The global automotive brake system market is experiencing robust growth, driven by increasing vehicle production, rising safety regulations, and a growing emphasis on enhanced braking performance. According to a report by Mordor Intelligence, the automotive brakes market was valued at USD 28.5 billion in 2023 and is projected to grow at a CAGR of over 5.2% from 2024 to 2029. A critical yet often overlooked component within this system is the brake pedal bushing, which ensures smooth pedal operation, reduces noise, and extends the lifespan of braking components. With demand for precision-engineered, durable bushings rising in both OEM and aftermarket segments, manufacturers are investing heavily in advanced materials and production technologies. As the shift toward electric and lightweight vehicles accelerates, the need for high-performance brake pedal bushings has become more pronounced. Here’s a data-driven look at the top 9 brake pedal bushing manufacturers shaping this evolving landscape.

Top 9 Brake Pedal Bushing Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 Pedal Bushings

Domain Est. 2000

Website: bimmerforums.com

Key Highlights: Brand new clutch pedal w/delrin bushings, springs etc.. Brake pedal with oem plastic split bushing. Last edited by bmwstephen; 01-11-2025 at ……

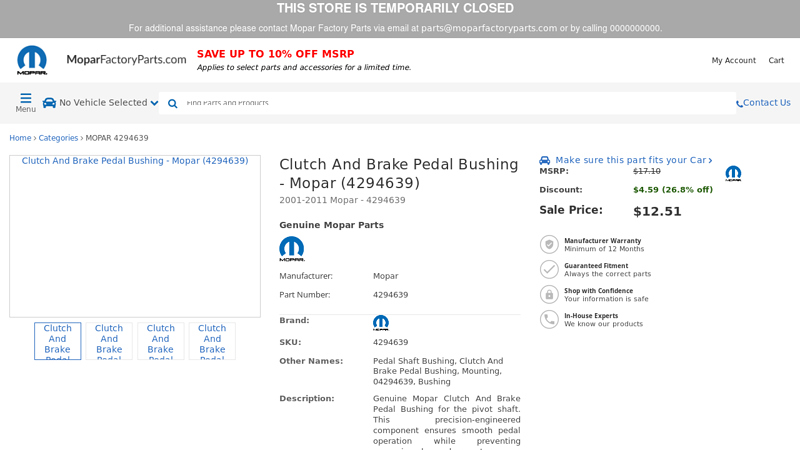

#2 Clutch And Brake Pedal Bushing

Domain Est. 2013

Website: moparfactoryparts.com

Key Highlights: 4–8 day delivery 30-day returnsYour Clutch And Brake Pedal Bushing will specifically fit your 2001-2011 vehicle. Affordable, reliable and built to last, OEM Mopar parts stand out a…

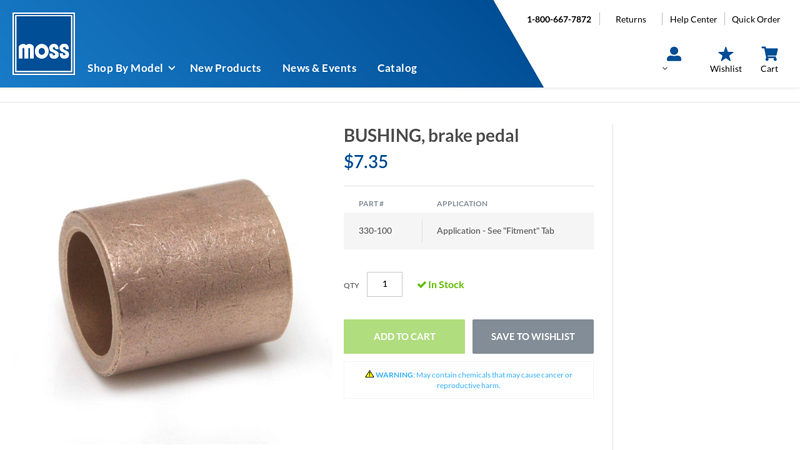

#3 BUSHING, brake pedal

Domain Est. 1996

#4 OER K1448 4 Piece Nylon Brake/Clutch Pedal Bushing Set

Domain Est. 1996

Website: speedwaymotors.com

Key Highlights: Out of stock Rating 4.6 10 OER K1448 4 Piece Nylon Brake/Clutch Pedal Bushing Set made by OER, for as low as $6.49. Order ships free when this item is included and exceeds $175….

#5 Brake & Clutch Pedal Bushing

Domain Est. 1997

Website: dennis-carpenter.com

Key Highlights: 3–9 day delivery 30-day returnsBrake / Clutch Pedal Bushing – 1967-79 Ford Truck, 1966-79 Ford Bronco, 1957-72 Ford Car. Part #: B7AZ-2471-A (1 , Write Review). FLAT RATE SHIPPING …

#6 Brake Pedal Bushing

Domain Est. 2001

Website: dormanproducts.com

Key Highlights: This brake pedal bushing is designed to match the fit and function of the original part on specified vehicles. Made of quality materials….

#7 Brake Pedal Bushing.

Domain Est. 2002

Website: us.sparex.com

Key Highlights: 30-day returnsSuitable For Make/Model · Allis Chalmers. 5040, 5045, 5050 · Fiat. 450, 480, 500, 540, 550, 600, 640 · Ford / New Holland. 3010, 3010S, 4010S, 5010, 5010S, TT50, ……

#8 Bronze Clutch & Brake Pedal Bushings (Fits most BMW

Domain Est. 2011

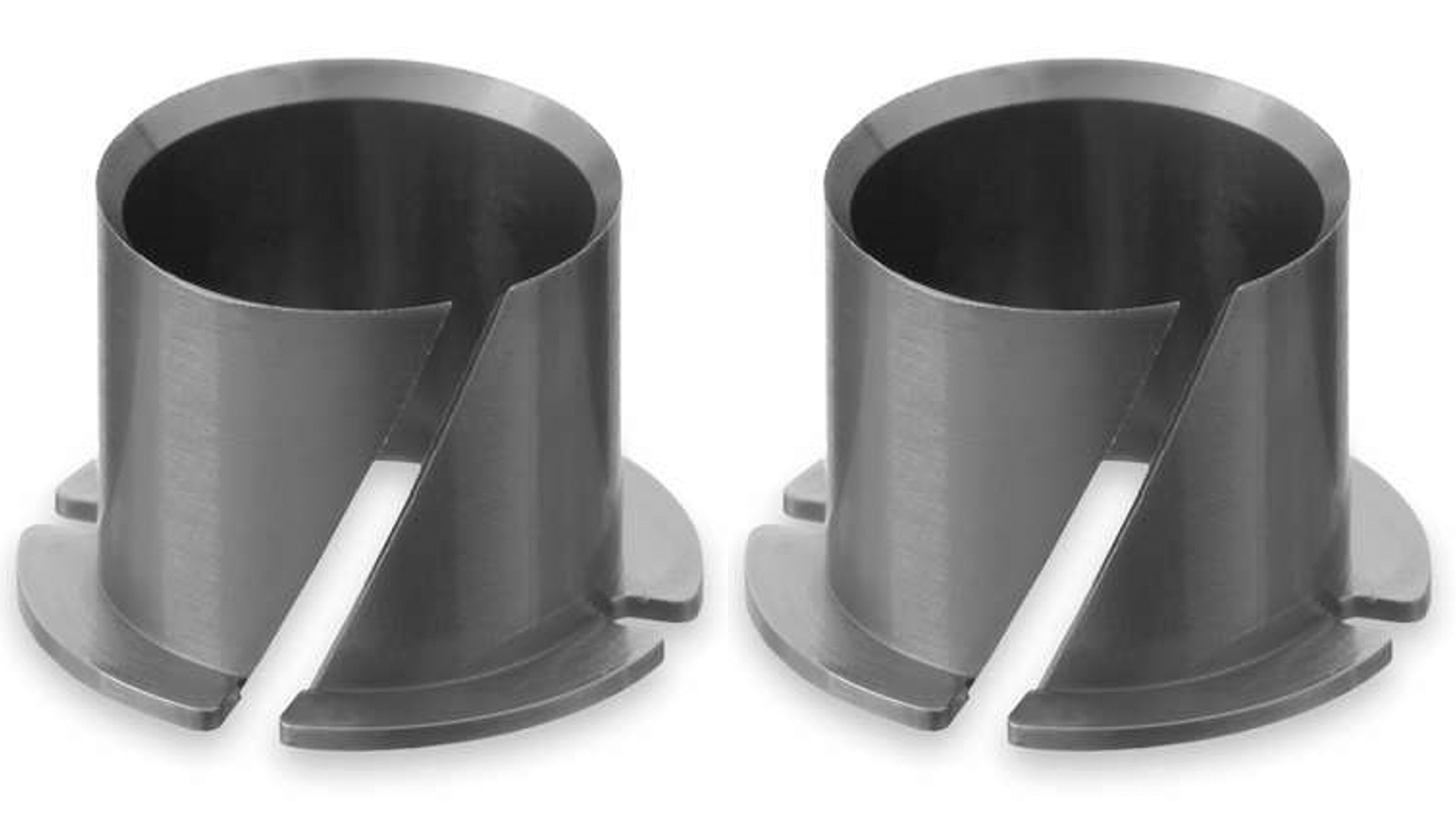

#9 Brake/Clutch Pedal Bushings 2

Domain Est. 2018

Expert Sourcing Insights for Brake Pedal Bushing

H2: 2026 Market Trends for Brake Pedal Bushing

The global brake pedal bushing market is expected to undergo notable shifts by 2026, driven by advancements in automotive technology, evolving regulatory standards, and changing consumer demand. As a critical component in the vehicle braking system, brake pedal bushings contribute to pedal feel, noise reduction, and overall safety. The following trends are projected to shape the market landscape in 2026:

1. Increased Demand from Electric Vehicles (EVs)

With the rapid expansion of the electric vehicle sector, brake pedal bushings are adapting to new braking system designs, including regenerative braking. While EVs use less traditional friction braking, the need for optimized pedal feedback and NVH (noise, vibration, harshness) control remains critical. This is creating demand for high-performance bushings made from advanced elastomers and composite materials tailored for EV applications.

2. Shift Toward Lightweight and Durable Materials

Automotive manufacturers are prioritizing weight reduction to improve fuel efficiency and extend EV range. As a result, brake pedal bushings are increasingly fabricated using lightweight polymers, thermoplastic elastomers (TPE), and self-lubricating composites. These materials offer improved durability, corrosion resistance, and reduced maintenance compared to traditional rubber or metal bushings.

3. Stringent Safety and Noise Regulations

Global safety standards, such as those from Euro NCAP and NHTSA, continue to emphasize driver comfort and system reliability. This is pushing OEMs to adopt bushings that minimize pedal noise and ensure consistent performance over time. Suppliers are responding with precision-engineered solutions that meet tighter tolerances and longer lifespan requirements.

4. Growth in Aftermarket Replacement Demand

As the global vehicle parc ages, especially in emerging markets, the aftermarket for brake system components—including pedal bushings—is expanding. Worn bushings can lead to spongy pedal feel or excessive play, driving consumer awareness and replacement demand. Online distribution channels and e-commerce platforms are making replacement parts more accessible, further boosting aftermarket growth.

5. Regional Market Dynamics

Asia-Pacific, led by China, India, and Japan, is expected to dominate the brake pedal bushing market in 2026 due to high vehicle production volumes and a growing middle class. Meanwhile, North America and Europe will see steady growth, primarily driven by EV adoption and vehicle electrification programs. Localized manufacturing and supply chain resilience are becoming strategic priorities for key players.

6. Technological Integration and Smart Diagnostics

While still in early stages, there is growing interest in integrating sensor technologies into brake system components. Future iterations of brake pedal bushings may include embedded wear indicators or materials with self-diagnostics capabilities, especially in premium and autonomous vehicle segments.

In summary, the 2026 brake pedal bushing market will be shaped by the convergence of electrification, material innovation, and regulatory pressures. Suppliers that invest in R&D, sustainability, and agile manufacturing will be best positioned to capture emerging opportunities across both OEM and aftermarket channels.

Common Pitfalls Sourcing Brake Pedal Bushing (Quality, IP)

Sourcing brake pedal bushings requires careful attention to both quality and intellectual property (IP) considerations. Overlooking these aspects can lead to safety risks, supply chain disruptions, legal issues, and reputational damage. Below are key pitfalls to avoid:

Poor Material and Manufacturing Quality

Using substandard materials or inadequate manufacturing processes can compromise the functionality and safety of brake pedal bushings. Low-quality bushings may degrade prematurely, leading to excessive pedal play, inconsistent brake response, or even failure under stress. Sourcing from suppliers without proper quality certifications (e.g., IATF 16949) increases the risk of receiving non-conforming parts.

Lack of Dimensional Accuracy and Fit

Brake pedal bushings must meet tight tolerances to ensure proper fit and function within the pedal assembly. Inaccurate dimensions can cause misalignment, accelerated wear, noise (squeaking or rattling), and reduced pedal feel. Sourcing from suppliers without robust quality control and measurement systems often results in inconsistent part-to-part variance.

Inadequate Testing and Validation

Bushing performance under real-world conditions—such as temperature extremes, humidity, and mechanical stress—must be validated. Suppliers that skip or minimize environmental and durability testing (e.g., compression set, elongation, fatigue testing) may deliver bushings prone to cracking, hardening, or deformation over time, compromising brake system reliability.

Non-Compliance with OEM Specifications

Many brake pedal bushings are engineered to meet specific OEM (Original Equipment Manufacturer) requirements. Sourcing generic or non-OEM-compliant parts risks incompatibility and failure to meet performance standards. Always verify that the supplier adheres to the technical specifications, material grades, and performance criteria defined by the OEM.

Intellectual Property (IP) Infringement

Sourcing bushings that replicate patented designs or trademarks without authorization exposes buyers to legal liability. Many OEM and Tier 1 designs are protected by IP rights. Procuring counterfeit or reverse-engineered bushings—especially from unverified suppliers—can result in cease-and-desist orders, fines, or product recalls.

Unclear or Missing Documentation

Lack of proper documentation, such as material certifications (e.g., RoHS, REACH), test reports, traceability records, and IP disclaimers, increases risk. Without these, it’s difficult to verify compliance, ensure batch traceability, or defend against liability claims in case of failure.

Overreliance on Low-Cost Suppliers Without Due Diligence

While cost is a factor, selecting suppliers solely on price often leads to compromised quality and IP risks. Suppliers offering unusually low prices may cut corners on materials, testing, or legal compliance. Conduct thorough due diligence, including factory audits and sample validation, before committing to a supplier.

Failure to Secure IP Rights in Contracts

Even when sourcing custom-designed bushings, failing to include clear IP clauses in procurement contracts can lead to disputes. Ensure contracts explicitly state that tooling rights, design ownership, and usage rights belong to the buyer or are properly licensed to avoid future legal complications.

Mitigating these pitfalls requires a proactive sourcing strategy that emphasizes supplier qualification, technical validation, compliance verification, and legal diligence—ensuring both performance reliability and IP safety.

Logistics & Compliance Guide for Brake Pedal Bushing

This guide outlines the essential logistics and compliance considerations for the handling, transportation, and regulatory adherence of Brake Pedal Bushings throughout the supply chain.

Product Classification and HS Code

Brake Pedal Bushings are typically classified under automotive spare parts or suspension/steering components. The appropriate Harmonized System (HS) code may vary by country but commonly falls under:

- HS Code Example: 8708.29 (Parts and accessories of braking systems for motor vehicles)

Always verify the exact HS code with local customs authorities, as misclassification can result in delays, fines, or incorrect duty assessments.

Packaging and Labeling Requirements

- Packaging: Brake Pedal Bushings must be packaged to prevent damage during transit. Use moisture-resistant, shock-absorbent materials (e.g., bubble wrap, foam inserts) within sturdy corrugated cardboard or plastic containers.

- Labeling: Each package must include:

- Part number and description

- Quantity

- Manufacturer name and country of origin

- Batch/lot number (for traceability)

- Handling symbols (e.g., “Fragile,” “Do Not Stack”)

- Barcodes or QR codes if required by the customer

Ensure compliance with international labeling standards (e.g., ISO 780 for packaging symbols).

Transportation and Handling

- Mode of Transport: Suitable for road, air, and sea freight. For air transport, ensure packaging meets IATA regulations for weight and dimensions.

- Handling: Avoid exposure to extreme temperatures, moisture, and direct sunlight. Use pallets for bulk shipments and secure loads to prevent shifting.

- Storage: Store in a dry, temperature-controlled environment (15–25°C recommended). Keep away from chemicals and oils that could degrade rubber or polymer components.

Import/Export Documentation

Mandatory documentation includes:

– Commercial Invoice

– Packing List

– Bill of Lading or Air Waybill

– Certificate of Origin (COO)

– Export Declaration (if required by exporting country)

– Import License (if required by importing country)

Ensure all documents accurately reflect product details and value to avoid customs scrutiny.

Regulatory and Safety Compliance

- DOT/SAE Standards (USA): Confirm compatibility with FMVSS (Federal Motor Vehicle Safety Standards) through OEM validation. While bushings themselves may not be directly regulated, they must support compliant brake system performance.

- ECE Regulations (Europe): Compliance with UNECE Regulation No. 13 (Braking) may be required for vehicle homologation. Component suppliers should provide technical documentation upon request.

- REACH & RoHS (EU): Verify that materials (e.g., rubber compounds, lubricants) do not contain restricted substances (e.g., SVHCs, lead, cadmium).

- Conflict Minerals (U.S. SEC Rule 13p-1): Declare if the product contains tin, tantalum, tungsten, or gold sourced from conflict-affected areas.

Quality and Traceability

- Implement a documented quality management system (e.g., IATF 16949).

- Maintain batch-level traceability from raw materials to finished goods.

- Provide Material Safety Data Sheets (MSDS/SDS) upon request, especially if bushings contain synthetic rubber or chemical additives.

Returns and Reverse Logistics

- Establish a clear returns authorization (RMA) process for defective or incorrect shipments.

- Label return packages with RMA number and reason for return.

- Inspect returned items for compliance and safety before re-entry into inventory.

Environmental and Disposal Compliance

- Dispose of non-reusable bushings in accordance with local waste regulations.

- Avoid landfill disposal where recycling options exist (e.g., rubber recycling programs).

- Comply with WEEE directives if bushings are part of larger assemblies classified as electronic waste.

Adherence to this guide ensures efficient logistics operations and full regulatory compliance for Brake Pedal Bushings across global markets.

Conclusion for Sourcing Brake Pedal Bushing:

After a thorough evaluation of available suppliers, material specifications, quality standards, and cost considerations, it is concluded that sourcing brake pedal bushings requires a balanced approach focusing on quality, durability, and reliability to ensure optimal vehicle safety and performance. Original Equipment Manufacturer (OEM) specifications should be strictly adhered to, particularly regarding material composition—typically nylon or high-grade polymer—to withstand constant mechanical stress and temperature variations.

Sourcing from certified suppliers with proven track records in automotive component manufacturing is recommended to ensure compliance with industry standards such as ISO/TS 16949. While cost-efficiency is important, prioritizing lower-cost alternatives without adequate quality verification may lead to premature failure, increased warranty claims, and potential safety risks.

In summary, the ideal sourcing strategy involves partnering with reliable suppliers who offer high-quality, durable brake pedal bushings that meet OEM standards, supported by robust quality assurance processes and timely delivery. This ensures long-term performance, customer satisfaction, and overall safety in automotive applications.