The global agricultural and industrial machinery market has seen steady expansion, driven by rising demand for efficient material handling and cleaning solutions across sectors such as warehousing, construction, and municipal services. According to Grand View Research, the global industrial sweepers market size was valued at USD 1.3 billion in 2022 and is expected to grow at a compound annual growth rate (CAGR) of 5.8% from 2023 to 2030. This growth is fueled by increasing urbanization, stricter cleanliness regulations, and a shift toward mechanized cleaning to reduce labor costs and improve operational efficiency. Broom tractors—key assets in maintaining large paved areas—have become essential in both public and private infrastructure. With technological advancements such as electric drive systems, IoT-enabled maintenance alerts, and improved brush materials, manufacturers are racing to deliver more sustainable and high-performance machines. Against this backdrop, identifying the leading broom tractor manufacturers requires an analysis of innovation, global footprint, market share, and customer-centric design. Below are the top 10 broom tractor manufacturers shaping the industry through reliability, scalability, and data-driven engineering.

Top 10 Broom Tractor Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 Broce Broom

Domain Est. 2002

Website: brocebroom.com

Key Highlights: Broce Broom is the leading producer of construction & industrial street sweepers to help accommodate any milling & surface treatment projects….

#2 Superior Broom

Domain Est. 2005

Website: superiorbroom.com

Key Highlights: SB Manufacturing offers commercial Street Sweepers & Kick Brooms for sale. We are a road sweeper manufacturer with hundreds of dealers….

#3 Rotary Broom for Tractors

Domain Est. 1995

Website: caseih.com

Key Highlights: Easy to attach and remove without tools. Featuring rugged bristles, an adjustable broom angle up to 25 degrees, adjustable ground pressure and available side ……

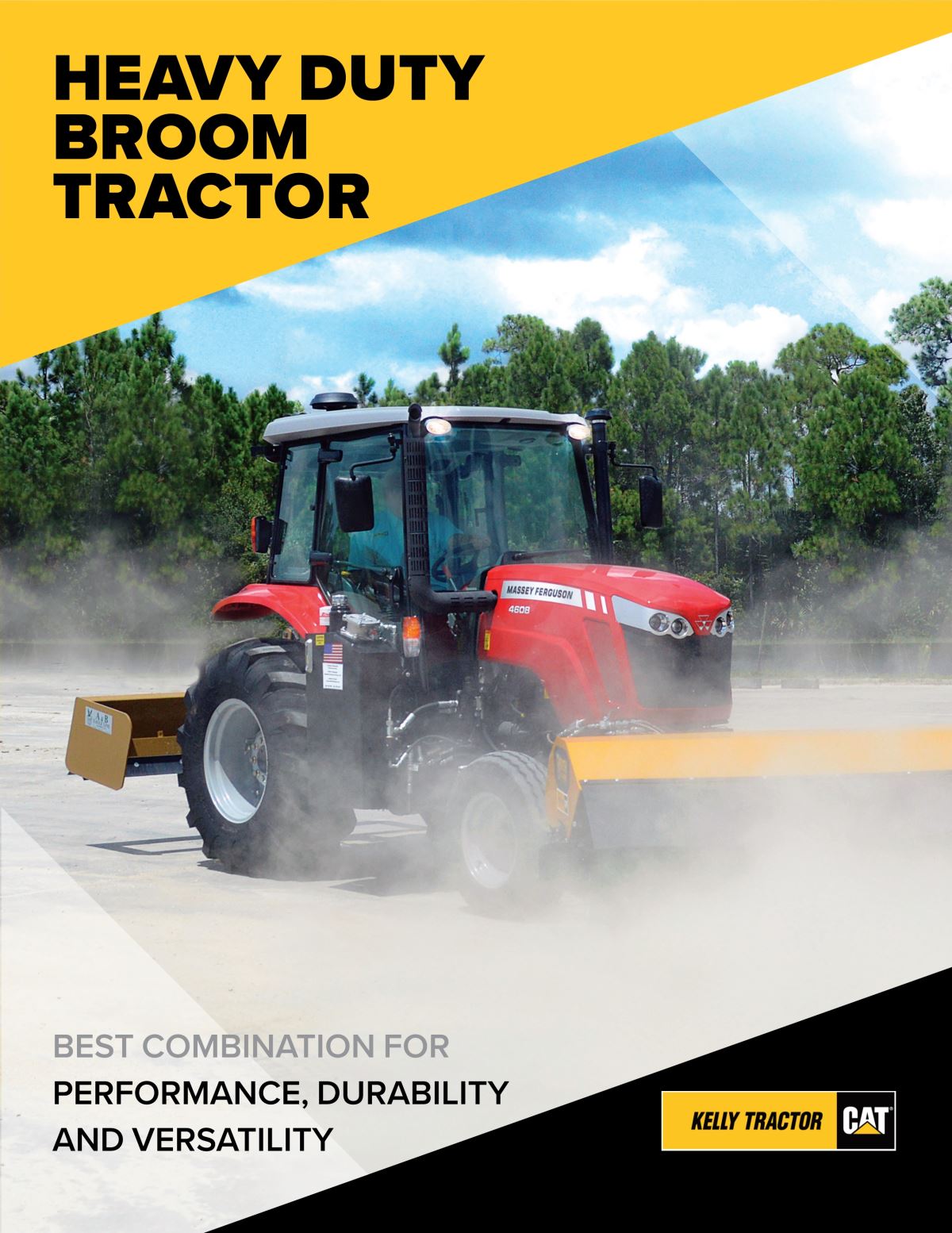

#4 Offered by Kelly Tractor Co.

Domain Est. 1996

Website: kellytractor.com

Key Highlights: We carry and distribute Smith Challenger sweepers and broom combination sweepers at Kelly Tractor Co. We also offer parts and service for Smith Challenger ……

#5 Angle Broom Articulating Tractor Attachment

Domain Est. 1997

Website: bobcat.com

Key Highlights: The fully adjustable angle broom attachment for the Bobcat AT450 delivers power on demand to clear away dirt, debris, light snow and more from solid ……

#6 Front

Domain Est. 1997

Website: agriculture.newholland.com

Key Highlights: New Holland Rotary Brooms: choose from 43-, 55-, 60- and 67-inch broom widths to sweep away leaves, clippings and snow from paved areas….

#7 Brooms Archives

Domain Est. 1998

Website: thompsontractor.com

Key Highlights: Broom attachments are sweeping tools that conveniently connect to skid steer loaders, compact track loaders, and other heavy equipment. Their high-quality ……

#8 Broom

Domain Est. 1999

Website: bercomac.com

Key Highlights: Bercomac is a family owned business that manufactures accessories to equip tractors from Lawn & Garden to Agricultural models, as well as recreational vehicles….

#9 Sweeper

Domain Est. 2012

Website: paladinattachments.com

Key Highlights: These brooms fit a wide range of applications and are excellent for road cleanup, construction, landfills, snow removal and general cleanup. Features & Benefits ……

#10 Superior Broom

Domain Est. 2016

Website: tec1943.com

Key Highlights: The Superior Broom has many features not found on any other Side Cast Sweepers, including low noise level in the cab, rear leaf spring suspension, and touch ……

Expert Sourcing Insights for Broom Tractor

H2: Projected Market Trends for Broom Tractors in 2026

As urbanization and municipal cleanliness standards continue to rise globally, the demand for efficient street maintenance equipment is expected to grow significantly by 2026. Among specialized machinery, broom tractors—compact, versatile vehicles designed for sweeping roads, sidewalks, and industrial areas—are poised to benefit from several key market trends.

1. Increased Urban Infrastructure Investment

By 2026, many cities, particularly in emerging economies across Asia, Africa, and Latin America, are projected to expand their urban infrastructure. Governments are investing heavily in smart city initiatives, which include automated and eco-friendly street cleaning solutions. Broom tractors, with their maneuverability and cost-effectiveness, are becoming preferred choices for cleaning narrow streets and pedestrian zones where larger sweepers cannot operate efficiently.

2. Shift Toward Sustainable Technologies

Environmental regulations are driving a transition from diesel-powered to electric and hybrid broom tractors. By 2026, the electric broom tractor segment is expected to grow at a compound annual growth rate (CAGR) of over 8%, fueled by zero-emission mandates in urban centers and incentives for green municipal fleets. Leading manufacturers are responding with innovations in battery life, charging infrastructure, and regenerative braking systems tailored for stop-start urban operations.

3. Integration of Smart Features and IoT

The 2026 market will see broader adoption of Internet of Things (IoT) technology in broom tractors. Features such as GPS tracking, route optimization, real-time diagnostics, and remote monitoring will enhance operational efficiency for municipal and private cleaning services. Predictive maintenance alerts and data analytics will reduce downtime and lower total cost of ownership, making smart broom tractors more appealing to fleet managers.

4. Growth in Private and Industrial Applications

Beyond municipal use, demand is rising in industrial parks, airports, logistics hubs, and commercial facilities. With e-commerce driving warehouse expansion, maintaining clean indoor and outdoor environments is critical for safety and compliance. Compact broom tractors that can operate in tight spaces and on various surfaces will see increased adoption in these sectors.

5. Regional Market Expansion

While North America and Europe remain strong markets due to aging fleets and replacement cycles, the fastest growth is expected in Southeast Asia, the Middle East, and parts of Eastern Europe. Countries investing in tourism and city beautification—such as Thailand, UAE, and Turkey—are deploying broom tractors to maintain high cleanliness standards in public areas.

6. Competitive Landscape and Innovation

By 2026, the broom tractor market will likely see consolidation among manufacturers, with a focus on product differentiation through automation, ergonomics, and low-noise operation. Partnerships with tech firms for AI-driven navigation and obstacle detection could further enhance functionality, especially for semi-autonomous models.

In summary, the 2026 broom tractor market will be shaped by sustainability mandates, smart technology integration, and growing urbanization. Companies that invest in electric drivetrains, digital connectivity, and application-specific designs will be best positioned to capture market share in this evolving landscape.

Common Pitfalls Sourcing Broom Tractors: Quality and Intellectual Property (IP) Concerns

Sourcing broom tractors, especially from international or unfamiliar suppliers, can present significant challenges related to both product quality and intellectual property protection. Being aware of these pitfalls is crucial to avoid costly mistakes, operational disruptions, and legal risks.

Quality-Related Pitfalls

1. Inconsistent Build Quality and Materials

Suppliers, particularly lower-cost manufacturers, may use substandard materials or inconsistent manufacturing processes. This can lead to premature wear, frequent breakdowns, and increased maintenance costs. Components such as hydraulic systems, broom assemblies, and chassis frames may not meet expected durability standards, reducing the machine’s lifespan and reliability.

2. Lack of Standard Compliance and Certifications

Some broom tractors may not adhere to regional safety, emissions, or performance standards (e.g., CE, EPA, OSHA). Non-compliant machines can lead to regulatory issues, fines, or operational bans. Always verify that the equipment meets the required certifications for your target market.

3. Poor After-Sales Support and Spare Parts Availability

Sourcing from distant or unestablished suppliers often results in limited access to spare parts and technical support. This can cause extended downtime during repairs. Ensure the supplier offers a reliable support network and parts supply chain before finalizing procurement.

4. Inadequate Testing and Validation

Some manufacturers may not rigorously test their machines under real-world conditions. Without proper validation, performance issues such as inefficient debris collection, poor maneuverability, or electrical faults may only surface after deployment.

Intellectual Property (IP) Risks

1. Risk of Infringing on Patented Designs

Broom tractors often incorporate patented technologies in their sweeping mechanisms, hydraulic systems, or control interfaces. Sourcing from suppliers who replicate branded designs without licensing can expose your company to IP infringement lawsuits, especially when importing or selling in regulated markets like the U.S. or EU.

2. Use of Counterfeit or Clone Equipment

Some suppliers offer “compatible” or “OEM-style” broom tractors that closely mimic well-known brands. These may be unauthorized copies violating trademarks and design patents. Purchasing such equipment can lead to legal liability, reputational damage, and customs seizures.

3. Unclear Ownership of Customized Designs

If you request modifications or custom features, ensure IP ownership is clearly defined in contracts. Without explicit agreements, the supplier may retain rights to design improvements, limiting your ability to reproduce or modify the equipment in the future.

4. Lack of Documentation and Traceability

Reputable suppliers provide detailed technical documentation, including schematics, compliance certificates, and IP disclaimers. A lack of transparency may indicate IP violations or poor manufacturing practices, increasing your legal and operational risks.

Mitigation Strategies

- Conduct thorough due diligence on suppliers, including site audits and reference checks.

- Require proof of compliance with relevant industry standards and certifications.

- Include IP indemnification clauses in procurement contracts.

- Work with legal counsel to assess potential IP risks before importing or deploying equipment.

- Prioritize suppliers with a transparent supply chain and verifiable design origins.

By proactively addressing quality and IP concerns, organizations can ensure reliable performance, legal compliance, and long-term value from their broom tractor investments.

Logistics & Compliance Guide for Broom Tractor

This guide provides essential information for the safe, efficient, and compliant transportation, operation, and maintenance of a Broom Tractor—a specialized vehicle used primarily for street sweeping and cleaning operations. Adherence to logistics and regulatory standards ensures optimal performance and legal compliance.

Overview of Broom Tractor Use

Broom Tractors are typically heavy-duty vehicles equipped with rotating brushes and debris collection systems. They are commonly used in municipal maintenance, airport operations, and industrial site cleaning. Due to their size and function, they are subject to various transportation, safety, and environmental regulations.

Regulatory Compliance Requirements

Federal and State Vehicle Regulations

Broom Tractors must comply with Department of Transportation (DOT) standards, including:

– Commercial Driver’s License (CDL): Operators may require a CDL depending on the vehicle’s Gross Vehicle Weight Rating (GVWR). Vehicles over 26,001 lbs typically require a Class B CDL.

– Vehicle Registration and Titling: Must be registered with the appropriate state motor vehicle agency, with proper classification for utility or commercial use.

– Inspection Requirements: Compliance with annual or periodic safety inspections as mandated by state law (e.g., DOT inspections for commercial fleets).

Environmental and Emissions Standards

- EPA Regulations: Engines must meet current Environmental Protection Agency (EPA) emissions standards (e.g., Tier 4 Final for diesel engines).

- Noise Ordinances: Operation in urban areas may be restricted by local noise regulations—ensure sound levels comply with municipal codes.

- Debris Disposal: Collected waste must be disposed of in accordance with local environmental regulations. Hazardous materials (e.g., oil, chemicals) require special handling and documentation.

Transport and Logistics Operations

On-Road Transit

- Routing and Permits: If transporting the Broom Tractor via trailer, verify route restrictions (e.g., bridge clearances, weight limits). Oversize or overweight loads may require special permits.

- Markings and Lighting: When in transit, ensure proper signage, reflective tape, and lighting are in place per FMVSS (Federal Motor Vehicle Safety Standards).

On-Site Deployment

- Scheduling: Coordinate cleaning routes to minimize traffic disruption and comply with local operating hours.

- Storage and Fueling: Store in secure, designated areas. Fueling must follow OSHA and fire code requirements, especially for diesel-powered units.

Safety and Operational Compliance

Operator Training

- All operators must complete certified training programs covering:

- Equipment operation and emergency shutdown procedures

- Defensive driving techniques

- Understanding of job site safety zones and traffic control

- Maintain training records as part of compliance documentation.

Workplace Safety (OSHA Compliance)

- Follow OSHA 29 CFR 1910 and 1926 standards for:

- Lockout/Tagout (LOTO) during maintenance

- Personal Protective Equipment (PPE), including high-visibility clothing, gloves, and eye protection

- Safe work practices around moving equipment and traffic

Maintenance and Recordkeeping

Preventive Maintenance

- Adhere to manufacturer-specified maintenance schedules for:

- Brush assembly and hydraulic systems

- Filters, oil, and fluid levels

- Tire and brake inspections

- Use certified service providers when required.

Documentation and Audits

- Maintain logs for:

- Daily pre-operation inspections (e.g., Federal Motor Carrier Safety Administration Form)

- Repair and maintenance records

- Operator certifications and training

- These records may be subject to audit by regulatory agencies.

Special Considerations for Municipal and Contracted Use

- Right-of-Way Permits: Obtain necessary permits for operation on public roads or private property.

- Insurance Requirements: Ensure adequate liability, property, and workers’ compensation insurance coverage is in place.

- Data Reporting: Municipal fleets may need to report operational hours, route completion, and environmental impact metrics.

Conclusion

Proper logistics planning and strict adherence to compliance standards are critical for the effective deployment of Broom Tractors. By following federal, state, and local regulations, and implementing robust safety and maintenance protocols, organizations can ensure efficient operations while minimizing legal and environmental risks. Regular training and documentation further support a culture of compliance and operational excellence.

In conclusion, sourcing a broom tractor requires a comprehensive evaluation of operational needs, budget constraints, supplier reliability, and long-term maintenance considerations. By clearly defining the intended application—whether for large-scale agricultural harvesting, industrial cleaning, or municipal sweeping—organizations can select a broom tractor that delivers optimal performance and efficiency. Prioritizing quality, after-sales support, and compatibility with existing equipment ensures a sustainable investment. Additionally, comparing quotes from multiple reputable suppliers and considering factors such as warranty, spare parts availability, and operator training contributes to a successful procurement process. Ultimately, a well-sourced broom tractor enhances productivity, reduces labor costs, and supports operational excellence.