The global fleece fabric market is experiencing robust growth, driven by rising consumer demand for comfortable, lightweight, and sustainable textiles in activewear, outdoor apparel, and home furnishings. According to Grand View Research, the global technical textiles market—which includes performance-driven fleece fabrics—was valued at USD 237.5 billion in 2022 and is expected to expand at a CAGR of 5.8% from 2023 to 2030. Fleece, in particular, benefits from its versatility, thermal insulation, and growing adoption in eco-conscious manufacturing, with recycled polyester fleece gaining traction across major apparel brands. As demand surges, especially in North America and Asia-Pacific, sourcing reliable bulk fleece fabric has become critical for manufacturers and brands aiming to scale sustainably. To support strategic procurement, we’ve identified the top 9 bulk fleece fabric manufacturers known for production capacity, quality consistency, innovation in sustainable materials, and global supply chain reach.

Top 9 Bulk Fleece Fabric Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 Fleece Fabric

Domain Est. 2001

Website: tvfinc.com

Key Highlights: TVF is a leading supplier of fleece fabric. Comfortable, cozy fleece fabric is used for a variety of apparel and home décor applications….

#2 Robert Kaufman Fabrics

Domain Est. 1997 | Founded: 1942

Website: robertkaufman.com

Key Highlights: Wholesale supplier of quality textiles and fabrics for quilting, fashion and manufacturing since 1942….

#3 Polartec®

Domain Est. 1998

Website: polartec.com

Key Highlights: We’re the pioneers of fleece. We know how to make insulated fabrics that keep you comfortable and warm in any condition. We’re the pioneers of fleece….

#4 Wholesale Polar Fleece Fabric by the Bolt

Domain Est. 2001

Website: voguefabricsstore.com

Key Highlights: $7 delivery 30-day returnsShop for wholesale fleece fabric by the bolt today at Vogue Fabrics! Our anti-pill polar fleece fabric is perfect for making hoodies, scarves and bathrobe…

#5 Wholesale Fabric: Polar Fleece

Domain Est. 2003

Website: fabricmerchants.com

Key Highlights: As a trusted supplier, we offer a vast selection of high-quality Polar Fleece Fabric solids in bulk, perfect for retailers, designers, and craft enthusiasts….

#6 Exclusive Licensed College fabrics of NCAA, NHL and more

Domain Est. 2004

Website: sykelenterprises.com

Key Highlights: Show your school spirit College Fans! We have Exclusive Licensed College fabrics featuring logos with over 90 schools to choose from….

#7 Fleece Fabric

Domain Est. 2007

#8 Fleece Fabric Stocklots Made in the USA

Domain Est. 2010

Website: worldwiseusa.com

Key Highlights: Want fleece fabric made in the USA in bulk for a price that will blow you away, visit worldwiseusa.com to see all the products they offer….

#9 Fleece Fabric By The Yard

Domain Est. 2014

Expert Sourcing Insights for Bulk Fleece Fabric

H2: 2026 Market Trends for Bulk Fleece Fabric

The global bulk fleece fabric market in 2026 is poised for steady growth, driven by enduring consumer demand, sustainability imperatives, and technological advancements. Key trends shaping the market include:

1. Dominance of Recycled and Sustainable Materials:

Environmental concerns are fundamentally reshaping the fleece industry. By 2026, a significant portion of bulk fleece production—especially for apparel and outdoor brands—will shift toward recycled polyester (rPET), primarily sourced from post-consumer plastic bottles. Major retailers and brands are setting aggressive sustainability targets, demanding suppliers provide traceable, low-impact fleece. Expect stricter certifications (e.g., GRS, RCS) and innovations in bio-based fleece alternatives to gain traction, although cost and scalability remain challenges.

2. Demand for Performance and Functional Enhancements:

Consumers increasingly seek fleece with added value beyond warmth. Bulk fleece suppliers will focus on integrating performance features such as:

* Moisture Management: Fabrics wicking sweat efficiently for activewear and outdoor use.

* Odor Resistance: Anti-microbial treatments for extended wear.

* Wind and Water Resistance: Lightly treated or laminated fleece for transitional outerwear.

* Lightweight and Packability: High-loft, low-weight options for travel and layering systems.

3. Diversification of End-Use Applications:

While apparel (jackets, sweatshirts, loungewear) remains the largest segment, growth is accelerating in non-apparel sectors:

* Home Textiles: Fleece blankets, throws, pet beds, and upholstery linings offer comfort and durability.

* Industrial and Technical Uses: Insulation liners, protective covers, and cleaning wipes leverage fleece’s absorbency and thermal properties.

4. Supply Chain Resilience and Regional Shifts:

Geopolitical tensions and past disruptions have prompted buyers to diversify sourcing. While Asia (China, India, Bangladesh) remains dominant due to scale and cost, nearshoring and friend-shoring trends will boost production in regions like Turkey, Mexico, and Eastern Europe for brands targeting faster turnaround and reduced logistics risks. Digital platforms will enhance supply chain transparency.

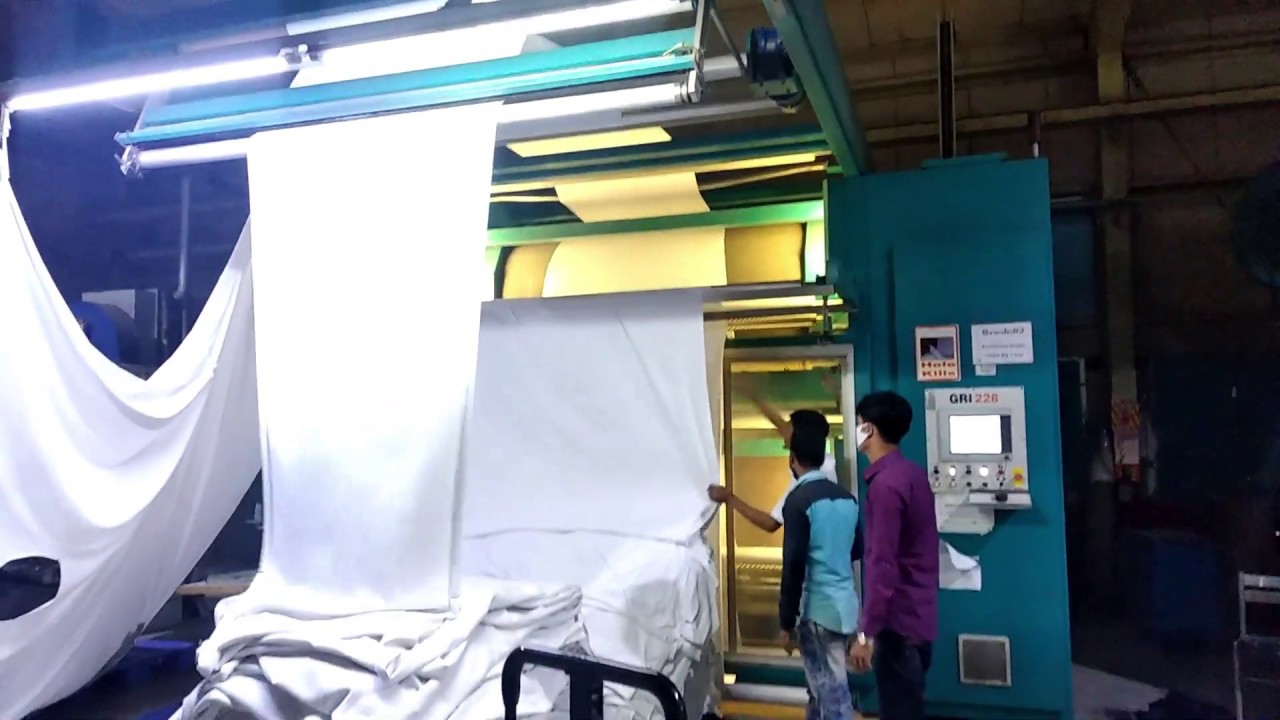

5. Automation and Digitalization in Manufacturing:

To maintain competitiveness amidst rising labor costs and demand for consistency, bulk fleece manufacturers are investing in:

* Automated knitting and finishing lines.

* Digital printing for small-batch customization and reduced waste.

* AI-driven quality control and predictive maintenance.

6. Focus on Cost Efficiency and Value Engineering:

Economic volatility will keep price sensitivity high. Suppliers will innovate to offer cost-effective solutions through optimized fiber blends, efficient production processes, and value-engineered fabric constructions (e.g., thinner, lighter fleece with comparable warmth).

Conclusion:

The 2026 bulk fleece fabric market will be defined by a dual focus: sustainability leadership and performance innovation. Success will depend on suppliers’ ability to deliver scalable, traceable recycled materials, integrate advanced functionalities, diversify applications, and operate resilient, efficient supply chains. Brands prioritizing eco-credentials and technical performance will drive demand, shaping a more sophisticated and environmentally conscious fleece market.

Common Pitfalls When Sourcing Bulk Fleece Fabric (Quality and Intellectual Property)

Sourcing bulk fleece fabric can be cost-effective, but it comes with significant risks related to quality consistency and intellectual property (IP) issues. Being aware of these pitfalls helps avoid costly mistakes and reputational damage.

Poor or Inconsistent Fabric Quality

One of the most frequent challenges is receiving fleece fabric that does not meet expected quality standards. This includes variations in weight (GSM), pilling resistance, softness, colorfastness, and shrinkage. Low-cost suppliers may use inferior raw materials or cut corners in manufacturing, resulting in fabric that feels rough, wears out quickly, or shrinks excessively after washing. Inconsistent dye lots can also cause color mismatches across production batches, affecting final product uniformity.

Lack of Quality Control and Certifications

Many bulk suppliers, especially in emerging markets, may lack robust quality control systems or third-party certifications (e.g., OEKO-TEX®, GRS for recycled content). Without these, there’s no assurance that the fabric is free from harmful chemicals or produced sustainably. Buyers risk receiving non-compliant materials that could lead to product recalls or legal issues, particularly when selling in regulated markets like the EU or North America.

Misrepresentation of Fabric Specifications

Suppliers may exaggerate or falsify technical details such as fiber content (e.g., claiming 100% polyester when it’s a blend), GSM, or performance features (e.g., moisture-wicking, anti-pilling). This misrepresentation can result in products that underperform or fail to meet customer expectations. Always request lab test reports and physical samples before placing large orders.

Intellectual Property Infringement Risks

Sourcing fleece fabric with proprietary textures, patterns, or performance technologies (e.g., branded fleece like Polartec®) from unauthorized suppliers can lead to IP violations. Some manufacturers replicate patented fabric finishes or trademarks without licensing, exposing buyers to legal action, seizure of goods at customs, or forced product recalls. Using counterfeit or unlicensed “look-alike” fabrics may save costs upfront but poses serious legal and brand integrity risks.

Inadequate Supply Chain Transparency

Many bulk suppliers subcontract production to unvetted mills, making it difficult to trace the origin of materials. This lack of transparency increases the risk of forced labor, environmental violations, or unintentional use of restricted substances. Without clear chain-of-custody documentation, brands may face reputational harm or compliance issues, especially under modern slavery or environmental regulations.

Minimum Order Quantity (MOQ) and Flexibility Issues

While low MOQs are attractive, they may indicate lower production standards or reliance on remnant stock. Conversely, very high MOQs can tie up capital and lead to overstock if demand forecasts are inaccurate. Suppliers may also be inflexible with customizations, limiting your ability to differentiate products or respond to market changes.

Communication and Cultural Barriers

Misunderstandings due to language differences, time zone challenges, or differing business practices can lead to errors in specifications, delays, or unmet expectations. Clear, documented communication and regular quality audits are essential to mitigate these risks.

Conclusion

To avoid these pitfalls, conduct thorough due diligence on suppliers, request physical samples and lab tests, verify IP rights, and consider third-party inspections. Building long-term relationships with reputable manufacturers and investing in supply chain transparency can safeguard both quality and compliance in bulk fleece sourcing.

Logistics & Compliance Guide for Bulk Fleece Fabric

Overview

Bulk fleece fabric is a popular textile product used in apparel, home goods, and outdoor gear manufacturing. Due to its volume, weight, and material composition, shipping and compliance require careful planning. This guide outlines key logistics considerations and regulatory requirements for importing or exporting bulk fleece fabric internationally.

Packaging & Handling

- Roll Packing: Fleece fabric is typically shipped in rolls, protected with plastic wrapping or kraft paper to prevent moisture, dust, and mechanical damage.

- Palletization: Rolls should be securely strapped or stretch-wrapped onto standard pallets (e.g., 48” x 40”) for stability during transport.

- Labeling: Each pallet must include clear labels with product description, SKU, roll count, weight, lot number, and handling instructions (e.g., “Keep Dry,” “Do Not Stack”).

- Moisture Control: Use desiccants inside packaging in humid environments to prevent mold growth during transit.

Transportation & Shipping

- Mode of Transport:

- Ocean Freight: Most cost-effective for large volumes. Use dry container shipping (20′ or 40′ containers). Ensure proper ventilation to avoid condensation.

- Air Freight: Suitable for urgent or smaller shipments. Higher cost, but faster delivery.

- Overland (Truck/Rail): Ideal for regional distribution; ensure tarpaulin cover for open trucks.

- Weight & Dimensions: Confirm fabric roll dimensions and total shipment weight to avoid overloading and ensure compliance with carrier limits.

- Cargo Insurance: Purchase all-risk cargo insurance to cover potential damage, loss, or delay.

Customs & Import/Export Compliance

- HS Code Classification:

- Typical HS code for fleece fabric: 5515.13 (man-made staple fibers, fleece type). Confirm country-specific codes for accuracy.

- Documentation Requirements:

- Commercial Invoice (with detailed description, unit price, total value)

- Packing List (roll count, dimensions, weights per package)

- Bill of Lading (for ocean freight) or Air Waybill

- Certificate of Origin (required for preferential tariffs under trade agreements)

- Textile Declaration (some countries require fiber content disclosure)

- Duties & Taxes: Research applicable import duties, VAT, and textile-specific quotas or restrictions in the destination country.

- Restricted Substances: Ensure compliance with regulations such as REACH (EU), CPSIA (USA), or OEKO-TEX® Standard 100 if selling to consumer markets.

Regulatory & Safety Standards

- Flammability Standards: In some regions (e.g., USA, EU), fleece used in children’s sleepwear must meet flammability testing (e.g., 16 CFR Part 1615/1616 in the U.S.).

- Labeling Requirements: Country-of-Origin, fiber content (e.g., 100% polyester), and care instructions may be required on final products or bulk rolls depending on destination.

- Environmental Compliance: Adhere to restrictions on hazardous dyes, formaldehyde, and APEOs (alkylphenol ethoxylates) under environmental regulations.

Quality Control & Inspection

- Pre-Shipment Inspection (PSI): Conduct third-party inspections to verify fabric width, weight (GSM), color fastness, pilling resistance, and roll integrity.

- Sampling: Use AQL (Acceptable Quality Level) standards (e.g., AQL 2.5 for major defects) during inspection.

- Lab Testing: Provide test reports for colorfastness, shrinkage, and pilling (e.g., ASTM D4970 or ISO 12945) upon request.

Storage & Warehousing

- Dry, Ventilated Environment: Store rolls in a clean, temperature-controlled warehouse to prevent moisture absorption and mildew.

- Off the Floor: Keep pallets elevated on racks or pallets to avoid ground moisture.

- Rotation: Use FIFO (First In, First Out) inventory management to prevent aging of stock.

Sustainability & Traceability

- Supply Chain Transparency: Maintain records of raw material sources and manufacturing processes to support ESG initiatives.

- Recyclability: Provide information on fabric recyclability, especially if made from recycled polyester (rPET).

- Carbon Footprint: Optimize shipping routes and consolidate loads to reduce environmental impact.

Conclusion

Successful logistics and compliance for bulk fleece fabric depend on proper packaging, accurate documentation, regulatory adherence, and quality assurance. Partnering with experienced freight forwarders, customs brokers, and testing labs ensures smooth international trade operations and minimizes delays or penalties. Regular audits and supplier evaluations further enhance compliance and supply chain reliability.

In conclusion, sourcing bulk fleece fabric requires careful consideration of quality, price, supplier reliability, and sustainability. By identifying reputable suppliers—whether domestic or international—and negotiating favorable terms, businesses can secure cost-effective, high-quality materials that meet production demands. Evaluating fabric weight, fiber content, certifications, and environmental impact further ensures the chosen fleece aligns with brand standards and customer expectations. Establishing long-term relationships with trustworthy suppliers, coupled with consistent quality control, ultimately supports efficient, scalable, and responsible manufacturing. With thorough research and strategic planning, sourcing bulk fleece fabric can be both economical and sustainable, providing a solid foundation for successful textile production.