The global electrical panel and breaker market is experiencing robust growth, driven by rising infrastructure investments, increasing adoption of smart grid technologies, and growing demand for reliable power distribution systems. According to Grand View Research, the global circuit breaker market size was valued at USD 13.6 billion in 2022 and is expected to expand at a compound annual growth rate (CAGR) of 5.8% from 2023 to 2030. Similarly, Mordor Intelligence projects steady growth in the switchgear and panelboard sector, fueled by industrialization, urbanization, and the integration of renewable energy sources into power networks. As breaker panel systems become more critical in both commercial and residential applications, the demand for high-quality, reliable components has intensified. This increasing need has elevated the importance of specialized manufacturers capable of delivering innovative, code-compliant, and durable breaker panel parts. Below is a curated list of the top nine manufacturers leading the market through technological advancement, global reach, and product reliability.

Top 9 Breaker Panel Parts Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 All Manufacturers

Domain Est. 1996

Website: circuitbreaker.com

Key Highlights: Circuit Breaker Sales supplies new, surplus, and remanufactured low- and medium-voltage circuit breakers of all types and from all OEMs….

#2 Paneltronics

Domain Est. 1996 | Founded: 1979

Website: paneltronics.com

Key Highlights: Since 1979, Paneltronics has been the industry-leading manufacturer of high quality electrical control panels and assemblies….

#3 Electrical circuit breakers

Domain Est. 1996

Website: eaton.com

Key Highlights: Eaton’s electrical circuit breakers provide premium protection and prevent downtime in commercial, industrial applications and in residential settings….

#4 Myers Power Products

Domain Est. 2002

Website: myerspower.com

Key Highlights: More than three decades proven performance and protection, with hundreds in operation in transit, utility and industrial settings….

#5 NOARK Electric

Domain Est. 2010

Website: na.noark-electric.com

Key Highlights: Explore NOARK Electric’s high-quality electrical components for industrial applications. Reliable circuit protection and motor control solutions….

#6 Circuit Breakers & Accessories

Domain Est. 1995

Website: parts.ruud.com

Key Highlights: 30-day returnsUse the search bar above to find: Search by Part Number; Search by Description; Search by HVAC Model Number Search by HVAC Model or Serial Number; Search by WH ……

#7 Circuit Breakers & Accessories

Domain Est. 1995

Website: parts.rheem.com

Key Highlights: Free delivery over $25 30-day returnsA circuit breaker is designed to trip if a connected electrical device is drawing more amps from the electrical circuit that it is rated for….

#8 Panelboards / Switchboards and Switchgear

Domain Est. 1997

Website: se.com

Key Highlights: Browse Schneider Electric and Square D UL listed low voltage circuit breaker and fusible panelboards. Featuring NQ, NF, I-Line, I-Line Combo and QMB panelboards ……

#9 Midwest Electric Products

Domain Est. 1997

Website: midwestelectric.com

Key Highlights: Midwest Electric Products is an industry leader in manufacturing quality weatherproof electrical equipment. Our product portfolio is focused on commercial ……

Expert Sourcing Insights for Breaker Panel Parts

2026 Market Trends for Breaker Panel Parts

The global market for breaker panel parts is poised for significant transformation by 2026, driven by technological innovation, regulatory shifts, and growing demand for energy efficiency and smart infrastructure. This analysis explores key trends shaping the industry, including advancements in smart technology, sustainability initiatives, regional market dynamics, and supply chain evolution.

Growth in Smart and IoT-Enabled Components

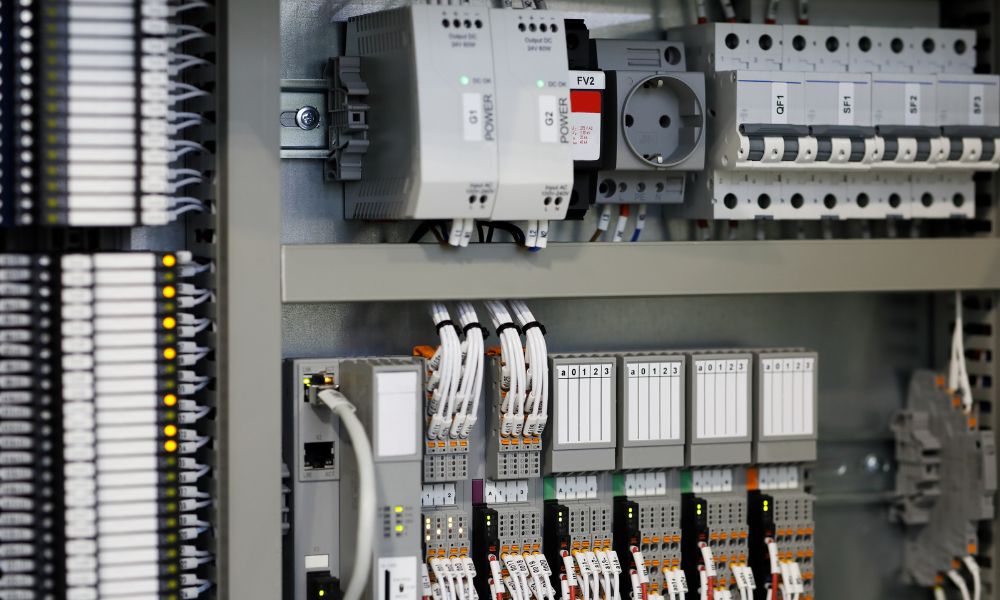

A dominant trend in the 2026 market is the increasing integration of smart technology into breaker panel parts. Circuit breakers, busbars, load centers, and monitoring modules are being embedded with IoT sensors and communication capabilities. These intelligent components enable real-time monitoring of electrical loads, predictive maintenance alerts, and remote control via mobile applications or building management systems. The adoption of smart panels—especially in residential and commercial sectors—is accelerating due to consumer demand for energy transparency and utility incentives for load management.

Expansion of Renewable Energy Integration

As solar, wind, and battery storage systems become mainstream, breaker panel parts are being redesigned to accommodate bidirectional power flow and grid interactivity. By 2026, demand is rising for arc-fault and ground-fault circuit interrupters (AFCI/GFCI) that support hybrid inverter connections and microgrid compatibility. Panelboards are increasingly modular to allow easy integration of renewable energy sources, driving innovation in components such as dual-power input breakers and advanced surge protection devices.

Regulatory and Safety Standards Driving Innovation

Stringent electrical codes and safety regulations—such as the National Electrical Code (NEC) updates in North America and IEC standards globally—are mandating enhanced safety features in breaker panels. These include expanded AFCI coverage, tamper-resistant designs, and improved fire resistance. Manufacturers are responding with next-generation components that comply with these standards while improving performance and longevity. The push for fire-safe building materials is also leading to increased use of arc-resistant enclosures and thermally optimized busbar systems.

Sustainability and Circular Economy Practices

Environmental concerns are influencing material selection and manufacturing processes. By 2026, leading suppliers are adopting recycled metals, reducing hazardous substances, and designing for disassembly and reuse. Regulatory frameworks like the EU’s Ecodesign Directive are pressuring manufacturers to improve energy efficiency and lifecycle sustainability of breaker panel components. Additionally, remanufactured and refurbished parts are gaining acceptance in cost-sensitive markets, contributing to a circular economy model.

Regional Market Diversification

North America and Europe remain key markets due to aging infrastructure and strong regulatory environments. However, rapid urbanization in Asia-Pacific—especially in India, Southeast Asia, and China—is fueling demand for modern electrical distribution systems. Latin America and parts of Africa are witnessing growth in off-grid and mini-grid installations, creating niche demand for rugged, scalable breaker panel solutions. Regional preferences are influencing product design, with compact, high-density components preferred in space-constrained urban environments.

Supply Chain Resilience and Localization

Ongoing geopolitical tensions and past disruptions have prompted manufacturers to diversify sourcing and localize production. By 2026, many companies are establishing regional manufacturing hubs to reduce dependency on single-source suppliers and mitigate logistics risks. This shift is also accelerating the adoption of digital twin technology and AI-driven inventory management to enhance supply chain visibility and responsiveness.

Conclusion

The 2026 market for breaker panel parts is characterized by digitalization, regulatory compliance, and sustainability. As energy systems evolve, breaker panel components are no longer passive infrastructure but active participants in intelligent power management. Companies that invest in R&D, embrace smart technologies, and align with global sustainability goals are likely to lead the market in this transformative period.

Common Pitfalls When Sourcing Breaker Panel Parts (Quality, IP)

Poor Quality Components

Sourcing low-quality breaker panel parts can lead to premature failures, safety hazards, and non-compliance with electrical codes. Counterfeit or substandard circuit breakers, bus bars, or enclosures may not meet required thermal and mechanical performance standards, increasing the risk of overheating, arcing, or fire. Always verify certifications (e.g., UL, CE, IEC) and purchase from reputable suppliers to ensure reliability and safety.

Inadequate Ingress Protection (IP) Rating

Selecting parts with an insufficient IP rating for the environment is a critical mistake. For example, using an IP40-rated enclosure in a damp or dusty industrial setting can allow moisture or debris to enter, causing short circuits or corrosion. Always match the IP rating to the installation environment—such as IP65 or higher for outdoor or washdown areas—to ensure long-term durability and safety.

Non-Compliance with Regional Standards

Electrical standards vary by region (e.g., NEC in the U.S., IEC in Europe). Using parts that don’t comply with local regulations can result in failed inspections, legal liability, or voided insurance. Ensure all components meet the applicable national and local codes before procurement.

Lack of Traceability and Documentation

Failing to obtain proper documentation—such as test reports, material certifications, or serial traceability—can hinder compliance audits and complicate maintenance or warranty claims. Always request and retain technical documentation for every part sourced.

Incompatible Components

Mixing parts from different manufacturers or incompatible series can compromise system performance and safety. Not all breakers or accessories are interchangeable, even if they appear to fit. Verify compatibility with the panel’s make and model to maintain listed assembly integrity.

Supply Chain and Lead Time Risks

Relying on unreliable suppliers can cause project delays, especially for obsolete or specialized parts. Always assess supplier reliability, lead times, and availability of long-term support to avoid disruptions in maintenance or new installations.

Logistics & Compliance Guide for Breaker Panel Parts

This guide outlines essential logistics and compliance considerations for the safe and legal handling, transportation, import/export, and use of breaker panel parts. Adhering to these guidelines ensures operational continuity, regulatory compliance, and personnel safety.

Regulatory Compliance

Compliance with national and international standards is critical for breaker panel parts. Non-compliant components can lead to safety hazards, project delays, and legal penalties.

-

Electrical Safety Standards: Ensure all parts meet recognized standards such as UL (Underwriters Laboratories) 508A in the U.S., CSA C22.2 No. 301 in Canada, or IEC 61439 internationally. Certification marks must be clearly displayed on products.

-

RoHS and REACH Compliance: Verify that components are free of restricted hazardous substances per the EU’s Restriction of Hazardous Substances (RoHS) and Registration, Evaluation, Authorization, and Restriction of Chemicals (REACH) regulations. Documentation must be available upon request.

-

Country-Specific Approvals: Confirm compliance with local regulations such as NEC (National Electrical Code) in the U.S., CE marking in the European Economic Area, and CCC (China Compulsory Certification) for shipments to China.

Import and Export Requirements

Cross-border movement of breaker panel parts requires adherence to trade regulations and customs documentation.

-

Harmonized System (HS) Codes: Classify parts accurately using correct HS codes (e.g., 8536.30 for electrical circuit breakers) to determine tariffs and import duties.

-

Export Controls: Check if components are subject to export restrictions under regulations such as the U.S. Export Administration Regulations (EAR). Some high-voltage or industrial control parts may require export licenses.

-

Customs Documentation: Prepare commercial invoices, packing lists, certificates of origin, and compliance certificates (e.g., UL, CE) to expedite customs clearance.

Packaging and Handling

Proper packaging ensures parts arrive undamaged and maintains compliance with safety and handling standards.

-

ESD-Safe Packaging: Use anti-static bags and containers for sensitive electronic components (e.g., control modules, relays) to prevent electrostatic discharge damage.

-

Secure Crating: Employ robust, moisture-resistant packaging with adequate cushioning to protect fragile parts such as busbars, insulators, and arc chutes during transit.

-

Labeling Requirements: Clearly label packages with part numbers, handling instructions (e.g., “Fragile,” “This Side Up”), and compliance marks. Include hazardous material warnings if applicable (e.g., for parts containing SF6 gas).

Transportation and Shipping

Select appropriate shipping methods based on part type, volume, and destination.

-

Mode of Transport: Use ground freight for domestic shipments and air freight for urgent international deliveries. Sea freight is cost-effective for bulk orders but requires longer lead times.

-

Temperature and Humidity Control: Monitor environmental conditions during transport, especially for parts with sensitive coatings or electronic components. Avoid exposure to extreme temperatures or moisture.

-

Insurance and Tracking: Insure high-value shipments and use real-time tracking to monitor location and delivery status.

Inventory and Warehouse Management

Efficient storage supports compliance and ensures part availability.

-

Climate-Controlled Storage: Store parts in dry, temperature-stable environments to prevent corrosion and degradation of insulating materials.

-

Segregation by Type and Compliance Status: Keep certified and non-certified parts separate. Clearly mark obsolete or non-compliant inventory to prevent accidental use.

-

First-In, First-Out (FIFO): Implement FIFO practices to ensure older stock is used first, minimizing the risk of using outdated components.

Documentation and Recordkeeping

Maintain accurate records to support audits and traceability.

-

Compliance Certificates: Retain copies of UL, CE, RoHS, and other relevant certifications for each part batch.

-

Bill of Materials (BOM): Keep updated BOMs that include part numbers, suppliers, and compliance status.

-

Chain of Custody Logs: Document handling, storage, and movement of parts to ensure accountability and traceability, especially for safety-critical components.

Disposal and End-of-Life Management

Dispose of defective or obsolete parts in accordance with environmental regulations.

-

Waste Electrical and Electronic Equipment (WEEE): Follow WEEE directives in applicable regions for the proper recycling of electrical components.

-

Hazardous Waste Disposal: Handle parts containing hazardous materials (e.g., PCBs, certain insulating oils) through licensed waste disposal providers.

-

Recycling Partnerships: Collaborate with certified e-waste recyclers to ensure environmentally responsible disposal.

By following this guide, organizations can ensure that the logistics and compliance processes for breaker panel parts meet industry standards, reduce risk, and support safe, efficient operations.

In conclusion, sourcing breaker panel parts requires careful consideration of safety, compatibility, and regulatory compliance. It is essential to identify the correct manufacturer, model, and specifications to ensure proper function and prevent potential hazards such as electrical fires or system failures. Purchasing parts from reputable suppliers, verifying certifications (such as UL or NEC compliance), and consulting with licensed electricians when necessary are critical steps in the process. Whether for replacement, repair, or upgrade, a well-informed sourcing strategy ensures reliable performance, extends the lifespan of the electrical system, and supports overall electrical safety in residential, commercial, or industrial environments.