Introduction: Navigating the Global Market for Bright Beer Tanks

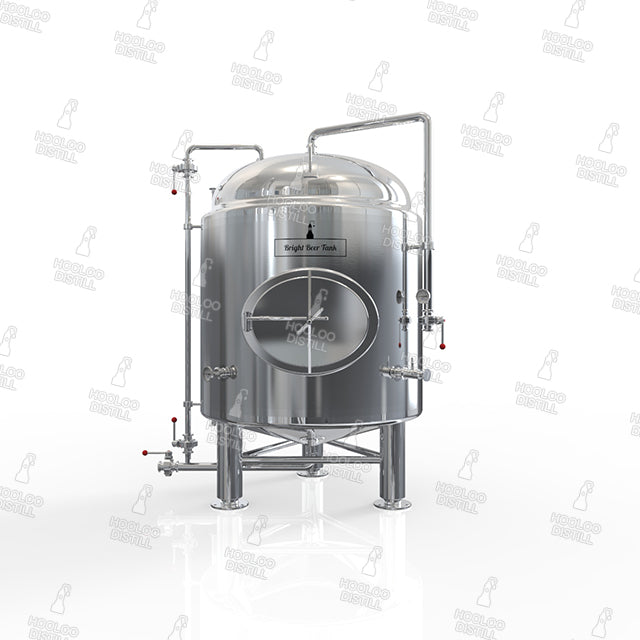

For breweries scaling production or optimizing packaging workflows, the bright beer tank represents a critical investment decision. This pressure-rated, temperature-controlled vessel serves as the final checkpoint before your beer reaches the package—whether bottles, kegs, or direct-to-tap systems in brewpub operations.

The challenge? The global market offers hundreds of bright tank configurations across dozens of manufacturers, each with varying specifications, price points, and lead times. Buyers in the USA and Europe face distinct considerations:

| Region | Key Considerations |

|——–|———————|

| USA | Domestic vs. imported options, TTB compliance, shipping logistics |

| Europe | CE marking requirements, regional supplier networks, metric specifications |

Beyond geography, procurement teams must evaluate:

- Capacity requirements (from 5 BBL brewpub units to 500+ BBL production vessels)

- Carbonation methods (in-line vs. carbonation stone configurations)

- Construction standards (304 vs. 316 stainless steel, weld quality, surface finish)

- Ancillary features (CIP fittings, sample ports, pressure ratings, cooling jacket design)

Whether you’re filtering to true brightness or holding unfiltered craft beer for packaging, the right bright tank directly impacts product consistency, carbonation accuracy, and operational efficiency.

Illustrative Image (Source: Google Search)

This guide covers:

- Technical specifications and sizing considerations

- Regional supplier analysis (North America and Europe)

- Quality benchmarks and certification requirements

- Total cost of ownership factors

- RFQ templates and evaluation frameworks

Let’s examine what separates adequate equipment from optimal investments for your operation.

Article Navigation

- Top 10 Bright Beer Tank Manufacturers & Suppliers List

- Introduction: Navigating the Global Market for bright beer tank

- Understanding bright beer tank Types and Variations

- Key Industrial Applications of bright beer tank

- 3 Common User Pain Points for ‘bright beer tank’ & Their Solutions

- Strategic Material Selection Guide for bright beer tank

- In-depth Look: Manufacturing Processes and Quality Assurance for bright beer tank

- Practical Sourcing Guide: A Step-by-Step Checklist for ‘bright beer tank’

- Comprehensive Cost and Pricing Analysis for bright beer tank Sourcing

- Alternatives Analysis: Comparing bright beer tank With Other Solutions

- Essential Technical Properties and Trade Terminology for bright beer tank

- Navigating Market Dynamics and Sourcing Trends in the bright beer tank Sector

- Frequently Asked Questions (FAQs) for B2B Buyers of bright beer tank

- Strategic Sourcing Conclusion and Outlook for bright beer tank

- Important Disclaimer & Terms of Use

Top 10 Bright Beer Tank Manufacturers & Suppliers List

1. Stainless Steel Brite Tanks – Heritage Equipment

Domain: heritage-equipment.com

Registered: 1998 (27 years)

Introduction: BCast brite tanks are custom-made for craft breweries of all sizes. Contact us today to request a custom quote for your particular needs today!…

2. 800L 8HL bright beer tank for microbrewery – Senmo Machinery

Domain: senmobrew.com

Registered: 2021 (4 years)

Introduction: With an 800-liter (8HL) capacity, our bright beer tank is ideal for microbreweries seeking a balance between production efficiency and maintaining a diverse ……

Illustrative Image (Source: Google Search)

Understanding bright beer tank Types and Variations

Understanding Bright Beer Tank Types and Variations

Selecting the appropriate bright beer tank configuration directly impacts operational efficiency, product quality, and packaging flexibility. This section examines the primary tank types available to commercial breweries, their distinguishing features, and optimal applications.

Bright Beer Tank Classification Overview

| Type | Key Features | Primary Applications | Pros/Cons |

|---|---|---|---|

| Single-Wall Bright Tanks | Basic construction, no insulation, ambient temperature operation | Small brewpubs, seasonal operations, budget-conscious startups | ✓ Lower capital cost ✓ Simple maintenance ✗ No temperature control ✗ Limited to climate-controlled spaces |

| Jacketed Bright Tanks | Glycol cooling jackets, precise temperature control, insulated construction | Production breweries, lager conditioning, year-round operations | ✓ Consistent product quality ✓ Extended holding times ✗ Higher initial investment ✗ Requires glycol system |

| Unitank/Dual-Purpose Vessels | Combined fermentation and bright tank functionality, conical bottom with dish option | Craft breweries seeking flexibility, space-constrained facilities | ✓ Reduced equipment footprint ✓ Operational versatility ✗ Scheduling constraints ✗ Compromise on optimization |

| Serving/Bright Tank Hybrids | Direct-draw capability, integrated tap connections, pub-ready design | Brewpubs, taprooms, on-premise service | ✓ Eliminates transfer losses ✓ Freshest possible product ✗ Limited to draft service ✗ Fixed location requirements |

| Horizontal Bright Tanks | Low-profile design, high volume capacity, space-efficient footprint | Large production facilities, height-restricted buildings | ✓ Maximizes floor space ✓ Easier access for maintenance ✗ Different sediment dynamics ✗ Specialized installation |

Detailed Type Analysis

Single-Wall Bright Tanks

Single-wall bright tanks represent the most economical entry point for small-scale operations. These vessels lack integrated cooling systems, relying entirely on ambient conditions or external refrigeration within cold rooms.

Specifications typically include:

– 304 or 316 stainless steel construction

– Dish-bottom configuration for complete drainage

– Pressure ratings from 15-30 PSI

– Manual or semi-automated CIP connections

Ideal deployment scenarios: Nano-breweries producing fewer than 1,000 barrels annually, seasonal operations, or facilities with existing cold storage infrastructure.

Illustrative Image (Source: Google Search)

Jacketed Bright Tanks

Jacketed bright tanks constitute the industry standard for commercial brewing operations. The glycol jacket system enables precise temperature maintenance between 28-38°F (−2 to 3°C), critical for proper carbonation retention and product stability.

Technical considerations:

– Dimple or channel jacket designs affect cooling efficiency

– Jacket coverage (typically 30-100% of sidewall) determines temperature response

– Insulation thickness (50-100mm polyurethane) impacts energy consumption

– Integrated carbonation stones (sintered stainless steel or porous stone) enable in-tank CO₂ adjustment

Quality assurance integration: As noted in industry standards, the bright tank stage represents the final quality checkpoint before packaging. Jacketed tanks facilitate the laboratory testing protocols essential for carbonation verification and product consistency.

Unitank/Dual-Purpose Vessels

Unitanks blur the distinction between fermentation and conditioning vessels, offering breweries operational flexibility at the cost of scheduling complexity. These vessels feature the conical geometry typical of fermenters combined with the pressure ratings and carbonation capabilities of dedicated bright tanks.

Operational trade-offs:

– Reduces capital equipment requirements by 30-40%

– Extends batch cycle times due to combined functions

– Requires careful scheduling to prevent production bottlenecks

– May compromise optimization for either fermentation or conditioning

Best suited for: Growing craft breweries managing cash flow constraints, operations producing primarily unfiltered styles where extended conditioning occurs in-vessel.

Serving/Bright Tank Hybrids

Brewpubs and taproom-focused operations benefit from serving tanks that function as the final vessel before the tap. These systems eliminate the transfer step to kegs, reducing oxygen exposure and preserving volatile aromatics.

Configuration elements:

– Direct-draw fittings compatible with draft systems

– Integrated pressure regulation for consistent pours

– Typically sized between 3.5-15 BBL for manageable turnover

– Often positioned within customer view as visual merchandising

Illustrative Image (Source: Google Search)

Practical applications: As referenced in brewing literature, these tanks enable additions of honey, coffee extracts, or other volatile flavoring components that benefit from minimal handling before service.

Horizontal Bright Tanks

Large-scale production facilities and buildings with height restrictions employ horizontal bright tank configurations. While less common in craft brewing, these vessels offer distinct advantages for high-volume operations.

Engineering distinctions:

– Modified sediment collection systems accommodate horizontal orientation

– Requires different CIP spray ball configurations

– Structural support considerations differ from vertical installations

– Typically available in larger capacities (50+ BBL)

Deployment rationale: Facilities processing 50,000+ barrels annually, operations in retrofitted industrial spaces, or breweries prioritizing ground-level maintenance access.

Illustrative Image (Source: Google Search)

Selection Criteria for B2B Buyers

When evaluating bright tank configurations, procurement teams should assess:

- Production volume projections — Match tank capacity to 2-3 week inventory requirements

- Facility infrastructure — Existing glycol capacity, ceiling heights, floor load ratings

- Product portfolio — Filtered vs. unfiltered styles, carbonation requirements, holding times

- Packaging operations — Bottling line speeds, kegging frequency, direct-draw requirements

- Expansion timeline — Modular scalability vs. single large-vessel investment

Key Industrial Applications of bright beer tank

Key Industrial Applications of Bright Beer Tank

Bright beer tanks serve critical functions across multiple segments of the beverage industry. Below is a comprehensive breakdown of primary applications and their specific operational benefits.

| Industry Segment | Primary Applications | Key Benefits |

|---|---|---|

| Craft Breweries | Carbonation, flavor additions (honey, coffee, extracts), blending, bottle-conditioning preparation | Flexibility for recipe customization; enables post-fermentation flavor adjustments without compromising volatile aromatics |

| Large-Scale Production Breweries | Final conditioning, carbonation adjustment, color correction, bitterness/aroma modification using hop extracts or oils | Standardization of product consistency across batches; efficient high-volume throughput |

| Brewpubs | Dual-purpose conditioning and serving vessel | Direct-to-tap service eliminates transfer losses; reduced equipment footprint and capital expenditure |

| Contract Brewing Operations | Blending multiple beer batches, final QA staging | Enables creation of consistent blended products; centralized quality control checkpoint |

| Beverage Co-Packers | Pre-packaging holding, carbonation verification | Streamlined packaging workflow; ensures carbonation specifications before bottling/kegging |

Operational Benefits by Function

Carbonation Control

– In-line carbonation between fermenter and bright tank delivers fully carbonated product on arrival

– Integrated carbonation stones (porous stone or sintered stainless steel) enable precise in-tank CO₂ adjustment

– Pressure-rated construction maintains carbonation integrity during holding

Quality Assurance Staging

– Final checkpoint for laboratory testing before packaging

– Carbonation levels verified and adjusted as needed

– Color, bitterness, and aroma corrections performed at this stage in larger operations

Illustrative Image (Source: Google Search)

Blending and Flavor Integration

– Controlled environment for combining multiple batches

– Post-fermentation addition of heat-sensitive ingredients (honey, coffee) preserves flavor profiles

– Mixing capability for priming sugar and conditioning yeast in bottle-conditioned products

Temperature Management

– Temperature-controlled design maintains product stability

– Prevents unwanted secondary fermentation or flavor degradation during holding periods

3 Common User Pain Points for ‘bright beer tank’ & Their Solutions

3 Common User Pain Points for Bright Beer Tanks & Their Solutions

Pain Point 1: Inconsistent Carbonation Levels Across Batches

Scenario: A mid-sized craft brewery experiences batch-to-batch carbonation variability, leading to customer complaints and rejected kegs from distributors.

Problem: Without precise carbonation control, breweries struggle to maintain consistent CO2 levels—particularly when relying on in-tank carbonation versus in-line systems. Carbonation stones can become clogged or deliver uneven bubble distribution, resulting in over- or under-carbonated product.

Illustrative Image (Source: Google Search)

Solution:

| Approach | Implementation |

|———-|—————-|

| Upgrade carbonation stones | Install sintered stainless steel stones for finer, more consistent bubble dispersion |

| Implement in-line carbonation | Carbonate between fermenter and bright tank for arrival at target levels |

| Establish QA protocols | Test carbonation at multiple points; calibrate monitoring equipment regularly |

Pain Point 2: Contamination Risk at the Final Packaging Stage

Scenario: A regional brewery identifies microbial contamination in packaged beer traced back to bright tank operations, resulting in costly recalls and brand damage.

Problem: As the last vessel before packaging, bright tanks present critical contamination risk. Additions at this stage—honey, coffee extracts, priming sugar, or blending operations—introduce potential vectors for spoilage organisms.

Solution:

– Sanitation protocols: Implement CIP (Clean-in-Place) systems with validated cycles between batches

– Ingredient handling: Source pasteurized or sterile-filtered adjuncts; maintain dedicated addition ports

– Environmental controls: Ensure positive tank pressure; use sterile CO2 blankets during transfers

– Testing: Conduct rapid micro testing before packaging release

Illustrative Image (Source: Google Search)

Pain Point 3: Limited Tank Versatility Constraining Production Flexibility

Scenario: A growing brewpub needs bright tanks that serve multiple functions—conditioning, serving, blending, and bottle-conditioning prep—but current equipment limits operational agility.

Problem: Standard bright tank configurations may lack features required for diverse applications: serving directly to taps, blending multiple beers, or preparing bottle-conditioned products with priming sugar and yeast additions.

Solution:

| Requirement | Specification to Specify |

|————-|————————-|

| Multi-use functionality | Dish-bottom design with variable pressure ratings |

| Direct serving capability | Integrated glycol jackets for temperature control; tap-ready fittings |

| Blending operations | Multiple inlet ports; sample valves at various heights |

| Bottle-conditioning prep | Mixing capability; sanitary addition ports for sugar/yeast |

Recommendation: Specify tanks with modular configurations during procurement to accommodate current and anticipated production needs.

Strategic Material Selection Guide for bright beer tank

Strategic Material Selection Guide for Bright Beer Tanks

Selecting the appropriate material for your bright beer tank directly impacts product quality, operational efficiency, and total cost of ownership. This guide examines the primary material options available to breweries, their performance characteristics, and application suitability.

Stainless Steel: The Industry Standard

304 Stainless Steel remains the predominant choice for bright beer tank construction across both craft and industrial brewing operations. This austenitic steel offers an optimal balance of corrosion resistance, durability, and cost-effectiveness.

Key properties include:

– Excellent resistance to organic acids present in beer

– Non-reactive surface that preserves flavor integrity

– Ease of cleaning and sanitization

– Weldability for custom fabrication

– Compliance with FDA and EU food-contact regulations

316 Stainless Steel provides enhanced corrosion resistance due to its molybdenum content (2-3%). This grade is recommended for:

– Breweries using aggressive cleaning chemicals

– High-salinity water environments

– Extended tank lifecycles in demanding production schedules

– Facilities producing high-acid beer styles

Illustrative Image (Source: Google Search)

The additional investment in 316 stainless typically ranges 20-30% above 304 grade pricing but delivers measurably longer service life in corrosive conditions.

Surface Finish Considerations

Surface finish quality directly affects sanitation effectiveness and beer clarity. Industry specifications typically reference Ra (roughness average) values:

- Ra ≤ 0.8 µm (32 µin): Standard brewery finish; adequate for most applications

- Ra ≤ 0.5 µm (20 µin): Enhanced finish; recommended for bright tanks where product clarity is critical

- Ra ≤ 0.4 µm (16 µin): Pharmaceutical-grade; specified for premium installations

Electropolished surfaces reduce micro-pitting and bacterial harborage points, improving CIP (clean-in-place) efficiency and reducing chemical consumption over the tank’s operational life.

Alternative Materials: Limited Applications

Copper historically served brewing applications but presents significant drawbacks for bright tank use:

– Reactive with acidic beer components

– Difficult to maintain sanitary conditions

– Regulatory compliance challenges in food-contact applications

– Higher maintenance requirements

Illustrative Image (Source: Google Search)

Copper-clad or copper-accent tanks occasionally appear in brewpub environments for aesthetic purposes, with stainless steel interior surfaces maintaining product contact.

Polymer-lined carbon steel offers cost advantages for large-volume installations but introduces risks:

– Liner degradation over time

– Potential off-flavor transfer

– Limited repair options

– Shorter effective service life

Carbonation Stone Material Selection

Bright tanks equipped for in-tank carbonation require careful stone material selection:

Sintered Stainless Steel Stones

– Superior durability and longevity

– Consistent pore size distribution

– Compatible with CIP systems

– Higher initial cost offset by extended service life

Illustrative Image (Source: Google Search)

Porous Ceramic/Stone

– Lower acquisition cost

– Adequate performance for lower-volume operations

– More frequent replacement required

– Potential for breakage during handling

Jacketing and Insulation Materials

Temperature control jackets typically utilize:

– Dimple plate jacketing: Welded stainless steel providing efficient heat transfer

– Glycol-compatible materials: Ensuring compatibility with cooling systems

– Polyurethane foam insulation: Industry standard for thermal efficiency

Material Selection Comparison Table

| Criteria | 304 Stainless | 316 Stainless | Polymer-Lined Carbon Steel |

|---|---|---|---|

| Corrosion Resistance | Good | Excellent | Moderate |

| Initial Cost | Moderate | Higher (+20-30%) | Lower |

| Service Life | 20-30 years | 25-40 years | 10-15 years |

| Cleaning Efficiency | Excellent | Excellent | Good |

| Flavor Neutrality | Excellent | Excellent | Variable |

| Weldability/Repair | Excellent | Excellent | Limited |

| Regulatory Compliance | Full | Full | Conditional |

| Recommended Application | Standard brewing operations | Aggressive environments, premium installations | Budget-constrained, non-critical applications |

Procurement Recommendations

- Specify material certifications: Request mill certificates confirming alloy composition

- Define surface finish requirements: Include Ra specifications in purchase orders

- Verify weld quality standards: Ensure compliance with ASME or equivalent standards

- Confirm passivation procedures: Post-fabrication treatment critical for corrosion resistance

- Evaluate total cost of ownership: Factor maintenance, longevity, and operational efficiency beyond acquisition price

For most brewing operations in North America and Europe, 304 stainless steel with appropriate surface finishing represents the optimal balance of performance and value. Facilities with specific environmental challenges or premium quality requirements should evaluate 316 stainless steel despite higher capital expenditure.

In-depth Look: Manufacturing Processes and Quality Assurance for bright beer tank

In-depth Look: Manufacturing Processes and Quality Assurance for Bright Beer Tanks

The manufacturing of bright beer tanks demands precision engineering and rigorous quality control to produce vessels capable of maintaining beer clarity, carbonation levels, and microbial integrity under pressure. This section examines the complete manufacturing workflow and the quality standards that distinguish reliable equipment suppliers.

Illustrative Image (Source: Google Search)

Manufacturing Process Overview

Bright beer tank fabrication follows a systematic progression from raw material selection through final testing. Each stage directly impacts the tank’s performance, longevity, and compliance with food-safety regulations.

Stage 1: Material Preparation

| Process Step | Description | Critical Parameters |

|---|---|---|

| Material Selection | 304 or 316L stainless steel sheet and plate procurement | Mill certifications, chemical composition verification |

| Incoming Inspection | Surface defect analysis, thickness verification | Surface roughness ≤0.8 µm Ra for product contact surfaces |

| Cutting | Plasma, laser, or waterjet cutting of shell and head blanks | Dimensional tolerance ±1mm |

| Edge Preparation | Beveling and grinding for weld preparation | Consistent bevel angles (typically 30-37.5°) |

316L stainless steel is preferred for bright tanks due to its superior corrosion resistance, particularly important given the acidic nature of beer (pH 4.0-4.5) and the chloride content in cleaning chemicals.

Stage 2: Forming Operations

Shell Rolling

– Flat plates are fed through pyramid or four-roll bending machines

– Multiple passes achieve the required cylindrical diameter

– Roundness tolerance maintained within 1% of diameter

Head Forming

– Dish-bottom heads are formed using hydraulic pressing or spinning

– Standard configurations include:

– Torispherical heads (most common for bright tanks)

– Elliptical 2:1 heads (higher pressure ratings)

– Crown radius and knuckle radius must meet ASME specifications

Illustrative Image (Source: Google Search)

Cone Formation (for conical-bottom variants)

– Cone angles typically range from 60° to 90° included angle

– Formed from single or segmented plates depending on diameter

Stage 3: Welding and Assembly

Welding represents the most critical manufacturing phase, as weld integrity determines both pressure containment and sanitary performance.

Welding Sequence:

- Longitudinal shell seams – Joined first using automated TIG (GTAW) or plasma welding

- Circumferential seams – Shell sections welded together

- Head-to-shell welds – Dish bottom and top head attached

- Nozzle installation – All ports, manholes, and fittings welded

- Internal component mounting – Carbonation stone ports, spray ball mounts, sample valves

Welding Standards:

– Full penetration welds required on all pressure-containing joints

– Back-purging with argon to prevent oxidation on internal surfaces

– Weld reinforcement ground flush on product contact surfaces

– No crevices or dead legs that could harbor bacteria

Illustrative Image (Source: Google Search)

Assembly Components:

| Component | Function | Installation Considerations |

|---|---|---|

| Pressure relief valve port | Overpressure protection | Sized per ASME calculations |

| CIP spray ball | Cleaning coverage | Positioned for 360° coverage |

| Carbonation stone port | CO₂ injection | Located near tank bottom |

| Racking arm | Beer transfer | Adjustable height preferred |

| Sample valve | QC sampling | Sanitary design, zero dead-leg |

| Glycol jacket | Temperature control | Full coverage on cylindrical section |

| Level sensors | Inventory management | Sanitary tri-clamp connections |

Stage 4: Surface Finishing

Interior surface finish directly impacts cleanability and beer quality:

- Mechanical polishing – Progressive grit sequence (80 → 120 → 180 → 240)

- Electropolishing – Electrochemical process achieving ≤0.5 µm Ra

- Passivation – Nitric or citric acid treatment to restore chromium oxide layer

Target surface finishes for bright tanks:

– Product contact surfaces: ≤0.8 µm Ra (32 µin) minimum

– Premium specification: ≤0.4 µm Ra (16 µin)

Quality Assurance Protocols

Quality assurance for bright beer tanks encompasses material verification, in-process inspection, and final acceptance testing.

Illustrative Image (Source: Google Search)

Applicable Standards and Certifications

| Standard | Scope | Geographic Relevance |

|---|---|---|

| ISO 9001:2015 | Quality management systems | Global |

| ASME Section VIII, Div. 1 | Pressure vessel design and fabrication | USA, international |

| PED 2014/68/EU | Pressure equipment directive | European Union |

| 3-A Sanitary Standards | Hygienic design criteria | USA (dairy-derived, widely adopted) |

| EHEDG Guidelines | Hygienic equipment design | Europe |

| FDA 21 CFR 117 | Food safety requirements | USA |

In-Process Quality Control

Weld Inspection Methods:

- Visual inspection (VT) – 100% of welds examined per AWS D18.1

- Dye penetrant testing (PT) – Detects surface-breaking defects

- Radiographic testing (RT) – Required for ASME code compliance on pressure seams

- Hydrostatic testing – Tanks pressurized to 1.3-1.5× MAWP (Maximum Allowable Working Pressure)

Dimensional Verification:

– Shell roundness and straightness

– Nozzle orientation and projection

– Overall height and diameter

– Jacket coverage area

Final Quality Documentation Package

Compliant manufacturers provide comprehensive documentation:

- Material test reports (MTRs) with heat numbers

- Weld maps and welder qualification records

- Non-destructive examination reports

- Hydrostatic test certificates

- Surface finish measurements

- Pressure relief valve certification

- CE marking declaration (EU) or ASME U-stamp (USA)

- Operation and maintenance manual

Pressure Rating Considerations

Bright tanks must accommodate carbonation pressures and transfer operations:

Illustrative Image (Source: Google Search)

| Application | Typical Operating Pressure | Recommended MAWP |

|---|---|---|

| Standard bright beer | 15-30 psi (1-2 bar) | 45 psi (3 bar) |

| Highly carbonated styles | 30-45 psi (2-3 bar) | 60 psi (4 bar) |

| Serving tank (brewpub) | 10-15 psi (0.7-1 bar) | 30 psi (2 bar) |

Supplier Evaluation Criteria

When assessing bright beer tank manufacturers, verify:

- Certifications held – ISO 9001, ASME U-stamp, PED Module H or equivalent

- Welding program – Documented WPS/PQR, certified welders

- Surface finish capability – In-house polishing and electropolishing

- Testing equipment – Calibrated instruments, third-party NDT services

- Reference installations – Track record with comparable brewery operations

- Warranty terms – Coverage for materials, workmanship, and pressure containment

Key Takeaways

- Bright beer tank manufacturing requires specialized stainless steel fabrication capabilities and adherence to both pressure vessel and sanitary design codes

- Surface finish quality (≤0.8 µm Ra) is non-negotiable for cleanability and beer quality preservation

- Full weld documentation and NDT records provide assurance of pressure integrity

- ISO 9001 certification indicates systematic quality management; ASME or PED certification confirms pressure vessel compliance

- Request complete documentation packages before accepting delivery to verify specification conformance

Practical Sourcing Guide: A Step-by-Step Checklist for ‘bright beer tank’

Practical Sourcing Guide: A Step-by-Step Checklist for Bright Beer Tanks

Use this comprehensive checklist to streamline your bright beer tank procurement process and ensure you select equipment that meets your operational requirements.

Phase 1: Pre-Sourcing Preparation

Define Operational Requirements

- [ ] Calculate required tank capacity based on batch sizes and production schedule

- [ ] Determine number of tanks needed for adequate packaging buffer

- [ ] Identify carbonation method: in-line (pre-tank) or in-tank carbonation stone

- [ ] Specify pressure rating requirements for your carbonation levels

- [ ] Define temperature control range needed for your beer styles

- [ ] List any secondary functions: blending, flavor additions, bottle conditioning, or direct serving (brewpubs)

Establish Technical Specifications

| Specification | Your Requirement |

|---|---|

| Capacity (BBL/HL) | ___ |

| Working Pressure (PSI/BAR) | ___ |

| Temperature Range | ___ |

| Interior Finish (Ra value) | ___ |

| Jacket Type | ___ |

| Orientation (vertical/horizontal) | ___ |

Phase 2: Supplier Identification

- [ ] Research manufacturers serving USA/Europe markets

- [ ] Verify suppliers hold relevant certifications (ASME, PED, CE marking)

- [ ] Request references from breweries of similar scale

- [ ] Confirm lead times align with your project timeline

- [ ] Evaluate domestic vs. international sourcing (import duties, shipping, support)

Phase 3: Request for Quotation (RFQ)

Include in Your RFQ:

- [ ] Tank capacity and quantity

- [ ] Pressure and temperature specifications

- [ ] Required fittings and ports:

- [ ] Carbonation stone port

- [ ] Sample valve

- [ ] CIP spray ball

- [ ] Pressure relief valve

- [ ] Level indicator

- [ ] Racking arm

- [ ] Glycol jacket configuration

- [ ] Surface finish requirements (interior/exterior)

- [ ] Documentation needs (material certs, weld logs, pressure test reports)

- [ ] Delivery location and installation requirements

Phase 4: Supplier Evaluation

| Evaluation Criteria | Weight | Supplier A | Supplier B | Supplier C |

|---|---|---|---|---|

| Price | ||||

| Lead Time | ||||

| Build Quality/Materials | ||||

| Warranty Terms | ||||

| After-Sales Support | ||||

| References/Reputation | ||||

| Compliance/Certifications |

Phase 5: Pre-Purchase Verification

- [ ] Review detailed engineering drawings

- [ ] Confirm all fittings match your existing tri-clamp/connection standards

- [ ] Verify glycol connection compatibility with your chiller system

- [ ] Clarify warranty coverage and duration

- [ ] Establish spare parts availability

- [ ] Confirm inspection and testing procedures before shipment

- [ ] Negotiate payment terms and milestones

Phase 6: Order and Delivery

- [ ] Issue purchase order with complete specifications

- [ ] Schedule factory inspection (if applicable)

- [ ] Arrange freight and confirm delivery logistics

- [ ] Prepare installation site: floor drains, glycol lines, CO2 supply

- [ ] Coordinate rigging and placement

- [ ] Conduct receiving inspection upon delivery

Phase 7: Post-Delivery Commissioning

- [ ] Verify tank dimensions and fittings match order specifications

- [ ] Pressure test before connecting to production systems

- [ ] Perform initial CIP cycle

- [ ] Calibrate temperature and pressure instrumentation

- [ ] Test carbonation stone function (if equipped)

- [ ] Document commissioning for QA records

Key Questions to Ask Suppliers

- What is the standard lead time, and can it be expedited?

- Are carbonation stones included, and what material options are available (sintered stainless steel vs. porous stone)?

- What pressure testing documentation is provided?

- Do you offer installation support or technical guidance?

- What is your warranty policy on welds and jackets?

Pro Tip: For brewpubs using bright tanks as serving tanks, confirm the tank supports direct-draw fittings and meets local health code requirements for serving vessels.

Comprehensive Cost and Pricing Analysis for bright beer tank Sourcing

Comprehensive Cost and Pricing Analysis for Bright Beer Tank Sourcing

Understanding the full cost structure of bright beer tank procurement enables informed purchasing decisions and budget optimization. This analysis breaks down all cost components and provides actionable strategies for cost reduction.

Illustrative Image (Source: Google Search)

Total Cost of Ownership Breakdown

| Cost Category | Percentage of Total Cost | Key Variables |

|---|---|---|

| Materials & Manufacturing | 45-55% | Steel grade, tank size, pressure rating |

| Labor & Fabrication | 15-25% | Origin country, customization level |

| Logistics & Shipping | 10-20% | Distance, tank dimensions, delivery method |

| Installation & Commissioning | 5-10% | Site complexity, rigging requirements |

| Ancillary Equipment | 5-15% | Carbonation stones, glycol jackets, controls |

Materials Cost Analysis

Base Material Pricing Factors:

- 304 Stainless Steel: Standard choice for most applications; cost-effective for non-corrosive environments

- 316L Stainless Steel: 20-30% premium; recommended for coastal locations or aggressive cleaning regimens

- Surface Finish: Electropolished interiors (Ra ≤ 0.5 µm) add 8-12% to base tank cost versus standard mechanical polish

Component Cost Hierarchy:

| Component | Cost Impact | Specification Considerations |

|---|---|---|

| Pressure rating | High | 15 PSI (standard) vs. 30+ PSI (force carbonation capable) |

| Cooling jacket | Medium-High | Dimple jacket vs. glycol channel configuration |

| Carbonation stone | Low-Medium | Sintered stainless steel vs. porous stone |

| Manway design | Medium | Top vs. side entry; oval vs. round |

| Instrumentation ports | Low | Number and placement of sample valves, thermowells |

Labor and Manufacturing Costs

Regional Manufacturing Cost Comparison:

| Manufacturing Region | Relative Cost Index | Lead Time | Quality Considerations |

|---|---|---|---|

| United States | 100 (baseline) | 8-14 weeks | ASME certification standard; domestic support |

| Western Europe | 95-110 | 10-16 weeks | High precision; PED compliance |

| Eastern Europe | 70-85 | 12-18 weeks | Variable quality; verify certifications |

| China | 50-70 | 14-24 weeks | Requires rigorous QC; shipping adds cost |

Labor Cost Variables:

- Custom fabrication (non-standard dimensions): +15-25% labor premium

- Dual-zone cooling jackets: +10-15% fabrication time

- CIP-optimized internal geometry: +5-10% engineering and welding costs

Logistics and Shipping Costs

Domestic (USA) Shipping Estimates:

| Tank Volume | Shipping Method | Estimated Cost Range |

|---|---|---|

| 5-15 BBL | Freight truck (LTL) | $800-$2,500 |

| 20-60 BBL | Dedicated flatbed | $2,500-$6,000 |

| 60+ BBL | Oversized load permit | $5,000-$15,000+ |

International Shipping Considerations:

- Ocean freight (40′ container): $4,000-$12,000 depending on origin port

- Customs duties: USA typically 0-3% for stainless steel vessels; EU varies by classification

- Port handling and inland transport: Add $1,500-$4,000

- Import documentation and brokerage: $500-$1,500

Hidden Logistics Costs:

- Liftgate or crane requirements at delivery site

- Rigging through non-standard building access

- Storage fees if site not ready for installation

- Insurance for oversized or high-value shipments

Installation and Commissioning Costs

| Service | Typical Cost Range | Duration |

|---|---|---|

| Professional rigging (crane/forklift) | $500-$3,000 | 2-8 hours |

| Glycol system connection | $1,000-$4,000 | 4-12 hours |

| CIP integration | $800-$2,500 | 4-8 hours |

| Pressure testing and certification | $300-$1,000 | 2-4 hours |

| Staff training | $500-$1,500 | 4-8 hours |

Cost-Saving Strategies

Procurement Optimization:

- Order in multiples: Purchasing 2+ tanks simultaneously typically yields 8-15% discount on unit price

- Standardize specifications: Custom dimensions increase costs; standard sizes (7 BBL, 15 BBL, 30 BBL, 60 BBL) offer better pricing

- Negotiate payment terms: 50/50 split (deposit/delivery) is standard; some manufacturers offer 2-3% discount for full prepayment

- Time purchases strategically: Q1 orders often see better lead times and pricing before peak brewing season demand

Specification Decisions That Reduce Cost:

| Decision | Potential Savings | Trade-off |

|---|---|---|

| 304 SS vs. 316L SS | 20-30% | Reduced corrosion resistance |

| Standard pressure rating (15 PSI) | 10-15% | Limited force carbonation capability |

| Mechanical polish vs. electropolish | 8-12% | More difficult cleaning |

| Single-zone vs. dual-zone jacket | 10-15% | Less temperature control precision |

| Domestic vs. imported | Variable | Lead time, warranty support, quality assurance |

Logistics Cost Reduction:

- Consolidate shipments: Combine tank orders with other equipment purchases

- Flexible delivery windows: Allowing 2-3 week delivery flexibility can reduce freight costs 10-20%

- Direct-to-site delivery: Avoid warehousing fees by coordinating installation readiness

- Regional sourcing: For USA buyers, manufacturers in the Midwest often offer lower shipping to central locations

Long-Term Cost Considerations:

- Warranty terms: Extended warranties (2-3 years) add 3-5% upfront but reduce risk

- Spare parts availability: Domestic manufacturers typically offer faster, cheaper replacement components

- Energy efficiency: Well-insulated jackets reduce glycol system operating costs by 15-25% annually

- Resale value: Quality brands retain 40-60% value after 10 years; budget tanks depreciate faster

Budget Planning Guidelines

Estimated Total Landed Cost by Tank Size (USA Market):

| Tank Size | Budget Tier | Mid-Range | Premium |

|---|---|---|---|

| 7 BBL | $4,500-$6,500 | $6,500-$9,000 | $9,000-$12,000 |

| 15 BBL | $6,000-$9,000 | $9,000-$13,000 | $13,000-$18,000 |

| 30 BBL | $9,000-$14,000 | $14,000-$20,000 | $20,000-$28,000 |

| 60 BBL | $15,000-$22,000 | $22,000-$32,000 | $32,000-$45,000 |

Note: Prices include tank, standard fittings, and domestic shipping. Installation, glycol systems, and advanced instrumentation additional.

Request for Quote (RFQ) Cost Checklist

When soliciting quotes, ensure pricing includes:

- [ ] Tank vessel with specified pressure rating

- [ ] Cooling jacket type and coverage area

- [ ] All ports, valves, and fittings

- [ ] Carbonation stone (if required)

- [ ] Surface finish specification

- [ ] Legs/stands with leveling capability

- [ ] Shipping to delivery address

- [ ] Crating and packaging

- [ ] Documentation (material certs, pressure test reports, drawings)

- [ ] Warranty terms and duration

Alternatives Analysis: Comparing bright beer tank With Other Solutions

Alternatives Analysis: Comparing Bright Beer Tank With Other Solutions

When evaluating conditioning and serving vessel options, breweries must weigh operational requirements against capital investment and production goals. Below is a comprehensive comparison of bright beer tanks against the two primary alternatives.

Comparison Overview

| Factor | Bright Beer Tank | Unitank (Fermenter/Conditioner) | Serving Tank/Keg System |

|---|---|---|---|

| Primary Function | Final conditioning, carbonation, packaging preparation | Combined fermentation and conditioning | Direct dispensing to taps |

| Pressure Rating | High (typically 15-30 PSI) | Moderate to high | Low to moderate |

| Carbonation Control | Precise; carbonation stones standard | Limited; natural carbonation or basic injection | Minimal; relies on pre-carbonated beer |

| Filtration Compatibility | Optimized for post-filtration holding | Can receive filtered beer but not primary purpose | Not designed for filtration integration |

| Quality Assurance | Final checkpoint before packaging; lab testing standard | QA occurs mid-process | Limited QA capability |

| Blending Capability | Excellent; designed for flavor additions and blending | Possible but not ideal | Not practical |

| Capital Cost | Moderate | Higher (dual-purpose) | Lower |

| Space Efficiency | Dedicated footprint required | Consolidates fermentation/conditioning | Minimal footprint |

| Best For | Production breweries, packaging operations, brewpubs with high volume | Small-batch operations, breweries with space constraints | Brewpubs, taprooms with limited SKUs |

Detailed Analysis

Bright Beer Tank vs. Unitank

Unitanks consolidate fermentation and conditioning into a single vessel, reducing equipment needs. However, this approach limits production throughput—beer occupies the unitank longer, reducing annual batch capacity. Bright tanks enable parallel processing: while one batch conditions in the bright tank, another ferments in the unitank. For breweries scaling beyond 5,000 barrels annually, dedicated bright tanks typically deliver superior ROI through increased production velocity.

Bright tanks also provide superior carbonation precision. The dish-bottomed, pressure-rated design accommodates carbonation stones for controlled CO2 dissolution—critical for consistency across packaging runs. Unitanks can carbonate beer, but the conical bottom and yeast sediment complicate the process.

Bright Beer Tank vs. Serving Tank/Keg System

Serving tanks and direct-to-keg systems work for brewpubs with limited draft lines and immediate consumption models. However, they lack the quality control infrastructure inherent to bright tanks. Bright tanks serve as the final checkpoint where laboratories verify carbonation levels, clarity, and flavor profiles before packaging.

For operations requiring bottle conditioning, bright tanks function as mixing vessels for priming sugar and yeast additions—a capability absent in basic serving systems. Brewpubs with higher throughput increasingly adopt bright tanks that double as serving tanks, running directly to bar taps while maintaining packaging-ready standards.

Recommendation Framework

- Choose bright beer tanks when packaging for distribution, requiring precise carbonation, or blending multiple batches.

- Choose unitanks when space-constrained or producing small, single-batch volumes without packaging demands.

- Choose serving tanks for taproom-only operations with fewer than five rotating beers and no distribution plans.

Essential Technical Properties and Trade Terminology for bright beer tank

Essential Technical Properties and Trade Terminology for Bright Beer Tanks

Understanding the technical specifications and industry terminology is critical when sourcing bright beer tanks (also referred to as “brite tanks” in trade contexts). This section outlines the key properties buyers must evaluate and the standard B2B terms encountered during procurement.

Core Technical Properties

| Property | Description | Typical Specifications |

|---|---|---|

| Pressure Rating | Maximum operating pressure the vessel can safely withstand | 14.7–30 PSI (1–2 bar) standard; up to 45 PSI for high-carbonation applications |

| Temperature Control | Glycol jacket or dimple jacket for maintaining serving/storage temperatures | 28°F to 40°F (-2°C to 4°C) |

| Material Grade | Stainless steel grade affects corrosion resistance and longevity | 304 SS (standard); 316L SS (superior corrosion resistance) |

| Surface Finish | Interior polish level impacts cleanability and sanitation | Ra ≤ 0.5–0.8 µm (electropolished preferred) |

| Bottom Configuration | Dish-bottomed (standard) for complete drainage | ASME-rated dished heads |

| Carbonation Stone Port | For in-tank CO₂ dissolution | 0.5–2 micron sintered stainless steel or porous stone |

| Working Volume | Usable capacity vs. total capacity | Typically 80–90% of total vessel volume |

| CIP Compatibility | Clean-in-place system integration | Rotating spray ball, tri-clamp fittings |

Standard Tank Components

- Pressure relief valve (PRV) – Safety device preventing over-pressurization

- Racking arm/outlet valve – For transferring beer to packaging lines

- Sample valve – QA/QC sampling port

- Sight glass/level gauge – Visual volume monitoring

- Manway – Access port for inspection and cleaning (typically top-mounted)

- Glycol inlet/outlet connections – Temperature regulation interface

- Zwickel valve – Side-mounted sampling port for carbonation checks

Key B2B Trade Terminology

| Term | Definition |

|---|---|

| MOQ (Minimum Order Quantity) | Lowest unit count a supplier will sell; typically 1–5 units for tanks, higher for accessories |

| OEM (Original Equipment Manufacturer) | Custom manufacturing under buyer’s specifications or branding |

| ODM (Original Design Manufacturer) | Supplier provides design and manufacturing; buyer may rebrand |

| FOB (Free on Board) | Shipping term indicating where title/risk transfers (e.g., FOB Shanghai) |

| CIF (Cost, Insurance, Freight) | Seller covers shipping and insurance to destination port |

| Lead Time | Production-to-delivery timeline; standard is 6–12 weeks for custom tanks |

| HS Code | Harmonized System tariff classification (e.g., 8438.40 for brewery equipment) |

| ASME Certification | American Society of Mechanical Engineers pressure vessel standard |

| PED Certification | Pressure Equipment Directive compliance (required for EU market) |

| 3-A Sanitary Standards | U.S. dairy/food equipment hygiene certification (often requested) |

Specification Considerations for Procurement

Capacity Planning

– Match tank volume to packaging line throughput and batch sizes

– Account for 10–20% headspace for carbonation and foam

Certification Requirements

– USA: ASME U-stamp for pressure vessels; UL listing for electrical components

– EU: CE marking, PED compliance mandatory for pressurized vessels

Customization Options

– Leg height and footprint adjustments

– Multiple carbonation stone ports

– Integrated blending manifolds

– Custom jacket configurations for specific glycol systems

Quality Documentation

– Material certificates (mill test reports)

– Weld inspection records

– Hydrostatic test certificates

– Surface finish verification reports

Common Trade Specifications to Request from Suppliers

- Detailed GA (General Arrangement) drawings with dimensions

- P&ID (Piping and Instrumentation Diagram)

- Pressure test documentation

- Surface roughness certification

- Warranty terms and after-sales support scope

- Spare parts availability and pricing

Navigating Market Dynamics and Sourcing Trends in the bright beer tank Sector

Navigating Market Dynamics and Sourcing Trends in the Bright Beer Tank Sector

Market Evolution and Current Landscape

The bright beer tank market has undergone significant transformation alongside the craft brewing revolution. What began as standardized equipment for large-scale commercial breweries has evolved into a diverse product category serving operations of all sizes—from multinational brewing conglomerates to neighborhood brewpubs where tanks double as serving vessels connected directly to tap lines.

Key Market Drivers:

– Continued global craft beer growth, particularly in North America and Western Europe

– Increasing demand for multi-functional equipment that maximizes floor space ROI

– Stricter quality assurance requirements at the packaging stage

– Rising interest in bottle-conditioned and specialty beer production

Sourcing Considerations for B2B Buyers

| Factor | Standard Production Tanks | Craft/Specialty Tanks |

|---|---|---|

| Capacity Range | 50-500+ BBL | 1-30 BBL |

| Carbonation Options | In-line systems | Integrated carbonation stones (sintered stainless steel or porous stone) |

| Pressure Rating | Higher PSI for high-volume throughput | Variable based on conditioning needs |

| Lead Times | 8-16 weeks | 4-12 weeks |

| Primary Sourcing Regions | China, Germany, USA | USA, Czech Republic, Italy |

Sustainability Trends Reshaping Procurement

Environmental considerations now influence purchasing decisions at every level:

- Material efficiency: Manufacturers increasingly offer tanks with improved insulation, reducing energy consumption for temperature control

- Longevity over cost: Buyers prioritize durable construction and serviceability over lowest upfront pricing

- Local sourcing: European and American breweries show growing preference for regional manufacturers to reduce transportation emissions and simplify supply chain logistics

Functional Versatility Demands

Modern bright tanks serve purposes well beyond their traditional role of holding filtered, carbonated beer before packaging. B2B buyers now evaluate equipment based on multi-use capability:

- Blending operations for creating new beer profiles

- Flavor addition staging (honey, coffee extracts, hop oils)

- Mixing tanks for bottle-conditioning with priming sugar and yeast

- Direct-to-tap serving in brewpub configurations

This functional expansion means procurement teams must assess not just current needs but future production flexibility when specifying equipment.

Frequently Asked Questions (FAQs) for B2B Buyers of bright beer tank

Frequently Asked Questions (FAQs) for B2B Buyers of Bright Beer Tanks

1. What is a bright beer tank and what is its primary function?

A bright beer tank (also called a brite tank) is a dish-bottomed, pressure-rated, temperature-controlled vessel designed to hold beer in its final preparation stage before packaging. The term “bright” refers to beer that has been clarified through filtration, centrifugation, fining, or maturation. Primary functions include:

- Final conditioning and maturation

- Carbonation (in-line or in-tank)

- Quality assurance testing

- Direct packaging to bottles, cans, or kegs

- Serving directly to taps (common in brewpubs)

2. What are the key specifications to consider when purchasing a bright beer tank?

| Specification | Considerations |

|---|---|

| Capacity | Match to batch sizes and packaging workflow |

| Pressure Rating | Typically 15-30 PSI for standard carbonation needs |

| Temperature Control | Glycol jacket capability for precise temperature management |

| Material | Food-grade stainless steel (304 or 316) |

| Bottom Design | Dish or cone bottom for sediment collection |

| Ports & Fittings | Sample ports, CIP connections, carbonation stone ports, pressure relief valves |

3. What is the difference between a bright tank and a fermenter/unitank?

| Feature | Bright Tank | Fermenter/Unitank |

|---|---|---|

| Primary Purpose | Final conditioning & packaging prep | Primary/secondary fermentation |

| Bottom Shape | Dish or shallow cone | Steep cone (60-90°) for yeast harvesting |

| Pressure Rating | Higher (for carbonation) | Often lower or non-pressurized |

| Carbonation Stone | Standard feature | Optional |

| Typical Residence Time | Days to weeks | Weeks to months |

4. How is carbonation achieved in a bright beer tank?

Two primary methods:

In-Line Carbonation:

– CO2 injected under pressure between fermenter and bright tank

– Beer arrives fully carbonated

– Requires inline carbonation equipment

In-Tank Carbonation:

– Tank fitted with a carbonation stone (porous stone or sintered stainless steel)

– CO2 forced through stone, dispersing fine bubbles

– Allows precise carbonation adjustments before packaging

5. What additional processes can be performed in bright tanks?

Beyond standard conditioning and carbonation, bright tanks accommodate:

- Flavor additions: Honey, coffee, coffee extracts, fruit essences

- Hop adjustments: Pre-isomerized hop extracts or hop oils for bitterness/aroma

- Color adjustments: Common in larger production facilities

- Blending: Combining multiple beers to create new products

- Bottle-conditioning prep: Mixing with priming sugar and conditioning yeast

- Direct serving: Running beer to taps in brewpub operations

6. What capacity sizes are typically available for commercial operations?

Bright tank capacities vary based on operation scale:

| Operation Type | Typical Capacity Range |

|---|---|

| Brewpub/Nano | 1-7 BBL (117-819 liters) |

| Microbrewery | 7-30 BBL (819-3,500 liters) |

| Regional Craft | 30-120 BBL (3,500-14,000 liters) |

| Large Production | 120+ BBL (14,000+ liters) |

Recommendation: Size bright tank capacity to align with fermenter output and packaging line throughput to minimize bottlenecks.

7. What quality assurance considerations apply at the bright tank stage?

The bright tank represents the final checkpoint before packaging. Standard QA protocols include:

- Carbonation levels: Volumes of CO2 verification

- Dissolved oxygen: Critical for shelf stability

- Microbiological testing: Ensuring no contamination

- Clarity/turbidity: For filtered products

- Flavor/aroma evaluation: Sensory panel assessment

- Temperature verification: Ensuring packaging-ready conditions

Brewery laboratories typically conduct comprehensive testing at this stage before release.

8. What are the lead times and installation requirements for bright beer tanks?

| Factor | Typical Range |

|---|---|

| Standard Lead Time | 4-12 weeks (stock); 12-20 weeks (custom) |

| Installation Space | Vertical clearance for tank height + fittings |

| Utility Requirements | Glycol supply, CO2 lines, drainage, CIP connections |

| Certifications | ASME pressure vessel certification (USA); PED compliance (Europe) |

Note: Confirm voltage requirements for any integrated components and verify local code compliance for pressure vessels before ordering.

Strategic Sourcing Conclusion and Outlook for bright beer tank

Strategic Sourcing Conclusion: Bright Beer Tank Investment

Bright beer tanks represent a critical infrastructure investment that directly impacts product quality, operational efficiency, and packaging flexibility. For breweries scaling production or optimizing existing operations, strategic sourcing of these vessels delivers measurable returns.

Key Value Drivers

| Factor | Business Impact |

|---|---|

| Quality Control | Final carbonation adjustment, laboratory testing checkpoint before packaging |

| Operational Flexibility | Supports filtration, blending, flavor additions, and bottle-conditioning workflows |

| Production Efficiency | Frees fermentation capacity while beer awaits packaging |

| Revenue Optimization | Enables direct-to-tap service in brewpub applications |

Market Outlook

Demand for bright beer tanks continues strengthening across North American and European markets as craft breweries mature operations and larger producers seek greater process control. Manufacturers are responding with enhanced carbonation stone technology, improved temperature control systems, and modular sizing options.

Sourcing Recommendations

Prioritize suppliers offering:

– Pressure-rated, temperature-controlled specifications

– Dish-bottom designs for efficient sediment management

– Sintered stainless steel carbonation stones

– Scalable capacity aligned with projected growth

The right bright beer tank investment positions your brewery for consistent product quality and streamlined packaging operations—foundational elements for sustainable B2B competitiveness.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided is for informational purposes only. B2B buyers must conduct their own due diligence.