The global buck-boost transformer market is experiencing steady growth, driven by rising demand for voltage stabilization in commercial, industrial, and residential applications. According to Grand View Research, the global transformer market size was valued at USD 118.6 billion in 2022 and is expected to expand at a compound annual growth rate (CAGR) of 7.3% from 2023 to 2030. A significant portion of this growth can be attributed to the increasing adoption of buck-boost transformers, which offer a cost-effective and efficient solution for correcting voltage imbalances in power distribution systems. These transformers are particularly critical in regions with inconsistent grid supply and in facilities sensitive to voltage fluctuations, such as data centers, manufacturing plants, and healthcare infrastructure. With growing investments in smart grids and renewable energy integration, the need for reliable voltage regulation equipment continues to rise. As the market expands, several manufacturers have emerged as leaders through innovation, product reliability, and global distribution networks. Below is a data-driven overview of the top 10 buck-boost transformer manufacturers shaping the industry landscape.

Top 10 Buck Boost Transformers Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 Electrical

Domain Est. 2012

Website: temcoindustrial.com

Key Highlights: Free delivery 365-day returnsFederal Pacific – K1XGF16-1 – 1 Phase – 120×240 Volts Primary – 16/32 Volts Secondary – 1 kVA – Buck Boost Transformer – 60 Hz – Copper – NEMA 3R….

#2 Buck Boost Transformer Type QB

Domain Est. 1990

Website: electrification.us.abb.com

Key Highlights: Buck-boost transformers are small, single phase, dry type distribution transformers designed and shipped as insulating/isolating transformers….

#3 Buck

Domain Est. 1995

Website: store.hubbell.com

Key Highlights: 30-day returnsT181051. Buck-Boost Transformer – Single Phase, 120 X 240 – 12/24V, 500VA. $249.54. Add To Cart. Compare. Buck-Boost Transformer – Single Phase, ……

#4 Buck

Domain Est. 1995

Website: midmark.com

Key Highlights: Buck-Boost Transformers will increase or decrease incoming voltage by 10%. This accessory can be used for situations and installations with incoming line ……

#5 Buck Boost Transformers

Domain Est. 1995

Website: hubbell.com

Key Highlights: 30-day returnsExplore our buck boost transformers, ideal for adjusting voltage levels in electrical circuits to enhance device performance and ensure stability….

#6 Buck boost

Domain Est. 1996

Website: eaton.com

Key Highlights: Eaton’s buck boost, low-voltage transformers are ideally suited to applications where the available voltage needs to be slightly increased (“boosted”) or ……

#7 Buck Boost Transformers

Domain Est. 1996

Website: crescentelectric.com

Key Highlights: 3–9 day delivery 60-day returnsBuck boost transformers are single phase transformers that adjust voltages which are applied to alternating current systems. By increasing or ……

#8 Buck Boost Transformers, Low Voltage General Purpose

Domain Est. 1997

Website: se.com

Key Highlights: Schneider Electric USA. Browse our products and documents for Buck Boost Transformers, Low Voltage General Purpose – Economical space-saving design for ……

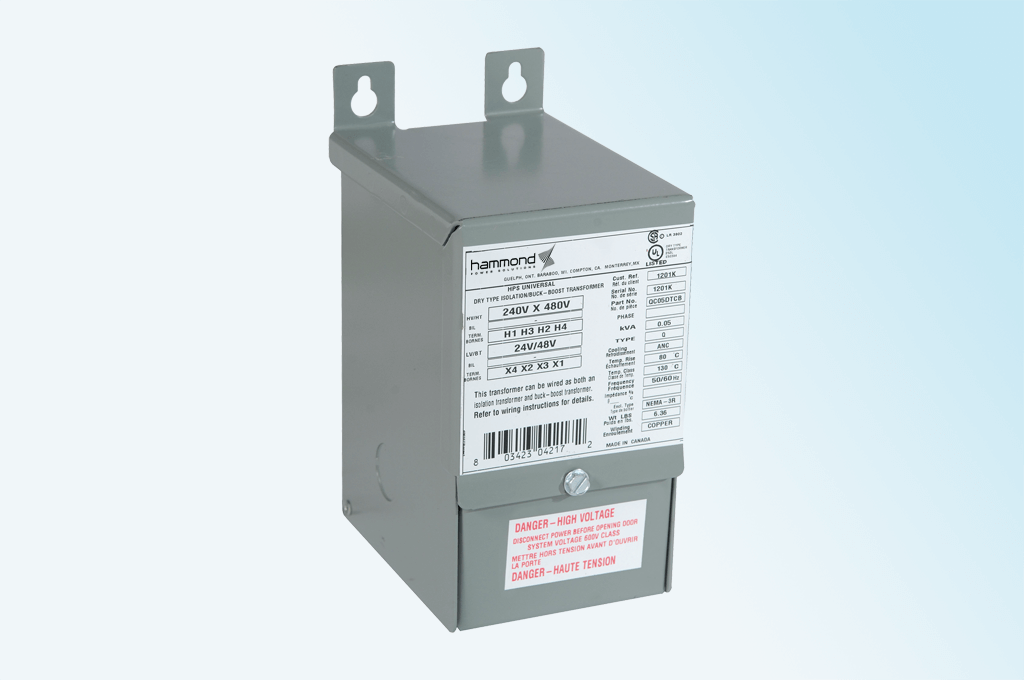

#9 Buck

Domain Est. 2000

Website: americas.hammondpowersolutions.com

Key Highlights: The HPS line of buck-boost transformers is an economical way to both raise supply voltage caused by line drop or lower voltage caused by increased system ……

#10 Buck

Domain Est. 2016

Website: solahdsales.com

Key Highlights: Free delivery over $1,000Buck-Boost Transformers provide a compact, energy efficient, low cost means for raising or lowering voltage by a relatively small amount – usually 5 to 27 …

Expert Sourcing Insights for Buck Boost Transformers

H2: 2026 Market Trends for Buck-Boost Transformers

Market Growth and Demand Drivers

The global buck-boost transformer market is projected to experience steady growth leading into 2026, driven by increasing demand for voltage regulation in commercial, industrial, and renewable energy applications. As energy efficiency standards become more stringent and infrastructure modernization accelerates—especially in emerging economies—buck-boost transformers are gaining traction as cost-effective solutions for compensating voltage fluctuations.

Key demand drivers include:

- Grid Modernization: Aging power infrastructure in North America and Europe necessitates the integration of voltage correction devices like buck-boost transformers to maintain stable power delivery.

- Industrial Automation Expansion: The rise of smart manufacturing and industrial IoT increases sensitivity to voltage inconsistencies, making buck-boost transformers essential for protecting precision equipment.

- Renewable Energy Integration: Solar and wind installations often experience variable voltage outputs. Buck-boost transformers help stabilize these fluctuations before grid connection or local consumption.

Technological Advancements

By 2026, the buck-boost transformer sector is expected to witness incremental technological improvements focused on efficiency, compactness, and digital integration. Innovations include:

- Low-Loss Core Materials: Adoption of amorphous metal and high-permeability silicon steel reduces core losses, improving overall efficiency.

- Modular and Scalable Designs: Manufacturers are offering more flexible configurations that allow end users to easily adjust voltage correction levels.

- Integration with Smart Grid Systems: Some advanced models now feature communication interfaces (e.g., Modbus, Ethernet) to enable remote monitoring and diagnostics, aligning with Industry 4.0 trends.

Regional Market Dynamics

- North America: Remains a leading market due to extensive retrofitting of old electrical systems and strong industrial base. The U.S. Department of Energy’s efficiency mandates support the adoption of high-efficiency buck-boost units.

- Europe: Growth is propelled by renewable energy targets and EU energy efficiency directives. Countries like Germany and France are investing in decentralized energy networks that benefit from localized voltage control.

- Asia-Pacific: Expected to be the fastest-growing region, driven by rapid industrialization in India and Southeast Asia, coupled with increasing investments in commercial construction and data centers.

Competitive Landscape

The market remains fragmented, with a mix of established players (e.g., ABB, Schneider Electric, Eaton) and regional manufacturers. Competitive strategies in 2026 center on:

- Expanding product portfolios to cover a wider range of kVA ratings and configurations.

- Enhancing supply chain resilience to mitigate raw material price volatility (especially copper and steel).

- Offering value-added services such as energy audits and custom engineering support.

Regulatory and Sustainability Trends

Environmental regulations are influencing design and manufacturing. By 2026, many buck-boost transformers are expected to comply with:

- DOE 2016 (U.S.) and Ecodesign Directive (EU): Mandating minimum efficiency levels.

- RoHS and REACH Compliance: Limiting hazardous substances in electrical equipment.

- Circular Economy Practices: Increased focus on recyclability and use of sustainable materials in packaging and core construction.

Challenges and Outlook

Despite positive growth, the market faces challenges including:

- Raw Material Price Volatility: Fluctuations in copper and steel prices can affect profitability.

- Competition from Solid-State Solutions: Emerging power electronics-based voltage regulators may displace traditional transformers in high-precision applications.

Nevertheless, the buck-boost transformer market is poised for moderate but stable growth through 2026, supported by enduring demand for reliable, low-cost voltage correction across diverse sectors. Its role in supporting energy transition and grid resilience ensures continued relevance in the evolving power ecosystem.

Common Pitfalls When Sourcing Buck-Boost Transformers: Quality and Intellectual Property

When sourcing buck-boost transformers—commonly used to adjust voltage levels in electrical systems—buyers often encounter critical challenges related to quality assurance and intellectual property (IP) risks. Overlooking these aspects can lead to equipment failure, safety hazards, or legal complications. Below are key pitfalls to avoid.

Inadequate Quality Control and Substandard Materials

One of the most frequent issues in sourcing buck-boost transformers, especially from low-cost manufacturers, is the use of substandard materials and poor workmanship. Transformers may use lower-grade copper windings, inferior insulation, or undersized cores, which reduce efficiency, increase heat generation, and shorten operational lifespan. Without proper testing and certification (e.g., UL, CSA, or IEC standards), units may fail under load or pose fire risks.

Buyers should demand comprehensive test reports, factory audits, and sample validation before placing bulk orders. Relying solely on datasheets without third-party verification increases the risk of receiving non-compliant or unreliable products.

Lack of Compliance with Regional Safety and Certification Standards

Buck-boost transformers must meet specific regulatory requirements depending on the target market (e.g., UL 1561 in North America, CE in Europe). Sourcing from suppliers who claim compliance without verifiable certification is a major pitfall. Counterfeit certifications or self-declared conformity can result in rejected shipments, fines, or liability in the event of equipment failure.

Ensure suppliers provide up-to-date, authentic certification documents traceable to recognized testing laboratories. Avoid vendors who offer “custom” certifications or cannot provide documentation upon request.

Intellectual Property Infringement Risks

Some low-cost suppliers may replicate proprietary designs or trademarks of well-known transformer brands without authorization. Sourcing from such manufacturers exposes buyers to IP infringement claims, especially when importing into jurisdictions with strong IP enforcement (e.g., the U.S. or EU). Even unintentional distribution of counterfeit or cloned products can result in legal action, seizure of goods, or reputational damage.

Due diligence is essential: verify that the supplier owns the design or has legitimate licensing agreements. Request design documentation and avoid suppliers offering “exact replicas” of branded models at suspiciously low prices.

Insufficient Technical Support and Documentation

Poorly sourced transformers often come with inadequate technical documentation, unclear schematics, or lack of support for installation and troubleshooting. This is particularly problematic for custom or application-specific buck-boost configurations. Without proper specs and support, integration into existing systems becomes risky and time-consuming.

Ensure suppliers provide detailed performance data, wiring diagrams, and accessible technical support. Evaluate responsiveness and expertise during the pre-sales phase as an indicator of long-term reliability.

Hidden Costs from Poor Efficiency and Reliability

While initial price may be low, subpar transformers often have lower efficiency, leading to higher energy losses and increased operating costs over time. Frequent failures also result in downtime and replacement expenses. These hidden costs can far exceed the savings from choosing a cheaper, unverified supplier.

Prioritize total cost of ownership by evaluating efficiency ratings (e.g., DOE 2016 compliance in the U.S.), expected lifespan, and warranty terms when comparing options.

By recognizing and addressing these pitfalls—focusing on verified quality, regulatory compliance, IP integrity, and long-term performance—buyers can mitigate risks and ensure reliable, safe, and legally sound sourcing of buck-boost transformers.

Logistics & Compliance Guide for Buck-Boost Transformers

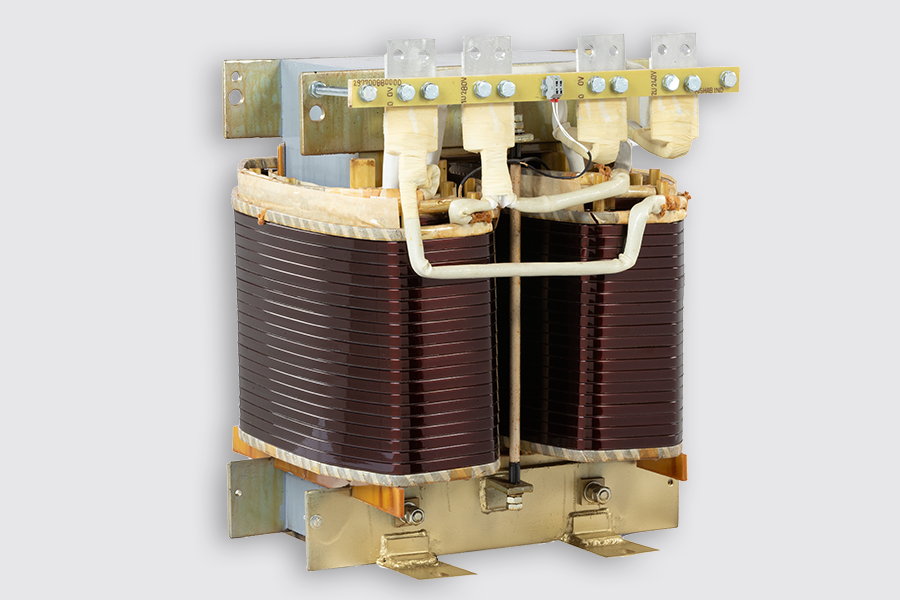

Overview of Buck-Boost Transformers

Buck-boost transformers are small single-phase transformers used to adjust (increase or decrease) line voltage by a small amount—typically 5% to 20%. They are commonly used in commercial, industrial, and residential applications to correct voltage imbalances, support equipment operation, and improve system efficiency. Proper logistics and compliance are essential to ensure safe handling, legal import/export, and adherence to performance and safety standards.

International Shipping & Transportation

When shipping buck-boost transformers globally, compliance with international transport regulations is critical. Packages must be securely boxed with adequate cushioning to prevent damage during transit. For air freight, ensure compliance with IATA Dangerous Goods Regulations—even though most dry-type buck-boost transformers are non-hazardous, documentation should clarify the absence of hazardous materials. For sea freight, proper labeling and moisture protection are required, especially for units with metallic components vulnerable to corrosion.

Packaging & Handling Requirements

Buck-boost transformers should be shipped in manufacturer-approved packaging that includes:

– Shock-absorbent materials (e.g., foam inserts, cardboard dividers)

– Moisture barriers (e.g., plastic wrapping) to prevent condensation

– Clear labeling of weight, orientation (“This Side Up”), and handling instructions

Avoid stacking heavy items on transformer packages. Use pallets for bulk shipments and secure loads to prevent shifting during transport.

Import/Export Compliance

Ensure compliance with destination country regulations:

– Harmonized System (HS) Codes: Typically fall under HS 8504.23 or 8504.31 (depending on voltage and rating)

– Customs Documentation: Include commercial invoice, packing list, certificate of origin, and bill of lading

– Export Controls: Verify if transformers exceed power or technical thresholds requiring export licenses (e.g., under EAR in the U.S.)

– Duty & Tariff Classification: Confirm tariff rates and potential trade agreement benefits (e.g., USMCA, EU trade preferences)

Safety & Certification Standards

Buck-boost transformers must meet regional safety and performance certifications:

– North America: UL 5085 (Standard for Safety of Transformers), CSA C22.2 No. 66 (Canada)

– European Union: Compliant with Low Voltage Directive (LVD) 2014/35/EU and carry CE marking; EN 61558-2-14 for safety of control transformers

– Other Regions: May require CCC (China), KC (Korea), or RCM (Australia/New Zealand) certification

Always verify that units are certified by an accredited testing laboratory and include certification marks on nameplates.

Environmental & RoHS Compliance

Ensure transformers comply with environmental directives:

– RoHS (Restriction of Hazardous Substances): Applies in the EU and other jurisdictions; limits lead, mercury, cadmium, and other substances

– REACH: Registration, Evaluation, Authorization, and Restriction of Chemicals—requires disclosure of SVHCs (Substances of Very High Concern)

– WEEE (Waste Electrical and Electronic Equipment): Producers may be responsible for take-back and recycling in applicable regions

Voltage & Frequency Regulations

Confirm that the transformer’s input/output voltage and frequency (e.g., 120/240V, 60Hz or 230V, 50Hz) are compatible with the destination’s electrical grid. Mismatches can lead to equipment failure and safety hazards. Provide technical documentation to support regulatory inspections or utility approvals.

Regulatory Labeling & Documentation

Each unit must display:

– Manufacturer name and model number

– Input/output voltage and kVA rating

– Frequency (Hz)

– Safety certification marks (e.g., UL, CE)

– Wiring diagram or reference

Include user manuals and installation guides in the local language for international markets.

Storage Conditions

Store buck-boost transformers in a clean, dry, temperature-controlled environment (typically 0°C to 40°C). Avoid exposure to moisture, dust, and corrosive atmospheres. Keep original packaging intact until installation to protect insulation and terminals.

End-of-Life & Recycling

Follow local e-waste regulations for disposal. Most components (copper windings, steel core, housing) are recyclable. Partner with certified e-waste handlers to ensure environmentally responsible recycling and compliance with WEEE or similar programs.

Summary

Proper logistics and compliance for buck-boost transformers involve secure packaging, adherence to international shipping rules, regulatory certifications, and environmental standards. Ensuring all documentation and labeling are in order minimizes delays and supports safe, legal deployment across global markets.

Conclusion on Sourcing Buck-Boost Transformers

Sourcing buck-boost transformers requires careful consideration of technical specifications, application requirements, and supplier reliability. These transformers are essential for adjusting voltage levels efficiently in various commercial, industrial, and utility applications, especially where minor voltage corrections are needed to ensure equipment performance and longevity.

When sourcing, it is crucial to evaluate factors such as input/output voltage requirements, kVA rating, phase configuration (single or three-phase), and environmental conditions. Partnering with reputable manufacturers and certified suppliers ensures compliance with safety standards (e.g., UL, CSA, IEEE) and guarantees product quality, reliability, and warranty support.

Additionally, considering energy efficiency, ease of installation, and future scalability will contribute to long-term operational savings and system stability. Customization options may also be necessary for unique voltage correction needs, making supplier expertise and technical support highly valuable.

In summary, successful sourcing of buck-boost transformers involves a balance of technical accuracy, quality assurance, and strategic supplier relationships to ensure reliable voltage regulation, optimal equipment performance, and cost-effective operation across diverse electrical systems.