The global brass metal market is experiencing steady expansion, driven by growing demand across industrial, architectural, and consumer goods sectors. According to a 2023 report by Mordor Intelligence, the global brass market was valued at USD 68.7 billion in 2022 and is projected to grow at a CAGR of 4.2% from 2023 to 2028. This growth is fueled by increasing applications in plumbing, electrical components, and decorative hardware, where brass-colored metals are favored for their durability, corrosion resistance, and aesthetic appeal. Additionally, Grand View Research highlights the rising demand in emerging economies, particularly in Asia-Pacific, due to rapid urbanization and infrastructure development. As manufacturers continue to innovate with lead-free and high-performance brass alloys, competition among key players intensifies. Below, we spotlight the top 10 brass-colored metal manufacturers leading this dynamic market with strong production capabilities, global reach, and technological advancements.

Top 10 Brass Colored Metal Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

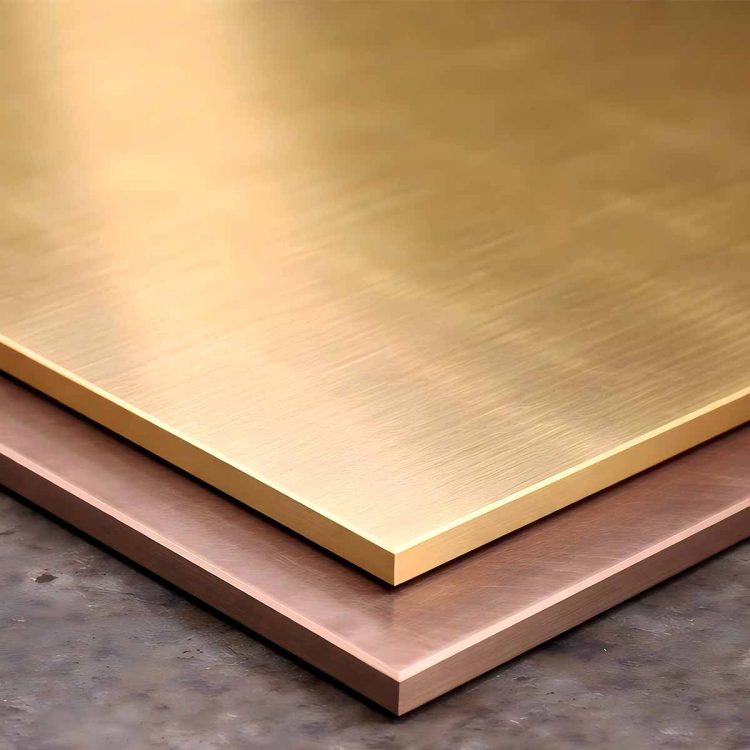

#1 Brass Sheet Metal

Domain Est. 1998

Website: polishedmetals.com

Key Highlights: Brass, or Yellow Brass as it is often referred to, is a copper alloy composed of 70% copper and 30% zinc. It has a bright yellowish or light gold color, ……

#2 Brass & Copper Metal Products

Domain Est. 1999

Website: industrialmetalsupply.com

Key Highlights: Industrial Metal Supply stocks brass in several forms including sheet, plate, bar, full sizes, pre-cuts, and decorative brass railing from Lavi Industries….

#3 Finkelstein Metals: High

Domain Est. 2006

Website: finkelstein-metals.com

Key Highlights: Finkelstein Metals is a leading manufacturer of extruded non-ferrous metals, specializing in brass and aluminum bronze alloys. Over 85 years of experience ……

#4 Krupalu Metals Ltd

Domain Est. 2013

Website: krupalumetals.com

Key Highlights: Welcome to Krupalu Metals Ltd, your trusted partner in manufacturing and supplying high-quality brass and metal products. We specialize in brass sheets, ……

#5 Aviva Metals

Domain Est. 2017

Website: avivametals.com

Key Highlights: Aviva Metals is the leading manufacturer of bronze, brass & copper alloys. We keep a ready stock of of these metals in a variety of shapes & sizes….

#6 Brass, Red Brass|Copper & Copper Alloy Business Unit …

Domain Est. 2020

Website: mitsubishi-copper.com

Key Highlights: Brass is an alloy of copper and zinc. It has relatively high conductivity compared with other alloys, and has strength compared with pure copper….

#7 Fabricated Brass

Domain Est. 1996

Website: steelartco.com

Key Highlights: Brass is an excellent choice for indoor or outdoor signage. Brass provides a distinguished, yellow gold-like appearance and virtually any finish looks beautiful ……

#8 Lewis Brass

Domain Est. 1998

Website: lewisbrass.com

Key Highlights: Over 60 years of experience in brass tubing and alloy supply · Over 1 million pounds of metal materials in stock, ready to order from our New York City warehouse….

#9 Brass Supplier

Domain Est. 1998

Website: sequoia-brass-copper.com

Key Highlights: Sequoia Brass & Copper has over 40 years of experience as a trusted supplier of high-quality nonferrous metals. Learn more about our brass offerings….

#10 Brass Supplier

Domain Est. 1999

Website: meadmetals.com

Key Highlights: We carry brass in a range of sizes and tempers. Available in sheets and coils. Request a quick quote for more details on inventory and availability….

Expert Sourcing Insights for Brass Colored Metal

2026 Market Trends for Brass-Colored Metal

Rising Demand in Sustainable and Biophilic Design

By 2026, brass-colored metal is expected to see increased adoption in architectural and interior applications driven by the growing emphasis on sustainability and biophilic design. As consumers and designers prioritize natural aesthetics that mimic organic materials, brass finishes—particularly those evoking aged or weathered brass—will be favored for their warmth and connection to natural elements. Advances in eco-friendly plating and coating technologies, such as PVD (Physical Vapor Deposition) with low environmental impact, will enable brass-colored finishes to align with green building standards like LEED and WELL, boosting their appeal in residential, commercial, and hospitality sectors.

Growth in Decorative Hardware and Consumer Electronics

The decorative hardware market—including faucets, door handles, lighting fixtures, and furniture accents—will remain a dominant application area for brass-colored metal finishes. By 2026, demand will be fueled by a resurgence of vintage and industrial design styles, where brass tones add elegance and timelessness. Concurrently, consumer electronics manufacturers are increasingly using brass-colored PVD coatings on premium devices (e.g., smartphones, wearables, audio equipment) to differentiate products with luxurious aesthetics. This crossover into tech will expand the market beyond traditional industries, driven by consumer appetite for premium, tactile finishes.

Shift Toward Alternative Materials and Cost-Efficient Finishes

Despite its appeal, rising base metal costs and supply chain volatility for copper and zinc (key brass components) will push manufacturers toward brass-colored alternatives. In 2026, expect increased use of aluminum, zinc alloys, or stainless steel substrates with advanced brass-tone coatings that mimic the visual appeal of real brass at a lower cost and with improved corrosion resistance. These engineered solutions will dominate mid-to-high-end markets, especially in regions where cost sensitivity and durability are paramount, such as emerging economies and large-scale construction projects.

Regional Market Diversification and E-Commerce Influence

Asia-Pacific, particularly China and India, will lead growth in brass-colored metal demand due to rapid urbanization and expanding middle-class consumption. Meanwhile, North America and Europe will focus on high-end, artisanal, and restoration applications, supported by stringent environmental regulations shaping production methods. E-commerce platforms will play a pivotal role by offering broader access to niche finishes and custom brass-colored products, enabling small designers and DIY consumers to influence market trends and drive demand for personalized, on-trend finishes.

Technological Innovation in Coating and Recycling

By 2026, advancements in nanocoatings and digital printing on metals will allow for more durable, customizable brass finishes with enhanced resistance to tarnishing and fingerprints—critical for high-traffic environments. Parallel progress in metal recycling technologies will support a circular economy model, with greater recovery and reuse of brass-colored scrap materials. This sustainability angle will become a key marketing point, especially among environmentally conscious brands and B2B clients committed to reducing their carbon footprint.

Common Pitfalls When Sourcing Brass-Colored Metal (Quality, IP)

Sourcing brass-colored metal components, especially when appearance and durability are critical, involves several potential pitfalls related to quality and surface finish integrity (such as Ion Plating or other PVD coatings). Being aware of these common issues helps ensure reliable supply and consistent product performance.

Inconsistent Coating Quality and Adhesion

One of the most frequent issues is variability in the thickness, uniformity, and adhesion of the brass-colored coating—especially when using Ion Plating (IP) or PVD techniques. Poor process control during coating can lead to flaking, peeling, or uneven color, particularly on complex geometries or sharp edges. Suppliers with inadequate quality assurance may ship batches that fail salt spray or abrasion tests.

Misrepresentation of Base Material

Suppliers may claim a high-quality base metal (e.g., zinc alloy, stainless steel) but deliver lower-grade materials such as low-density zamak or recycled alloys. This affects both mechanical strength and coating performance. A weak or porous substrate can compromise the adhesion of the IP coating and lead to premature failure under stress or environmental exposure.

Inadequate Corrosion Resistance

Even with a brass-colored IP finish, poor pre-treatment or substandard coating can result in premature corrosion. Components may fail salt spray tests far earlier than specified (e.g., <24 hours vs. required 48+ hours). This is often due to insufficient layer density, pinholes, or inadequate sealing of the coating.

Color and Gloss Variation Between Batches

Brass color is highly sensitive to coating parameters such as gas mix, temperature, and deposition time. Without strict process controls, color (hue, tone) and gloss levels can vary significantly between production runs. This is problematic for brands requiring consistent aesthetics across product lines or over time.

Lack of IP Process Certification or Traceability

Some suppliers claim to use Ion Plating but may use cheaper alternatives like electroplating or wet painting with a brass-like finish. Without proper documentation, material certifications, or access to process audits, buyers risk receiving non-compliant parts that don’t meet durability or environmental standards (e.g., RoHS, REACH).

Poor Edge Coverage and Coverage on Complex Geometries

IP coatings are line-of-sight processes, making full coverage on internal cavities, undercuts, or sharp edges challenging. Inexperienced coaters may not optimize fixturing or rotation, leading to thin or absent coating in critical areas—increasing the risk of corrosion and wear.

Unverified Durability and Wear Performance

Many suppliers provide optimistic performance claims without third-party testing. Without verified data on abrasion resistance (e.g., Taber test), scratch resistance, or long-term UV stability, the brass finish may degrade quickly in real-world use, especially in high-touch applications.

Cost-Cutting Leading to Short-Term Failures

To offer lower prices, some suppliers reduce coating cycles, skip pre-treatment steps, or use thinner layers. While initial appearance may be acceptable, the reduced coating lifespan leads to customer complaints and product returns after only months of use.

Avoiding these pitfalls requires thorough supplier vetting, clear technical specifications, batch testing, and ongoing quality monitoring. Prioritizing certified processes and transparency ensures durable, visually consistent brass-colored metal components.

Logistics & Compliance Guide for Brass Colored Metal

Overview of Brass Colored Metal

Brass colored metal typically refers to metal surfaces that have a brass-like appearance, either through the use of actual brass alloys or through surface treatments such as plating, coating, or PVD (Physical Vapor Deposition) on base metals like steel, zinc, or aluminum. While not always solid brass, these materials must still comply with various international regulations regarding material composition, environmental impact, and safe handling during logistics.

Material Classification and Identification

Proper classification is essential for regulatory compliance and efficient logistics. Brass colored metal should be identified based on:

– Base material (e.g., steel, aluminum, zinc alloy)

– Surface treatment (e.g., brass electroplating, brass-tone powder coating, PVD finish)

– Intended application (consumer goods, construction, automotive, etc.)

This information determines applicable HS codes, safety data sheets (SDS), and transportation requirements.

International Shipping and Customs Compliance

When shipping brass colored metal products internationally:

– Assign the correct Harmonized System (HS) code. Common codes include:

– 7418.10: Table, kitchen or other household articles of brass

– 8302.50: Base metal mountings, fittings, and similar articles with brass plating

– 7407.10: Bars, rods, and profiles of brass (if solid brass)

– Provide accurate commercial invoices, packing lists, and certificates of origin.

– Declare any coatings or plating that may contain regulated substances (e.g., hexavalent chromium in some plating processes).

Environmental and Chemical Regulations

Brass colored metal products may be subject to chemical compliance standards:

– REACH (EU): Regulates substances of very high concern (SVHC). Monitor for restricted substances such as lead, nickel, and certain chromium compounds used in plating.

– RoHS (EU): Applies to electrical/electronic components. Limits lead, cadmium, and other hazardous substances. Brass alloys may contain lead; ensure compliance if used in applicable products.

– Proposition 65 (California, USA): Requires warnings if products expose users to lead or nickel, common in brass alloys and plating.

– TSCA (USA): Ensure compliance with toxic substances regulations, particularly if importing into the U.S.

Packaging and Handling Requirements

To prevent damage and ensure safety:

– Use anti-corrosion packaging (e.g., VCI paper) for plated or coated items to prevent tarnishing.

– Secure items to prevent scratching or abrasion during transit.

– Label packages with handling instructions (e.g., “Fragile,” “Do Not Stack,” “Protect from Moisture”).

– For bulk shipments, use pallets with edge protectors and shrink wrap.

Transportation Mode Considerations

- Air Freight: Subject to IATA Dangerous Goods Regulations if packaging includes desiccants or aerosols. Most brass colored metals are non-hazardous but verify coating materials.

- Ocean Freight: Use moisture-resistant packaging to prevent saltwater corrosion. Monitor container humidity.

- Ground Transport: Comply with ADR (Europe) or DOT (USA) regulations if transporting large volumes or if packaging includes regulated materials.

Import and Export Documentation

Ensure all shipments include:

– Commercial invoice with detailed product description, material composition, and value

– Packing list

– Bill of Lading or Air Waybill

– Certificate of Origin (especially for preferential tariffs)

– SDS (Safety Data Sheet) if required by destination country or carrier

– Test reports for compliance with REACH, RoHS, or other standards if requested

End-of-Life and Recycling Compliance

Brass colored metal products must comply with waste directives:

– WEEE (EU): Applies if part of electrical/electronic equipment. Requires proper take-back and recycling.

– ELV (End-of-Life Vehicles): For automotive applications, ensure materials are recyclable and free from banned substances.

– Clearly label recyclability where applicable, and design for disassembly when possible.

Summary and Best Practices

- Accurately identify the base and surface materials.

- Maintain up-to-date compliance documentation.

- Partner with certified suppliers who provide material declarations.

- Regularly audit supply chain for regulatory updates.

- Train logistics staff on proper handling and documentation requirements.

Adhering to this guide ensures smooth international logistics and compliance with global environmental and safety standards for brass colored metal products.

In conclusion, sourcing brass-colored metal requires a careful balance between aesthetic requirements, material performance, and cost-effectiveness. While actual brass offers an authentic finish and excellent workability, alternatives such as brass-plated steel, bronze, or aluminum with brass-colored powder coating or PVD finishes can provide similar visual appeal with enhanced durability or reduced cost. Key considerations include the intended application, environmental exposure, longevity requirements, and compliance with industry standards. Establishing reliable suppliers, verifying material certifications, and conducting sample testing ensure consistency and quality in the final product. Ultimately, the choice depends on project-specific needs, with brass-colored coatings or alloys often offering a practical and visually appealing solution when solid brass is not economically or functionally viable.