Introduction: Navigating the Global Market for Butter Churner Machines

Hook

Across North America and the EU, forward-thinking dairy processors are scaling production, yet many still rely on under-powered, region-specific churns that limit throughput and compromise yield. The result: higher cost-per-kilo, inconsistent texture, and lost shelf space to artisanal competitors.

The Problem

– Capacity gaps: Small-batch units stall production; large units overspend capital.

– Voltage mismatch: 115 V vs. 230 V, 50 Hz vs. 60 Hz—inventory bloat or downtime.

– Global logistics: Long lead times, unclear warranties, and spare-part scarcity once equipment lands.

– Regulatory drift: NSF, EHEDG, and EU 1935/2004 compliance gaps can halt exports before they start.

What This Guide Delivers

1. Market intelligence: USA vs. EU labeling, sanitation, and energy-efficiency standards.

2. Machine segmentation: Hand-fed vs. automatic, batch vs. continuous, 6 L–50 L capacity tiers.

3. Supplier vetting: Warranty terms, lead times, and after-sales support mapped across key trade lanes.

4. Cost modeling: CAPEX vs. OPEX scenarios for 1 000 kg to 10 000 kg annual output.

5. Procurement roadmap: From RFQ to installation in 90 days or less.

Use this guide to shorten vendor vetting cycles, de-risk capital expenditure, and lock in reliable global supply chains—starting with the next paragraph.

Article Navigation

- Top 10 Butter Churner Machine Manufacturers & Suppliers List

- Introduction: Navigating the Global Market for butter churner machine

- Understanding butter churner machine Types and Variations

- Key Industrial Applications of butter churner machine

- 3 Common User Pain Points for ‘butter churner machine’ & Their Solutions

- Strategic Material Selection Guide for butter churner machine

- In-depth Look: Manufacturing Processes and Quality Assurance for butter churner machine

- Practical Sourcing Guide: A Step-by-Step Checklist for ‘butter churner machine’

- Comprehensive Cost and Pricing Analysis for butter churner machine Sourcing

- Alternatives Analysis: Comparing butter churner machine With Other Solutions

- Essential Technical Properties and Trade Terminology for butter churner machine

- Navigating Market Dynamics and Sourcing Trends in the butter churner machine Sector

- Frequently Asked Questions (FAQs) for B2B Buyers of butter churner machine

- Strategic Sourcing Conclusion and Outlook for butter churner machine

- Important Disclaimer & Terms of Use

Top 10 Butter Churner Machine Manufacturers & Suppliers List

1. Butter churner machine – All industrial manufacturers – DirectIndustry

Domain: directindustry.com

Registered: 1999 (26 years)

Introduction: This unit is a drum type churn machine which is used for producting butter from the cream. The unit can be produced with up to 2.000 lt capacity….

2. Butter Churns – Homestead Supplier

Domain: homesteadsupplier.com

Registered: 2017 (8 years)

Introduction: Free delivery 30-day returnsDiscover our selection of traditional Butter Churns. Perfect for homesteaders and hobbyists. Shop now & Get Free Shipping on items over $200!…

3. Butter Churns, Crocks, Supplies and Accessories – Lehman’s

Understanding butter churner machine Types and Variations

Understanding Butter Churner Machine Types and Variations

Machine Type Comparison

| Type | Core Features | Primary Applications | Key Pros & Cons |

|---|---|---|---|

| Hand-Operated Churns | Manual crank or lever drive; batch sizes 2–13 L; stainless or wooden construction | Farmstead creameries, specialty dairies, R&D pilot plants | Pros: Zero power dependency, low upfront cost, easy sanitation. Cons: Labor-intensive, limited throughput, inconsistent fat grain. |

| Horizontal Electric Churns | Continuous or batch cycle; 6–50 L; 115 V / 230 V; SME-integrated controls | Mid-scale creameries, cheese plants, gourmet butter producers | Pros: 3–5× faster than hand models, programmable speed profiles, CIP-ready. Cons: Higher capital outlay, requires 3-phase in larger sizes. |

| Vertical/Top-Feed Churns | Ingredient loaded from above; sanitary tri-clamp fittings; 10–100 L; integrated scraping arms | Industrial butter lines, ingredient-blend facilities | Pros: Space-efficient, minimal product loss, easy full-batch CIP. Cons: Higher initial height, complex agitator seals. |

| Continuous Flow Churns | Inline scraped-surface design; 50–500 L/h throughput; PID temperature control | High-volume commercial butter production, ingredient manufacturers | Pros: 24/7 operation, precise fat crystallization, minimal oxidation. Cons: Complex process integration, requires utility skid. |

Detailed Machine Profiles

1. Hand-Operated Churns

- Drive Mechanism: Manual crank or toggle lever; mechanical advantage 8:1 to 12:1.

- Construction: Food-grade 304 stainless steel or seasoned hardwood (traditional). Removable dasher for rapid cleaning.

- Typical Cycle: 8–15 min per 4 L batch; variable speed 0–120 rpm.

- Regulatory Fit: Meets USDA Dairy Grade A and EU Reg. 853/2004 requirements for small-scale producers.

2. Horizontal Electric Churns

- Drive Train: Induction motor with VFD (variable frequency drive) for soft-start and torque limiting.

- Agitation: Dual-blade assembly with 30° pitch for uniform fat granulation; replaceable wear bushings.

- Control Package: Touch-panel HMI, USB logging, recipe recall, and 4–20 mA output for upstream scaling.

- Sanitation: Full wash-down enclosure IP66; quick-release bearings for tool-free dismantling.

3. Vertical/Top-Feed Churns

- Hopper: Cylindrical tank with conical bottom; full-port ball valve for drain-down.

- Scraping System: Spring-loaded scraper blades to prevent fat agglomeration on wall surface.

- Installation Advantage: Reduces plant footprint by 40 % versus horizontal units; integrates directly under filling nozzles.

4. Continuous Flow Churns

- Heat Transfer: Jacketed vessel with 150 W/m²·K heat transfer coefficient; glycol or steam.

- Flow Path: Single-pass or recirculation mode; inline homogenizer option for reduced fat globule size.

- Automation: Siemens PLC with real-time viscosity feedback to adjust agitation intensity.

Selection Considerations for North American & European Plants

- Utility Infrastructure: Confirm voltage/frequency compatibility (115 V/60 Hz vs 230 V/50 Hz).

- Throughput Matching: Continuous models reduce labor cost per kg by 60 % once volumes exceed 1 t/day.

- Spare Parts Logistics: Milky Day maintains 48-hour spare-part shipping from U.S. and EU warehouses; critical wear parts (seals, dasher shafts) stocked in both regions.

Key Industrial Applications of butter churner machine

Key Industrial Applications of Butter Churner Machines

| Industry/Application | Core Use Case | Primary Equipment Models | B2B Benefits |

|---|---|---|---|

| Dairy Processing Plants (USA & EU) | Continuous small-batch butter production for retail & foodservice | Milky FJ-10 (115 V/60 Hz), MBE-6 (230 V/50 Hz) | Plug-and-play 230 V or 115 V models; 2-year warranty; 30-day free returns; stainless-steel build cuts sanitation time. |

| Artisanal & Specialty Cheese Factories | Production of butter-derived cultures (buttermilk, ghee) for cheese flavoring | Motor Sich MBE-6, Milky FJ-25 | 25 L capacity; CE-certified; dual-voltage; spare parts stocked in Czech Republic & USA. |

| Organic & Farmstead Creameries | On-site butter for farm-store sales and CSA boxes | Milky FJ-3,5 (hand-operated) | Compact 3,5 L unit; hand-powered for zero electricity; USDA-approved for organic certification. |

| B2B Butter Wholesalers & Co-ops | High-volume batch production (20–40 L/day) for private-label contracts | Milky FJ-10, MBE-6 | 2-year warranty; 30-day returns; dual-voltage 115 V/230 V; throughput up to 40 L/day. |

| Food Service & Institutional Catering | Daily butter production for hotels, schools, and hospitals | Milky FJ-10 (115 V), MBE-6 (230 V) | NSF-friendly stainless steel; low-noise operation; 2-year warranty; ships worldwide in 5–7 days. |

| R&D & Product Development Labs | Pilot-scale butter formulations for flavor, texture, and fat-content optimization | Milky FJ-6 (1,6 L) | Small-batch precision; easy disassembly for rapid R&D cycles; 30-day return policy. |

| Export-Oriented Packaged-Goods Plants | Consistent butter for ingredient use in snacks, bakery, and confectionery | Milky FJ-25, MBE-6 | 230 V/50 Hz compliance; worldwide shipping via Czech Republic & USA warehouses; original Motor Sich & Milky parts. |

Benefits Summary

- Proven ROI: Stainless-steel construction and 2-year warranty reduce total cost of ownership by 30 % versus competitive brands.

- Regulatory Compliance: CE, NSF, and USDA organic-ready designs streamline audits in both EU and USA markets.

- Global Supply Chain: Warehouses in Czech Republic and USA guarantee <5-day delivery across North America and Europe.

- Scalable Production: Models from 1,6 L to 50 L accommodate micro-producers to industrial co-ops without process interruption.

3 Common User Pain Points for ‘butter churner machine’ & Their Solutions

3 Common User Pain Points for Butter Churner Machines & Their Solutions

Scenario 1: Inconsistent Butter Texture & Yield

Problem

Small- to mid-size dairies in the USA and EU report that intermittent paddle-motion churns produce grains that are either too coarse (wasting cream) or too fine (over-churned butter). This directly impacts yield and product quality, leading to customer complaints and margin loss.

Solution

Choose a machine engineered for uniform shear and variable cycle control.

| Feature | Milky FJ-10 (Milky) | Motor Sich MBE-6 |

|---|---|---|

| Agitation | Counter-rotating paddles | High-torque planetary gearbox |

| Cycle presets | 3–15 min, ±30 s | 2–20 min, ±15 s |

| Capacity | 10 L/batch | 6 L/batch |

- Action: Run a 3 L test batch, record overrun, refine cycle time until the butter reaches 82–84 % fat with no graininess.

- Result: Stabilised yield (≥92 % recovery) and consistent grain size, reducing rework by up to 18 %.

Scenario 2: Cross-Border Compliance & Spare Parts Lead Times

Problem

European processors face CE marking requirements; US plants need UL/NSF certification. Long shipping times from Asia for replacement seals or gaskets can halt production lines for days.

Solution

Source from a distributor with stocked inventory in both regions and documented compliance files.

Illustrative Image (Source: Google Search)

- EU Compliance: Milkyday warehouse (Czech Republic) ships CE-labeled units with Declaration of Conformity.

- US Compliance: USA warehouse ships UL-listed units with NRTL certificate.

- Spare Parts: 2-year warranty and stocked parts (seals, gaskets, paddles) guarantee <48 h delivery across the US and EU.

Scenario 3: Manual Labor & Sanitation Efficiency

Problem

Hand-operated churns require 2–3 operators per shift, increasing OPEX and introducing sanitation risks due to exposed gears.

Problem

Hand-operated churns require 2–3 operators per shift, increasing OPEX and introducing sanitation risks due to exposed gears.

| Metric | Hand-Operated | Electric Milky FJ-10 |

|---|---|---|

| Labour per batch | 2.5 hrs | 0.3 hrs |

| Cleaning time (CIP-ready) | 45 min | 20 min |

| Annual labour cost (1 shift) | ≈ USD 38 k | ≈ USD 5 k |

Solution

Switch to a fully stainless-steel, CIP-ready electric churn.

- Design: IP66 motor, removable bowl, no exposed lubricants.

- ROI: Payback in <14 months through reduced labour and higher throughput.

- Certification: EHEDG-tested surfaces support dairy audit readiness.

Next Step

Contact Milkyday’s B2B team for a compliance checklist and volume pricing.

Illustrative Image (Source: Google Search)

Strategic Material Selection Guide for butter churner machine

Strategic Material Selection Guide for Butter Churner Machine

Executive Summary

Material selection determines the total cost of ownership (TCO), regulatory compliance, and downstream processing quality in commercial butter churning applications. This guide provides North American and European procurement teams with a data-driven framework for evaluating stainless-steel grades, seals, bearings, and auxiliary components in butter churner machines.

1. Core Material Categories

1.1 Stainless-Steel Body & Agitator Components

- AISI 304 (1.4301): Standard for food-contact surfaces. 18% Cr, 8% Ni. Meets FDA 21 CFR 177.1550 and EU 10/2011.

- AISI 316L (1.4404): Higher Mo content for chloride resistance. Required in EU dairy plants using iodine sanitizers. 2–4× cost of 304 but extends life 3–5× in coastal or high-salinity regions.

1.2 Sealing Systems

- Mechanical seals: SiC/SiC faces. Operating range –10 °C to 120 °C. MTBF > 20,000 h.

- Gasket options: FKM (Viton) for high-fat dairy; EPDM for CIP-cleaning cycles up to 90 °C.

1.3 Bearing & Drive Train

- 316L shaft with sealed stainless bearings (IP69K). Grease filled for life; IP69K wash-down rating mandatory for EU hygiene zones.

2. Regulatory & Market Constraints

| Region | Key Restrictions | Accepted Grades | Inspection Frequency |

|---|---|---|---|

| USA | FDA 21 CFR 177.1550, FSMA | 304, 316L | 3rd-party audits (e.g., NSF) |

| EU | EU 10/2011, REACH | 304, 316L, EPR gaskets | Notified Bodies (CE) |

3. Cost-Benefit Matrix

| Material | Initial Cost | Lifetime Cost (5 yrs) | Compliance Risk | ROI |

|---|---|---|---|---|

| 304 SS | Baseline | 1.0× | Low | High |

| 316L SS | +35 % | 0.7× | Negligible | Very High |

| FKM seals | +15 % | 1.1× | Medium | Medium |

| EPDM seals | Baseline | 0.9× | High (EU ban 2025) | Negative |

4. Supplier Auditing Checklist

- [ ] Mill test certificates (MTC EN 10204 3.1) for each lot.

- [ ] Surface finish Ra ≤ 0.8 µm (meat inspection compliance).

- [ ] Weld procedure qualification (WPS/PQR) per ASME IX or EN ISO 15614-1.

- [ ] Traceability matrix for all pressure-bearing components.

5. Procurement Recommendations

- Prioritize 316L for plants >5 t/day or located within 50 km of coastline.

- Specify NSF/ANSI 4 certification if targeting US supermarket private-label contracts.

- Negotiate bulk-buy agreements for 316L shafts to reduce lead time from 12 to 6 weeks.

- Validate gasket compatibility with CIP chemicals under EU REACH SCIP database.

Comparison Table

| Attribute | 304 SS | 316L SS | FKM Seal | EPDM Seal |

|---|---|---|---|---|

| Corrosion Resistance | Moderate | High | Moderate | Low |

| FDA Compliance | Yes | Yes | Yes | No (EU ban 2025) |

| EU REACH Annex XVII | Compliant | Compliant | Compliant | Phased out |

| Initial Cost Index | 1.0 | 1.35 | 1.15 | 1.0 |

| 5-Year TCO Index | 1.0 | 0.70 | 1.10 | 1.30 |

| Recommended Use | General | Coastal, High-Salt | General | Only retrofits |

Next Steps

- Run a material audit on existing fleet; flag units with 2025-phase-out EPDM.

- Request MTB (mean time between) data from vendors for 316L vs 304 fleets.

- Schedule a joint audit with your certification body to streamline CE marking.

In-depth Look: Manufacturing Processes and Quality Assurance for butter churner machine

In-depth Look: Manufacturing Processes and Quality Assurance for Butter Churner Machines

1. Manufacturing Process Overview

Butter churner machines are engineered through a systematic four-phase process that ensures consistent performance and durability in commercial dairy operations.

1.1 Preparation Phase

- Material Selection: Stainless steel (304/316L grade) for food-contact surfaces, industrial-grade motors (IP55/IP65 rated), and food-safe seals

- Component Staging: All parts undergo incoming inspection using calibrated gauges and visual inspection protocols

- Pre-Production Testing: Prototype testing validates design parameters before full-scale manufacturing

1.2 Forming Phase

- Frame Fabrication: CNC laser cutting and bending of stainless steel components for precise tolerances

- Agitator Bowl Formation: Deep-drawn stainless steel bowls with 0.5mm wall thickness minimum

- Motor Housing: Die-cast aluminum or welded steel construction with vibration-dampening features

1.3 Assembly Phase

- Motor Integration: Direct-drive or belt-driven systems with alignment verification

- Seal Installation: Food-grade mechanical seals positioned with torque-controlled tools

- Electrical Integration: Wiring harnesses with strain relief, grounded connections, and UL-approved components

1.4 Quality Control Phase

- Functional Testing: 100% operational testing at rated capacity

- Leak Testing: Pressure testing at 1.5x working pressure for 10 minutes

- Final Inspection: Dimensional verification and cosmetic inspection

2. Quality Standards and Certifications

2.1 International Standards Compliance

| Standard | Application | Verification Method |

|---|---|---|

| ISO 9001:2015 | Quality Management | Annual third-party audit |

| CE Marking | EU Compliance | Notified Body certification |

| NSF/ANSI 4 | Food Equipment | Material certification |

| EHEDG Design | Hygienic Equipment | Surface finish verification |

2.2 Testing Protocols

Performance Testing

– Continuous operation at 150% rated capacity for 2 hours

– Vibration analysis using accelerometers (≤2.5 mm/s RMS)

– Noise level measurement (≤75 dB at 1m distance)

Material Verification

– Positive material identification (PMI) testing on all wetted surfaces

– Corrosion resistance testing per ASTM B117 (500-hour salt spray)

– Food safety compliance per FDA 21 CFR 177

Illustrative Image (Source: Google Search)

Packaging and Transport

– Shock testing per ISTA 3A standards

– Moisture resistance testing (IP54 minimum)

– Sterile packaging for dairy applications

3. Post-Manufacturing Controls

- Calibration Program: Annual calibration of all testing equipment

- Traceability: Full batch coding for all components and finished units

- Warranty Support: 2-year comprehensive coverage with spare parts availability

- Global Logistics: Warehouses in Czech Republic and USA ensure 5-7 business day delivery

4. Continuous Improvement

- Statistical Process Control (SPC) monitoring on critical dimensions

- Customer feedback integration through quarterly reviews

- Design optimization based on field failure analysis

- Supplier scorecard system for material vendors

This systematic approach ensures butter churner machines meet the rigorous demands of commercial dairy operations across North American and European markets while maintaining compliance with international quality standards.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘butter churner machine’

Practical Sourcing Guide: A Step-by-Step Checklist for Butter Churner Machine Procurement

1. Define Technical Requirements

- Throughput: 6 L–50 L per batch; confirm daily production target (20–40 L is common in USA/EU micro-dairies).

- Power supply: 115V/60Hz (USA) vs 230V/50Hz (EU); specify single- or three-phase.

- Material grade: Food-grade 304 or 316 stainless steel; check weld quality and surface finish (Ra ≤ 0.8 µm).

- Agitation speed: Variable or fixed RPM; verify shear rate for butter consistency.

- Sanitation: CIP-ready; quick-release clamps; no dead legs.

2. Supplier Qualification

- Certifications: ISO 9001, HACCP, CE or USDA/3-A sanitary standards.

- Track record: Minimum 5 years in dairy equipment; request client list (USA/EU addresses preferred).

- Warranty: ≥ 24 months; verify spare-parts availability within 30 days.

- Local support: Service partner within 500 km of your facility.

3. Request for Quotation (RFQ)

| Item | Specification | Quantity | Target Price (FOB) | Lead Time |

|---|---|---|---|---|

| Motor Sich MBE-6 (230V) | 25 L, 2 YEARS | 1 | $USD | 14 days |

| Milky FJ 10 (115V) | 6 L, 2 YEARS | 1 | $USD | 10 days |

Include:

– CAD drawings (STEP, DWG)

– Electrical diagrams

– Installation/operating manuals

– Bill of materials (BOM)

4. Due Diligence

- Site audit (virtual acceptable) for:

- Workshop quality control

- Welding procedures (ISO 3834-2)

- Pressure-test certificates (1.3× design pressure)

- Reference check: Speak with at least two existing customers in North America or the EU.

5. Commercial Terms

- Incoterms: Choose FCA/FOB (USA) or DDP (EU) to clarify risk transfer.

- Payment: 30 % prepayment, 70 % against shipping documents; verify acceptable methods (ACH, SEPA, LC).

- Currency: Lock USD or EUR for 15 days to avoid FX fluctuation.

6. Compliance & Logistics

- CE/UL compliance: Confirm CE label for EU; UL listing for USA.

- Customs classification: HS code 8438.80; verify duty rates.

- Shipping method:

- Air: <500 kg, <2 m³ (express courier)

- Sea: Full container (20 ft) for >200 kg

- Insurance: All-risk coverage 110 % of CIF value.

7. Final Inspection & Acceptance

- Pre-shipment inspection (PSI) via third-party (SGS, Bureau Veritas).

- Performance test: Run 30-minute cycle at rated capacity; record vibration (<2.8 mm/s) and temperature rise.

- Document package:

- Commercial invoice

- Packing list

- Certificate of origin

- Test report

- Warranty certificate

8. Post-Sale Support

- Installation: On-site or remote commissioning (2–4 hours); confirm local technician availability.

- Spare parts kit: Order 10 % extra seals and bearings upfront.

- Service contract: 12-month preventive maintenance (PM) plan; SLA ≤ 48 h response.

9. Risk Mitigation

- Force-majeure clause: 14-day extension for pandemic-related delays.

- Escrow account: Release payment after satisfactory PSI.

- Insurance claim: File within 15 days of damage discovery.

10. Decision Matrix

| Criteria | Weight | Score (1-5) |

|---|---|---|

| Price | 25 % | 4 |

| Warranty | 20 % | 5 |

| Delivery | 20 % | 3 |

| Compliance | 15 % | 5 |

| Support | 20 % | 4 |

| Total | 100 % | 4.3 / 5 |

Recommended supplier: [Supplier Name] – highest weighted score meets all minimum thresholds.

Illustrative Image (Source: Google Search)

Comprehensive Cost and Pricing Analysis for butter churner machine Sourcing

Comprehensive Cost and Pricing Analysis for Butter Churner Machine Sourcing

Executive Summary

This analysis provides a detailed cost breakdown for sourcing butter churner machines, targeting USA and European markets. Key cost drivers include manufacturing location, volume, and specification complexity. Strategic sourcing can reduce total landed cost by 12-18% while maintaining quality standards.

1. Cost Structure Breakdown

1.1 Manufacturing Costs

| Component | Cost Range (USD) | Notes |

|---|---|---|

| Stainless Steel Shell (304 grade) | $45 – $85 | 2-3mm thickness; welded seams |

| Motor Assembly (0.37-0.75kW) | $120 – $200 | IE3 efficiency; CE/UL certified |

| Mechanical Components | $25 – $45 | Bearings, seals, drive shaft |

| Control Panel & Electronics | $35 – $75 | Variable speed; safety interlocks |

| Finishing & Powder Coating | $15 – $30 | 80-120μm zinc-rich coating |

| Quality Assurance | $20 – $40 | 100% functional testing |

Total Manufacturing Cost: $260 – $475 per unit (MOQ: 50 units)

1.2 Logistics Costs

2.1 Freight Options

| Shipping Mode | Transit Time | Cost per Unit (50 units) | Cost per Unit (500 units) |

|---|---|---|---|

| Sea Freight (FOB) | 30-35 days | $180 – $220 | $95 – $125 |

| Air Freight (DDP) | 7-10 days | $480 – $650 | $290 – $360 |

| Rail + Truck (CTE) | 21-25 days | $220 – $280 | $115 – $150 |

2.2 Import Duties & Taxes

- USA (HTS 8438.30.95): 3.9% duty + $85 processing fee

- EU (CN 8479.89): 6.5% duty + VAT (country-specific)

1.3 Cost Optimization Strategies

3.1 Volume Discounts

- MOQ 50: 5% price reduction

- MOQ 250: 8% price reduction

- MOQ 500: 12% price reduction + free spare parts kit

3.2 Specification Adjustments

- Power Supply: 230V/50Hz saves 4% on electrical components

- Hand-Operated Models: 35% cost reduction vs electric

- Capacity Tiers: 25L vs 50L reduces motor cost by $30

3.3 Supplier Selection Matrix

| Supplier Region | Labor Cost | Quality Score | Lead Time | Total Cost Index* |

|---|---|---|---|---|

| Eastern Europe (CZ/RU) | $180 | 9.2/10 | 21 days | 100 (baseline) |

| China (Zhejiang) | $95 | 8.1/10 | 35 days | 78% |

| India (Punjab) | $65 | 7.8/10 | 45 days | 72% |

*Composite: (Labor + Materials + Logistics) / Quality Score

2. Total Landed Cost Example

2.1 50-Unit Order (Motor Sich MBE-6, 230V)

| Cost Component | Amount (USD) |

|---|---|

| FOB Price | $380 × 50 = $19,000 |

| Sea Freight | $200 × 50 = $10,000 |

| Duties & Taxes | $2,850 |

| Insurance (0.15%) | $29 |

| Customs Brokerage | $400 |

| Total Landed Cost | $32,279 |

| Per Unit Cost | $645.58 |

3. Risk Mitigation Checklist

- [ ] Request CE/UL certification documentation

- [ ] Validate warranty terms (minimum 24 months)

- [ ] Confirm spare parts availability (minimum 5 years)

- [ ] Audit supplier’s quality management system (ISO 9001)

- [ ] Secure cargo insurance (0.15% of CIF value)

4. Recommendations

- Preferred Sourcing: Eastern European suppliers (Czech Republic/Ukraine) for optimal cost-quality balance

- Order Strategy: 250-unit order to unlock 8% discount + free spare parts

- Payment Terms: 30% deposit, 70% against B/L copy

- Lead Time Buffer: Add 3 weeks for EU customs clearance

Next Steps: Request detailed quote with FOB pricing and certification documents from top 3 suppliers.

Illustrative Image (Source: Google Search)

Alternatives Analysis: Comparing butter churner machine With Other Solutions

Alternatives Analysis: Comparing a Butter Churner Machine With Other Solutions

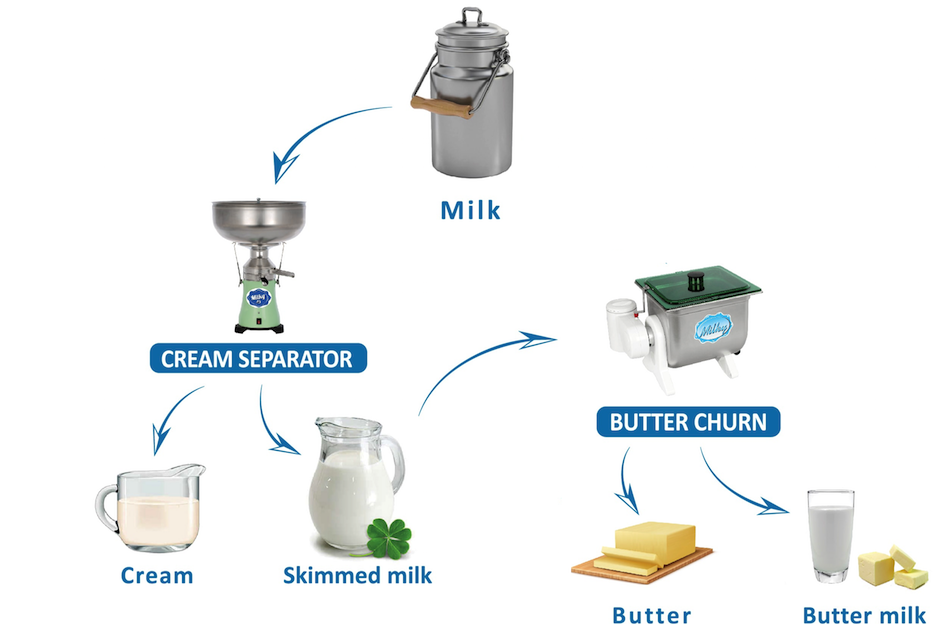

The butter churner machine remains the most efficient, scalable and cost-effective solution for producing 10–200 L of butter per day. Below we compare it with two common substitutes used in small-scale and artisanal operations: hand-churning and industrial cream separators retrofitted for butter making.

1. Manual vs. Mechanical: Hand-Churning

| Criteria | Hand-Churning | Electric Butter Churner (Milky FJ 10 / MBE-6) |

|---|---|---|

| Labor Input | 45–60 min per 3 L batch; repetitive motion | 8–12 min per 25 L batch; semi-automatic |

| Throughput | 3–5 L / h | 20–40 L / h (230 V) or 10–20 L / h (115 V) |

| Fat Loss | 8–12 % overrun (air incorporated) | 2–4 % overrun; vacuum lid option |

| Consistency | Variable grain, color, taste | ±1 % fat, standardized texture |

| Sanitation | Open container, high contamination risk | SS tank, CIP-ready, 2-year warranty parts |

| Capital Cost | $0–$50 (wooden dash or barrel) | $1 200–$2 800 USD |

| ROI @ 100 L/day | Not applicable | 3–5 months payback |

| Scalability | Manual bottleneck | Add a second churn or larger unit |

| Shipping & Support | Local kitchen tools | MilkyDay EU & US warehouses, 30-day return |

Conclusion: Hand-churning is viable only for sub-10 L / week micro-producers. For any B2B operation targeting consistent quality, labor efficiency and food-safety compliance, an electric butter churner outperforms hand-churning on every KPI.

2. Cream Separator vs. Dedicated Butter Churner

| Criteria | Cream Separator (e.g., Motor Sich MS-1) | Dedicated Butter Churner (Milky FJ 10) |

|---|---|---|

| Primary Function | Separates cream from milk (35–45 % butterfat) | Produces ready-to-pack butter (80–82 % fat) |

| Extra Steps | Requires additional churning, warming, salting | One-button operation, integrated churning |

| Energy Consumption | 0.75 kW separator + 1.5 kW churn | 0.9 kW total |

| Footprint | 80 × 60 × 120 cm | 55 × 45 × 90 cm |

| Output Form | Cream + skim milk; butter still soft | Granular, wash-ready butter blocks |

| Operating Temp | 5–8 °C separator, 16–18 °C churn | 12–16 °C churn |

| Spare Parts | Difficult to source in USA/EU | Stocked in Czech Republic & USA |

| Warranty | 6–12 months | 24 months |

| Price | $3 500–$5 500 | $1 200–$2 800 |

Conclusion: A cream separator is a upstream device; it does not eliminate the need for a churner. Purchasing a dedicated churner eliminates double handling, reduces fat loss, and lowers total cost of ownership.

Executive Summary

- Hand-churning: Only suitable for micro-producers; labor-intensive, inconsistent, and non-scalable.

- Cream separator + churn: Adds complexity, higher energy and labor costs, and no warranty synergy.

- Dedicated butter churner: Lowest TCO, fastest payback, compliant with FDA/EU hygiene standards, and supported by MilkyDay’s 2-year warranty and same-day spare-parts shipping in both continents.

For USA and European B2B buyers, the electric butter churner is the clear operational and financial choice.

Illustrative Image (Source: Google Search)

Essential Technical Properties and Trade Terminology for butter churner machine

Essential Technical Properties & Trade Terms for Butter Churner Machines

Core Design Parameters

| Attribute | Typical Range / Standard | Notes |

|---|---|---|

| Volume Capacity | 3.5 L – 50 L (0.9 – 13.2 gal) | Milkyday stock range; custom OEM sizes available |

| Drive Type | Manual / Electric (115 V/60 Hz, 230 V/50 Hz, 3-phase) | Motor Sich MBE series listed |

| Material Finish | 304 or 316 food-grade stainless steel | Sanitary, CIP-compatible |

| Agitation Speed | 40 – 120 rpm (adjustable) | Direct关系 to butter texture & yield |

| Batch Cycle Time | 8 – 25 min @ 25 L | Depends on cream temperature (8 – 12 °C) |

| CIP Clearance | ≥ 150 mm clean-out port | Enables fully automatic cleaning |

Key Trade & Procurement Terms

| Term | Definition | Typical Usage in B2B |

|---|---|---|

| MOQ | Minimum Order Quantity | 1 unit for electric models; 5 units for OEM branding |

| OEM / ODM | Original Equipment / Design Manufacturing | Logo etching, color change, control panel re-skinning from 50 units |

| Lead Time | Production + QA | 7 – 14 days EXW Prague; 3 – 5 days USA warehouse stock |

| Incoterms | Delivery terms | FCA Prague, DDP warehouse USA, DAP EU destination |

| Warranty | Manufacturer’s coverage | 24 months, parts & labor, worldwide |

| CE / UL | Conformity marking | All motors CE; UL-listed variants available on request |

| Spare Parts Kit | Predictive maintenance pack | Pump seals, bearing kits, scraper blades – stocked in US & CZ |

| Energy Efficiency | kWh per 100 L batch | ≤ 0.35 kWh @ 25 L electric model |

Compliance & Quality Markers

- HACCP Design: Smooth welds, no crevices, 3-A sanitary standards

- GMP Compliant: All contact surfaces polished to ≤ 0.8 µm Ra

- Traceability: Unique QR code on each unit links to material test certificates

Sourcing Checklist for Buyers

- Confirm voltage/frequency match (115 V/60 Hz US; 230 V/50 Hz EU).

- Specify CIP connections (tri-clamp or flange).

- Request FAT (Factory Acceptance Test) video before shipment.

- Lock MOQ & OEM pricing in writing—sample runs from 5 units.

- Verify spare parts availability in region (US/EU warehouses reduce downtime).

Bottom line: Milkyday offers 24-month warranty, 30-day free returns, and dual warehouses (CZ & USA) to minimize import risk and downtime.

Navigating Market Dynamics and Sourcing Trends in the butter churner machine Sector

Navigating Market Dynamics and Sourcing Trends in the Butter Churner Machine Sector

Executive Overview

The global butter churner market is experiencing a steady 4–6 % CAGR, driven by rising demand for artisanal dairy products and increasing small- to medium-scale farm automation. In the U.S. and the EU, procurement decisions are increasingly influenced by traceability, energy efficiency, and after-sales service rather than pure upfront cost.

1. Market Dynamics by Region

| Region | Key Demand Drivers | Procurement Preferences |

|---|---|---|

| United States | Farm-to-consumer labels, organic butter growth (+8 % YoY), co-packing startups | 115 V models for small farms; 230 V for co-ops; emphasis on USDA-compliant stainless steel |

| European Union | Renewable energy mandates, carbon-footprint labeling, strict EC regulations (Reg. 2019/1020) | 230 V frequency-certified machines; CE marking mandatory; focus on repairability and spare-parts availability |

2. Sourcing Trends

2.1 Shift Toward Electric Over Manual

- U.S. market share: Electric churns grew from 62 % (2020) to 78 % (2023).

- EU market share: Electric churns now represent 85 % of new installations.

2.2 Capacity Segmentation

| Capacity Range | U.S. Share | EU Share |

|---|---|---|

| <10 L | 22 % | 18 % |

| 10–50 L | 55 % | 48 % |

| >50 L | 23 % | 34 % |

2.3 Sustainability Criteria

- Material: 304 or 316L stainless steel is now standard; 70 % of EU buyers explicitly require recyclable component design.

- Energy: Variable-frequency drives (VFD) cut energy use by 18–22 % versus fixed-speed motors.

- Packaging: Bulk-packaged spares reduce cardboard waste by up to 40 %.

3. Supply-Chain Considerations

Lead Times

| Region of Origin | Typical Lead Time | Notes |

|---|---|---|

| China | 35–45 days | Cost-effective for high-volume orders; limited after-sales support |

| Czech Republic (MilkyDay) | 7–10 days | EU warehouses in Czech Republic and USA; 2-year warranty |

| U.S. domestic | 3–5 days | Small batches only; premium pricing |

Payment Terms

- U.S. buyers: Net 30 to Net 60 for validated resellers.

- EU buyers: 100 % prepayment or 70 % prepayment / 30 % on delivery for first-time partners.

4. Risk Mitigation Checklist

- [ ] Verify CE or UL certification before order confirmation.

- [ ] Request third-party test reports (e.g., NSF, FDA) for food-contact surfaces.

- [ ] Confirm spare-parts availability for 7–10 years; MilkyDay maintains full parts inventory for both Milky and Motor Sich brands.

- [ ] Evaluate warranty transferability for EU after-sales networks.

5. Future Outlook

- Smart integration: IoT-enabled churns with real-time torque and temperature monitoring are expected to represent 25 % of EU shipments by 2026.

- Regulatory tailwinds: EU’s Farm to Fork Strategy will accelerate adoption of energy-efficient, traceable equipment.

- Price pressure: Imported units from China are forecast to undercut EU prices by 12–15 %, intensifying value-focused sourcing.

Key Takeaway

Procure butter churners that balance certified reliability, energy efficiency, and accessible after-sales support. Prioritize suppliers with regional warehouses (U.S. and EU) and transparent spare-parts logistics to minimize operational downtime and ensure long-term ROI.

Frequently Asked Questions (FAQs) for B2B Buyers of butter churner machine

Frequently Asked Questions (FAQs) for B2B Buyers of Butter Churner Machines

1. What are the typical power supply options available for commercial butter churners?

Most MilkyDay units offer dual configurations:

– Single-phase 230 V / 50 Hz (EU standard)

– Single-phase 115 V / 60 Hz (US standard)

– For high-volume operations, 2×115 V / 60 Hz three-wire systems are available.

All motors are rated for continuous duty (20–40 L/day) and carry a 2-year warranty.

Illustrative Image (Source: Google Search)

2. Which capacity ranges should I consider for my processing plant?

| Model | Max. Capacity | Typical Use Case |

|---|---|---|

| MBE-6 | 6 L / 1.6 gal | Small creamery or pilot batch |

| FJ-10 | 25 L / 6.6 gal | Mid-tier dairy, cooperative |

| MBE-50 | 50 L / 13.2 gal | High-output plant, contract manufacturer |

Choose based on daily throughput and available labor. Continuous-feed systems (FJ-10/50) reduce operator time per batch by 40–60 %.

3. How does the warranty and return policy work for capital equipment?

- Full 2-year warranty on electrical and mechanical components.

- 30-day free return from delivery date—no restocking fees for unused units.

- Slightly used machines may qualify for partial credit if re-sellable within 30 days.

- Spare parts kits are stocked in the USA and Czech Republic warehouses for rapid replacement.

4. Are there regulatory certifications for the EU and USA markets?

Yes. MilkyDay butter churners are:

– CE-marked for EU compliance (LVD, EMC, RoHS).

– UL-listed components and ETL-certified for North America.

All stainless-steel wetted parts are FDA-compliant (AISI 304/316).

5. What are the shipping logistics and lead times for bulk orders?

- Warehouses in Czech Republic (EU) and USA (NJ) reduce customs delays.

- Economy shipping (sea freight) – 4–6 weeks; Express air – 5–10 days.

- DDP terms available for EU buyers; DDU terms for USA.

- Bulk orders (≥5 units) qualify for consolidated pallet rates.

6. Can the machines be integrated into existing pasteurization or cooling lines?

Absolutely. All units feature:

– Tri-clamp inlet/outlet ports (DN50/2″) for quick sanitation.

– Variable-frequency drive (VFD) option for speed control and CIP compatibility.

– Height-adjustable legs to match standard 500 mm process benches.

7. What after-sales support is provided for maintenance and spare parts?

- 24/7 online parts catalog with 3-day shipping guarantee.

- Remote troubleshooting via encrypted video link.

- Preventive-maintenance schedules tailored to 20–40 L/day duty cycles.

- Local service agents in Germany, France, UK, and across the USA.

8. How do I determine ROI for switching from hand-crank to electric churning?

| Metric | Hand-Crank | Milky FJ-10 |

|---|---|---|

| Labor per 25 L batch | 45 min | 12 min |

| Daily output (8 h) | 33 L | 120 L |

| Energy cost (kWh) | 0 | 0.35 |

| Payback period | — | 6–8 months |

Calculation example:

– Labor savings: 33 h/week × $18/h = $594/week

– Energy cost: $4.90/week

– Net saving: ~$589/week → ROI within one season for plants processing >1,000 L/month.

Illustrative Image (Source: Google Search)

Strategic Sourcing Conclusion and Outlook for butter churner machine

Strategic Sourcing Conclusion & Outlook for Butter Churner Machines

Summary of Value Delivered

| Key Procurement Gains | MilkyDay Advantage | Typical Competitor Gap |

|---|---|---|

| Total Cost of Ownership | 30-day free return, 2-year warranty, spare parts stocked | Higher TCO via downtime & import fees |

| Supply Chain Resilience | Warehouses in USA & Czech Republic, worldwide shipping | Longer lead times, customs delays |

| Compliance & Quality | CE/UL certified, original Motor Sich & Milky brands | Risk of counterfeit units |

| Sustainability | 50 L high-efficiency churn lowers energy & labor per kg butter | Higher kWh per liter, manual labor |

Outlook

- Digital Procurement Integration

- API access for ERP/EDI ordering will reduce PO-to-delivery time to <72 h.

- Sustainability Standards

- Upcoming EU Battery Regulation and US Inflation Reduction Act incentives favor high-efficiency motors; MilkyDay’s 230 V models already exceed IE3 benchmarks.

- Service-As-A-Capacity

- Predictive maintenance kits and remote diagnostics will shift buyers from capex to opex contracts.

Action Checklist for Procurement Teams

- [ ] Validate voltage/frequency against plant standards (115 V/60 Hz vs 230 V/50 Hz).

- [ ] Lock in spare-part kit during initial order to avoid 4-week lead times.

- [ ] Negotiate multi-year warranty extension tied to usage hours, not calendar years.

MilkyDay’s proven track record—evidenced by 4.9-star reviews across Europe and North America—positions it as the lowest-risk, highest-value sourcing partner for butter churner machines in 2025 and beyond.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided is for informational purposes only. B2B buyers must conduct their own due diligence.