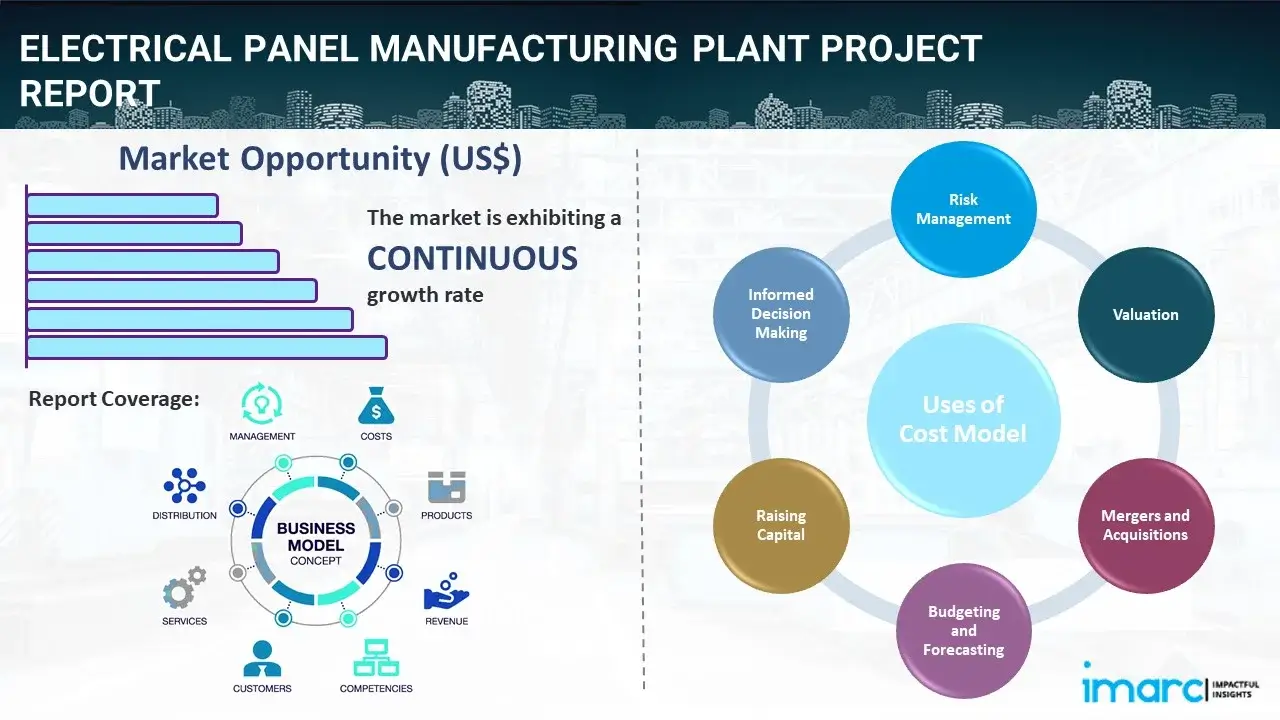

The global circuit breaker market is experiencing robust growth, driven by rising electrification, infrastructure development, and increased demand for reliable power distribution systems. According to Mordor Intelligence, the market was valued at USD 11.68 billion in 2024 and is projected to reach USD 15.63 billion by 2029, growing at a CAGR of 6.03% during the forecast period. This expansion reflects heightened investments in smart grid technologies and industrial automation, particularly in emerging economies. As demand for efficient and safe electrical distribution grows, so does the need for cost-effective breaker box solutions. Based on pricing analysis, production scale, and regional manufacturing advantages, the following seven manufacturers have emerged as leaders in delivering high-quality breaker boxes at competitive price points—balancing performance, compliance, and affordability in a rapidly evolving market landscape.

Top 7 Breaker Box Cost Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 Paneltronics

Domain Est. 1996 | Founded: 1979

Website: paneltronics.com

Key Highlights: Since 1979, Paneltronics has been the industry-leading manufacturer of high quality electrical control panels and assemblies….

#2 Leviton Load Center

Domain Est. 1995

Website: leviton.com

Key Highlights: Leviton offers a comprehensive catalog of load center products including main breaker, main lug, indoor, outdoor, branch circuit breakers, and accessories….

#3 Panelboard fundamentals

Domain Est. 1996

Website: eaton.com

Key Highlights: A load center (i.e., breaker box, fuse box) takes electricity from the utility source and distributes it throughout a facility to support reliable electrical ……

#4 Electrical Panels and Switchboards for Panel Builders

Domain Est. 1997

Website: se.com

Key Highlights: Schneider Electric electrical panels / switchboards provide industry-leading performance. Offering advanced protection, fault protection and seamless ……

#5 All About Electrical Panels

Domain Est. 2002

Website: nyserda.ny.gov

Key Highlights: Electric panel upgrades often cost between $3,000 and $5,000. It’s possible that a home already has a 200-amp service level, even if the panel is 100-150 amps ……

#6 Cost to Replace the Electrical Panel for Your

Domain Est. 2009

#7 How Much Cost to Upgrade Your Electrical Panel in Massachusetts?

Domain Est. 2018

Website: sumzeroenergysystems.com

Key Highlights: Discover the costs and benefits of upgrading your electrical panel in Massachusetts. Ensure safety, support new appliances, and boost your ……

Expert Sourcing Insights for Breaker Box Cost

H2: 2026 Market Trends for Breaker Box Cost

As the global construction and electrical infrastructure sectors evolve, the market for breaker boxes—also known as electrical panels or load centers—is expected to undergo significant changes by 2026. Driven by technological advancements, regulatory shifts, and increasing demand for energy efficiency and smart home integration, breaker box costs are likely to be influenced by a confluence of factors. Below is an analysis of key market trends expected to impact breaker box pricing and demand in 2026.

-

Rising Demand from Residential and Commercial Construction

The continued growth in residential construction, particularly in emerging economies and urban redevelopment zones, will drive demand for electrical panels. Additionally, the expansion of commercial infrastructure, including data centers and green buildings, will require advanced breaker boxes capable of managing higher loads. This increased demand may exert upward pressure on costs, especially if supply chain constraints persist. -

Integration of Smart Technology

Smart breaker boxes equipped with IoT capabilities, remote monitoring, energy usage analytics, and integration with home automation systems are becoming more prevalent. By 2026, these advanced models are expected to capture a larger market share. While smart panels typically command a premium price, increased production scale and competition could moderate costs over time. However, entry-level smart models may still be priced higher than traditional panels, affecting overall market cost averages. -

Regulatory and Safety Standards

Stricter electrical codes and safety regulations—especially in North America and Europe—are pushing for arc-fault and ground-fault protection, as well as improved fire resistance in electrical systems. Compliance with updated NEC (National Electrical Code) standards in the U.S. and similar regulations abroad will require more sophisticated breaker box designs, contributing to higher manufacturing and installation costs. -

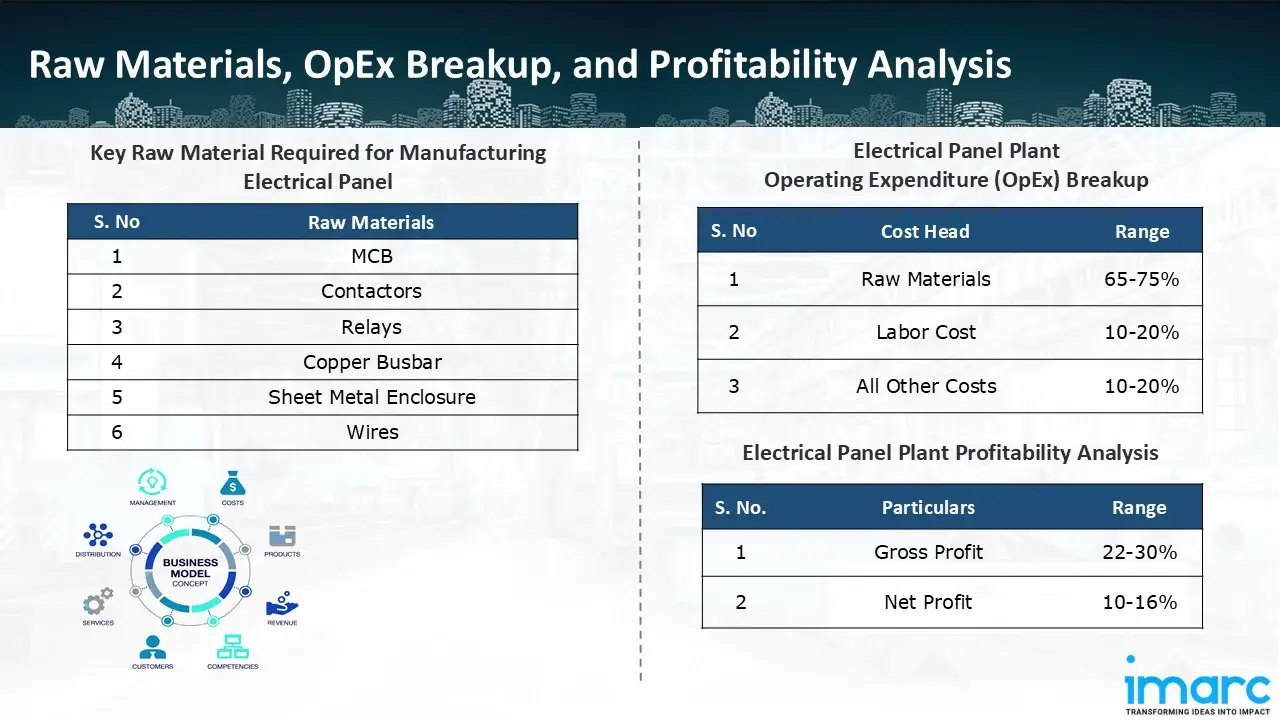

Material and Supply Chain Influences

The cost of raw materials such as copper, aluminum, and specialized plastics remains volatile. Geopolitical tensions, trade policies, and supply chain disruptions could impact the availability and pricing of these components. By 2026, manufacturers may continue to pass on increased material costs to consumers, especially if recycling initiatives and sustainable sourcing add complexity to production. -

Shift Toward Renewable Energy Integration

With the global push for renewable energy, homes and businesses are increasingly adopting solar power, battery storage, and bidirectional energy flow systems. Breaker boxes that support solar interconnection, load management, and hybrid inverter integration will be in higher demand. These specialized panels often come with higher price tags due to added features and certification requirements, influencing the overall cost trends in the market. -

Regional Market Variations

Cost trends will vary significantly by region. Developed markets like the U.S., Canada, and Western Europe may see higher average prices due to advanced technology adoption and regulatory compliance. In contrast, emerging markets in Asia-Pacific, Latin America, and Africa could experience lower price points due to simpler designs and competitive local manufacturing—though quality and safety standards may vary. -

Increased Competition and Market Consolidation

The breaker box market is seeing both increased competition from new entrants offering innovative solutions and consolidation among established players. This dynamic could lead to price stabilization or even reductions in certain segments, especially for standard models. However, premium and custom solutions are likely to maintain higher price points.

Conclusion

By 2026, the average cost of breaker boxes is expected to rise moderately, driven by technological enhancements, regulatory demands, and integration with smart and renewable energy systems. While basic models may remain relatively affordable, the growing preference for intelligent, safe, and energy-efficient electrical panels will shift the market toward higher-value products. Consumers and contractors should anticipate paying a premium for advanced functionality, but long-term savings from energy monitoring and system efficiency may offset initial costs.

Common Pitfalls When Sourcing Breaker Box Costs (Quality, IP)

Sourcing breaker boxes—especially with considerations for quality and Ingress Protection (IP) ratings—can lead to costly mistakes if not managed carefully. Being aware of these common pitfalls helps ensure safety, compliance, and long-term reliability.

Underestimating Quality Differences Between Suppliers

Not all breaker boxes are created equal, even if they appear similar on paper. Low-cost suppliers may use substandard materials such as thinner gauge metal, inferior insulation, or non-compliant internal components. These compromises can lead to overheating, short circuits, or premature failure. Always verify certifications (e.g., UL, CE, IEC) and consider third-party testing to confirm quality claims.

Ignoring IP Rating Requirements for the Environment

The Ingress Protection (IP) rating defines a breaker box’s resistance to dust and moisture. A common mistake is selecting a box with an insufficient IP rating for its environment—such as using an IP40-rated box outdoors or in damp industrial areas. This leads to corrosion, electrical faults, and safety hazards. Always match the IP rating to the installation environment (e.g., IP65 or higher for outdoor or washdown areas).

Prioritizing Upfront Cost Over Total Cost of Ownership

Focusing solely on the lowest purchase price can backfire. Cheaper breaker boxes may require more frequent maintenance, fail earlier, or pose safety risks, increasing downtime and repair costs. A higher initial investment in a quality, appropriately rated unit often delivers better long-term value and reduces lifecycle costs.

Overlooking Certification and Compliance Standards

Using non-compliant or uncertified breaker boxes can violate local electrical codes and void insurance coverage. Always ensure the product meets regional standards (e.g., NEC in the U.S., IEC in Europe) and carries proper certification marks. Sourcing from reputable suppliers with verifiable compliance documentation is essential.

Failing to Verify Supplier Reliability and After-Sales Support

Some suppliers, especially offshore or online vendors, may offer attractive pricing but lack technical support, spare parts availability, or warranty service. This becomes critical during maintenance or failures. Evaluate supplier reputation, lead times, and support infrastructure before committing.

Mismatching IP Rating with Installation Conditions

Even if a breaker box has a high IP rating, improper installation—such as poorly sealed cable entries or damaged gaskets—can compromise protection. Ensure installation practices maintain the intended IP integrity and train technicians accordingly.

Assuming All “Industrial-Grade” Boxes Are Suitable

Marketing terms like “industrial-grade” are not standardized. Without verifying actual IP ratings, temperature tolerances, and material specs, assumptions can lead to unsuitable selections. Always request detailed technical data sheets and avoid vague product descriptions.

By addressing these pitfalls early in the sourcing process, organizations can ensure they select breaker boxes that are safe, durable, and fit for purpose—balancing cost with quality and protection needs.

Logistics & Compliance Guide for Breaker Box Costs

Understanding the logistics and compliance factors influencing breaker box costs is essential for accurate budgeting, project planning, and regulatory adherence. These elements can significantly impact the total installed price beyond the unit’s sticker cost.

Supply Chain and Logistics Considerations

Shipping distances, availability, and delivery timelines directly affect the final cost of breaker boxes. Logistics challenges such as carrier delays, port congestion, or regional shortages can lead to price volatility and increased transportation fees.

- Freight Costs: Heavy electrical panels require specialized shipping; costs vary by region, fuel prices, and delivery urgency.

- Inventory Availability: High-demand models or specific configurations (e.g., arc-fault, smart panels) may have lead times, potentially increasing project costs due to delays.

- Bulk Purchasing: Contractors often reduce per-unit costs through volume orders, but storage and warehousing must be factored in.

Regulatory and Compliance Requirements

Breaker boxes must meet national and local electrical codes to ensure safety and legality. Non-compliant installations can result in fines, rework, or insurance issues.

- NEC (National Electrical Code): Mandates specifications for overcurrent protection, labeling, and installation methods (e.g., NEC Article 408).

- UL Certification: All breaker boxes must be UL-listed (Underwriters Laboratories) to verify safety standards.

- Local Amendments: Jurisdictions may impose additional requirements (e.g., CA Title 24 for energy efficiency), affecting equipment selection and cost.

- Inspection Fees: Compliance often requires third-party inspections, adding to the project’s total cost.

Environmental and Safety Standards

Environmental regulations can influence materials and disposal practices, particularly for older or hazardous components.

- RoHS Compliance: Restricts hazardous substances in electrical equipment, potentially increasing manufacturing costs.

- Recycling and Disposal: Decommissioned panels may contain recyclable copper and hazardous materials, requiring certified disposal methods.

Import/Export and Tariff Impacts

For internationally sourced breaker boxes, tariffs, customs duties, and trade regulations can increase procurement costs.

- Section 301 Tariffs: May apply to panels or components imported from certain countries, raising landed cost.

- Documentation Requirements: Accurate customs declarations and compliance with import regulations prevent delays and penalties.

Best Practices for Cost Management

- Verify local code requirements early in project planning.

- Partner with certified suppliers who ensure compliance and reliable logistics.

- Budget for freight, handling, and potential supply chain disruptions.

- Maintain documentation for inspections and warranty claims.

By addressing these logistics and compliance factors proactively, stakeholders can avoid unexpected costs and ensure a safe, code-compliant electrical installation.

Conclusion on Sourcing Breaker Box Costs:

Sourcing a breaker box involves evaluating several cost factors, including brand, amperage rating (e.g., 100A, 200A), number of circuits, type (main breaker vs. main lug, load center, etc.), and whether it’s a new construction or retrofit application. Prices can vary significantly—from around $100 for basic models to over $500 for higher-capacity or smart-enabled panels from premium brands like Square D, Siemens, or Eaton.

Additionally, cost considerations extend beyond the unit price to include shipping, local availability, required accessories (such as breakers, grounding kits, or accessories), and professional installation fees, which can range from $500 to $1,500 or more depending on complexity and local labor rates.

To achieve the best value, it is recommended to compare prices across suppliers (local electrical distributors, home improvement stores, and online retailers), consider rebates or bulk pricing, and ensure compatibility with existing electrical systems. While upfront savings are attractive, investing in a quality, code-compliant breaker box from a reputable manufacturer ensures long-term safety, reliability, and ease of maintenance. Proper sourcing—balancing cost, quality, and compliance—leads to a cost-effective and safe electrical system upgrade or installation.