The global cleaning equipment market is experiencing robust growth, driven by increasing demand for efficient, sustainable, and labor-saving solutions across commercial, industrial, and residential sectors. According to Grand View Research, the global floor cleaning equipment market was valued at USD 3.6 billion in 2022 and is projected to expand at a compound annual growth rate (CAGR) of 5.8% from 2023 to 2030. This growth is fueled by rising hygiene standards, urbanization, and the expansion of facility management services worldwide. As sustainability becomes a priority, manufacturers are innovating with eco-friendly brush materials, water-efficient designs, and energy-saving technologies. In this evolving landscape, brush cleaner floor manufacturers play a pivotal role in delivering high-performance cleaning tools that meet both operational efficiency and environmental standards. Based on market presence, product innovation, and technological advancement, the following list highlights the top 10 brush cleaner floor manufacturers shaping the industry today.

Top 10 Brush Cleaner Floor Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 Brush Design & Manufacturing

Domain Est. 1998

Website: gordonbrush.com

Key Highlights: Gordon Brush Mfg. Co., Inc., is a private company that has a rich history as an American manufacturer of brooms and brushes….

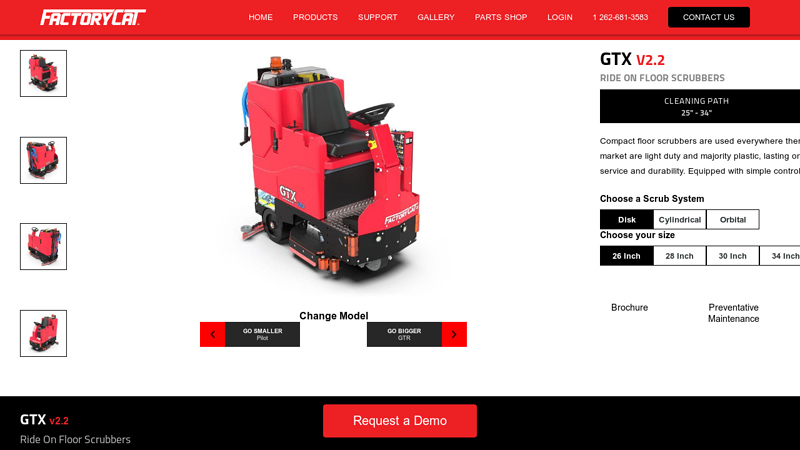

#2 Heavy Duty Floor Scrubber for Tough Cleaning

Domain Est. 1997

Website: factorycat.com

Key Highlights: Compact ride on floor scrubber covering more area than traditional auto scrubbers. Easily clean and navigate facilities with this automatic floor scrubber….

#3 Floor Cleaner Machines

Domain Est. 1998

Website: minutemanintl.com

Key Highlights: Minuteman International offers industrial and commercial floor cleaning machines for retail, manufacturing & distribution, office buildings, and much more….

#4 Perfex Corporation

Domain Est. 2000

Website: perfex.com

Key Highlights: PERFEX is a world leading manufacturer of professional cleaning tools for pharmaceutical and food manufacturing industries….

#5 Brushes and Accessories

Domain Est. 1995

Website: carlislefsp.com

Key Highlights: Floor Brushes & Brooms · Mopping Solutions · Squeegee & Window Cleaning · Handles · Brushes and Accessories · Color-Coded Products · Equipment & Foodservice….

#6 The Malish Corporation

Domain Est. 1996

Website: malish.com

Key Highlights: For over 80 years, Malish has pioneered innovative floor care solutions, including concrete and terrazzo polishing systems….

#7 Brushtec

Domain Est. 1997

Website: brushtec.com

Key Highlights: Brushtec is one of the world’s leaders in the design, and manufacturing of brushes. Our expertise ranges as wide from road sweeper brushes to food production ……

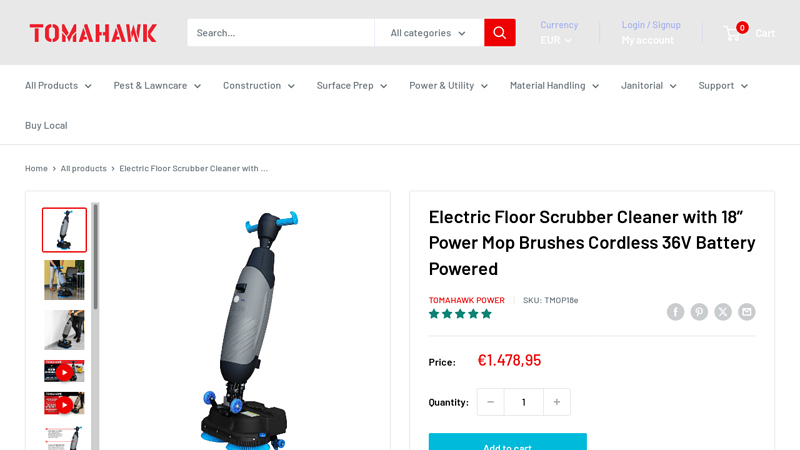

#8 Electric Floor Scrubber Cleaner 18″ Power Mop Cordless 36V

Domain Est. 2012

Website: tomahawk-power.com

Key Highlights: In stock Rating 5.0 (15) EXTENDED BATTERY LIFE. Scrub up to 2 hours on a single charge to complete large jobs indoors and outdoors! CLEAN FASTER. 5x faster than a mop!…

#9 Cloroxtools.com

Domain Est. 2015

Website: cloroxtools.com

Key Highlights: At Cloroxtools.com, you can find a wide range of reliable cleaning tools such as mops, brooms, toilet bowl brushes, and plungers….

#10 Leebein Scrubber Company

Domain Est. 2023

Website: leebein.com

Key Highlights: Leebein makes cleaning a breeze. We focus on developing various electric rotary floor scrubbers to achieve smart and easy cleaning using the simplest tools….

Expert Sourcing Insights for Brush Cleaner Floor

H2: 2026 Market Trends for Brush Cleaner Floors

The global brush cleaner floor market is poised for significant transformation by 2026, driven by technological advancements, growing demand for automated cleaning solutions, and heightened hygiene awareness across commercial, industrial, and residential sectors. Key trends shaping the market include:

-

Rise in Automation and Smart Technology Integration

By 2026, brush cleaner floor systems are expected to increasingly incorporate IoT (Internet of Things), AI-driven navigation, and sensor-based obstacle detection. Smart floor cleaners with app-based controls, voice assistant compatibility, and real-time monitoring will dominate premium segments, particularly in smart homes and commercial facilities. -

Expansion in Commercial and Industrial Applications

Demand from healthcare facilities, warehouses, shopping malls, and food processing plants will accelerate due to stringent sanitation regulations. Brush cleaner floors with durable bristles, high-efficiency particulate filtration, and chemical resistance will be in high demand to meet industrial cleaning standards. -

Sustainability and Eco-Friendly Designs

Environmental regulations and consumer preference for green products will push manufacturers to adopt recyclable materials, energy-efficient motors, and water-saving cleaning mechanisms. Biodegradable brush components and low-noise operations will become competitive differentiators. -

Growth in Emerging Markets

Asia-Pacific, Latin America, and the Middle East will witness robust market growth due to urbanization, rising disposable incomes, and expanding infrastructure. Localized product designs tailored to regional floor types (e.g., tile, concrete, epoxy) will enhance market penetration. -

Product Innovation and Customization

Manufacturers will focus on modular brush systems, adjustable pressure settings, and multi-surface compatibility to cater to diverse cleaning needs. Customizable brush heads for specialized applications—such as anti-static brushes for cleanrooms—will gain traction. -

Increased Competition and Market Consolidation

The market will see heightened competition between established players and new entrants, leading to strategic partnerships, mergers, and R&D investments. Brands will emphasize branding, service networks, and post-purchase support to build customer loyalty.

In conclusion, by 2026, the brush cleaner floor market will be characterized by intelligent automation, sustainability, and tailored solutions, positioning it for sustained global growth across multiple end-user industries.

Common Pitfalls When Sourcing Brush Cleaner Floor (Quality, IP)

Sourcing brush cleaner floor machines—especially with specific quality standards and Ingress Protection (IP) ratings—can be challenging. Avoiding common pitfalls ensures you get a durable, safe, and effective machine for your cleaning environment.

Poor Quality Materials and Build

One of the most frequent issues is selecting machines made with substandard materials. Low-cost models may use thin plastics, weak motors, or low-grade brushes that wear out quickly. This leads to frequent breakdowns, inconsistent cleaning performance, and higher long-term costs due to repairs or replacements.

Inaccurate or Missing IP Rating Certification

The IP (Ingress Protection) rating is critical for floor brush cleaners used in wet or dusty environments. A common pitfall is assuming a machine is water-resistant based on marketing claims without verified IP certification. Machines lacking proper IP65 or higher ratings may suffer electrical damage or safety hazards when exposed to water or debris, especially in industrial or outdoor settings.

Mismatched IP Rating for Application

Even when an IP rating is provided, selecting a machine with an insufficient rating for the intended environment is a major oversight. For example, using an IP44-rated machine in a high-pressure washdown area can result in motor failure or safety risks. Always match the IP rating—such as IP65 or IP67—to the specific demands of your cleaning environment.

Lack of Quality Control from Suppliers

Sourcing from suppliers without rigorous quality control processes increases the risk of receiving inconsistent or defective units. This is especially common with overseas or budget manufacturers. Without third-party testing or certifications (e.g., CE, ISO), it’s difficult to verify performance and durability claims.

Inadequate Brush and Motor Performance

Some machines are equipped with underpowered motors or inappropriate brush types for the floor surface. This leads to poor cleaning results and increased wear on both the machine and floor. Ensure the brush material (e.g., poly, nylon, or steel) and motor power are suited to your floor type (concrete, tile, epoxy, etc.).

Ignoring After-Sales Support and Spare Parts Availability

Even high-quality machines require maintenance. A critical pitfall is failing to verify supplier support—such as availability of spare brushes, motors, or repair services. Limited access to parts or technical assistance can lead to extended downtime and increased operational costs.

Overlooking Safety and Compliance Standards

Beyond IP ratings, machines must comply with regional safety standards (e.g., UL in the U.S., CE in Europe). Sourcing non-compliant equipment can result in safety hazards, failed inspections, or legal liabilities. Always confirm that the machine meets local electrical and safety regulations.

By carefully evaluating build quality, verifying IP ratings, and partnering with reputable suppliers, you can avoid these common pitfalls and ensure reliable, long-term performance from your brush cleaner floor machines.

Logistics & Compliance Guide for Brush Cleaner Floor

Product Overview

Brush Cleaner Floor is a specialized cleaning solution designed for efficiently removing paint, ink, and other residues from brushes and tools used in industrial, commercial, or artistic applications. This guide outlines essential logistics and compliance considerations for the safe and legal handling, storage, transport, and disposal of this product.

Regulatory Classification

Brush Cleaner Floor is typically classified as a flammable liquid and may contain hazardous chemicals such as solvents (e.g., mineral spirits, acetone, or glycol ethers). As such, it is subject to various international, national, and regional regulations including but not limited to:

– GHS (Globally Harmonized System of Classification and Labelling of Chemicals)

– OSHA Hazard Communication Standard (29 CFR 1910.1200)

– EPA regulations under TSCA and RCRA

– DOT (Department of Transportation) 49 CFR for transportation

– REACH and CLP in the European Union

Always consult the Safety Data Sheet (SDS) provided by the manufacturer for the exact classification and regulatory details applicable to your product batch.

Packaging & Labeling Requirements

Ensure all containers meet the following standards:

– Use UN-rated, leak-proof containers suitable for flammable liquids.

– Affix GHS-compliant labels displaying:

– Product identifier

– Signal word (e.g., “Danger”)

– Hazard statements (e.g., “Highly flammable liquid and vapor”, “Causes skin irritation”)

– Pictograms (Flame, Health Hazard, etc.)

– Precautionary statements

– Supplier information

– Include secondary packaging for added protection during transit.

Storage Guidelines

- Store in a well-ventilated, cool, and dry area away from direct sunlight and heat sources.

- Maintain storage temperatures between 40°F (4°C) and 100°F (38°C).

- Keep away from oxidizers, acids, and incompatible materials.

- Use approved flammable storage cabinets if quantities exceed local regulatory thresholds.

- Limit stockpiling; practice FIFO (First In, First Out) inventory management.

Transportation & Shipping

- Classify the product as UN 1139, Paint remover, flammable, n.o.s. (solvent naphtha), Class 3, PG II (verify with SDS).

- Use ground transport compliant with 49 CFR (USA) or ADR (Europe) for road shipments.

- For air transport, comply with IATA Dangerous Goods Regulations; may be restricted or prohibited depending on concentration and volume.

- Ensure all transport documents include proper shipping name, UN number, hazard class, packing group, and emergency contact information.

- Use spill-proof pallets and secure loads to prevent shifting.

Handling Procedures

- Only trained personnel should handle Brush Cleaner Floor.

- Use in well-ventilated areas or with local exhaust ventilation.

- Prohibit smoking, open flames, and sparks near handling areas.

- Use non-sparking tools and grounded containers to prevent static discharge.

- Implement spill containment measures (e.g., drip trays, absorbent materials).

Personal Protective Equipment (PPE)

Mandatory PPE includes:

– Chemical-resistant gloves (e.g., nitrile or neoprene)

– Safety goggles or face shield

– Lab coat or chemical-resistant apron

– Respiratory protection (e.g., NIOSH-approved organic vapor respirator) if ventilation is inadequate

Environmental & Disposal Compliance

- Do not discharge into drains, waterways, or soil.

- Collect used or waste cleaner as hazardous waste under RCRA (USA) or Waste Framework Directive (EU).

- Dispose through licensed hazardous waste contractors.

- Recycle or reclaim solvents where feasible to reduce environmental impact.

- Follow local regulations for waste manifesting and recordkeeping.

Emergency Response

- In case of spill:

- Evacuate non-essential personnel.

- Contain with absorbent materials (e.g., spill kits).

- Ventilate the area.

- Collect contaminated material and dispose as hazardous waste.

- In case of fire:

- Use alcohol-resistant foam, dry chemical, or CO₂ extinguishers.

- Do not use water jet.

- For first aid:

- Skin contact: Wash with soap and water.

- Eye contact: Flush with water for at least 15 minutes; seek medical attention.

- Inhalation: Move to fresh air; seek medical help if symptoms persist.

- Ingestion: Do not induce vomiting; seek immediate medical attention.

Documentation & Recordkeeping

Maintain up-to-date records of:

– Safety Data Sheets (SDS) – accessible to all employees

– Employee training logs for hazardous materials handling

– Shipping manifests and hazardous waste disposal records

– Spill and incident reports

– Regulatory permits (e.g., EPA ID number, storage licenses)

Compliance Audits & Continuous Improvement

- Conduct regular internal audits to verify adherence to logistics and compliance protocols.

- Review and update procedures annually or after regulatory changes.

- Engage third-party consultants for compliance verification if necessary.

Adherence to this guide ensures the safe, legal, and sustainable management of Brush Cleaner Floor across the supply chain. Always refer to the manufacturer’s SDS and consult local regulatory authorities for jurisdiction-specific requirements.

In conclusion, sourcing a floor brush cleaner requires careful consideration of your specific cleaning needs, operational environment, and budget. Whether for industrial, commercial, or residential use, selecting the right brush cleaner involves evaluating factors such as durability, compatibility with floor types, ease of maintenance, and availability of replacement parts. Sustainable sourcing practices, including choosing eco-friendly materials and energy-efficient models, can further enhance long-term value. By partnering with reliable suppliers and conducting thorough market research, businesses can ensure they invest in a high-performing, cost-effective floor brush cleaning solution that supports efficiency, hygiene, and operational success.