The global market for hydraulic and pneumatic components has seen steady expansion, driven by increasing demand from industrial manufacturing, automotive, and oil & gas sectors. According to Mordor Intelligence, the global hydraulic equipment market was valued at USD 29.7 billion in 2023 and is projected to grow at a CAGR of over 4.8% through 2029. A critical yet often overlooked element within this ecosystem is the BSP to NPT converter, a key adapter enabling compatibility between British Standard Pipe (BSP) and National Pipe Tapered (NPT) thread standards. With regional differences in threading standards—BSP being prevalent in Europe and much of the Commonwealth, and NPT dominant in North America—the need for reliable conversion solutions has grown alongside cross-border equipment integration. As industrial automation and global supply chains expand, demand for high-quality, precision-engineered BSP to NPT converters continues to rise. This has led to a competitive landscape of manufacturers focusing on durability, leak prevention, and material innovation. Based on market dynamics and performance metrics, we’ve identified the top 10 BSP to NPT converter manufacturers leading in product quality, global reach, and technological consistency.

Top 10 Bsp To Npt Converter Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

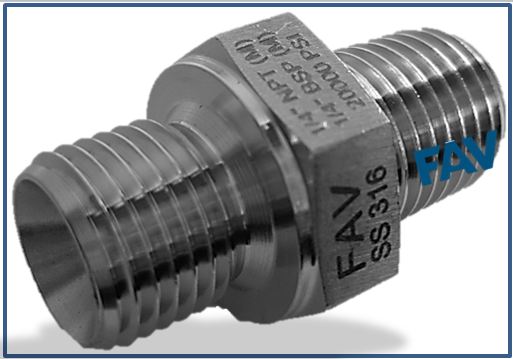

#1 Hex Adaptor BSP Male X NPT Male

Domain Est. 2017

Website: favfittings.com

Key Highlights: FAV is the manufacturer of High Pressure Hex Adaptor BSP Male X NPT Male 10000 psi , 700 Bars . We make Variety of high pressure pipe couplings & fittings….

#2 Female BSP Taper to Male NPT Adapter

Domain Est. 1995

Website: ipd.parker.com

Key Highlights: Female BSP Taper to Male NPT Adapter ; Connection Type · FBSPT x MNPT ; BSPT Thread T1 · 1/8-28 ; NPT Thread T2 · 1/8-27 ; W HEX · 9/16 in ; D · 1.09 in ……

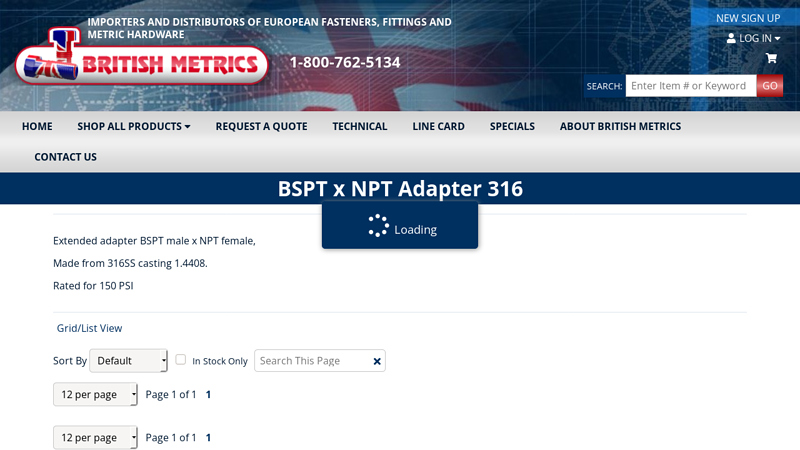

#3 BSPT x NPT Adapter 316

Domain Est. 1996

Website: britishmetrics.com

Key Highlights: Made from 316 stainless-steel casting, these extended pipe adapters have BSPT male and NPT female threads. Get a 316SS extended adapter from British ……

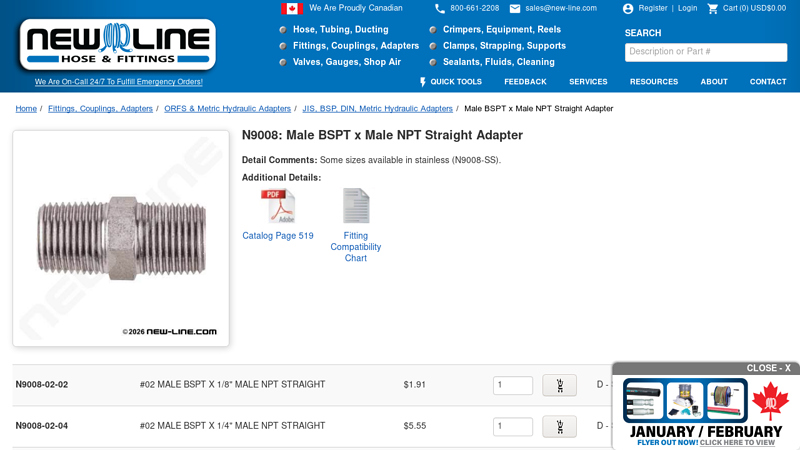

#4 Male BSPT x Male NPT Straight Adapter

Domain Est. 1996

Website: new-line.com

Key Highlights: N9008: Male BSPT x Male NPT Straight Adapter. Detail Comments: Some sizes available in stainless (N9008-SS). Additional Details: Catalog Page 519….

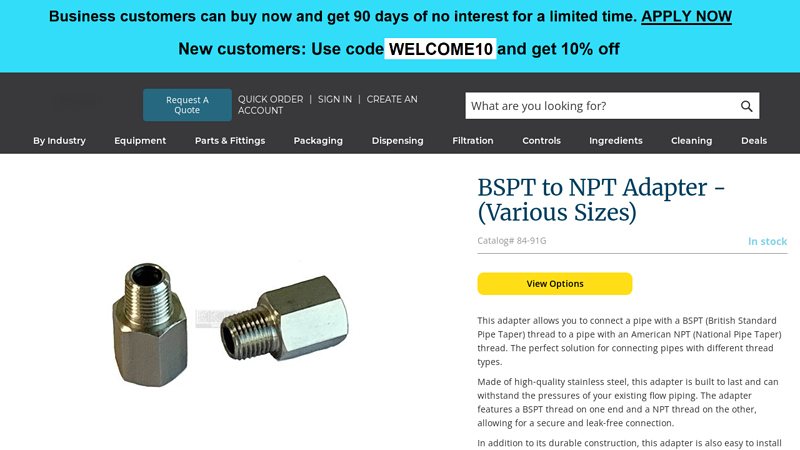

#5 BSPT to NPT Adapter

Domain Est. 1999

#6 Adaptall

Domain Est. 2000

Website: adaptall.com

Key Highlights: Adaptall specializes in the conversion of hydraulic adapters & fittings, between International (Metric) and American (Imperial) thread types: British (BSPP, ……

#7 Fitting Adapters for Pipe Threads

Domain Est. 2000

Website: koolance.com

Key Highlights: 5-day delivery 30-day returnsThread adapters are used to convert between different fitting or pipe threads, such as BSP and NPT….

#8 Adaptor 1/4″ NPT (M) to BSP (F)

Domain Est. 2005

#9 MALE BSPT TO FEMALE NPT ADAPTERS

Domain Est. 2010

#10 8008-08-08 by AdaptAll

Domain Est. 2012

Website: hosewarehouse.com

Key Highlights: In stock Rating 5.0 1 Adaptall specializes in the conversion of hydraulic adapters and fittings, between International (“Metric”) and American (“Imperial”) thread types. These …..

Expert Sourcing Insights for Bsp To Npt Converter

2026 Market Trends for BSP to NPT Converter

The market for BSP to NPT converters is poised for continued growth and evolution by 2026, driven by globalization in industrial supply chains, infrastructure development, and increasing demand for interoperability in fluid systems. These essential fittings bridge the gap between British Standard Pipe (BSP) and National Pipe Taper (NPT) thread standards, which dominate different regions and industries. Understanding the key trends shaping this niche but critical component market is vital for manufacturers, distributors, and end-users.

Growing Demand from Cross-Regional Industrial Projects

As multinational companies expand manufacturing, energy, and process facilities globally, the need to integrate equipment using different thread standards intensifies. Equipment manufactured in Europe or Asia (typically using BSP) must often interface with piping systems in North America (predominantly using NPT). This convergence drives consistent demand for reliable BSP to NPT converters, particularly in sectors like oil & gas, chemical processing, and water treatment. By 2026, the rise in cross-border infrastructure investments and retrofitting of legacy systems will further amplify this need.

Advancements in Materials and Coatings

To meet stringent performance requirements in harsh environments, manufacturers are increasingly offering BSP to NPT converters in advanced materials such as 316 stainless steel, brass with anti-corrosion plating, and specialty alloys. Enhanced surface treatments like PTFE coating or nickel plating are becoming standard to improve leak resistance, durability, and compatibility with aggressive media. These innovations not only extend product life but also support compliance with industry regulations, making them a key differentiator in the 2026 marketplace.

Standardization and Quality Assurance Emphasis

With safety and system integrity at stake, end-users and regulators are placing greater emphasis on certified, high-quality conversion fittings. ISO and ASME compliance, along with third-party testing and traceability, are becoming market expectations rather than optional features. Distributors and OEMs are increasingly sourcing from suppliers with robust quality management systems, pushing smaller players to upgrade or risk obsolescence.

E-Commerce and Digital Supply Chain Integration

The procurement of industrial components like BSP to NPT converters is shifting toward digital platforms. By 2026, e-commerce marketplaces and integrated supply chain solutions will dominate, offering real-time inventory, technical specifications, and compatibility tools. Augmented reality (AR) product visualizers and digital twins may assist engineers in selecting the correct converter size and material, reducing errors and downtime.

Sustainability and Circular Economy Considerations

While a minor trend today, sustainability is beginning to influence material choices and packaging. Recyclable metals and reduced packaging waste are emerging as value propositions. Additionally, the repair and reuse of existing systems—rather than wholesale replacement—will sustain demand for conversion fittings as a cost-effective and environmentally sound solution.

In conclusion, the 2026 market for BSP to NPT converters will be characterized by rising demand driven by global integration, enhanced product performance, digital procurement channels, and a focus on quality and sustainability. Companies that innovate in materials, ensure compliance, and embrace digital distribution will be best positioned to lead in this specialized but essential segment.

Common Pitfalls When Sourcing BSP to NPT Converters: Quality and IP Concerns

Sourcing BSP to NPT converters may seem straightforward, but several critical pitfalls—particularly related to quality and intellectual property (IP)—can lead to system failures, safety hazards, and legal complications. Being aware of these issues helps ensure reliable performance and compliance.

Poor Material Quality and Manufacturing Standards

Many low-cost BSP to NPT converters are manufactured using substandard materials such as low-grade brass or non-compliant alloys that corrode easily or fail under pressure. Inferior threading due to poor machining can result in leaks or cross-threading during installation. Always verify that the converters meet recognized standards such as ASTM, ISO, or ANSI, and request material certifications from suppliers.

Inaccurate Thread Dimensions and Tolerances

BSP (British Standard Pipe) and NPT (National Pipe Taper) threads differ in thread angle (55° vs. 60°), pitch, and taper design. A poorly made converter may not maintain precise dimensional accuracy, leading to misalignment, leakage, or connection failure. Ensure the product is manufactured to exacting tolerances and tested for thread compatibility.

Lack of Pressure and Temperature Ratings

Some converters lack proper pressure and temperature ratings or are inaccurately labeled. Using an under-rated converter in high-pressure or high-temperature applications can result in catastrophic failure. Always validate the rated specifications with third-party test reports or certifications like CE, UL, or NSF, where applicable.

Counterfeit or Misrepresented Products

In global supply chains, counterfeit or rebranded converters are common. These may appear identical to genuine parts but fail under operating conditions. Be cautious with suppliers offering unusually low prices, and verify authenticity through traceability, branding, and documentation.

Intellectual Property (IP) Infringement Risks

Using or sourcing BSP to NPT converters that replicate patented designs—especially those with proprietary sealing mechanisms or integrated features—can expose your company to IP litigation. Always vet suppliers for adherence to IP laws and avoid generic copies of branded, patented fittings unless properly licensed.

Inadequate Documentation and Traceability

Reliable sourcing requires full traceability, including batch numbers, material test reports, and compliance documentation. Suppliers that cannot provide these may be cutting corners, increasing the risk of non-compliant or unsafe components entering your system.

Conclusion

To avoid these pitfalls, partner with reputable suppliers, demand full certification and testing data, and conduct periodic quality audits. Prioritizing quality and IP compliance not only ensures operational safety but also protects your organization from legal and financial risks.

Logistics & Compliance Guide for BSP to NPT Converter

When importing, exporting, or distributing BSP (British Standard Pipe) to NPT (National Pipe Taper) converters, adherence to logistics and compliance standards is essential to ensure product safety, regulatory approval, and smooth operations across international markets. This guide outlines key considerations for handling these mechanical adapters in global supply chains.

Understanding BSP to NPT Converters

BSP to NPT converters are threaded pipe fittings used to connect plumbing or pneumatic systems that use different thread standards—BSP (common in Europe, Asia, and the UK) and NPT (predominant in North America). These adapters must meet precise dimensional, material, and performance standards to ensure leak-free connections and system integrity. Due to their use in critical applications (e.g., industrial machinery, oil & gas, HVAC), compliance with international standards is mandatory.

International Standards and Certifications

Ensure all BSP to NPT converters comply with recognized standards:

- ISO 7-1: Specifies requirements for BSP threads.

- ASME B1.20.1: Covers NPT thread dimensions and tolerances.

- ISO 9001: Quality management system certification for manufacturers.

- PED (Pressure Equipment Directive) 2014/68/EU: Required for products used in pressurized systems within the European Union.

- CRN (Canadian Registration Number): May be required in Canada depending on application and pressure rating.

- NSF/ANSI 61: Applicable if converters are used in potable water systems.

Verify that suppliers provide test reports, material certifications (e.g., 316 stainless steel, brass), and compliance documentation.

Packaging and Labeling Requirements

Proper packaging and labeling ensure product integrity and regulatory compliance:

- Packaging: Use moisture-resistant, shock-absorbent materials to prevent thread damage during transit. Bulk packaging must prevent loosening or abrasion.

- Labeling: Each package should include:

- Product name and description (e.g., “1/2\” BSP Male to NPT Female Adapter”)

- Material type (e.g., “Brass, Lead-Free”)

- Size and thread specifications

- Manufacturer name and country of origin

- Batch/lot number and date of production

- Compliance marks (e.g., CE, UKCA, RoHS)

Import/Export Regulations

Navigate customs and trade requirements based on origin and destination:

- HS Code Classification: Use appropriate Harmonized System (HS) codes (e.g., 7307.29 for pipe fittings of iron or steel; 7412.10 for copper fittings).

- Country-Specific Regulations:

- USA: Comply with EPA lead-free regulations (Safe Drinking Water Act) if used in water systems.

- EU: Adhere to REACH (Registration, Evaluation, Authorization, and Restriction of Chemicals) and RoHS (Restriction of Hazardous Substances).

- UK: Follow UKCA marking requirements post-Brexit; CE still accepted until 2025 in most cases.

- China: May require CCC (China Compulsory Certification) for certain industrial applications.

- Documentation: Prepare commercial invoices, packing lists, certificates of origin, and conformity assessments for customs clearance.

Transportation and Storage

Follow best practices to maintain product quality:

- Transportation: Use secure, temperature-stable shipping methods. Avoid exposure to extreme humidity or corrosive environments.

- Storage: Keep in dry, indoor conditions away from direct sunlight and chemicals. Store vertically or in bins to prevent thread deformation.

Environmental and Safety Compliance

Address environmental and workplace safety concerns:

- Material Safety: Ensure converters do not contain restricted substances (e.g., lead in excess of 0.25% for wetted surfaces in the US).

- Disposal: Follow local regulations for metal waste recycling or disposal.

- Workplace Handling: Provide safety data sheets (SDS) if applicable and train staff on safe handling of metal fittings.

Quality Assurance and Traceability

Maintain robust traceability systems:

- Implement batch tracking for recalls or audits.

- Conduct incoming inspections for thread accuracy, surface finish, and material verification.

- Partner with suppliers who follow documented quality control processes.

Conclusion

Successfully managing the logistics and compliance of BSP to NPT converters requires attention to technical standards, regulatory frameworks, and supply chain best practices. By ensuring certifications, proper documentation, and adherence to international requirements, businesses can minimize delays, reduce risk, and deliver reliable products to global markets.

Conclusion: Sourcing a BSP to NPT Converter

Sourcing a BSP (British Standard Pipe) to NPT (National Pipe Taper) converter requires careful consideration of technical specifications, material compatibility, application environment, and regulatory standards. While BSP and NPT threads are both commonly used in plumbing and industrial applications, they differ in thread angle, pitch, and sealing methods, making direct interchangeability risky without an appropriate adapter.

The successful implementation of a BSP to NPT converter hinges on selecting a high-quality adapter made from suitable materials—such as brass, stainless steel, or nylon—depending on the operating conditions, including pressure, temperature, and exposure to corrosive substances. It is essential to verify thread dimensions and ensure proper sealing, often with the use of thread sealant or tapered design features, to prevent leaks and maintain system integrity.

Additionally, sourcing from reputable suppliers who adhere to international standards (e.g., ISO, ANSI, or BS) ensures reliability and performance. In critical applications such as hydraulic systems, gas lines, or process industries, using certified components and consulting with engineering or technical experts is highly recommended.

In summary, while BSP to NPT converters are readily available, proper selection, installation, and sourcing from trusted vendors are crucial to ensuring a safe, leak-free, and long-lasting connection between differing thread standards.