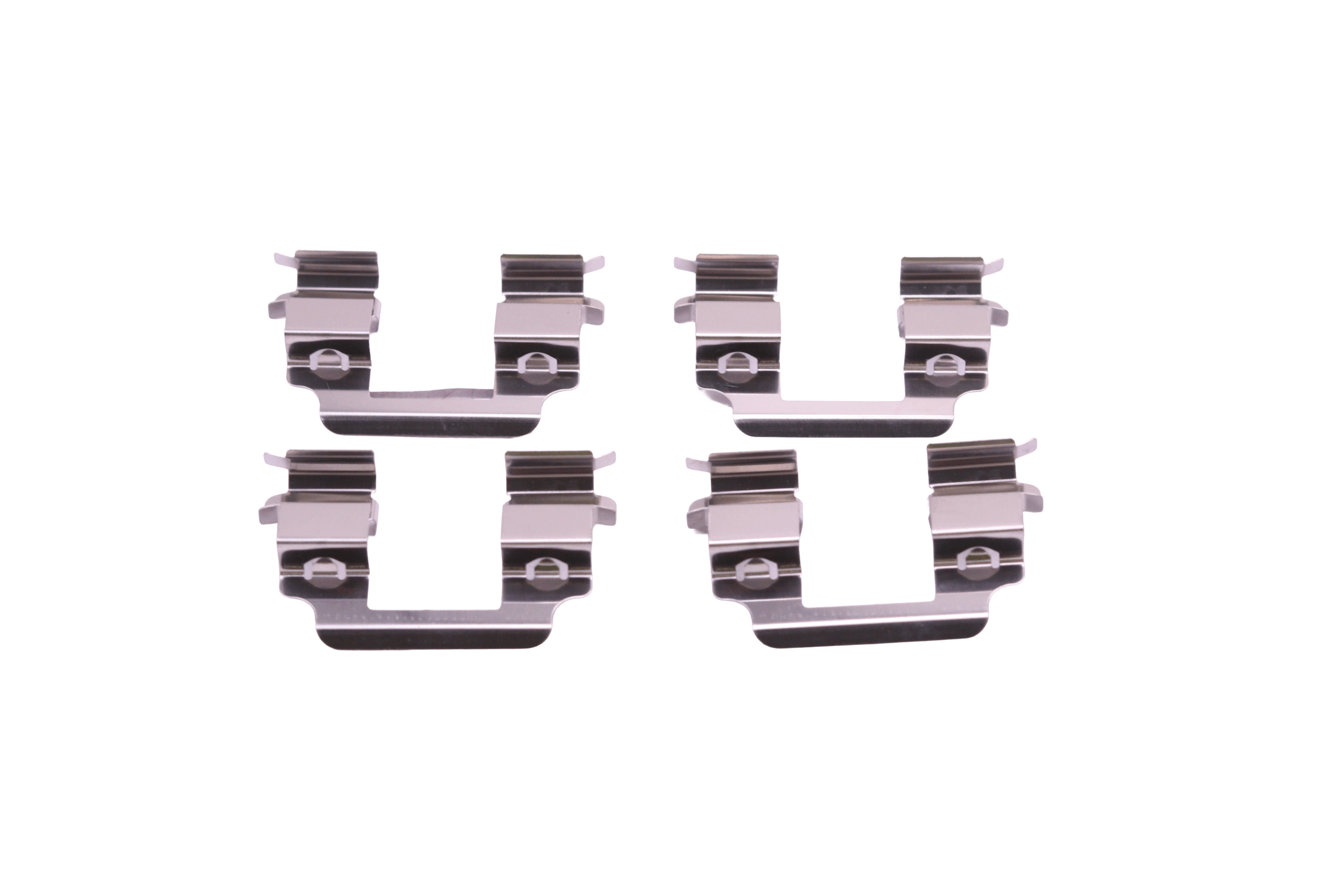

The global brake pad market is experiencing steady growth, driven by rising vehicle production, increasing demand for automotive safety components, and the expansion of the aftermarket sector. According to Mordor Intelligence, the brake pad market was valued at approximately USD 13.5 billion in 2023 and is projected to grow at a CAGR of over 4.5% from 2024 to 2029. This growth is further fueled by technological advancements in friction materials and the rising adoption of electric vehicles, which still require traditional braking systems for regenerative and emergency braking functions. As demand surges, the need for comprehensive brake pad fitting kits—containing hardware such as shims, anti-rattle clips, and lubricants—has also increased. These kits ensure proper installation, reduce noise, and extend the life of braking components. With the aftermarket segment accounting for a significant share of sales, manufacturers specializing in high-quality, vehicle-specific fitting kits are gaining prominence. Based on market presence, product range, innovation, and global distribution, the following are the top 10 brake pad fitting kit manufacturers shaping the industry landscape.

Top 10 Brake Pad Fitting Kit Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 Textar Brake Technology

Domain Est. 1996

Website: textar.com

Key Highlights: Textar manufactures brake pads itself and provides original equipment manufacturer quality….

#2 Wilwood Disc Brakes

Domain Est. 1997

Website: wilwood.com

Key Highlights: Wilwood Engineering is a global leader and manufacturer of high-performance, Original Equipment (OE), disc brake solutions….

#3 Braking Systems

Domain Est. 1996

Website: aftermarket.zf.com

Key Highlights: TRW is one of the largest global brake pad manufacturers in the independent aftermarket and follows the pillars of ZF Aftermarket’s standards of safety ……

#4 Reliable OEM Brake Kits

Domain Est. 2013

Website: dynamicfriction.com

Key Highlights: Upgrade your vehicle with our reliable OEM Brake Kits from the trusted brand, Dynamic Friction Company. Shop now for top-notch quality and performance….

#5 Brake Kits

Domain Est. 1999

Website: porterfield-brakes.com

Key Highlights: 30-day returnsBrake Fluid · Brake Kits · Brake Pads · Brake Pads for Racing Calipers · Brake Shoes · Chassis Component · Clutches · Fittings and Hose · Fluids and Oil · Heat ……

#6 USA Brake Kits

Domain Est. 2000

Website: ebcbrakes.com

Key Highlights: EBC Brakes are the leading online brake company offering brakes, pads, discs, rotors for automotive, motorcycle, mountain bike & racing – USA Brake Kits….

#7 PFC Brakes

Domain Est. 2000

Website: pfcbrakes.com

Key Highlights: We’ve built a culture of performance, crafting high-performance brake calipers, discs, and pads in our state-of-the-art facility located in Clover, South ……

#8

Domain Est. 2002

Website: akebonobrakes.com

Key Highlights: Akebono manufactures ceramic brake pads in three distinct brands, each specifically formulated for domestic and Asian, European, or performance vehicles….

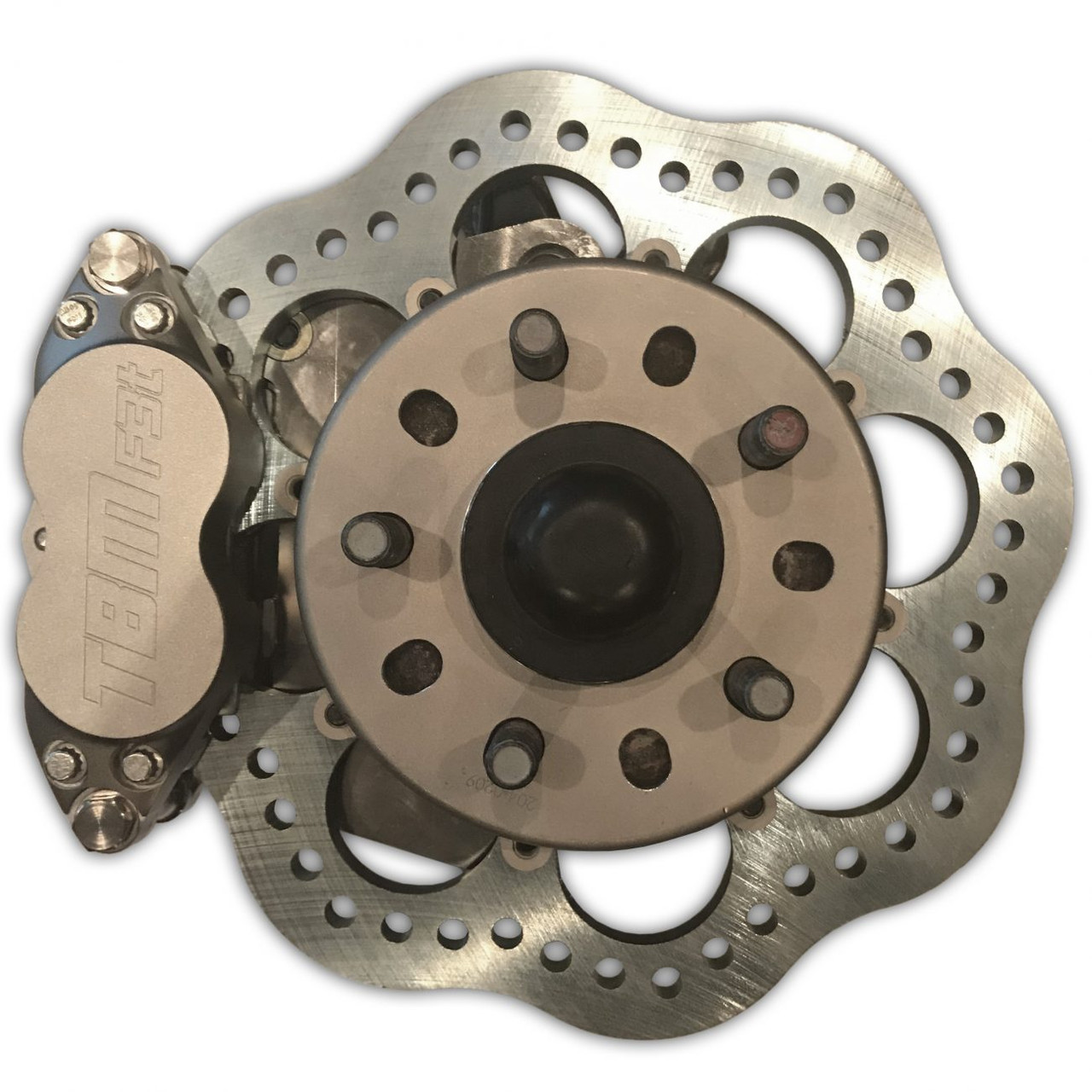

#9 TBM Brakes

Domain Est. 2012

Website: tbmbrakes.com

Key Highlights: 6–7 day delivery 30-day returnsHigh Quality racing brakes, Made in the USA, for drag racing, road racing, sprint car, late model, top fuel, circle track, monster trucks and much mo…

#10 Alcon Brake Kits

Domain Est. 2012

Website: alconkits.com

Key Highlights: Alcon Brake Kits supplies performance brake kits for sports cars and heavy duty trucks for armored and off-road trucks worldwide. Find replacement brake pads,…

Expert Sourcing Insights for Brake Pad Fitting Kit

H2: 2026 Market Trends for Brake Pad Fitting Kit

The global brake pad fitting kit market is poised for steady growth through 2026, driven by increasing vehicle production, rising demand for aftermarket automotive components, and growing emphasis on vehicle safety and maintenance. Below is an analysis of key market trends shaping the industry in 2026:

-

Rising Aftermarket Demand

As vehicle fleets age globally, particularly in mature markets such as North America and Western Europe, the need for replacement brake components—including fitting kits—is increasing. Brake pad fitting kits, which typically include anti-rattle clips, shims, and lubricants, are essential for ensuring optimal brake performance and noise reduction. The growing preference for DIY automotive repairs and maintenance further fuels aftermarket sales. -

Growth in Electric and Hybrid Vehicle Adoption

While electric vehicles (EVs) utilize regenerative braking—reducing wear on traditional brake systems—hybrid and plug-in hybrid vehicles still require conventional braking systems. As EV and hybrid production expands, manufacturers and suppliers are adapting fitting kits to meet the specific requirements of these vehicles, including corrosion resistance and noise suppression under frequent stop-start cycles. -

Stringent Safety and Noise Regulations

Governments and regulatory bodies are enforcing stricter vehicle safety and noise emission standards. This is prompting original equipment manufacturers (OEMs) and aftermarket suppliers to enhance the quality of brake components. High-performance fitting kits that reduce brake squeal and improve pad retention are increasingly in demand, driving innovation and premium product offerings. -

Expansion in Emerging Markets

Rapid urbanization, rising disposable incomes, and expanding automotive ownership in regions such as Asia-Pacific (especially India and Southeast Asia), Latin America, and Africa are contributing to increased demand for brake maintenance products. Local distribution networks and affordable product variants are helping suppliers capture market share in these regions. -

Focus on Premium and Multi-Component Kits

Consumers and professional mechanics are showing a growing preference for comprehensive brake pad fitting kits that include all necessary hardware and lubricants. This shift is driven by convenience, time efficiency, and assurance of compatibility. As a result, suppliers are offering tiered product lines, including economy, standard, and premium kits tailored to different vehicle models and performance needs. -

Supply Chain and Material Innovations

The industry is witnessing a shift toward the use of advanced materials such as stainless steel and high-temperature-resistant polymers to enhance durability and performance. Additionally, manufacturers are optimizing supply chains through automation and regional sourcing to mitigate disruptions and reduce costs—particularly important amid fluctuating raw material prices. -

E-Commerce Growth and Distribution Channels

Online sales platforms are becoming a dominant channel for brake pad fitting kits. Retailers and suppliers are investing in digital marketing, product education, and compatibility tools to improve customer experience. This trend is especially pronounced among younger, tech-savvy consumers seeking convenience and competitive pricing.

In conclusion, the brake pad fitting kit market in 2026 is characterized by innovation, regional diversification, and a strong alignment with evolving vehicle technologies and consumer expectations. Companies that prioritize product quality, regulatory compliance, and digital engagement are expected to lead the market in the coming years.

Common Pitfalls Sourcing Brake Pad Fitting Kit (Quality, IP)

Sourcing Brake Pad Fitting Kits involves critical considerations beyond simple cost, particularly regarding quality consistency and intellectual property (IP) risks. Overlooking these areas can lead to safety issues, legal liabilities, supply chain disruptions, and reputational damage.

Quality Inconsistencies and Performance Failures

Brake Pad Fitting Kits—comprising slide pins, bushings, shims, clips, and lubricants—must meet strict performance standards to ensure braking efficiency and safety. Sourcing from suppliers with inconsistent quality control often results in substandard components. For example, improperly hardened slide pins may seize, while low-grade anti-rattle clips can fracture under thermal stress. Poorly formulated lubricants may degrade at high temperatures, leading to brake noise or uneven pad wear. These failures increase warranty claims, compromise vehicle safety, and damage brand credibility. Without rigorous supplier vetting and incoming quality inspections, buyers risk integrating components that fail under real-world conditions.

Intellectual Property (IP) Infringement and Legal Exposure

Many OEM-designed Brake Pad Fitting Kits are protected by patents, trademarks, or technical specifications. Sourcing generic or copycat kits from suppliers who replicate these designs without licensing exposes buyers to significant IP infringement risks. Legal action from OEMs or patent holders can result in costly litigation, import seizures, or forced product recalls. Additionally, counterfeit or reverse-engineered kits may lack proper testing and certification, further compounding liability. To mitigate this, buyers must verify that suppliers operate within legal frameworks, provide IP indemnification, and possess legitimate design rights or licenses—especially when targeting specific vehicle makes and models.

Logistics & Compliance Guide for Brake Pad Fitting Kit

Product Overview

A Brake Pad Fitting Kit typically includes hardware such as anti-rattle clips, shims, lubricants, and mounting bolts designed to facilitate the proper installation of brake pads. These kits are essential for ensuring quiet operation, reducing vibration, and extending brake system life. Due to their automotive safety function, proper logistics handling and regulatory compliance are critical.

Classification & HS Code

The correct Harmonized System (HS) code for a Brake Pad Fitting Kit is essential for international shipping and customs clearance. Common classifications include:

– HS Code 8708.39.00: Parts and accessories for braking systems of motor vehicles.

– HS Code 8484.90.00: Gaskets and similar articles for mechanical applications (if shims or seals are the primary components).

Note: Final classification may vary by country and exact kit composition. Consult local customs authority or a licensed customs broker for precise code determination.

Regulatory Compliance

Brake Pad Fitting Kits must meet regional and international regulations:

– DOT (U.S. Department of Transportation): Not typically required for non-structural hardware, but kits used in vehicles subject to FMVSS (Federal Motor Vehicle Safety Standards) must not interfere with compliance.

– ECE R90 (Europe): While ECE R90 certification applies directly to brake pads, fitting kits must not compromise the certified performance of the braking system.

– REACH & RoHS (EU): Ensure all materials comply with chemical restrictions (e.g., no restricted heavy metals like lead or cadmium).

– California Proposition 65: Disclose if any component contains listed carcinogens or reproductive toxins (e.g., certain lubricants or metallic elements).

Packaging & Labeling Requirements

- Packaging: Use durable, moisture-resistant materials to prevent corrosion of metal components. Individual parts should be clearly separated or labeled.

- Labeling: Include:

- Product name and part number

- Manufacturer/importer name and address

- Country of origin

- Safety warnings (e.g., “For automotive use only”)

- Compliance markings (e.g., CE mark if applicable)

- UPC/EAN barcode for retail distribution

Shipping & Storage

- Temperature & Humidity: Store in a dry, temperature-controlled environment (10–30°C; 30–70% RH) to prevent rust or degradation of lubricants.

- Stacking & Handling: Limit stack height to avoid crushing lower packages. Use pallets for bulk shipments.

- Transportation: Comply with IATA/IMDG regulations if shipping internationally, especially if kit includes lubricants classified as hazardous. Most fitting kits are non-hazardous, but verify with SDS (Safety Data Sheet) for included lubricants.

Import/Export Documentation

Ensure the following documents are prepared for customs:

– Commercial Invoice

– Packing List

– Certificate of Origin

– Bill of Lading or Air Waybill

– Compliance Declarations (if required by destination country)

– SDS (for lubricants or chemical components)

Environmental & Disposal Compliance

- Dispose of obsolete kits in accordance with local waste regulations. Metal components may be recyclable.

- Lubricants or grease included in the kit must be disposed of as hazardous waste if classified as such.

Quality Assurance & Traceability

- Maintain batch records for traceability in case of recalls.

- Conduct routine quality checks on incoming and outgoing inventory for damage or non-compliance.

- Implement a system for tracking customer complaints related to fitment or performance.

Final Notes

Always verify compliance requirements with the target market’s regulatory bodies. Partner with certified suppliers and logistics providers experienced in automotive parts to ensure seamless distribution and adherence to all legal standards.

Conclusion for Sourcing Brake Pad Fitting Kit:

After a comprehensive evaluation of potential suppliers, cost considerations, quality standards, and availability, sourcing a brake pad fitting kit requires a balanced approach that prioritizes safety, reliability, and value for money. It is essential to partner with reputable suppliers who provide kits that meet or exceed OEM specifications, including all necessary hardware such as caliper slides, clips, shims, and anti-rattle components. Opting for high-quality, corrosion-resistant materials ensures longevity and optimal brake performance, reducing the risk of noise, vibration, and premature wear.

Additionally, considering logistical factors such as lead times, packaging, and after-sales support contributes to operational efficiency. Whether sourcing for aftermarket distribution, fleet maintenance, or retail, aligning supplier capabilities with technical and regulatory requirements ensures customer satisfaction and compliance with safety standards.

In conclusion, a strategic sourcing decision—focused on quality, consistency, and supplier reliability—will not only enhance braking system performance but also support long-term cost savings and customer trust.