The global water filtration market is experiencing robust growth, driven by rising concerns over waterborne diseases, increasing urbanization, and growing awareness of clean drinking water. According to a report by Mordor Intelligence, the global water treatment systems market was valued at USD 302.93 billion in 2023 and is projected to reach USD 461.54 billion by 2029, growing at a CAGR of 7.24% during the forecast period. This surge in demand has significantly boosted the adoption of point-of-use (POU) solutions, particularly bucket water filters, which are widely used in both rural and semi-urban areas across developing regions. Their affordability, ease of installation, and minimal maintenance make them a preferred choice for households without access to centralized water treatment infrastructure. As the need for decentralized water purification escalates, manufacturers of bucket water filters are scaling production, improving filtration efficacy, and expanding distribution networks—solidifying their role in bridging the clean water gap. Here are the top 7 bucket water filter manufacturers leading innovation and market penetration in this expanding sector.

Top 7 Bucket Water Filter Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 5 GALLON BUCKET SYSTEM

Domain Est. 2004

Website: bdavidwater.com

Key Highlights: This easy to use and portable system incorporates a four stage process that includes a two phase pre-filtration, Nanotechnology filtration, and a specialty ……

#2 Water Purification & Filtration Systems

Domain Est. 2007

Website: adyawater.com

Key Highlights: The best, most effective counter-top filter & purifier system. Reduces over 250 contaminants. Provides safe, healthy, great-tasting drinking water for the ……

#3 Water Filtration Systems

Domain Est. 1997

Website: culligan.com

Key Highlights: Make your water cleaner & safer throughout your home with Culligan’s water filters. Discover our water filtration solutions today….

#4 LAKOS Filtration Solutions

Domain Est. 1998

Website: lakos.com

Key Highlights: LAKOS has a variety of filtration solutions that are uniquely designed to easily remove unwanted sand from your residential water supply….

#5 Mobile and Emergency Water Filtration System

Domain Est. 2010

#6 AquaTru

Domain Est. 2013

Website: aquatruwater.com

Key Highlights: AquaTru water purifiers use patented 4-Stage Reverse Osmosis purification that transforms your tap water into pure, delicious, clean water you can trust….

#7 Inline Disc Filter

Domain Est. 2016

Expert Sourcing Insights for Bucket Water Filter

H2: 2026 Market Trends for Bucket Water Filters

The global market for bucket water filters is poised for significant transformation by 2026, driven by rising awareness of waterborne diseases, increasing urbanization in developing regions, and growing demand for affordable, off-grid water purification solutions. As governments and non-governmental organizations continue to prioritize safe drinking water access, bucket water filters—known for their low cost, ease of use, and scalability—are gaining renewed focus.

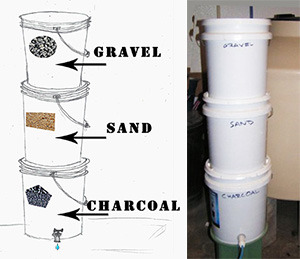

One major trend shaping the 2026 outlook is the integration of advanced filtration technologies into traditional bucket systems. Manufacturers are increasingly incorporating multi-stage filtration, including activated carbon, ceramic, and hollow fiber membranes, to enhance removal of bacteria, viruses, and chemical contaminants. This technological improvement is expanding the use of bucket filters beyond emergency relief to long-term household applications in rural and peri-urban areas.

Additionally, sustainability pressures are influencing product design. By 2026, there is a clear shift toward eco-friendly materials and modular components that extend filter lifespan and reduce plastic waste. Companies are also exploring biodegradable bucket materials and refillable filter cartridges to align with global circular economy principles.

Geographically, Asia-Pacific and Sub-Saharan Africa remain the largest markets due to widespread water contamination and limited infrastructure. However, Latin America and parts of Southeast Asia are emerging as high-growth regions, supported by public-private partnerships and international aid programs promoting decentralized water treatment.

Lastly, digital monitoring and smart labeling—such as QR codes tracking filter usage and replacement schedules—are beginning to enter the market, improving user compliance and maintenance tracking, especially in humanitarian contexts.

In conclusion, the 2026 bucket water filter market reflects a convergence of affordability, innovation, and sustainability, positioning these systems as vital tools in achieving universal access to safe drinking water.

Common Pitfalls When Sourcing Bucket Water Filters (Quality & Intellectual Property)

Sourcing bucket water filters, especially for humanitarian, development, or commercial distribution, involves navigating several critical challenges related to product quality and intellectual property (IP). Overlooking these pitfalls can lead to ineffective filtration, health risks, legal issues, and reputational damage.

Poor or Inconsistent Product Quality

One of the most significant risks when sourcing bucket filters is receiving units that fail to meet basic performance standards. Common quality pitfalls include:

- Inadequate Filtration Performance: Filters may not effectively remove pathogens (bacteria, protozoa) or reduce turbidity as claimed. Sourced units might lack proper certification (e.g., NSF/ANSI 62 or WHO guidelines), leading to unsafe drinking water.

- Low-Durability Materials: Buckets, taps, and filter housings made from substandard plastic can crack, leak, or degrade quickly under field conditions, reducing the filter’s lifespan.

- Inconsistent Manufacturing: Suppliers, particularly low-cost or unverified ones, may produce filters with variable pore sizes, uneven ceramic quality, or improper assembly, resulting in batch-to-batch performance differences.

- Lack of Quality Control Documentation: Reputable suppliers provide test reports, QC checklists, and batch certifications. Absence of these documents increases the risk of receiving non-compliant products.

Intellectual Property (IP) Infringement Risks

Many effective bucket filter designs are protected by patents, trademarks, or technical know-how. Sourcing from unauthorized manufacturers can lead to legal and ethical complications:

- Counterfeit or Copycat Products: Some suppliers sell filters that mimic well-known designs (e.g., the “Ceramic Water Filter” based on Potters for Peace models) without proper licensing. These copies may lack performance validation and expose buyers to liability.

- Patent Violations: Certain filtration technologies (e.g., specific ceramic formulations, silver impregnation methods, or structural designs) are patented. Using or distributing infringing products—even unknowingly—can result in legal action, shipment seizures, or fines.

- Reputational Damage: Distributing IP-infringing products can harm partnerships with NGOs, governments, or donors who require ethical sourcing compliance.

- Lack of Technical Support and Training: Legitimate IP holders often provide installation, maintenance training, and technical support. Copycat suppliers rarely offer such resources, reducing long-term effectiveness.

Mitigation Strategies

To avoid these pitfalls:

– Verify certifications (e.g., WHO, NSF, or local regulatory approvals).

– Request third-party test reports for microbial reduction and flow rate.

– Conduct factory audits or use trusted sourcing agents.

– Review IP status of the design and ensure suppliers have proper licensing.

– Engage directly with recognized manufacturers or licensed producers.

Proactively addressing quality and IP concerns ensures that sourced bucket water filters deliver safe, reliable, and legally compliant water treatment solutions.

Logistics & Compliance Guide for Bucket Water Filter

Product Overview and Intended Use

The Bucket Water Filter is a point-of-use water purification system designed to remove sediment, bacteria, and protozoa from untreated water sources. It typically consists of a ceramic or hollow fiber membrane filter element installed in a standard food-grade plastic bucket. This guide outlines key logistics considerations and compliance requirements for its distribution, import, and sale.

Regulatory Classifications and Standards

The Bucket Water Filter may be classified as a water treatment device under international and national regulations. Key standards include:

– EPA Guide Standard and Protocol for Testing Microbiological Water Purifiers (U.S. EPA): Required for claims of bacteria and protozoa reduction.

– NSF/ANSI 42 and 53: Covers aesthetic effects (e.g., chlorine taste) and health contaminants (e.g., cysts, turbidity), respectively. Certification is recommended for market access in North America.

– WHO Guidelines for Drinking-Water Quality: Provides performance benchmarks for use in humanitarian and developing contexts.

– CE Marking (European Union): May require conformity with the EU Drinking Water Directive (Council Directive 98/83/EC) and relevant EN standards for materials in contact with drinking water.

Import and Export Requirements

Ensure compliance with destination country regulations:

– Labeling: Include product name, filter specifications (pore size, flow rate), manufacturer details, and compliance marks. Bilingual labeling may be required (e.g., English and local language).

– Customs Documentation: Provide commercial invoice, packing list, bill of lading/airway bill, and certificate of origin.

– Restricted Substances: Verify that materials (e.g., plastics, filter media) comply with REACH (EU), RoHS, or other chemical safety regulations.

– Phytosanitary or Fumigation Certificates: Not typically required unless wooden pallets are used in shipping.

Packaging and Shipping Specifications

- Primary Packaging: Each filter unit should be sealed in moisture-resistant packaging to prevent contamination. Include user instructions and safety warnings.

- Secondary Packaging: Use durable corrugated boxes with internal dividers to prevent damage during transit. Stackability and cube utilization should be optimized.

- Shipping Conditions: Avoid extreme temperatures and humidity. Store and transport in dry, covered environments.

- Marking: Apply standard handling labels (e.g., “Fragile,” “This Side Up,” “Keep Dry”) and any required regulatory symbols (e.g., recycling codes).

Storage and Handling

- Warehouse Requirements: Store in a clean, dry, temperature-controlled facility (10–30°C recommended). Elevate pallets off the floor to prevent moisture absorption.

- Shelf Life: Monitor shelf life of filter elements; some membranes may degrade if stored dry for extended periods. Adhere to manufacturer’s expiration guidelines.

- Inventory Rotation: Implement FIFO (First In, First Out) system to minimize obsolescence.

End-of-Life and Environmental Compliance

- Recycling: Inform users about proper disposal. Filter cartridges may contain materials requiring special handling; buckets may be recyclable (check local resin codes).

- WEEE (EU): If electronic components are included (e.g., flow indicators), comply with Waste Electrical and Electronic Equipment directives.

- Product Take-Back: Consider voluntary take-back programs for used filters in environmentally sensitive markets.

Documentation and Recordkeeping

Maintain records for a minimum of five years, including:

– Test reports from accredited laboratories (e.g., microbiological challenge tests)

– Certifications (NSF, CE, etc.)

– Batch numbers and manufacturing dates

– Import/export declarations and customs filings

– Customer complaints and corrective actions

Compliance Monitoring and Audits

- Conduct annual internal audits to verify adherence to quality and regulatory standards.

- Prepare for third-party inspections by certification bodies or customs authorities.

- Update compliance status promptly when regulations change (e.g., new EU Drinking Water Directive requirements).

Contact and Support Information

Include on packaging and manuals:

– Manufacturer name and address

– Customer service contact (phone/email)

– Website with product registration, FAQs, and replacement part ordering

– Regulatory compliance officer contact for official inquiries

This guide ensures safe, legal, and efficient distribution of the Bucket Water Filter while meeting international health, safety, and environmental standards.

In conclusion, sourcing a bucket water filter is a practical, cost-effective, and sustainable solution for providing safe drinking water, especially in areas with limited access to clean water infrastructure. These filters are easy to assemble, require minimal maintenance, and utilize simple yet effective filtration technologies such as ceramic, activated carbon, and sediment filters to remove contaminants and improve water quality. When sourcing, it is essential to consider factors such as filtration efficiency, material durability, certification standards (e.g., NSF, WHO), availability of replacement parts, and local water quality conditions. Partnering with reputable suppliers and considering long-term support and training can enhance the effectiveness and lifespan of the system. Overall, bucket water filters offer a scalable and community-friendly approach to improving water safety and public health.