The global market for breaker and lockout/tagout (LOTO) devices is experiencing steady growth, driven by escalating regulatory emphasis on workplace safety and increasing industrial automation. According to Mordor Intelligence, the global electrical safety devices market—which includes critical components like circuit breakers and LOTO equipment—is projected to grow at a CAGR of over 5.8% from 2023 to 2028. This expansion is supported by industries such as manufacturing, energy, and construction adopting stricter compliance standards like OSHA and NFPA 70E to prevent electrical hazards and unauthorized equipment startup. As operational safety becomes a core business priority, demand for reliable, high-performance breaker and LOTO solutions is rising sharply. In this evolving landscape, a select group of manufacturers have emerged as leaders, combining innovation, regulatory compliance, and global reach to dominate the market. Here’s a data-driven look at the top eight breaker and LOTO device manufacturers shaping the future of industrial safety.

Top 8 Breaker Loto Devices Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 E

Domain Est. 2003

Website: safetylock.net

Key Highlights: Lockout Tagout : E-Square is the leading lockout tagout manufacturer, supplier of LOTO products/devices. Avail best LOTO devices and services now….

#2 Brady Panel Lockout Device

Domain Est. 1993

Website: spi.com

Key Highlights: 30-day returnsBrady panel lockout device with 1 m cable and ABS body. Secures 12″–36″ panels, accepts 4 padlocks. OSHA compliant. Available at SPI Health and Safety….

#3 Large Handle Circuit Breaker Lockout

Domain Est. 1994

Website: panduit.com

Key Highlights: Show Only Offered Products. Home; / All Products; / Safety & Security; / Lockout Tagout Devices; / Large Handle Circuit Breaker Lockout. {{ ……

#4 Electrical Circuit Breaker Lockouts

Domain Est. 1997

Website: emedco.com

Key Highlights: 1–7 day deliveryThese essential Lockout/Tagout (LOTO) devices are designed to fit snugly on various breaker types, effectively preventing accidental switch-on and protecting ……

#5 Clamp

Domain Est. 1998

Website: bradyid.com

Key Highlights: 1-day delivery 7-day returnsClamp-on breaker lockouts are versatile and easy to install using the proprietary thumbwheel design – no screwdrivers needed!…

#6 Lockout Devices

Domain Est. 2012

#7 Electrical locking devices

Domain Est. 2012

Website: lockout-tagout-shop.com

Key Highlights: Locking devices for circuit breakers, inusation plugs, plugs and push buttons. Work as safe as possible with our solutions for electric hazards….

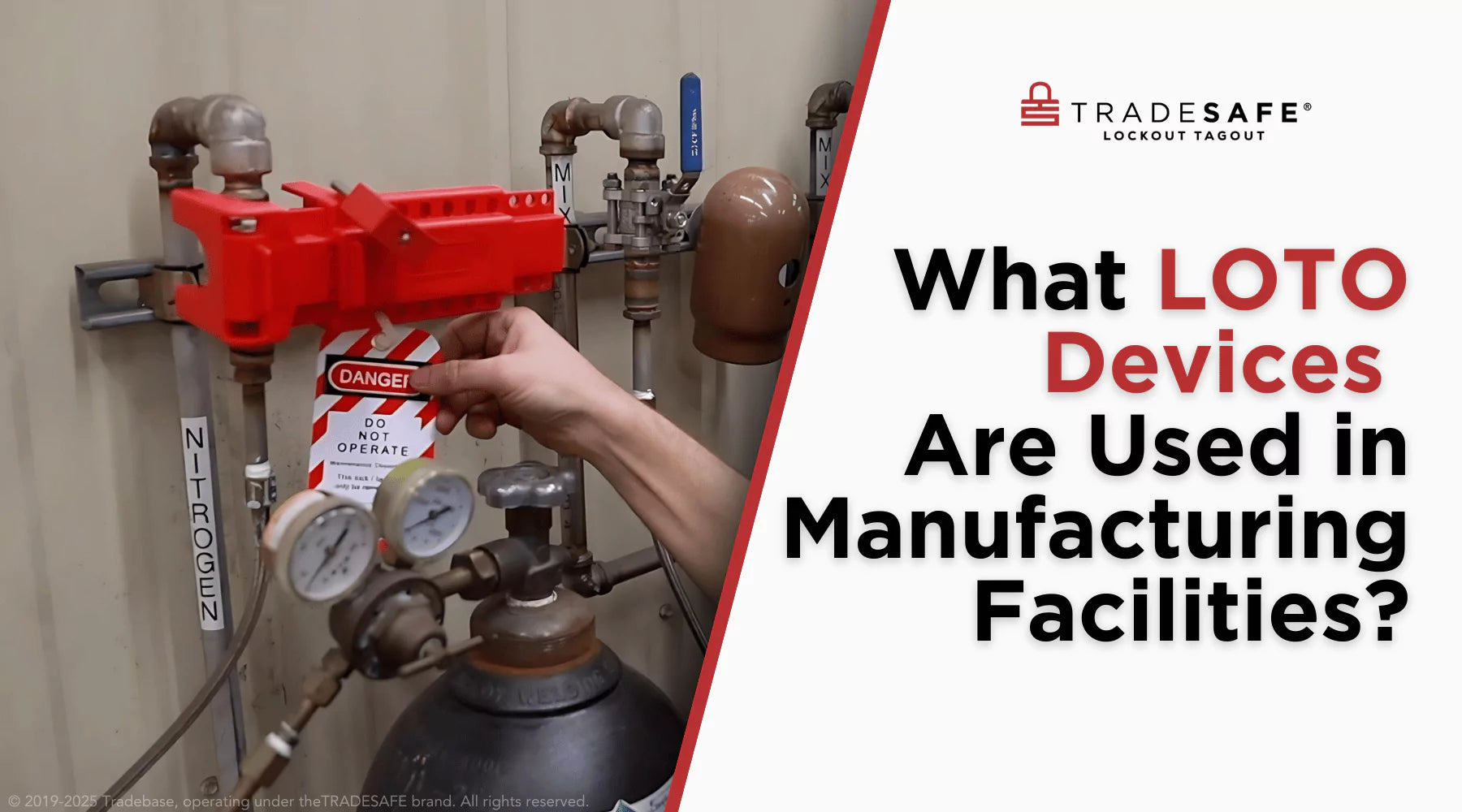

#8 Lockout Tagout Kits and Supplies

Domain Est. 2019

Website: trdsf.com

Key Highlights: Lockout tagout supplies from a reliable safety partner. Buy premium grade LOTO padlocks, stations, do not operate lockout tagout tags, kits, and lockout ……

Expert Sourcing Insights for Breaker Loto Devices

H2: Market Trends for Breaker Loto Devices in 2026

The global market for Breaker Lockout (Loto) devices is poised for significant transformation by 2026, driven by heightened industrial safety regulations, technological advancements, and increased automation across manufacturing, energy, and infrastructure sectors. As industries continue prioritizing worker safety and regulatory compliance, Breaker Loto devices—critical components of energy control programs—will experience rising demand and innovation.

1. Regulatory and Compliance Drivers

By 2026, stricter enforcement of OSHA (Occupational Safety and Health Administration) standards in North America and equivalent regulations in the EU (such as the Machinery Directive) and Asia-Pacific will compel industrial operators to adopt comprehensive Lockout/Tagout (LOTO) systems. Upcoming regulatory updates are expected to emphasize documentation, auditability, and integration with digital safety management systems, favoring advanced Breaker Loto solutions over traditional mechanical devices.

2. Smart and Connected Loto Devices

A key emerging trend is the integration of IoT (Internet of Things) and smart technology into Breaker Loto devices. By 2026, smart Loto systems with RFID tagging, Bluetooth connectivity, and cloud-based monitoring are projected to gain substantial market share. These systems enable real-time tracking of lockout status, user authentication, and automated compliance reporting—reducing human error and improving safety workflows in complex industrial environments.

3. Growth in Renewable Energy and Infrastructure

The rapid expansion of renewable energy projects—including solar farms and wind installations—will drive demand for specialized Breaker Loto devices. These environments require durable, weather-resistant, and high-voltage-compatible lockout solutions. Similarly, ongoing infrastructure modernization in regions like North America and Southeast Asia will increase the need for electrical safety devices during maintenance and retrofitting of power distribution systems.

4. Regional Market Dynamics

North America will remain the largest market due to mature safety standards and high industrial activity. However, the Asia-Pacific region—particularly China, India, and South Korea—will witness the highest growth rate, fueled by industrialization, foreign direct investment, and tightening safety norms. Local manufacturing of Loto devices is also expected to rise, reducing costs and improving supply chain efficiency.

5. Sustainability and Ergonomic Design

By 2026, sustainability will influence product development, with manufacturers favoring recyclable materials and longer product lifecycles. Additionally, ergonomic designs that improve ease of use and reduce installation time will become competitive differentiators, especially in high-turnover or training-intensive environments.

6. Competitive Landscape and Innovation

Major players such as 3M, Brady Corporation, and Master Lock are expected to expand their portfolios with modular, scalable Loto systems. At the same time, niche innovators will enter the market with patented designs for circuit breaker isolation, supporting hybrid and multi-energy lockout scenarios. Strategic partnerships with industrial IoT platforms may further accelerate integration into broader enterprise safety ecosystems.

In conclusion, the 2026 market for Breaker Loto devices will be characterized by digitalization, regulatory pressure, and sector-specific customization. Companies that invest in smart, compliant, and user-centric solutions will be best positioned to capture value in this evolving safety equipment landscape.

Common Pitfalls When Sourcing Breaker LOTO Devices: Quality and IP Protection

Sourcing Lockout/Tagout (LOTO) devices for circuit breakers involves specific challenges, particularly concerning product quality and intellectual property (IP) risks. Failing to address these can lead to safety hazards, non-compliance, and legal complications. Here are key pitfalls to avoid:

Inadequate Device Quality and Material Standards

Many low-cost LOTO devices are constructed from substandard plastics or metals that degrade quickly under industrial conditions. Poor-quality materials may become brittle in cold environments or warp in heat, compromising the lockout function. Devices that crack or deform can fail to secure the breaker properly, creating a serious safety risk during maintenance.

Lack of Compliance with Safety Certifications

A major pitfall is selecting LOTO devices that do not meet recognized safety standards such as OSHA 29 CFR 1910.147, CSA Z460, or ANSI/ASSE Z244.1. Some suppliers may claim compliance without proper third-party testing or certification. Using uncertified devices can result in regulatory penalties and invalidate workplace safety protocols.

Poor Fit and Compatibility with Breaker Models

Generic or poorly designed LOTO devices often fail to fit specific breaker types securely. A loose or improper fit can allow accidental energization. Sourcing devices without verifying compatibility with the exact breaker make, model, and configuration leads to ineffective lockout procedures and increased risk of arc flash or electrocution.

Insufficient Environmental Protection (IP Rating Misunderstanding)

Many industrial environments require LOTO devices with appropriate Ingress Protection (IP) ratings to withstand dust, moisture, or chemicals. A common mistake is assuming all devices are suitable for harsh conditions. Sourcing devices without verifying the correct IP rating (e.g., IP65 for dust-tight and water-resistant performance) can result in premature failure and unsafe conditions.

Counterfeit or IP-Infringing Products

Some suppliers offer LOTO devices that mimic patented designs from reputable manufacturers. These counterfeit products may infringe on intellectual property rights, exposing buyers to legal liability. Additionally, infringing devices often lack the engineering and safety testing of authentic products, increasing reliability and safety concerns.

Incomplete Documentation and Traceability

Reliable LOTO devices should come with clear installation instructions, compliance documentation, and traceable manufacturing details. Sourcing from suppliers who provide minimal or falsified documentation makes it difficult to verify quality, ensure training effectiveness, or defend compliance during audits.

Overlooking Supplier Due Diligence

Choosing suppliers based solely on price without vetting their manufacturing processes, quality control systems, or reputation increases the risk of receiving defective or non-compliant devices. Lack of direct communication or transparency from the supplier is a red flag for potential quality and IP issues.

By being aware of these pitfalls and conducting thorough due diligence—verifying certifications, material quality, compatibility, IP ratings, and supplier legitimacy—organizations can ensure they source safe, compliant, and legally sound Breaker LOTO devices.

Logistics & Compliance Guide for Breaker LOTO Devices

Overview of Breaker LOTO Devices

Breaker Lockout/Tagout (LOTO) devices are safety tools designed to ensure electrical breakers are securely isolated during maintenance, repair, or servicing. These devices prevent accidental re-energization of circuits, protecting workers from electrical hazards. Compliance with safety standards and proper logistics management are essential for effective implementation.

Regulatory Compliance Requirements

Breaker LOTO devices must comply with key regulatory standards, including:

– OSHA 29 CFR 1910.147 (Control of Hazardous Energy): Mandates the use of lockout/tagout procedures to control energy sources during servicing.

– NFPA 70E (Standard for Electrical Safety in the Workplace): Provides guidelines for electrical safety practices, including lockout application.

– ANSI Z244.1: Offers consensus standards for control of hazardous energy, supporting OSHA requirements.

Organizations must ensure that all LOTO devices meet these standards and are integrated into documented energy control programs.

Device Selection and Compatibility

Selecting the correct breaker LOTO device involves:

– Matching the device to the specific breaker type (e.g., toggle, rotary, DIN rail).

– Verifying compatibility with breaker size and manufacturer specifications.

– Using only non-reusable, resettable locks and tags where applicable.

– Ensuring devices are durable, tamper-resistant, and clearly labeled.

Procurement and Inventory Management

Effective logistics begins with strategic procurement:

– Source LOTO devices from certified suppliers compliant with ANSI/ISEA standards.

– Maintain an up-to-date inventory of all LOTO devices, including model numbers and locations.

– Use barcode or RFID tracking for easy auditing and reordering.

– Establish safety stock levels to prevent operational delays during maintenance.

Storage and Distribution

Proper storage ensures device availability and longevity:

– Store LOTO kits in accessible, labeled locations near electrical panels or in centralized safety stations.

– Protect devices from environmental damage (e.g., moisture, extreme temperatures).

– Implement a check-in/check-out system for accountability during use.

– Train supervisors on proper distribution and return procedures.

Training and Employee Awareness

Compliance depends on workforce knowledge:

– Conduct regular LOTO training covering device use, procedures, and emergency response.

– Include hands-on practice with actual breaker LOTO devices.

– Retrain employees annually or when procedures or devices change.

– Maintain training records for audit purposes.

Inspection and Maintenance

Routine device upkeep is critical:

– Inspect LOTO devices monthly for damage, wear, or tampering.

– Remove and replace defective or compromised devices immediately.

– Document inspections and maintenance activities.

– Follow manufacturer guidelines for device lifespan and replacement.

Audit and Compliance Verification

Regular audits ensure ongoing compliance:

– Conduct internal LOTO program audits at least annually.

– Verify that breaker LOTO devices are used correctly and consistently.

– Review incident reports for LOTO-related near-misses or failures.

– Update policies and procedures based on audit findings.

Documentation and Recordkeeping

Maintain comprehensive records, including:

– LOTO procedures specific to each breaker or energy source.

– Equipment-specific lockout instructions.

– Employee training certifications.

– Inventory logs, inspection reports, and audit results.

– Incident reports involving LOTO failures.

Emergency Procedures and Device Retrieval

Plan for exceptional situations:

– Establish a formal process for authorized lock removal (e.g., shift changes, employee absence).

– Use lockout hasps and multiple locks when multiple personnel are involved.

– Ensure supervisors can access master keys or combination codes under controlled conditions.

– Avoid bypassing LOTO procedures under any circumstances.

Continuous Improvement

Enhance logistics and compliance through:

– Soliciting feedback from maintenance teams on device usability.

– Evaluating new LOTO technologies (e.g., smart locks, digital tracking).

– Benchmarking against industry best practices.

– Updating the LOTO program to reflect changes in equipment or regulations.

By following this guide, organizations can ensure safe, compliant, and efficient use of Breaker LOTO devices across their operations.

Conclusion for Sourcing Lockout/Tagout (LOTO) Devices

Sourcing the appropriate Lockout/Tagout (LOTO) devices is a critical component of ensuring workplace safety, regulatory compliance, and the prevention of accidental equipment startup during maintenance or servicing. After evaluating various suppliers, product types, and safety standards, it is evident that selecting high-quality, durable, and standardized LOTO devices directly contributes to the effectiveness of an organization’s energy control program.

Key considerations such as compliance with OSHA and ANSI standards, compatibility with existing machinery, ease of use, durability, and employee training must guide the sourcing decision. Investing in a comprehensive LOTO system from reputable suppliers not only minimizes the risk of workplace injuries and fatalities but also reduces downtime, enhances operational efficiency, and demonstrates a strong commitment to employee safety.

Ultimately, a well-implemented LOTO program supported by reliable and appropriately sourced devices serves as a cornerstone of industrial safety. Organizations should prioritize long-term safety outcomes over short-term cost savings, ensuring that all LOTO equipment meets or exceeds industry standards. Regular audits, employee engagement, and continuous improvement further strengthen the program, making the proper sourcing of LOTO devices a vital step toward achieving a safer, more compliant work environment.