The global ceramic tiles market, which encompasses specialized finishes such as brass inlay tiles, is experiencing steady growth driven by rising demand in residential and commercial construction. According to a report by Grand View Research, the global ceramic tiles market was valued at USD 208.7 billion in 2023 and is expected to expand at a compound annual growth rate (CAGR) of 6.8% from 2024 to 2030. This growth is fueled by increasing urbanization, infrastructural development, and a growing consumer preference for premium, decorative finishes—particularly in emerging economies across Asia-Pacific and the Middle East. Brass inlay tiles, known for their intricate craftsmanship and luxurious appeal, are becoming a sought-after choice in high-end interiors, prompting manufacturers to innovate in design precision and material durability. As demand surges, a select group of manufacturers has emerged as leaders in quality, scalability, and design innovation. Below are the top 5 brass inlay tile manufacturers shaping this niche segment.

Top 5 Brass Inlay Tile Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 Wholesale Brass Inlay Tile Manufacturer and Supplier, Factory …

Domain Est. 2022

Website: wanpomosaic.com

Key Highlights: Brass Inlay Tile Manufacturers, Factory, Suppliers From China, We welcome you to definitely stop by our manufacturing facility and sit up for creating ……

#2 Custom Brass Inlay Strips For Tile Suppliers, Manufacturers

Domain Est. 2004

Website: tiletrim.com

Key Highlights: As one of the most professional brass inlay strips for tile manufacturers and suppliers in China, we’re featured by quality products and good service….

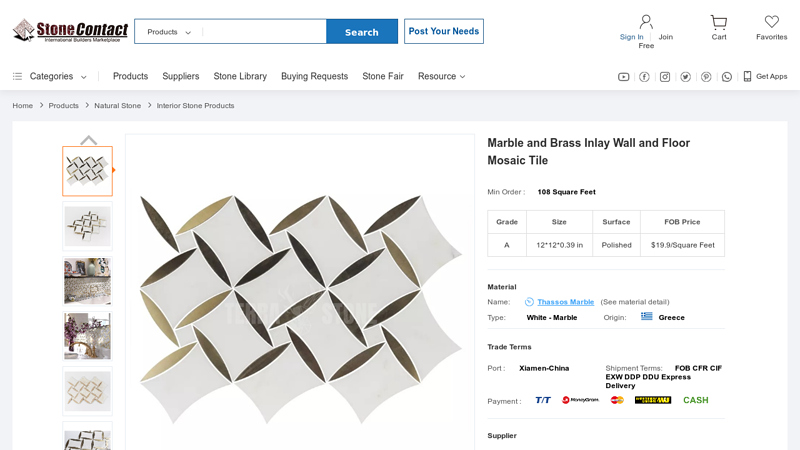

#3 Marble And Brass Inlay Wall And Floor Mosaic Tile from China

Domain Est. 2003

Website: stonecontact.com

Key Highlights: Marble And Brass Inlay Wall And Floor Mosaic Tile from China, The details include pictures,sizes,color,material and origin.You can contact the supplier ……

#4 3 <3 <3 Inlay Brass Tile <3 <3 <3

Domain Est. 2008

Website: tempesttileworks.com

Key Highlights: KAVIM from Tabarka Studio is a line brass inlay cement tile, inspired by Architect Luis Barragán. Sublte pink, green, grey and ……

#5 Brass Inlay Tile

Domain Est. 2012

Expert Sourcing Insights for Brass Inlay Tile

2026 Market Trends for Brass Inlay Tile

Rising Demand for Artisanal and Handcrafted Aesthetics

By 2026, Brass Inlay Tile is expected to see increased demand driven by a growing consumer preference for artisanal, handcrafted design elements. Homeowners and designers are increasingly valuing unique, one-of-a-kind finishes that reflect craftsmanship and cultural heritage. Brass inlay tiles, often handmade using traditional techniques, align with this trend toward authenticity and personalized interiors, particularly in high-end residential and boutique commercial spaces.

Expansion in Luxury Residential and Hospitality Sectors

The luxury real estate and hospitality markets are projected to be major growth drivers for Brass Inlay Tile. As developers and designers seek distinctive finishes to differentiate premium properties, brass inlay tiles offer a sophisticated blend of elegance and durability. Their use in feature walls, bathrooms, entryways, and custom flooring is expected to expand in luxury hotels, villas, and high-end urban lofts, especially in regions like North America, the Middle East, and Southeast Asia.

Integration with Biophilic and Warm Minimalist Design

Brass Inlay Tile is poised to gain traction within the biophilic design and warm minimalist movements. The natural warmth of brass complements organic materials like wood, stone, and terracotta, supporting a design ethos that emphasizes comfort and tactile richness. In 2026, expect to see these tiles used in spaces designed to foster well-being, combining metallic accents with neutral palettes and natural textures to create inviting, serene environments.

Increased Focus on Sustainability and Ethical Sourcing

Sustainability will play a critical role in the Brass Inlay Tile market by 2026. Consumers and specifiers are demanding transparency in material sourcing and production methods. Manufacturers are responding by adopting recycled brass, low-impact enameling processes, and ethical labor practices. Certifications and eco-labels are likely to become key differentiators, influencing purchasing decisions in both residential and commercial projects.

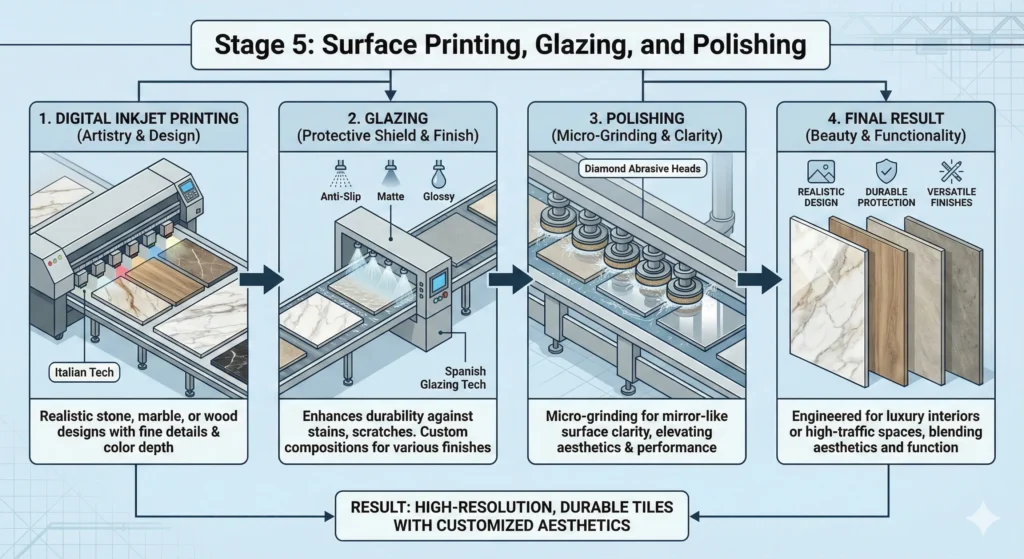

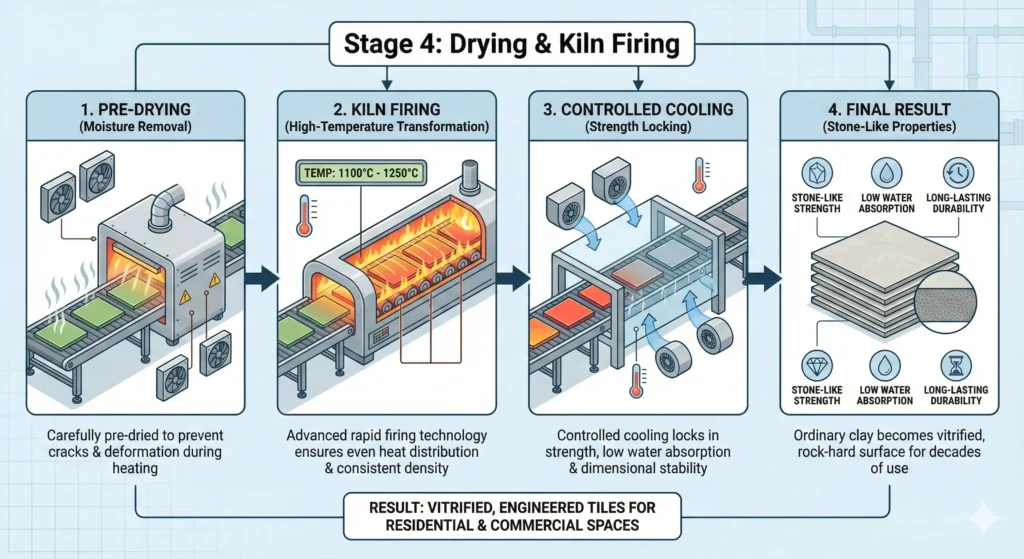

Technological Advancements in Production and Finishes

Advances in fabrication technology will enhance the accessibility and versatility of Brass Inlay Tile. Digital templating, precision laser cutting, and improved bonding techniques allow for more intricate patterns and greater design flexibility. Additionally, innovations in protective coatings will improve tarnish resistance and ease of maintenance, making brass inlay more practical for high-traffic areas and humid environments such as kitchens and bathrooms.

Geographic Market Growth and E-commerce Expansion

While traditional hubs like India and Italy remain strong producers, emerging markets in the Middle East and Southeast Asia are expected to drive regional demand. Simultaneously, e-commerce platforms will play a larger role in distribution, enabling global reach for niche tile makers. Online visualization tools and augmented reality (AR) will allow customers to preview Brass Inlay Tile installations, accelerating adoption beyond local design markets.

Design Customization and Personalization Trends

By 2026, customization will be a major trend, with clients seeking bespoke patterns, sizes, and brass finishes—ranging from polished gold to aged patina. Digital design tools will empower architects and homeowners to co-create unique tile layouts, integrating personal motifs or cultural symbols. This shift toward personalization will position Brass Inlay Tile as a premium, expressive design medium rather than a standard surfacing option.

Common Pitfalls When Sourcing Brass Inlay Tile (Quality, IP)

Sourcing brass inlay tiles can elevate a design, but several pitfalls—particularly related to quality and intellectual property (IP)—can lead to costly issues if not carefully managed.

Inconsistent Material Quality and Craftsmanship

Brass inlay tiles often vary significantly in quality due to differences in brass alloy composition, plating thickness, and artisan techniques. Low-quality tiles may use thin or impure brass that tarnishes quickly, chips easily, or lacks luster. Inconsistent inlay precision can result in misaligned patterns or uneven surfaces, compromising both aesthetics and durability.

Poor Adhesion and Structural Integrity

A common issue is inadequate bonding between the brass inlay and the base tile (often marble, ceramic, or stone). Inferior adhesives or improper setting techniques can lead to delamination over time, especially in high-moisture or high-traffic areas, resulting in safety hazards and costly repairs.

Misleading Brass Content and Plating Claims

Some suppliers market tiles as “solid brass inlay” when they actually use brass-plated base metals or minimal brass overlay. This misrepresentation can affect longevity and maintenance requirements. Buyers should verify material specifications and request third-party material certifications.

Lack of Quality Control in Artisan Production

Many brass inlay tiles are handcrafted, increasing the risk of inconsistencies in pattern alignment, finish, and dimensions. Without stringent quality control, batches may vary, making large installations difficult to execute seamlessly.

Intellectual Property (IP) Infringement Risks

Designs featuring intricate patterns or artistic motifs may be protected by copyright or design patents. Sourcing tiles that replicate proprietary designs—even unintentionally—can expose architects, designers, or developers to legal liability. Always confirm that the supplier owns or has licensed the right to produce and sell the design.

Inadequate Documentation for IP Clearance

Suppliers may not provide documentation proving design ownership or licensing. Relying solely on verbal assurances increases legal risk. Insist on written confirmation of IP rights, especially for custom or branded patterns.

Supply Chain Opacity and Ethical Concerns

Limited visibility into manufacturing origins can hide unethical labor practices or environmentally harmful processes. This not only poses reputational risk but may also affect compliance with green building standards or corporate social responsibility policies.

Failure to Request Samples and Conduct Site Testing

Skipping physical sample evaluation often leads to disappointment. Color, sheen, texture, and inlay depth can appear drastically different in real-world lighting and settings. Always test samples for durability, wear, and maintenance needs before bulk ordering.

Avoiding these pitfalls requires due diligence: vet suppliers thoroughly, demand material and IP documentation, inspect samples rigorously, and consider engaging legal or materials experts when sourcing high-value or custom brass inlay tiles.

Logistics & Compliance Guide for Brass Inlay Tile

Product Classification & Harmonized System (HS) Code

Brass Inlay Tiles are typically classified under HS Code 6907.90, which covers “Ceramic flagstones and paving blocks, bricks, roofing tiles and other ceramic construction items, whether or not glazed or decorated, other than of refractory materials.” However, due to the brass inlay, customs authorities may request additional documentation to confirm classification. Always verify with local customs or a licensed customs broker, as classifications can vary by country based on composition (ceramic vs. metal content).

Import/Export Documentation Requirements

Essential documents for international shipment include:

– Commercial Invoice (detailing product description, value, quantity, and Incoterms)

– Packing List (specifying weight, dimensions, and packaging type)

– Bill of Lading or Air Waybill

– Certificate of Origin (required by many countries for tariff assessment)

– Import/Export License (if applicable per country regulations)

For U.S. imports, a customs bond and entry filing via the Automated Commercial Environment (ACE) system are required.

Packaging & Handling Specifications

Brass Inlay Tiles must be securely packed to prevent damage during transit:

– Use sturdy, moisture-resistant corrugated cardboard boxes with internal dividers or foam padding.

– Stack tiles flat with protective spacers between layers to avoid scratching.

– Seal boxes with reinforced tape and label with “Fragile,” “This Side Up,” and handling instructions.

– Palletize shipments using stretch wrap and corner boards; use wooden or plastic pallets meeting ISPM 15 standards for international shipping.

– Avoid exposure to extreme temperatures and humidity during storage and transit.

Transportation & Freight Considerations

- Ocean freight is cost-effective for large volumes; use dry container shipping with desiccant bags to control moisture.

- Air freight is recommended for urgent or smaller shipments due to faster delivery and reduced handling risk.

- Ensure proper insurance coverage for high-value or fragile cargo.

- Confirm carrier experience with fragile or decorative building materials.

- For EU and U.S. shipments, comply with carrier-specific requirements for oversized or heavy packages.

Regulatory & Environmental Compliance

- REACH (EU): Comply with Registration, Evaluation, Authorization, and Restriction of Chemicals regulations. Verify that brass components do not contain restricted substances (e.g., lead or cadmium above permitted levels).

- RoHS (EU): Although primarily for electronics, ensure no hazardous substances are present if tiles incorporate electrical elements.

- TSCA (U.S.): Comply with Toxic Substances Control Act; confirm brass alloys meet applicable standards.

- CITES: Not typically applicable, but confirm if any organic inlays (e.g., wood or shell) are used.

- LEED & Green Building Standards: Provide product documentation (e.g., EPD or HPD) if marketing for sustainable construction projects.

Country-Specific Import Regulations

- United States: Subject to potential Section 301 tariffs on Chinese-origin goods. Confirm country of manufacture and consult U.S. Customs and Border Protection (CBP).

- European Union: Must comply with CE marking requirements for construction products (e.g., EN 14411 for ceramic tiles) if sold as building materials.

- United Kingdom: Requires UKCA marking post-Brexit; provide conformity documentation.

- Australia/New Zealand: Comply with AS/NZS 4459 standards for tile performance and slip resistance.

- Middle East (e.g., UAE, Saudi Arabia): May require SASO or ECAS certification; verify labeling in Arabic.

Labeling & Marking Requirements

- Clearly label each package with:

- Product name (“Brass Inlay Tile”)

- Quantity per box

- Net and gross weight

- Dimensions (L x W x H)

- Manufacturer and importer contact details

- Country of origin

- Handling symbols (fragile, moisture-sensitive)

- Include bilingual labeling if required (e.g., French in Canada, Arabic in Gulf countries).

Quality Control & Inspection Protocols

- Conduct pre-shipment inspections to verify:

- Tile dimensions, color consistency, and inlay alignment

- Absence of cracks, chips, or surface defects

- Packaging integrity

- Third-party inspection services (e.g., SGS, Bureau Veritas) recommended for bulk orders.

- Retain samples from each batch for compliance traceability.

Duty, Taxes, and Tariff Information

- Import duties vary by destination country and HS code classification. For example:

- U.S.: Typically 4–6% duty on ceramic tiles, but subject to anti-dumping or countervailing duties depending on origin.

- EU: Common Customs Tariff rates around 4–6% for ceramic tiles.

- VAT or GST applies upon import (e.g., 20% in UK, 10% in Japan).

- Use a customs broker to calculate landed costs accurately, including duties, taxes, and fees.

Sustainability & Disposal Compliance

- Brass is recyclable; provide end-of-life guidance to customers.

- Packaging should use recyclable materials; avoid non-compostable plastics where possible.

- Comply with WEEE or similar directives only if tiles contain electronic components.

- Document environmental attributes to support green procurement initiatives.

Always consult with legal, customs, and logistics professionals to ensure full compliance with evolving international trade regulations.

In conclusion, sourcing brass inlay tiles requires careful consideration of quality, design, supplier reliability, and cost. These tiles offer a unique blend of elegance and durability, making them ideal for high-end architectural and interior design applications. To ensure a successful procurement process, it is essential to work with reputable suppliers who provide authentic materials, consistent craftsmanship, and transparent sourcing practices. Evaluating samples, verifying material composition, and confirming lead times and customization options are crucial steps. Additionally, considering sustainability and ethical sourcing can enhance the long-term value of the project. With thorough research and strategic vendor selection, brass inlay tiles can be sourced effectively to achieve both aesthetic excellence and functional longevity in any design application.