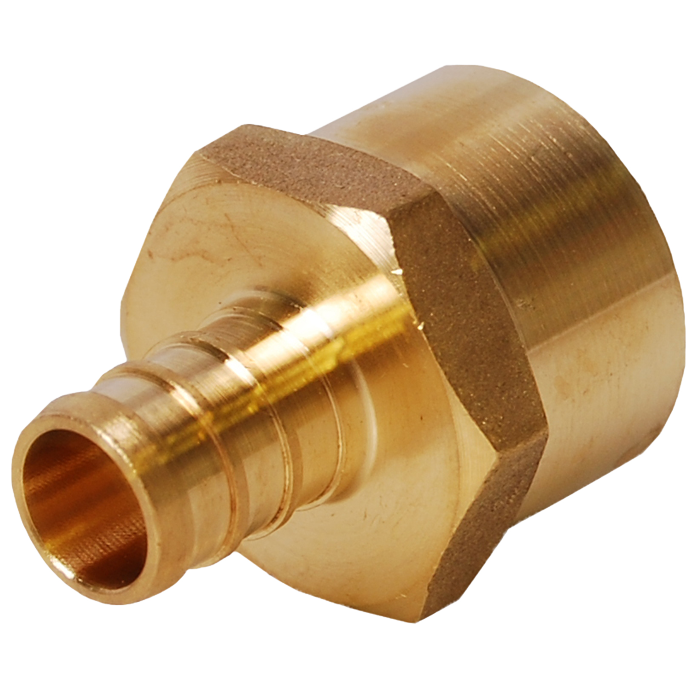

The global PEX fittings market is experiencing robust growth, driven by increasing demand for durable, corrosion-resistant plumbing solutions across residential and commercial construction sectors. According to Grand View Research, the global cross-linked polyethylene (PEX) pipes and fittings market size was valued at USD 3.8 billion in 2022 and is expected to expand at a compound annual growth rate (CAGR) of 8.1% from 2023 to 2030. This surge is fueled by the rising adoption of PEX systems due to their flexibility, ease of installation, and longevity compared to traditional materials. Brass PEX fittings, in particular, have gained prominence for their superior strength, leak resistance, and compatibility with various plumbing codes, making them a preferred choice in modern hydronic and potable water systems. As demand grows, a select group of manufacturers has emerged as leaders in innovation, quality, and market reach. Here’s a data-driven look at the top 10 brass PEX fittings manufacturers shaping the industry’s future.

Top 10 Brass Pex Fittings Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 Legend Valve

Domain Est. 1996

Website: legendvalve.com

Key Highlights: Legend provides high quality valves and fittings for plumbing, industrial, commercial and residential markets….

#2 Sioux Chief: Rough Plumbing Products

Domain Est. 1997

Website: siouxchief.com

Key Highlights: Tubing/Hose Fittings · Brass Compression Fittings · Nylon Compression Fittings · Brass Flare Fittings · Bar-Stock & Forged Fittings · Cast Brass Fittings ……

#3 BrassCraft

Domain Est. 1995

Website: brasscraft.com

Key Highlights: At BrassCraft our focus is providing the highest quality plumbing products manufactured today. Our products are well-engineered and need-based, with a proven ……

#4 Uponor

Domain Est. 1996

Website: uponor.com

Key Highlights: Uponor offers durable PEX piping, fittings, and other products for plumbing, radiant heating and cooling. Learn why PEX is preferred by plumbers, ……

#5 Jones Stephens

Domain Est. 1999

Website: jonesstephens.com

Key Highlights: PEX F1807 Fittings. Back; Brass PEX Fittings · Clamps · Crimp Rings · PEX F1960 Fittings. Back; Brass PEX Fittings · Expansion Rings · Plastic PEX Fittings….

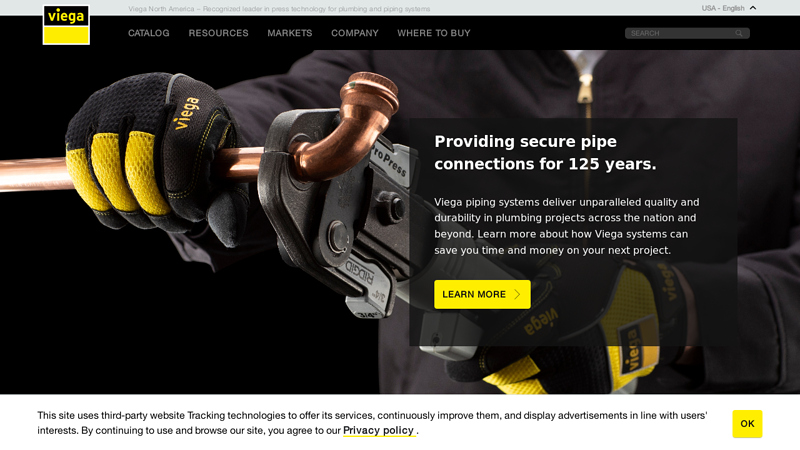

#6 Viega USA

Domain Est. 2002

Website: viega.us

Key Highlights: Providing secure pipe connections for 125 years. Viega piping systems deliver unparalleled quality and durability in plumbing projects across the nation and ……

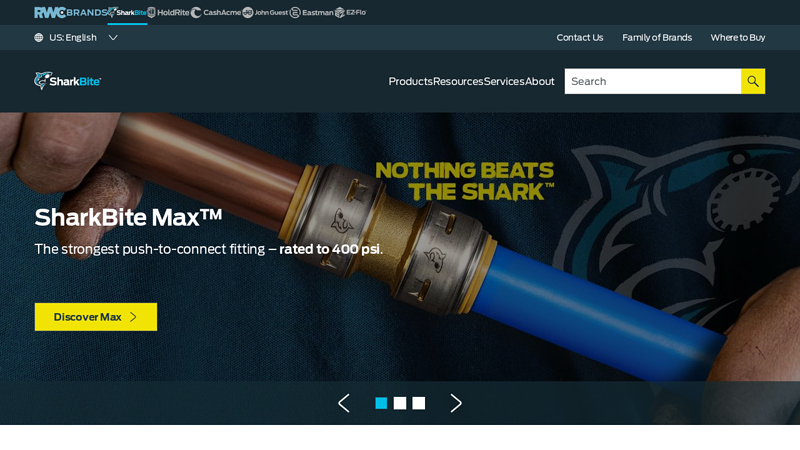

#7 SharkBite Plumbing Products

Domain Est. 2003

Website: sharkbite.com

Key Highlights: SharkBite Max brass push-to-connect couplings are used to connect PEX, copper, CPVC, PE-RT or HDPE SDR-9 pipe in any combination….

#8 SharkBite

Domain Est. 2004

Website: rwc.com

Key Highlights: Reliance Worldwide Corporation’s (RWC) SharkBite products are the world’s leading brass push-to-connect plumbing and heating system….

#9 Midland Industries

Domain Est. 2011

Website: midlandindustries.com

Key Highlights: NOW IN STOCK · Lead-Free Brass Forged Bodies · Full Port 3/4″ Drain Outlets · Ready to ship from Midland….

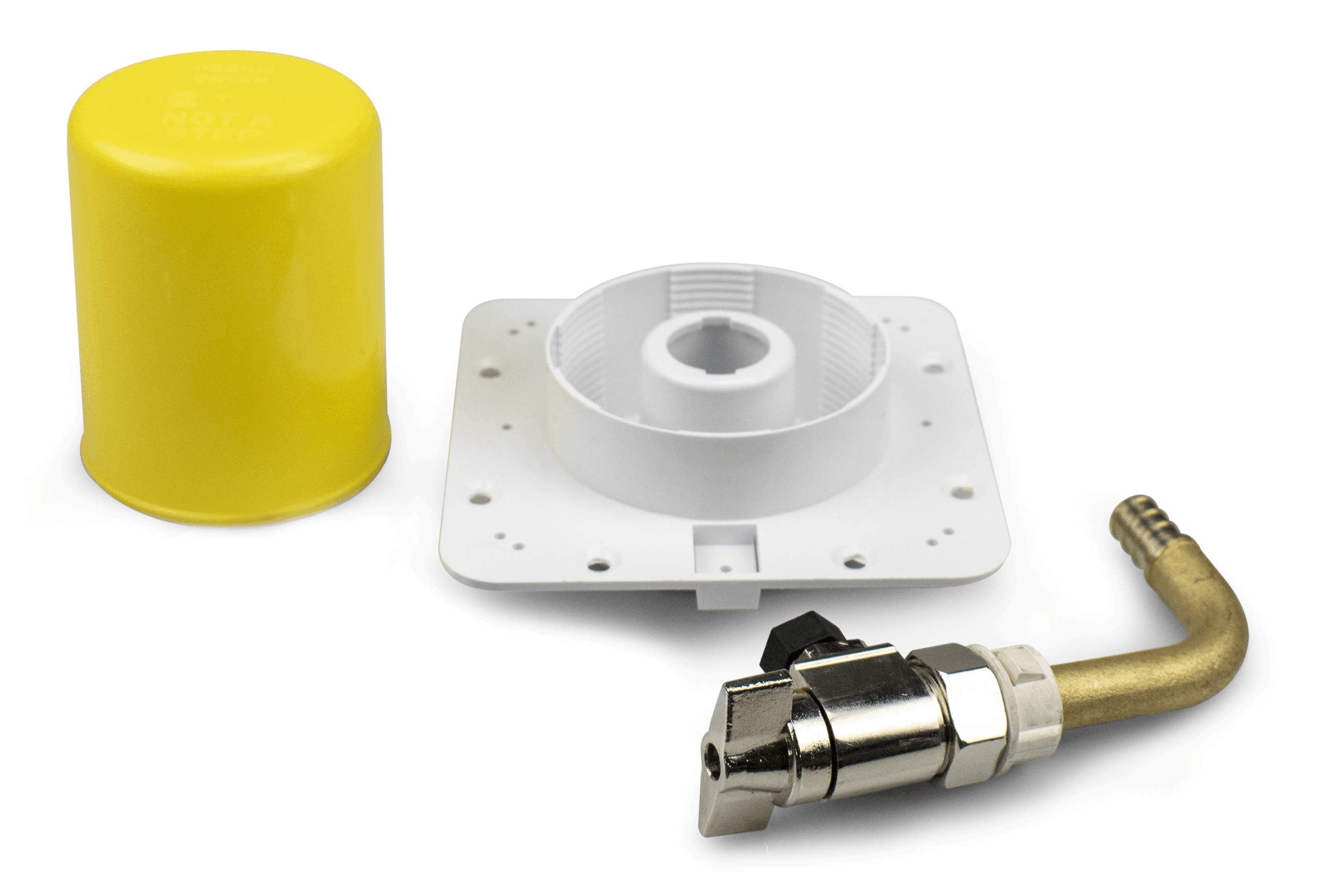

#10 PEX

Domain Est. 2013

Website: astralpipes.com

Key Highlights: ISO-certified plumbing pipes and fittings. PEX-a pipes available in sizes from 16 mm to 32 mm. Flexible piping fittings available in Brass or PPSU. Enquire Now ……

Expert Sourcing Insights for Brass Pex Fittings

H2: Projected Market Trends for Brass Pex Fittings in 2026

The global market for Brass PEX (cross-linked polyethylene) fittings is poised for significant evolution by 2026, driven by advancements in plumbing technologies, growing construction activities, and increasing demand for durable, corrosion-resistant materials. As a critical component in modern plumbing systems, brass PEX fittings offer reliability, ease of installation, and compatibility with both PEX tubing and existing metal piping systems. The following trends are anticipated to shape the Brass PEX Fittings market in 2026:

-

Growth in Residential and Commercial Construction

The expansion of urban infrastructure and rising investments in residential and commercial real estate—particularly in North America, Europe, and parts of Asia-Pacific—are expected to fuel demand for efficient plumbing solutions. With builders prioritizing long-term durability and leak prevention, brass PEX fittings are becoming a preferred choice over traditional copper or plastic fittings. -

Increased Adoption of PEX Plumbing Systems

PEX piping systems continue to gain market share due to their flexibility, freeze resistance, and reduced installation time. This shift is directly boosting demand for compatible brass fittings. Innovations such as press-fit, crimp, and expansion-style brass fittings are enhancing system reliability and installer efficiency, further accelerating adoption. -

Focus on Lead-Free and Eco-Friendly Materials

Regulatory standards, such as the U.S. Safe Drinking Water Act’s lead-free requirements (≤0.25% lead content), are pushing manufacturers to produce low-lead or lead-free brass fittings. By 2026, compliance with environmental and health regulations will be a key driver, with an increasing number of eco-certified and sustainable brass fittings entering the market. -

Technological Advancements and Smart Integration

The integration of smart home technologies into plumbing systems is expected to influence fitting design. While brass PEX fittings themselves are mechanical components, future iterations may be engineered to work seamlessly with leak-detection sensors and automated shut-off systems, supporting smart building ecosystems. -

Regional Market Dynamics

North America is expected to remain the largest market for brass PEX fittings in 2026 due to mature plumbing codes favoring PEX and a strong base of professional plumbing contractors. Meanwhile, the Asia-Pacific region, particularly China and India, is projected to witness the highest growth rates, driven by rapid urbanization and modernization of water infrastructure. -

Supply Chain Optimization and Cost Pressures

Fluctuations in copper and zinc prices—key components of brass—may impact production costs. Manufacturers are likely to focus on supply chain resilience, recycling initiatives, and alternative alloy formulations to mitigate cost volatility while maintaining product performance. -

Competition from Alternative Materials

While brass remains dominant, competition from high-performance polymer and stainless-steel fittings may increase. However, brass is expected to maintain its market leadership due to its superior mechanical strength, thermal conductivity, and proven track record in high-pressure applications.

In conclusion, by 2026, the Brass PEX Fittings market will be characterized by innovation, regulatory compliance, and sustained demand from the construction sector. Stakeholders who invest in sustainable manufacturing, product differentiation, and regional market expansion are likely to gain a competitive edge in this evolving landscape.

Common Pitfalls When Sourcing Brass Pex Fittings (Quality and Intellectual Property)

Sourcing brass PEX fittings can be fraught with risks, particularly regarding product quality and intellectual property (IP) infringement. Being aware of these pitfalls is crucial for ensuring system performance, safety, and legal compliance.

Poor Material Quality and Non-Compliance with Standards

One of the most significant risks is receiving fittings made from substandard materials. Some suppliers may use low-grade brass with high lead content or poor alloy composition, leading to premature corrosion, leaks, or contamination of potable water. Additionally, fittings may falsely claim compliance with ASTM, NSF, or CSA standards without proper certification. Always verify third-party certifications and request material test reports to ensure compliance with safety and performance standards.

Counterfeit or IP-Infringing Products

The PEX fitting market is susceptible to counterfeit products that mimic designs from reputable brands. These copies often infringe on patents and trademarks, posing legal risks for distributors and end users. Sourcing such products can lead to liability, project delays, and reputational damage. Conduct thorough due diligence on suppliers, verify brand authenticity, and avoid unusually low prices that may indicate IP violations.

Inconsistent Manufacturing and Thread Quality

Inferior manufacturing processes can result in inconsistent thread dimensions, poor surface finishes, or weak crimp zones. These flaws compromise the fitting’s ability to form watertight connections, increasing the risk of system failures. Inspect samples for dimensional accuracy and perform functional tests before large-scale procurement.

Lack of Traceability and Documentation

Reputable suppliers provide full traceability, including lot numbers, manufacturing dates, and compliance documentation. A lack of traceability makes it difficult to address quality issues or recalls. Ensure your supplier maintains robust quality control systems and can provide complete documentation for every batch.

Inadequate Corrosion Resistance and Plating

Some brass PEX fittings use thin or poorly applied plating (e.g., chrome or nickel) that wears off quickly, exposing the base metal to corrosion. This is especially problematic in aggressive water conditions. Confirm the type and thickness of protective plating and ensure it meets industry durability standards.

By recognizing these common pitfalls—particularly those related to material integrity and intellectual property—buyers can make informed sourcing decisions that ensure long-term system reliability and legal protection.

Logistics & Compliance Guide for Brass Pex Fittings

Overview

Brass Pex fittings are essential components in plumbing systems, connecting PEX (cross-linked polyethylene) tubing to fixtures, valves, and other piping. Ensuring proper logistics and regulatory compliance is critical for manufacturers, distributors, and installers to guarantee product safety, performance, and legal adherence.

Product Classification and HS Code

Brass Pex fittings typically fall under the following Harmonized System (HS) classification:

HS Code: 7412.20 – Fittings for pipes, tubes, or hoses, of copper (including brass).

Note: Confirm with local customs authorities, as sub-classifications may vary by country and specific product design.

Regulatory Compliance Standards

Brass Pex fittings must meet strict standards to ensure safety, durability, and performance in potable water systems. Key compliance requirements include:

NSF/ANSI 61 – Drinking Water System Components

- Certification ensures the product does not leach harmful levels of contaminants into drinking water.

- Mandatory in the U.S. and widely recognized in Canada and other regions.

- Look for NSF-pw (potable water) certification markings.

NSF/ANSI 372 – Lead Content Compliance

- Limits lead content to <0.25% weighted average across wetted surfaces.

- Required under U.S. Safe Drinking Water Act (SDWA) “lead-free” definition.

- Fittings must be labeled as “lead-free” compliant.

ASTM Standards

- ASTM B584: Standard specification for copper alloy sand castings (may apply to brass components).

- ASTM F1807: Standard specification for insert fittings for use with cross-linked polyethylene (PEX) and other plastic tubing.

- ASTM F2159: Standard specification for metal insert fittings utilizing cold expansion for connecting PEX, PE-RT, and PEX/AL/PEX tubes.

Uniform Plumbing Code (UPC) and International Plumbing Code (IPC)

- Fittings must be listed and labeled by an accredited third-party certification body (e.g., IAPMO, ICC-ES).

- Installation must comply with UPC or IPC depending on jurisdiction.

Packaging and Labeling Requirements

- Primary Packaging: Fittings should be sealed in moisture-resistant packaging to prevent corrosion.

- Labeling: Each package must include:

- Product name and model number

- Material composition (e.g., “Lead-Free Brass”)

- Compliance marks (NSF 61, NSF 372, ASTM)

- Manufacturer name and contact information

- UPC/IPC listing information

- Bulk Shipments: Use sturdy, labeled cartons with handling instructions (e.g., “Do Not Stack,” “Protect from Moisture”).

Shipping and Transportation

- Domestic (U.S./Canada): Use standard freight carriers; ensure temperature and humidity control during transit.

- International:

- Comply with import regulations in destination country (e.g., Health Canada, WRAS in the UK, DVGW in Germany).

- Provide accurate commercial invoices, packing lists, and certificates of compliance (NSF, RoHS where applicable).

- Include Material Safety Data Sheets (MSDS) if required.

- Hazard Classification: Brass fittings are non-hazardous; no special handling required under IATA/IMDG.

Storage Guidelines

- Environment: Store in dry, temperature-controlled areas (10°C to 30°C recommended).

- Shelving: Keep off concrete floors using pallets to prevent moisture absorption.

- Stock Rotation: Use FIFO (First In, First Out) to minimize aging and potential degradation.

- Security: Prevent tampering and unauthorized access in warehouse settings.

Import/Export Documentation

Ensure the following documents are prepared for international trade:

– Commercial Invoice

– Bill of Lading/Air Waybill

– Packing List

– Certificate of Origin

– NSF/ANSI 61 and 372 Certificates

– Test Reports (if required by destination country)

– Import License (if applicable)

Environmental and Safety Compliance

- RoHS (EU): Restriction of Hazardous Substances – applicable if exporting to Europe. Confirm lead and other restricted substance limits.

- REACH (EU): Registration, Evaluation, Authorization, and Restriction of Chemicals – declare SVHCs (Substances of Very High Concern) if present.

- WEEE (EU): Not typically applicable to fittings, as they are not electrical/electronic equipment.

- California Proposition 65: Provide warnings if products contain chemicals listed under Prop 65 (e.g., lead compounds), even if compliant with lead-free laws.

Quality Assurance and Traceability

- Maintain batch/lot tracking for all fittings.

- Conduct periodic third-party testing to verify continued compliance.

- Keep records of certifications and test reports for minimum 5 years.

Installation and End-Use Compliance

- Distributors and retailers must provide installation instructions and compliance documentation to contractors.

- Contractors must follow manufacturer guidelines and local plumbing codes.

- Non-compliant installations may void warranties and certifications.

Conclusion

Adhering to logistics and compliance standards for Brass Pex fittings ensures product integrity, legal conformity, and consumer safety. Manufacturers and distributors must stay current with evolving regulations in target markets and maintain transparent documentation throughout the supply chain.

In conclusion, sourcing brass PEX fittings requires careful consideration of quality, compliance, supplier reliability, and cost-effectiveness. High-quality brass fittings, especially those made from lead-free or low-lead brass (such as dezincification-resistant brass), are essential to ensure durability, prevent corrosion, and maintain water safety standards. It is crucial to verify that the fittings comply with relevant industry standards such as NSF/ANSI 61, ASTM F1807, and local plumbing codes.

When selecting suppliers, prioritize those with strong reputations, certifications, and consistent product traceability. Evaluating both domestic and international manufacturers can offer competitive pricing while balancing quality control. Additionally, considering factors such as minimum order quantities, lead times, and after-sales support contributes to a more reliable supply chain.

Ultimately, investing time in due diligence when sourcing brass PEX fittings helps avoid long-term issues such as leaks, contamination, or system failures—ensuring reliable performance in residential and commercial plumbing applications. A strategic sourcing approach supports both project efficiency and compliance with health and safety regulations.