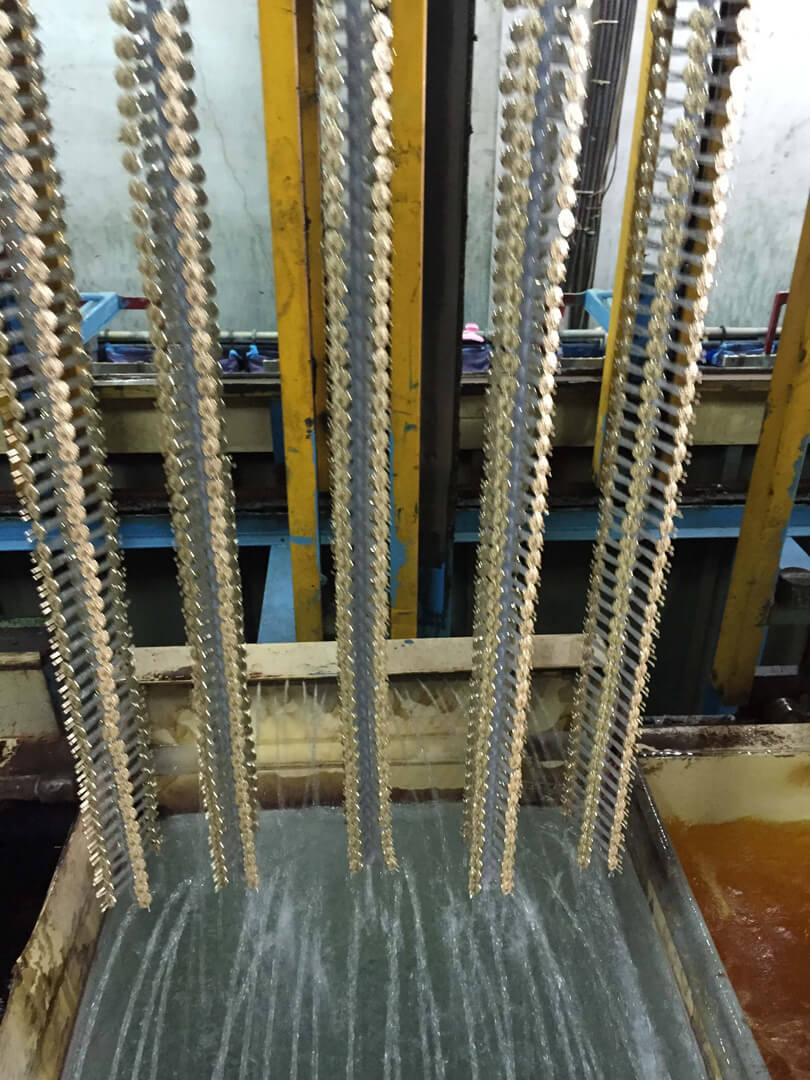

Technological Integration in Manufacturing

Automation and smart manufacturing will improve production efficiency and quality control in button fabrication. Wholesalers who adopt IoT-enabled inventory tracking, RFID tagging, and predictive analytics will enhance logistics and reduce lead times. Additionally, 3D printing may begin to play a role in prototyping and small-run specialty buttons, offering rapid turnaround for niche markets.

Regional Shifts in Sourcing and Production

Geopolitical factors and trade policies may continue to influence where buttons are manufactured. While Asia remains a dominant production hub, nearshoring and reshoring trends—particularly in North America and Europe—could grow for sustainability and supply chain resilience. Wholesalers with diversified sourcing strategies will be better positioned to manage disruptions and meet localized demand.

Increased Focus on Niche and Specialty Buttons

Beyond apparel, demand for specialty buttons—such as those used in medical textiles, automotive interiors, or smart clothing—will expand. Buttons with functional properties (e.g., antimicrobial coatings, conductive materials for wearable tech) will emerge as high-growth segments, requiring wholesalers to invest in R&D partnerships and technical expertise.

In summary, the 2026 buttons wholesale market will be characterized by sustainability, digital transformation, and customization. Success will depend on agility, innovation, and a customer-centric approach that aligns with broader industry shifts toward ethical production and personalized design.

Common Pitfalls Sourcing Buttons Wholesale: Quality and Intellectual Property Issues

Sourcing buttons in bulk can offer significant cost savings, but it also comes with risks—especially regarding quality consistency and intellectual property (IP) compliance. Ignoring these factors can lead to product failures, customer dissatisfaction, or even legal disputes. Below are two major pitfalls to watch out for when buying buttons wholesale.

Quality Inconsistencies and Material Defects

One of the most frequent challenges when sourcing buttons wholesale is inconsistent product quality. Suppliers, particularly those offering very low prices, may cut corners by using substandard materials or employing poor manufacturing practices. This can result in buttons that crack easily, fade after minimal use, have uneven coloring, or fail to withstand washing or regular wear.

Additionally, variations in size, thickness, or hole placement across batches can disrupt production lines or lead to mismatched garments. To mitigate this risk, always request physical samples before placing large orders and consider third-party quality inspections. Establish clear quality specifications in your contracts and maintain communication with suppliers to ensure consistency across shipments.

Intellectual Property Infringement Risks

Another critical pitfall is the unintentional sourcing of buttons featuring copyrighted designs, logos, or trademarks—especially when dealing with generic or unbranded suppliers. Many wholesale button suppliers offer decorative or novelty buttons that mimic popular characters, brand logos, or artistic designs without proper licensing. Using such buttons in your products can expose your business to legal action for trademark or copyright infringement.

Always verify that the designs on the buttons are either original, licensed, or in the public domain. Request documentation from the supplier confirming IP compliance, and avoid products that appear to replicate well-known brands or fictional characters. When in doubt, consult legal counsel to ensure your product lineup remains compliant and protects your brand reputation.

Logistics & Compliance Guide for Buttons Wholesale

Overview

This guide outlines the essential logistics and compliance procedures for Buttons Wholesale, a business specializing in the bulk distribution of buttons to retailers, manufacturers, and craft suppliers. Adhering to these practices ensures efficient operations, regulatory compliance, timely deliveries, and customer satisfaction.

Inventory Management

Maintain accurate stock levels through a centralized inventory management system. Conduct regular cycle counts and full audits quarterly to prevent overstocking or stockouts. Use barcode scanning for real-time tracking of button SKUs by size, material, color, and packaging type. Implement first-in, first-out (FIFO) principles to minimize obsolescence, especially for seasonally popular designs.

Warehousing & Storage

Store buttons in climate-controlled, dry environments to prevent damage from moisture or extreme temperatures. Organize storage by product category and turnover rate to optimize picking efficiency. Clearly label all bins and shelves. Ensure compliance with OSHA safety standards, including proper shelving load limits, fire extinguishers, and clear aisle markings.

Order Fulfillment

Process customer orders within 24 hours of receipt. Confirm order details, including quantity, specifications, and delivery deadlines. Pick, pack, and label orders accurately, using durable packaging to prevent spills or damage during transit. Include packing slips and compliance documentation (e.g., material safety data sheets if applicable) with each shipment.

Shipping & Carrier Coordination

Partner with reliable freight and parcel carriers to offer multiple delivery options (standard, expedited, international). Negotiate volume-based shipping rates to reduce costs. Use a transportation management system (TMS) to track shipments in real-time, optimize routing, and manage carrier performance. Provide customers with tracking information upon dispatch.

Domestic & International Compliance

Ensure all products comply with relevant regulations, such as the U.S. Consumer Product Safety Improvement Act (CPSIA) for children’s products, if applicable. For international sales, comply with destination country standards (e.g., REACH in the EU, CCC in China). Maintain up-to-date import/export licenses and file accurate customs documentation, including commercial invoices, packing lists, and certificates of origin.

Product Labeling & Packaging

Label all packaging with product description, SKU, quantity, batch/lot number, and handling instructions. Include required safety warnings or compliance marks when applicable (e.g., “Not for children under 3” if small parts). Use eco-friendly packaging materials where possible to align with sustainability goals and regulatory trends.

Recordkeeping & Documentation

Retain all logistics and compliance records for a minimum of seven years. This includes inventory logs, shipping manifests, customs filings, safety data sheets (SDS), and audit reports. Digitize records for easy retrieval during regulatory inspections or customer inquiries.

Risk Management & Business Continuity

Develop a risk mitigation plan addressing supply chain disruptions, natural disasters, or cyber threats. Maintain safety stock of high-demand items and identify alternate suppliers. Regularly test backup systems and update disaster recovery protocols to ensure uninterrupted service.

Training & Compliance Culture

Provide ongoing training for staff on logistics procedures, safety protocols, and compliance requirements. Conduct annual compliance reviews and update policies as regulations change. Foster a culture of accountability and continuous improvement across all operational teams.

Conclusion

Effective logistics and compliance management are critical to the success of Buttons Wholesale. By following this guide, the company can maintain operational efficiency, meet legal obligations, build customer trust, and support sustainable growth in a competitive marketplace.

In conclusion, sourcing buttons wholesale offers numerous advantages for businesses, including cost savings, consistent supply, and access to a wide variety of styles, materials, and finishes. By partnering with reliable suppliers and conducting thorough research into product quality, minimum order requirements, and ethical sourcing practices, companies can ensure they receive value and reliability. Establishing strong vendor relationships and staying informed about market trends further enhances the effectiveness of wholesale procurement. Overall, strategic wholesale sourcing of buttons supports efficient production, brand consistency, and long-term growth in the fashion, textile, and manufacturing industries.