The global bread manufacturing industry has experienced steady expansion driven by rising demand for convenient, ready-to-eat bakery products and increasing urbanization. According to Mordor Intelligence, the global bread market was valued at approximately USD 25.8 billion in 2023 and is projected to grow at a CAGR of 4.5% from 2024 to 2029. This growth is fueled by innovation in product offerings—such as fortified, organic, and gluten-free breads—as well as advancements in automated production technologies that enhance scalability and consistency. Additionally, Grand View Research highlights the expanding presence of large-scale manufacturers leveraging vertical integration and sustainable sourcing to meet both retail and foodservice demands. As competition intensifies and consumer preferences evolve, a select group of leading bread manufacturers have emerged, balancing efficiency, quality, and innovation to dominate regional and global market share. The following list identifies the top 10 bread manufacturers shaping the industry through production capacity, technological adoption, and market reach.

Top 10 Bread Manufactures Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

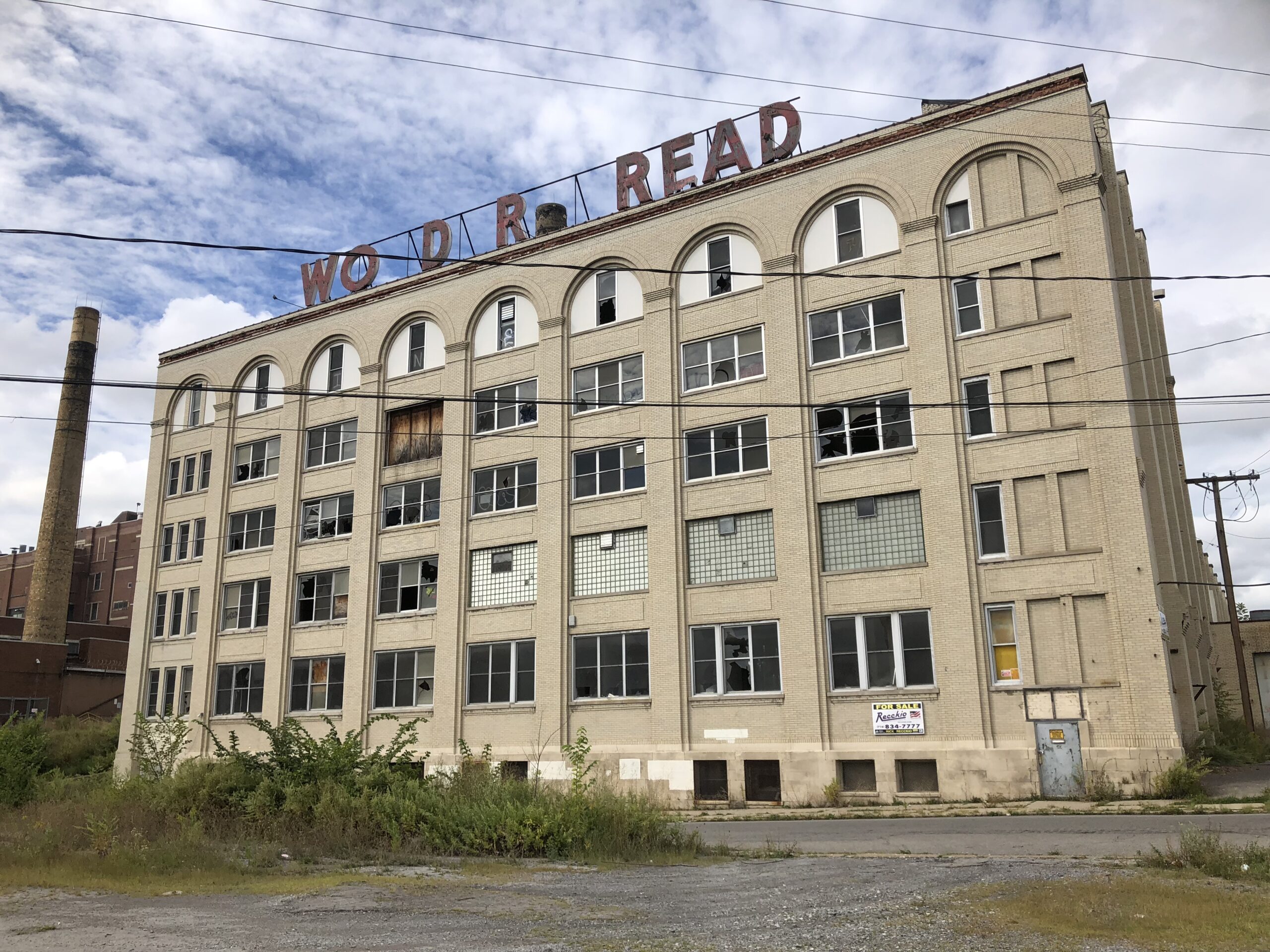

#1 Wonder bread

Domain Est. 1996

Website: wonderbread.com

Key Highlights: The company behind Wonder Bread Co., Flowers Foods, Inc., has more than 100 years of baking experience….

#2 Orlando Baking Company

Domain Est. 1997

Website: orlandobaking.com

Key Highlights: The Orlando Baking Company is one of the top manufacturers of consumer breads. Orlando is always innovating new types of artisan breads and consumer products….

#3 H&S Bakery

Domain Est. 1997

Website: hsbakery.com

Key Highlights: Based in Baltimore, Maryland, H&S Bakery is the largest food distributor and manufacturer of breads, rolls, and custom-crafted baked goods on the East ……

#4 BakeMark

Domain Est. 1998

Website: bakemark.com

Key Highlights: The largest global bakery manufacturer and distributors in North America, BakeMark brings you a wide range of high-quality products and ingredients….

#5 Alpha Baking Company

Domain Est. 1998

Website: alphabaking.com

Key Highlights: Alpha Baking Company, Inc. specializes in the baking and distribution of bread, buns, rolls, muffins and more for Fresh Foodservice, Nationwide Frozen ……

#6 Flowers Foods

Domain Est. 2000

Website: flowersfoods.com

Key Highlights: Flowers Foods is the second-largest producer and marketer of packaged bakery foods in the US with 2024 sales of $5.1 billion….

#7 Bimbo Bakeries USA

Domain Est. 1998

Website: bimbobakeriesusa.com

Key Highlights: Start your career with Bimbo Bakeries USA! Join the more than 20,000 associates who make our iconic bread, buns, bagels, English Muffins and sweet baked goods!…

#8 Klosterman Baking Company

Domain Est. 1998

Website: klostermanbakery.com

Key Highlights: Klosterman Bakery, a trusted nationwide wholesale bakery delivering artisan bread, buns, and donuts to restaurants, grocers & institutions across the U.S ……

#9 Arnold® Premium Breads

Domain Est. 2000

Website: arnoldbread.com

Key Highlights: At Arnold, baking the right way isn’t a goal, it’s our promise. So we’re bringing this commitment to life by showing how we bake like grandmas….

#10 Rise Baking Company

Domain Est. 2016

Website: risebakingcompany.com

Key Highlights: Rise Baking Company helps you create special moments for your customers. You can depend on our unrivaled product portfolio and world-class brands to deliver ……

Expert Sourcing Insights for Bread Manufactures

H2: 2026 Market Trends for Bread Manufacturers

As the global food industry evolves, bread manufacturers are facing a dynamic landscape shaped by shifting consumer preferences, technological advancements, sustainability demands, and economic factors. Looking ahead to 2026, several key trends are expected to influence the bread manufacturing sector:

-

Health and Wellness Driving Innovation

Consumers are increasingly seeking healthier bread options, including low-carb, high-protein, gluten-free, and fiber-enriched varieties. In 2026, bread manufacturers will likely prioritize clean labels—using recognizable, natural ingredients—and fortify products with functional ingredients like probiotics, seeds, and ancient grains (e.g., spelt, kamut, and teff). The rise in popularity of keto and plant-based diets will further fuel demand for alternative bread formulations. -

Sustainability and ESG Commitments

Environmental, Social, and Governance (ESG) factors will play a critical role. Bread manufacturers are expected to adopt sustainable sourcing practices, reduce food waste through improved production efficiency, and implement eco-friendly packaging solutions. Carbon footprint reduction and transparent supply chains will be key differentiators in a market where environmentally conscious consumers favor brands with demonstrable sustainability efforts. -

Automation and Digital Transformation

By 2026, advanced automation, AI-driven supply chain optimization, and predictive maintenance will be standard in large-scale bread production. Smart factories will enhance efficiency, reduce labor costs, and improve product consistency. Additionally, data analytics will help manufacturers anticipate demand fluctuations and personalize product offerings based on regional preferences. -

Expansion of Private Label and Value Segments

Inflation and economic uncertainty may drive more consumers toward private-label bread products. Retailers and manufacturers will respond by improving the quality and variety of store-brand offerings to compete with national brands. At the same time, premium artisanal and bakery-style breads will continue to grow, catering to consumers willing to pay more for taste, authenticity, and craftsmanship. -

Rise of Alternative and Plant-Based Breads

With the broader plant-based food movement gaining momentum, bread manufacturers are exploring alternatives to traditional wheat-based loaves. Products made from legume flours, almond flour, or upcycled ingredients are expected to gain traction. These alternatives cater to allergen-conscious consumers and align with clean-label and sustainable trends. -

Regionalization and Localization of Production

To reduce transportation emissions and respond faster to local tastes, many bread manufacturers are expected to invest in regional production hubs. Localized baking also supports the perception of freshness and supports “farm-to-table” narratives that resonate with modern consumers. -

E-commerce and Direct-to-Consumer (DTC) Channels

Online grocery sales are projected to grow steadily through 2026. Bread manufacturers will increasingly leverage e-commerce platforms, subscription models, and DTC websites to sell specialty or freshly baked products with extended shelf-life packaging or frozen delivery options.

In conclusion, the 2026 bread manufacturing landscape will be defined by innovation, sustainability, and responsiveness to health-conscious and environmentally aware consumers. Companies that adapt quickly to these trends—through product reformulation, operational efficiency, and strategic branding—will be best positioned for long-term success.

Common Pitfalls When Sourcing Bread Manufacturers (Quality, IP)

Sourcing bread manufacturers, especially internationally or for private-label production, involves significant risks related to both product quality and intellectual property (IP). Overlooking these pitfalls can lead to brand damage, legal disputes, and financial losses.

Quality-Related Pitfalls

Inconsistent Product Standards

Bread quality is highly sensitive to variations in ingredients, fermentation time, proofing conditions, and baking techniques. Without strict oversight, manufacturers may cut corners—using lower-grade flour, reducing fermentation time, or altering recipes—leading to inconsistent taste, texture, and shelf life across batches.

Lack of Ingredient Traceability

Sourcing manufacturers without robust supply chain transparency increases the risk of allergen contamination, use of substandard or non-compliant ingredients (e.g., non-GMO vs. GMO, organic authenticity), and failure to meet regional food safety regulations.

Inadequate Quality Control Systems

Many manufacturers—especially smaller or regional ones—may lack certified quality management systems (e.g., HACCP, ISO 22000). This increases the likelihood of microbiological contamination (e.g., mold, listeria), incorrect labeling, and failure to meet safety benchmarks.

Limited Scalability and Production Capacity

A manufacturer that performs well in small pilot batches may struggle with consistency and logistics when scaling up. Poor equipment maintenance or workforce training can further exacerbate quality issues during high-volume production.

Intellectual Property-Related Pitfalls

Unprotected Formulations and Recipes

Bread recipes, especially those involving proprietary blends, sourdough starters, or unique processing methods, are vulnerable to theft when shared with manufacturers lacking IP agreements. Without legal safeguards, the manufacturer may replicate or sell your recipe to competitors.

Absence of Confidentiality Agreements (NDAs)

Many sourcing engagements begin without signed NDAs, leaving recipe details, packaging designs, and branding strategies exposed. This is particularly risky in jurisdictions with weak IP enforcement.

Co-Manufacturer Ownership Claims

Some manufacturers may assert partial ownership over improvements made to your recipe during production (e.g., adjustments for machinery or local ingredients), potentially leading to disputes over IP rights or exclusivity.

Counterfeiting and Grey Market Diversion

If contracts don’t clearly prohibit unauthorized production or distribution, a manufacturer might produce excess units and sell them independently, undermining your brand’s control and market pricing.

Mitigation Strategies

To avoid these pitfalls, conduct thorough due diligence on potential manufacturers, require certifications, implement robust contracts with IP clauses, and consider third-party audits. Using escrow agreements for recipes and maintaining ownership through clear legal documentation are essential for protecting both quality and intellectual property.

Logistics & Compliance Guide for Bread Manufacturers

Ensuring efficient logistics and strict compliance is essential for bread manufacturers to deliver safe, high-quality products on time while meeting all regulatory requirements. This guide outlines key areas to focus on for operational excellence and legal adherence.

Raw Material Sourcing & Supplier Management

Maintain a qualified supplier program to ensure all ingredients (flour, yeast, additives, packaging) meet food safety and quality standards. Require certificates of analysis (COA), conduct supplier audits, and verify compliance with FDA, USDA, and relevant food safety regulations. Implement traceability systems to track raw materials from source to finished product.

Production Facility Compliance

Bread manufacturing facilities must comply with Current Good Manufacturing Practices (cGMPs) under 21 CFR Part 117. Key requirements include:

– Sanitation standard operating procedures (SSOPs)

– Allergen control and cross-contact prevention

– Pest infestation control

– Employee hygiene training and protocols

– Environmental monitoring for pathogens like Listeria

Adherence to a written Food Safety Plan under the FDA’s Food Safety Modernization Act (FSMA) is mandatory, including hazard analysis and risk-based preventive controls.

Temperature Control & Cold Chain Management

While most bread is ambient-stable, certain products (e.g., filled breads, par-baked items, dough) require temperature-controlled storage and transport. Monitor and document time-temperature profiles throughout storage and distribution to prevent spoilage, mold growth, or pathogen proliferation. Use calibrated monitoring devices and maintain cold chain integrity.

Packaging & Labeling Requirements

Ensure all packaging materials are food-grade and comply with FDA regulations (21 CFR). Labels must include:

– Product name

– Ingredient list (with major allergens clearly declared)

– Net weight

– Name and address of manufacturer

– Nutrition Facts panel

– Any required safe handling instructions (if applicable)

Labels must be accurate, legible, and compliant with FDA and FTC guidelines. Update labels promptly for formula changes.

Transportation & Distribution Logistics

Implement a robust transportation plan compliant with FSMA’s Sanitary Transportation Rule (21 CFR Part 1, Subpart O). Requirements include:

– Proper vehicle sanitation

– Preventing cross-contamination

– Temperature control during transit

– Training for drivers and handlers

– Documentation of sanitation and temperature records

Schedule deliveries to minimize in-transit time and maintain product freshness.

Inventory Management & Shelf Life Control

Use a first-expired, first-out (FEFO) or first-in, first-out (FIFO) inventory system to prevent expired product distribution. Clearly mark production and expiration dates on packaging. Monitor and validate shelf life through stability testing and microbial analysis.

Recall Preparedness & Traceability

Maintain a detailed traceability system (one step forward, one step back) to quickly identify affected batches in case of contamination or labeling errors. Develop and test a written recall plan that includes:

– Internal communication protocols

– Notification procedures for regulators (FDA, state authorities)

– Customer and public communication strategies

– Product recovery and disposal methods

Regulatory Inspections & Documentation

Prepare for routine inspections by FDA, state health departments, or third-party auditors (e.g., SQF, BRCGS). Maintain organized records including:

– Supplier approvals and COAs

– Sanitation logs

– Preventive control monitoring records

– Allergen cleaning verification

– Training records

– Recall test results

Regular internal audits help ensure ongoing compliance.

Sustainability & Waste Management

Adopt sustainable logistics practices such as optimizing delivery routes, using recyclable packaging, and partnering with food rescue organizations to donate unsold but safe bread. Comply with local waste disposal regulations and track waste metrics to improve efficiency.

By maintaining rigorous logistics and compliance standards, bread manufacturers can protect consumer health, enhance brand reputation, and ensure long-term success in a competitive marketplace.

In conclusion, sourcing bread manufacturers requires a strategic approach that balances quality, cost, scalability, and reliability. By thoroughly evaluating potential suppliers based on certification standards, production capacity, ingredient sourcing, and logistical capabilities, businesses can secure partners that align with their brand values and operational needs. Conducting site visits, requesting samples, and reviewing compliance with food safety regulations such as HACCP or FDA standards are critical steps in ensuring consistent product quality and safety. Additionally, fostering strong relationships with manufacturers can lead to flexibility, innovation, and long-term sustainability. Ultimately, effective sourcing not only supports product excellence but also enhances supply chain resilience and customer satisfaction in the competitive bakery market.