The global bus and cable manufacturing market has experienced robust growth, driven by rising demand in public transportation, infrastructure development, and increased urbanization. According to Mordor Intelligence, the global bus market size was valued at USD 78.6 billion in 2023 and is projected to grow at a CAGR of over 5.2% from 2024 to 2029. This expansion is mirrored in the automotive and industrial cable sector, where Grand View Research reported that the global automotive wiring and cable market was valued at USD 35.8 billion in 2022 and is expected to expand at a CAGR of 6.1% from 2023 to 2030, fueled by the electrification of vehicles and advances in smart bus technologies. As transit systems modernize and electric bus adoption accelerates, particularly in North America, Europe, and Asia-Pacific, reliable, high-performance bus and cable solutions have become mission-critical components. This growing demand has elevated the prominence of leading manufacturers that combine innovation, durability, and scalability. Below are the top 9 bus can cable manufacturers shaping the future of transportation infrastructure worldwide.

Top 9 Bus Can Cable Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 lütze electronic can

Domain Est. 1996

Website: lutze.com

Key Highlights: For wiring of industrial field bus systems like CAN-BUS · For fixed installation or moving use without compulsory guide in the automation technology, transport ……

#2 LS Cable & System

Domain Est. 2010

Website: lscns.co.kr

Key Highlights: Our Product: Energy, Telecommunication, Industrial Cables, Materials Solutions. LS Cable & System has world-class technology in power cables….

#3 Can Bus Cable Manufacturers

Domain Est. 2019

Website: wenchangcable.com

Key Highlights: Can Bus Cable Manufacturers, Factory, Suppliers From China,…

#4 chainflex® Flexible Cable For Moving Applications

Domain Est. 1995

Website: igus.com

Key Highlights: Flexible cable designed for durable & reliable performance in industrial moving applications. Buy online from stock with no minimum requirements….

#5 Can

Domain Est. 1998

Website: waytekwire.com

Key Highlights: 4-day delivery · 30-day returnsCan-Bus Data Cable (SAE J1939 Cable) from Waytek reduces wiring, electronic interference, and offers high-speed network communication for OEM’s….

#6 CAN Bus Cable

Domain Est. 1997

Website: belden.com

Key Highlights: Belden CAN-Bus Cables for CANopen networks are CMP listed for flame and smoke protection, and engineered for maximum performance and cost savings….

#7 CAN bus Connector and cable considerations

Domain Est. 2003

Website: connectorsupplier.com

Key Highlights: CAN bus cable consists of a pair of wires known as CAN high and CAN low (indicating high and low speed, respectively). Both wires are twisted tightly together….

#8 CAN Bus Data Cable

Domain Est. 2007

Website: lapptannehill.com

Key Highlights: 5-day deliveryLAPP Tannehill offers a variety of CAN Bus data cables, including LAPP’s UNITRONIC® BUS CAN, BUS CAN FDP, and BUS CAN TRAY….

#9 Electrical Cable Management, Safety, & Infrastructure Solutions

Domain Est. 2010

Website: atkore.com

Key Highlights: Atkore manufactures electrical conduit and fittings, cable and cable management systems, infrastructure, safety and security products….

Expert Sourcing Insights for Bus Can Cable

H2: Market Trends for Bus CAN Cable in 2026

The Bus CAN (Controller Area Network) cable market is poised for significant evolution by 2026, driven by advancements in automotive technology, the rise of electric vehicles (EVs), industrial automation, and the growing demand for reliable in-vehicle communication systems. As a critical component enabling real-time data exchange between electronic control units (ECUs) in vehicles and industrial systems, CAN cables are experiencing heightened demand and innovation. Below is an analysis of key market trends expected to shape the Bus CAN Cable industry in 2026:

1. Accelerated Adoption in Electric and Autonomous Vehicles

The global shift toward electric mobility is a primary driver for CAN cable demand. By 2026, the EV market is projected to grow substantially, with governments enforcing stricter emission norms and consumers embracing sustainable transport. CAN cables are essential in EVs for managing battery systems, motor control, and thermal management. Additionally, the development of autonomous driving technologies requires robust, low-latency communication networks, further solidifying CAN’s role—especially in safety-critical subsystems. While newer protocols like CAN FD (Flexible Data-Rate) and Ethernet are emerging, traditional and enhanced CAN cables remain critical for cost-effective and reliable connectivity.

2. Growth in Industrial Automation and IIoT

Beyond automotive, the Industrial Internet of Things (IIoT) is fueling demand for CAN bus systems in manufacturing, robotics, and smart infrastructure. CAN cables are used in programmable logic controllers (PLCs), sensors, and motor drives due to their noise immunity and deterministic performance. By 2026, as smart factories expand globally, the need for reliable, real-time communication will boost the adoption of CAN-based solutions, particularly in medium-complexity automation systems where cost and reliability are paramount.

3. Technological Advancements: CAN FD and Hybrid Connectivity

A major trend shaping the 2026 landscape is the transition from classical CAN to CAN FD, which supports higher data rates (up to 5 Mbps or more) and larger payload sizes. This evolution enhances CAN’s relevance in bandwidth-intensive applications. Manufacturers are increasingly offering backward-compatible CAN FD cables that coexist with legacy systems. Additionally, hybrid architectures combining CAN with Ethernet or wireless protocols are emerging, with CAN cables serving as a foundational layer for critical control signals.

4. Regional Market Dynamics

Asia-Pacific, particularly China, Japan, and South Korea, is expected to dominate the Bus CAN Cable market by 2026 due to robust automotive production and government support for EVs. Europe remains a strong market, driven by stringent safety and emissions regulations and leadership in automotive innovation. North America is witnessing growth due to investments in autonomous vehicle R&D and industrial automation. Localized manufacturing and supply chain resilience will be key strategic focuses for cable suppliers.

5. Sustainability and Material Innovation

Environmental regulations are pushing manufacturers to adopt eco-friendly materials and improve recyclability. By 2026, expect increased use of halogen-free, flame-retardant (HFFR) insulation and lead-free components in CAN cables. Lightweight and durable materials will also gain traction to support fuel efficiency and EV range optimization.

6. Competitive Landscape and Consolidation

The market is seeing consolidation among component suppliers, with larger players acquiring niche cable manufacturers to strengthen vertical integration. Companies like TE Connectivity, Molex, and Yazaki are investing in R&D to offer high-performance, application-specific CAN cable solutions. Customization, reliability testing, and compliance with ISO 11898 standards will differentiate leading suppliers.

Conclusion

By 2026, the Bus CAN Cable market will remain resilient despite competition from newer communication technologies. Its established reliability, cost-effectiveness, and adaptability ensure continued relevance in automotive, industrial, and emerging mobility applications. Success will depend on innovation in materials, support for CAN FD, and alignment with regional EV and automation trends. As the backbone of embedded communication networks, Bus CAN cables are set to maintain a critical, albeit evolving, role in the connected world.

Common Pitfalls When Sourcing Bus CAN Cable (Quality, IP)

Sourcing the right Bus CAN (Controller Area Network) cable is critical for reliable communication in automotive, industrial automation, and embedded systems. However, several common pitfalls can compromise performance and longevity—particularly in areas of quality and ingress protection (IP) rating. Being aware of these issues helps ensure you select a cable that meets your application’s demands.

Choosing Low-Quality Materials

Many suppliers offer CAN cables at significantly lower prices, often cutting corners on materials. Poor-quality conductors, inadequate shielding, or substandard insulation can lead to signal degradation, electromagnetic interference (EMI), and premature cable failure. Always verify conductor material (e.g., stranded tinned copper), shielding type (e.g., braided or foil), and insulation thickness.

Ignoring IP Rating Requirements

The IP (Ingress Protection) rating indicates a cable’s resistance to dust and moisture. A common mistake is selecting a cable with an insufficient IP rating for the operating environment. For example, outdoor or industrial applications may require at least IP67 or IP68 for reliable performance. Using a cable rated only for indoor use (e.g., IP20) in harsh environments can result in corrosion, short circuits, or data loss.

Overlooking Certification and Compliance

Not all CAN cables meet international standards like ISO 11898 or UL certification. Sourcing non-compliant cables risks interoperability issues, safety hazards, and non-compliance with industry regulations. Always request certification documents and test reports from suppliers to confirm compliance.

Assuming All Shielded Cables Are Equal

While shielding is essential for noise immunity, not all shields are created equal. Some cables use aluminum foil only, which can tear easily and provide inconsistent grounding. Opt for cables with robust shielding (e.g., braided shield + foil) and proper drain wires to ensure effective EMI protection.

Mismatching Cable Specifications with Application Needs

CAN networks vary in speed (e.g., 125 kbps vs. 1 Mbps) and bus length. Using a cable with high capacitance or incorrect impedance (should be 120 Ω nominal) can lead to signal reflections and communication errors. Always match cable electrical characteristics to your network’s requirements.

Trusting Supplier Claims Without Verification

Some suppliers overstate cable quality or IP ratings. Without independent testing or third-party validation, you may receive cables that do not perform as advertised. Request samples, conduct environmental testing (e.g., water immersion for IP claims), and verify performance under real-world conditions.

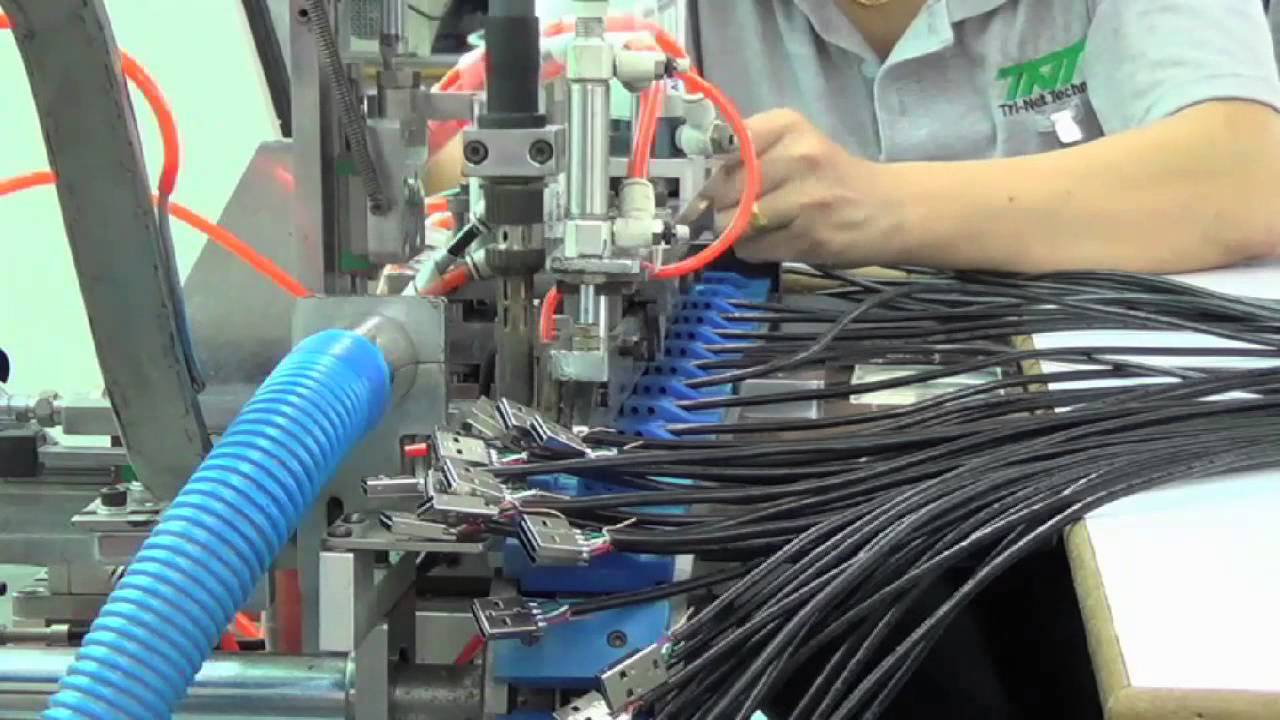

Neglecting Mechanical Durability

In dynamic environments (e.g., robotics or moving machinery), cables are subject to flexing, vibration, and abrasion. Using standard CAN cables instead of flexible, high-flex variants can lead to conductor breakage or jacket wear. Ensure the cable jacket material (e.g., PUR vs. PVC) suits mechanical and chemical exposure conditions.

By avoiding these common pitfalls—particularly in quality control and IP rating selection—you ensure reliable, long-lasting CAN communication in your system.

Logistics & Compliance Guide for BUS CAN Cable

Overview

BUS CAN (Controller Area Network) cables are essential components in automotive, industrial automation, and embedded systems, enabling reliable communication between electronic control units (ECUs). Ensuring proper logistics handling and regulatory compliance is critical to maintaining functionality, safety, and market access. This guide outlines best practices and requirements for the transportation, storage, and regulatory adherence of BUS CAN cables.

Packaging & Handling

Proper packaging prevents physical damage and electromagnetic interference (EMI) during transit.

– Use anti-static bags or conductive shielding for sensitive variants.

– Coil cables loosely to avoid kinking; secure with Velcro straps instead of tight ties.

– Label packages with “Fragile,” “Do Not Bend,” and “Electrostatic Sensitive Device” as applicable.

– Include desiccants in sealed packaging for humid environments to prevent moisture damage.

Storage Conditions

Maintain optimal environmental conditions to preserve cable integrity.

– Store in a dry, temperature-controlled environment (5°C to 35°C recommended).

– Avoid direct sunlight and high humidity (relative humidity < 60%).

– Keep away from strong electromagnetic fields and corrosive chemicals.

– Store on reels or racks to prevent long-term compression or deformation.

Transportation Requirements

Ensure safe and compliant shipment across domestic and international channels.

– Use padded containers with internal bracing to prevent movement.

– Comply with IATA, IMDG, or ADR regulations if shipping with related hazardous components (e.g., battery systems).

– Maintain documentation such as packing lists, commercial invoices, and material safety data sheets (MSDS) if required.

– For air freight, verify compliance with FAA or EASA guidelines for electronic components.

Regulatory Compliance

BUS CAN cables must meet region-specific standards depending on application and destination.

– RoHS (EU): Ensure lead-free construction and compliance with Directive 2011/65/EU.

– REACH (EU): Declare SVHCs (Substances of Very High Concern) as required.

– UL/CSA (North America): Use listed components for industrial or automotive applications.

– Automotive SPICE & ISO 16750: Required for automotive-grade cables in vehicle networks.

– EMC Directives (e.g., EU 2014/30/EU): Confirm electromagnetic compatibility for signal integrity.

Marking & Labeling

Accurate labeling supports traceability and regulatory verification.

– Include part number, manufacturer, date of production, and country of origin.

– Apply CE, UKCA, or FCC marks as applicable.

– Add RoHS compliance symbol (e.g., “RoHS compliant”) on packaging or product.

– For automotive use, ensure traceability codes (e.g., batch/lot numbers) are legible.

Documentation & Traceability

Maintain comprehensive records throughout the supply chain.

– Retain certificates of compliance (CoC) for materials and finished cables.

– Implement batch tracking for quality control and recalls.

– Provide technical specifications, including impedance (typically 120 Ω), shielding type, and temperature rating.

– Keep records of third-party test reports (e.g., flammability, durability).

Customs & Import Regulations

Prepare for cross-border logistics efficiently.

– Classify cables under correct HS codes (e.g., 8544.42 or 8544.49 for insulated wiring sets).

– Provide detailed product descriptions to avoid delays.

– Confirm duty rates and import restrictions in destination countries.

– For NAFTA/USMCA regions, verify rules of origin for preferential tariffs.

End-of-Life & Environmental Responsibility

Plan for responsible disposal and recycling.

– Design for disassembly and recyclability (per WEEE Directive 2012/19/EU).

– Partner with certified e-waste recyclers.

– Inform customers on proper disposal methods via user manuals or labels.

Conclusion

Effective logistics and compliance management for BUS CAN cables ensures product reliability, regulatory approval, and customer satisfaction. Adherence to international standards, proper handling, and thorough documentation are essential at every stage—from manufacturing to end-user deployment. Regular audits and updates to compliance protocols help maintain alignment with evolving global regulations.

Conclusion for Sourcing BUS CAN Cable

In conclusion, sourcing the appropriate CAN (Controller Area Network) bus cable requires careful consideration of several key factors including cable type (e.g., twisted pair shielded), impedance (typically 120 Ω), shielding quality, environmental durability, and compliance with industry standards such as ISO 11898. The selection should align with the specific application—whether automotive, industrial automation, or embedded systems—to ensure reliable communication, noise immunity, and long-term performance.

Supplier reliability, cost-effectiveness, and availability of technical support are also critical in the sourcing process. Engaging with reputable manufacturers or distributors that provide certified products and consistent quality helps mitigate risks related to signal integrity and system failure.

Ultimately, a well-sourced CAN bus cable contributes significantly to the stability and efficiency of the entire network. By balancing technical requirements with supply chain considerations, organizations can ensure optimal performance, reduce downtime, and support scalable and maintainable system designs.