The global sleepwear market is experiencing robust growth, driven by rising consumer demand for comfortable, stylish loungewear and an increasing focus on home-centric lifestyles. According to Grand View Research, the global sleepwear market size was valued at USD 34.8 billion in 2022 and is projected to expand at a compound annual growth rate (CAGR) of 5.2% from 2023 to 2030. This sustained expansion is creating strong opportunities for bulk manufacturers, particularly in the segment of pajama pants, where scalability, fabric innovation, and private-label customization are key competitive advantages. As brands seek reliable supply chain partners to meet growing demand, identifying top-tier bulk pajama pants manufacturers has become critical for retailers, e-commerce ventures, and fashion labels alike. The following list highlights the leading manufacturers excelling in production capacity, material sustainability, global compliance, and on-time delivery—key metrics that align with today’s data-driven sourcing strategies.

Top 10 Bulk Pajama Pants Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 Akcakaya Textile

Domain Est. 2005

Website: akcakaya.biz

Key Highlights: Akcakaya Textile is a leading clothing manufacturing company specializing in high-quality garments for women, men, children, and babies, crafted from premium ……

#2 Bulk pajama pants manufacturers

Domain Est. 2019

Website: cnpajama.com

Key Highlights: Cnpajama is an experienced and professional pyjama manufacturer for bulk pajama pants manufacture which mainly focuses on design, manufacture, and export ……

#3 Pajama Manufacturer

Domain Est. 2023

Website: appareify.com

Key Highlights: We specialize in crafting all sorts of pajamas using sustainable and ethically sourced materials, catering to any-scale clothing brands and fashion businesses….

#4 Wholesale pajama pants for your store

Domain Est. 1998

#5 Men’s Pajamas

Domain Est. 1999

Website: majesticinternational.com

Key Highlights: $5 deliveryMajestic International Men’s luxury pajamas available in the finest cotton, silk, easy care, and sateen….

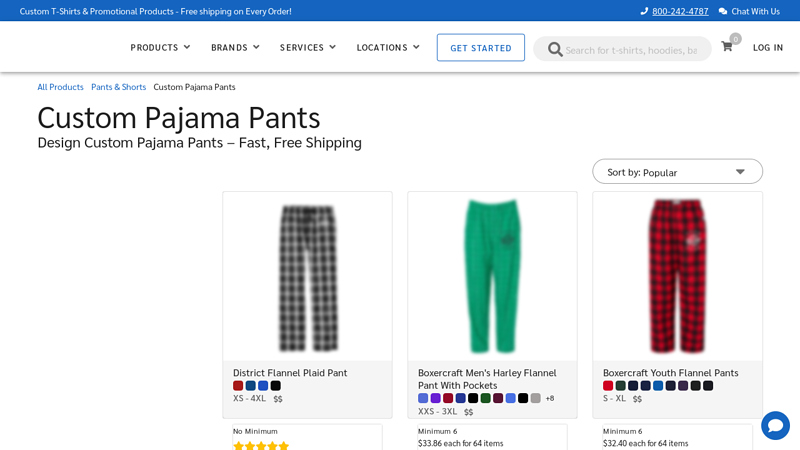

#6 Custom Pajama Pants

Domain Est. 2001

Website: undergroundshirts.com

Key Highlights: Free delivery over $50 30-day returnsPersonalize custom pajama pants for your business, team, or event. No minimums, bulk pricing, and free, fast shipping on all orders!…

#7 PJ Harlow Dreamwear

Domain Est. 2004

Website: pjharlow.com

Key Highlights: Bottoms · Loungewear … All content and material contained in the PJ Harlow website is protected by copyright, trademark and intellectual property rights….

#8 Wholesale Pajamas & Sleepwear

Domain Est. 2009

Website: eroswholesale.com

Key Highlights: Eros Wholesale offers wholesale Pajamas for the whole family. Check out the wide variety of PJs & Sleepwear we have in our inventory….

#9 Wholesale Flannel Pajama Pants Bulk

Domain Est. 2014

Website: flannelclothing.com

Key Highlights: Rating 4.8 (932) We have a huge range of flannel items- from crop pants, to slim fit ones, baggy pajamas, capris, ……

#10 Majesty Brands

Domain Est. 2015

Website: majestybrands.com

Key Highlights: Majesty Brands is a global leader in the design, manufacturing, and distribution of legwear, hosiery, sleepwear, intimates, slippers, and more…

Expert Sourcing Insights for Bulk Pajama Pants

H2: 2026 Market Trends for Bulk Pajama Pants

The global market for bulk pajama pants is expected to experience notable shifts by 2026, driven by evolving consumer preferences, sustainability demands, e-commerce growth, and supply chain innovations. Below is an analysis of key trends shaping the industry:

-

Rising Demand for Comfort and Lifestyle Wear

The continued normalization of remote work and stay-at-home lifestyles post-pandemic has solidified demand for comfortable, versatile sleepwear. Pajama pants, especially in bulk purchases for families, dormitories, and hospitality sectors, are increasingly being viewed as hybrid apparel—suitable for lounging, light outdoor use, and even casual wear. This trend supports higher volume sales, particularly in casual and athleisure-inspired designs. -

Sustainability and Eco-Friendly Materials

By 2026, sustainability will be a critical differentiator in the bulk apparel market. Buyers—including retailers, hotels, and institutional purchasers—are prioritizing pajama pants made from organic cotton, bamboo, TENCEL™, or recycled fibers. Certifications like OEKO-TEX and GOTS will carry more weight, with manufacturers investing in low-impact dyes and water-efficient production to meet environmental standards. -

Customization and Private Label Growth

Bulk purchasers, such as boutique hotel chains, spas, and subscription box services, are increasingly seeking customized pajama pants with branded logos, unique colors, or tailored fits. This trend favors manufacturers offering flexible MOQs (Minimum Order Quantities) and digital printing capabilities, enabling cost-effective personalization at scale. -

E-Commerce and B2B Digital Platforms

The rise of digital wholesale marketplaces (e.g., Alibaba, Faire, and Amazon Business) is streamlining bulk procurement. By 2026, seamless online ordering, virtual fabric sampling, and AI-driven size forecasting will become standard, allowing buyers to place large orders with greater confidence and efficiency. -

Regional Shifts in Manufacturing and Sourcing

While Asia remains a dominant producer, geopolitical factors and supply chain resilience are prompting diversification. Nearshoring to countries like Vietnam, Bangladesh, and Mexico is gaining traction, especially for North American and European buyers aiming to reduce lead times and carbon footprints. -

Focus on Inclusivity and Extended Sizing

Bulk buyers are demanding inclusive size ranges, reflecting broader market expectations for diversity and representation. Pajama pants offered in extended sizes (up to 5XL) and adaptive designs (e.g., easy-access features) will appeal to healthcare facilities, plus-size retailers, and inclusive lifestyle brands. -

Smart Fabrics and Functional Innovation

Though still emerging, smart textiles with moisture-wicking, temperature-regulating, or antimicrobial properties may gain traction in premium bulk segments—particularly in wellness resorts, medical sleepwear, and high-end hospitality.

Conclusion:

By 2026, the bulk pajama pants market will be shaped by a convergence of comfort, sustainability, customization, and digital efficiency. Manufacturers and suppliers who invest in eco-conscious production, flexible fulfillment, and customer-centric design will be best positioned to capture growing demand across retail, hospitality, and institutional sectors.

Common Pitfalls When Sourcing Bulk Pajama Pants: Quality and Intellectual Property Issues

Sourcing bulk pajama pants can be a cost-effective way to stock up on popular apparel, but it comes with significant risks—particularly concerning product quality and intellectual property (IP) infringement. Avoiding these common pitfalls is essential for maintaining brand reputation, ensuring customer satisfaction, and staying compliant with legal standards.

1. Inconsistent or Substandard Fabric Quality

One of the most frequent issues when sourcing bulk pajama pants is inconsistent fabric quality. Suppliers may use lower-grade materials than promised, such as thin cotton, rough polyester blends, or non-breathable fabrics. This results in discomfort, pilling, shrinking, or fading after washing—leading to customer complaints and returns.

Tip: Always request fabric swatches and lab test reports (e.g., for shrinkage, colorfastness, and composition) before placing large orders.

2. Poor Stitching and Construction

Low-cost manufacturers may cut corners on craftsmanship. Look out for loose threads, weak seams, uneven hems, or misaligned patterns. These flaws not only affect durability but also reflect poorly on your brand’s image.

Tip: Conduct pre-shipment inspections or hire a third-party quality control service to assess construction standards.

3. Misleading Size Sizing and Fit Variability

Sizing can vary significantly between suppliers and regions. Bulk pajama pants may run too small or too large, especially if the manufacturer uses non-standard sizing charts. Inconsistent sizing within the same order is another red flag.

Tip: Require detailed size charts and fit samples across multiple sizes before bulk production.

4. Use of Infringing Designs or Logos (IP Risks)

A major legal pitfall is unintentionally sourcing pajama pants with copyrighted patterns, trademarked characters (e.g., Disney, Marvel), or branded logos. Suppliers may offer “inspired by” designs that closely mimic protected IP, putting your business at risk of cease-and-desist letters, customs seizures, or lawsuits.

Tip: Avoid designs featuring cartoon characters, famous brand logos, or distinctive patterns without verified licensing. Conduct IP clearance checks when in doubt.

5. Lack of Compliance with Safety and Labeling Regulations

Pajama pants—especially those marketed for children—must meet flammability standards (e.g., CPSC regulations in the U.S.) and proper labeling requirements (fiber content, care instructions, country of origin). Non-compliant products can be blocked at customs or recalled.

Tip: Confirm that the supplier adheres to target market regulations and provide compliance documentation upon request.

6. Overreliance on Stock Photos and Unverified Supplier Claims

Many suppliers use professional stock images that don’t reflect the actual product. This can lead to surprises when the real samples arrive. Additionally, some suppliers falsely claim certifications (e.g., OEKO-TEX, organic cotton) without proof.

Tip: Always order physical samples, verify certifications independently, and consider visiting the factory or using a sourcing agent.

7. Communication and Language Barriers Leading to Errors

Miscommunication due to language differences can result in incorrect colors, patterns, or specifications. This is especially common when working with overseas manufacturers.

Tip: Use clear, detailed purchase orders with visual references and confirm understanding at every stage of production.

By being aware of these common pitfalls in quality and intellectual property, businesses can take proactive steps to source bulk pajama pants responsibly, reliably, and legally.

Logistics & Compliance Guide for Bulk Pajama Pants

Product Classification & HS Code

Pajama pants are typically classified under Harmonized System (HS) codes related to knitted or woven garments. For bulk shipments, the most common codes are:

– 6107.11 – Men’s or boys’ knitted or crocheted cotton pajamas

– 6107.19 – Other knitted or crocheted pajamas (synthetic fibers, blends, etc.)

– 6207.11 – Woven cotton pajamas for men/boys

– 6207.19 – Other woven pajamas

Note: Accurate classification by gender, material, and construction is essential. Always verify with local customs authorities.

Textile Labeling Requirements

Most countries require clear garment labeling. Compliance includes:

– Fiber Content: List all fabric components by percentage (e.g., 95% Cotton, 5% Spandex)

– Country of Origin: Label must state where the pajamas were manufactured (e.g., “Made in Vietnam”)

– Care Instructions: Include washing, drying, ironing, and bleaching symbols or text

– Size Labeling: Use local sizing standards (e.g., S, M, L or numeric EU/US sizes)

– Manufacturer/Retailer ID: Include company name, brand, or RN number (required in the U.S.)

Safety & Flammability Standards

Pajama pants, especially those for children, are subject to strict flammability regulations:

– United States (CPSC): Must comply with 16 CFR Part 1610 (flammability of clothing textiles). Children’s sleepwear (Sizes 0–14) must meet tighter standards under 16 CFR Part 1615/1616, requiring tight-fitting designs or flame-resistant fabrics.

– European Union: Requires compliance with REACH (chemical restrictions) and EN 14878 for children’s nightwear flammability.

– Canada: Follow SOR/2016-193 under the Canada Consumer Product Safety Act for children’s sleepwear.

– Australia/NZ: Must meet AS/NZS 1249 for children’s sleepwear.

Packaging & Shipping Logistics

Efficient and compliant packaging is crucial for bulk shipments:

– Inner Packaging: Use polybags (clear or branded) with proper ventilation holes to prevent moisture buildup

– Unit Packing: Typically 10–20 pairs per inner box; ensure boxes are sturdy to prevent damage

– Master Cartons: Clearly label with SKU, size breakdown, quantity, country of origin, and handling marks (e.g., “Fragile,” “Do Not Stack”)

– Palletization: Secure cartons on pallets with stretch wrap; use corner boards for added protection

– Shipping Marks: Include ship-to address, purchase order number, carton count (e.g., 1 of 50), and barcode for tracking

Import/Export Documentation

Ensure all required documents accompany bulk shipments:

– Commercial Invoice: Detailed description, quantities, unit/total prices, Incoterms (e.g., FOB, CIF), and HS codes

– Packing List: Itemizes contents per carton and total shipment volume/weight

– Bill of Lading (BOL): Issued by carrier; essential for ocean freight

– Certificate of Origin: May be required for preferential tariffs under trade agreements (e.g., USMCA, ASEAN)

– Phytosanitary Certificate: Not typically required for apparel unless packaging includes raw wood materials

– Test Reports/Certifications: Include lab reports for flammability, chemical compliance (e.g., AZO dyes, formaldehyde)

Incoterms & Risk Management

Select appropriate Incoterms to define responsibility:

– FOB (Free On Board): Seller delivers goods to port; buyer assumes risk and cost thereafter

– CIF (Cost, Insurance, Freight): Seller pays shipping and insurance to destination port

– DDP (Delivered Duty Paid): Seller handles all logistics and customs clearance – ideal for inexperienced buyers but increases seller liability

Environmental & Ethical Compliance

Increasingly required by retailers and regulators:

– REACH (EU): Restricts hazardous substances like phthalates and heavy metals

– Prop 65 (California): Requires warnings if products contain listed chemicals (e.g., certain dyes)

– OEKO-TEX® STANDARD 100: Voluntary certification proving textiles are free from harmful levels of toxic substances

– SMETA or BSCI Audits: Demonstrate ethical labor practices at manufacturing facilities

Storage & Handling Best Practices

- Warehouse Conditions: Store in dry, temperature-controlled areas to prevent mildew or fabric degradation

- Inventory Rotation: Use FIFO (First In, First Out) to avoid obsolescence

- Dust Protection: Keep packaged goods covered to maintain cleanliness

Returns & Reverse Logistics

Plan for:

– Defective Goods: Establish protocols for inspection, quarantine, and return shipping

– Labeling Errors: Keep spare labels or relabeling tools on hand

– Recalls: Maintain batch traceability through lot numbers or RFID tags if applicable

By adhering to these logistics and compliance guidelines, importers and exporters can ensure smooth, legal, and efficient movement of bulk pajama pants across international markets. Always consult with customs brokers and legal experts to confirm country-specific requirements.

In conclusion, sourcing bulk pajama pants requires careful consideration of several key factors including material quality, manufacturing reliability, cost-efficiency, and compliance with safety and ethical standards. By identifying reputable suppliers, negotiating favorable terms, and conducting thorough quality control checks, businesses can secure a consistent and dependable supply of comfortable, stylish, and durable pajama pants. Additionally, building strong long-term relationships with suppliers and staying informed about market trends and customer preferences will enhance competitiveness and ensure sustained success in the sleepwear market. Proper due diligence and strategic planning ultimately lead to a profitable and scalable bulk sourcing operation.