The global bracelet materials market is experiencing robust growth, driven by rising consumer demand for fashion accessories and increasing product diversification across metals, leather, textiles, and sustainable composites. According to Grand View Research, the global jewelry market was valued at USD 305.7 billion in 2022 and is expected to grow at a compound annual growth rate (CAGR) of 5.5% from 2023 to 2030, with accessory components like bracelet materials representing a significant segment. This expansion is further fueled by e-commerce penetration, evolving fashion trends, and heightened interest in ethically sourced and recycled materials. As brands seek reliable suppliers to meet quality and scalability demands, identifying leading manufacturers becomes critical. Based on production capacity, material innovation, and market reach, the following eight companies stand out as key players in the global bracelet materials supply chain.

Top 8 Bracelet Materials Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

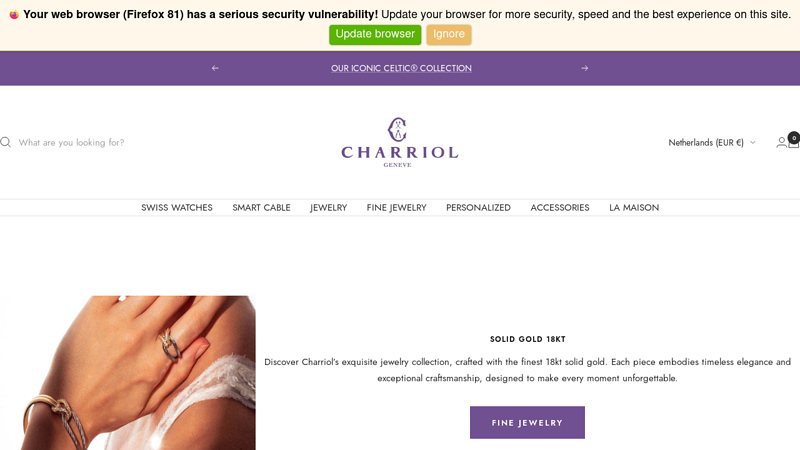

#1 Charriol Cable Bracelets Collection

Domain Est. 1995

Website: charriol.com

Key Highlights: 4–12 day delivery 21-day returnsDiscover Charriol’s exquisite jewelry collection, crafted with the finest 18kt solid gold. Each piece embodies timeless elegance and exceptional cra…

#2 Nomination Italy

Domain Est. 1996

Website: nomination.com

Key Highlights: Visit Nomination Italy official website and discover a wide range of charms, bracelets, earrings and watches. Create your own jewel online!…

#3 Chan Luu Handmade Bracelets

Domain Est. 2002

Website: chanluu.com

Key Highlights: Free deliveryMade using techniques including wire wrapping and weaving, our bracelets add a uniquely handmade touch. Wear them solo or stacked, as we like to do….

#4 Bracelet Making Supplies for DIY Jewelry Designers

Domain Est. 2003

Website: continentalbeadsuppliers.com

Key Highlights: 4–5 day delivery 90-day returns…

#5 Beaded Bracelets Collection

Domain Est. 2004

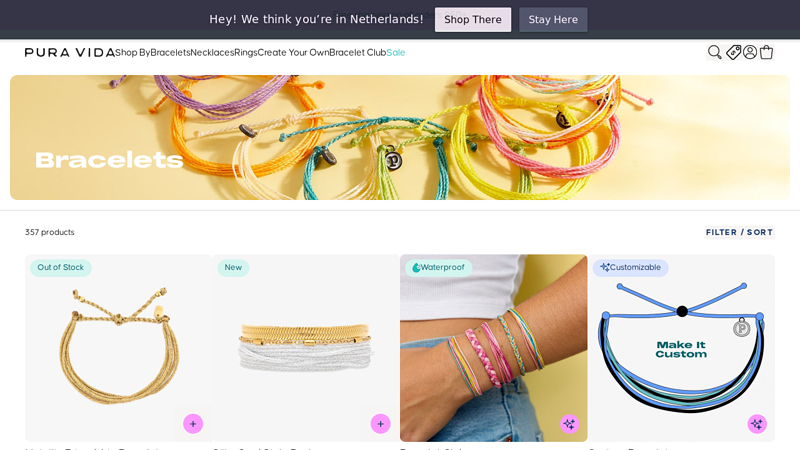

#6 Unique Bracelets

Domain Est. 2010

Website: puravidabracelets.com

Key Highlights: Free delivery over $50Our unique, handmade bracelets are a great choice for any occasion. Explore all our stunning artisan bracelets today! Read More ……

#7 Sailormade

Domain Est. 2011

Website: sailormadeusa.com

Key Highlights: Free delivery over $50Unique nautical jewelry and accessories for men, women, and sailors. Marine rope bracelets with high quality handmade stainless steel and brass maritime ……

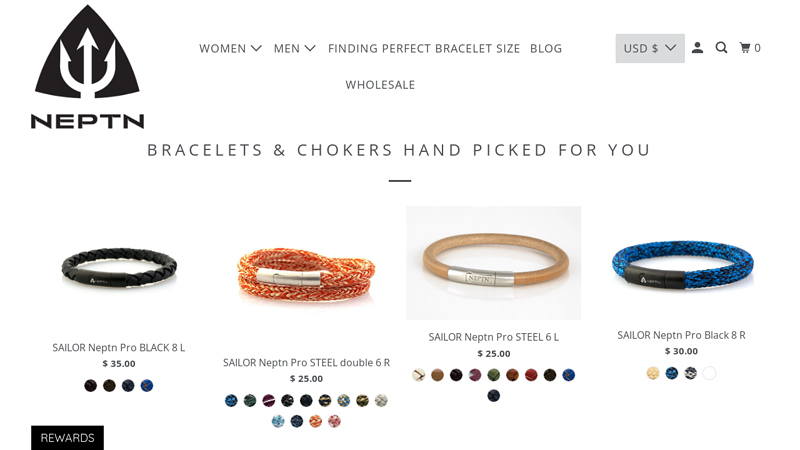

#8 NEPTN® Maritime Bracelets handcrafeted in USA

Domain Est. 2016

Website: neptn.us

Key Highlights: $5 delivery 14-day returnsExplore NEPTN’s handcrafted bracelets and chokers made in the USA from premium Italian leather and exclusive Dutch sailing rope….

Expert Sourcing Insights for Bracelet Materials

2026 Market Trends for Bracelet Materials

As we approach 2026, the global bracelet market is undergoing a significant transformation driven by evolving consumer preferences, technological advancements, and growing environmental awareness. The materials used in bracelet production are at the forefront of this shift, with sustainability, innovation, and personalization shaping key industry trends.

Sustainable and Eco-Friendly Materials

Environmental consciousness continues to influence purchasing decisions, leading to increased demand for bracelets made from sustainable materials. Recycled metals, such as reclaimed silver and gold, are gaining popularity as consumers seek ethically sourced alternatives. Plant-based bioplastics, bamboo, and organic cotton are also rising in use, particularly among eco-conscious brands and younger demographics. Additionally, recycled ocean plastics are being repurposed into stylish, durable bracelets, aligning with circular economy principles and supporting ocean conservation efforts.

Lab-Grown and Alternative Gemstones

Lab-grown diamonds and gemstones are expected to dominate the luxury and fashion jewelry sectors by 2026. These materials offer ethical and cost-effective alternatives to mined stones without compromising on quality or aesthetics. Innovations in material science have enabled the production of lab-created sapphires, emeralds, and rubies that are chemically identical to natural counterparts. As consumer skepticism diminishes and transparency improves, adoption rates are projected to rise significantly.

Advanced and Smart Materials

The integration of technology into wearable accessories is propelling the use of smart materials in bracelet design. Conductive textiles, shape-memory alloys, and flexible polymers are being incorporated into fitness and wellness bracelets that monitor vital signs, track activity, and even provide haptic feedback. By 2026, advancements in biocompatible materials will enable longer skin contact with minimal irritation, enhancing user comfort and wearability. Furthermore, self-healing polymers and color-changing materials responsive to temperature or UV exposure are emerging in fashion-forward designs.

Personalization Through Novel Composites

Customization is a major driver in the 2026 bracelet market, with manufacturers leveraging composite materials to enable unique, personalized products. 3D-printed resins infused with wood, metal particles, or recycled fibers allow for intricate, bespoke designs. These composites offer durability, lightweight properties, and a wide range of aesthetic finishes, appealing to consumers seeking individuality. Brands are increasingly using AI-driven design platforms to let customers co-create their bracelets, further boosting demand for adaptable materials.

Ethical and Traceable Sourcing

Transparency in the supply chain is becoming a competitive advantage. By 2026, blockchain-enabled tracking of raw materials—from mining to finished product—will be standard for premium bracelet brands. This ensures ethical labor practices and environmental compliance, especially for materials like gold, leather, and rare earth elements used in smart bracelets. Certifications such as Fairtrade Gold and Responsible Jewellery Council (RJC) accreditation will influence consumer trust and purchasing behavior.

In conclusion, the 2026 bracelet materials landscape is defined by sustainability, technological integration, and personalization. As environmental regulations tighten and consumer expectations evolve, material innovation will remain central to the industry’s growth and differentiation.

Common Pitfalls When Sourcing Bracelet Materials (Quality, IP)

Sourcing materials for bracelet production involves navigating a complex landscape of quality control and intellectual property (IP) concerns. Overlooking key pitfalls can lead to product failures, legal disputes, and reputational damage. Here are critical areas to watch:

Inadequate Material Quality Assessment

Many suppliers, especially low-cost overseas vendors, may provide materials that appear suitable but fail under real-world conditions. Common issues include using substandard metals that tarnish quickly, elastic bands that lose elasticity, or gemstones with poor clarity and durability. Without rigorous testing—such as plating thickness analysis, tensile strength checks, or salt spray corrosion tests—brands risk delivering products that disappoint customers and increase return rates.

Misrepresentation of Material Composition

Suppliers might mislabel materials to cut costs, such as advertising “sterling silver” when the product is actually silver-plated base metal, or claiming “natural gemstones” when using synthetic or dyed alternatives. This not only deceives consumers but can violate advertising standards and import regulations. Always demand material certifications (e.g., assay certificates for precious metals) and conduct third-party lab testing when necessary.

Lack of Supply Chain Transparency

Without visibility into the full supply chain, brands may inadvertently source conflict minerals or materials produced under unethical labor conditions. This poses serious reputational and regulatory risks, especially in markets with strict due diligence laws (e.g., EU Conflict Minerals Regulation). Insist on traceability documentation and conduct supplier audits to ensure ethical sourcing.

Intellectual Property Infringement Risks

Using design elements, logos, or patented closure mechanisms without proper authorization can lead to costly legal action. Some suppliers may offer molds or designs that mimic popular branded jewelry, exposing buyers to IP violations. Always verify that designs are original or properly licensed, and include IP indemnification clauses in supplier contracts.

Overreliance on Supplier Claims Without Verification

Taking a supplier’s word about quality or compliance at face value is a common mistake. Without on-site inspections or independent quality control checks, defects may go unnoticed until after mass production. Implement a robust QC process, including pre-shipment inspections and sample batch testing, to catch issues early.

Inconsistent Batch-to-Batch Quality

Even with a reliable supplier, material quality can vary between production runs. Changes in raw material sources or manufacturing processes can affect color, durability, or finish. Establish clear quality benchmarks and require suppliers to provide batch-specific documentation to ensure consistency across orders.

Avoiding these pitfalls requires due diligence, clear communication, and ongoing oversight. Investing in trusted suppliers, verifying claims, and protecting IP upfront can save significant costs and safeguard your brand’s integrity in the long run.

Logistics & Compliance Guide for Bracelet Materials

Material Sourcing and Procurement

Ensure all raw materials (e.g., metals, beads, threads, gemstones, recycled components) are sourced from reputable, certified suppliers. Prioritize suppliers compliant with environmental and labor regulations such as the Responsible Minerals Initiative (RMI) or ISO 14001 standards. Verify documentation for material origin, especially for conflict minerals (e.g., tin, tungsten, tantalum, gold) as required under the U.S. Dodd-Frank Act Section 1502.

Regulatory Compliance

Adhere to international and regional regulations governing product safety and chemical content. Key standards include:

– REACH (EU): Restrict hazardous substances like lead, nickel, and phthalates.

– RoHS (EU): Limit specific hazardous materials in electrical/electronic components (if applicable).

– CPSIA (USA): Comply with lead and phthalate limits, especially for children’s jewelry.

– Proposition 65 (California): Provide warnings for products containing listed carcinogens or reproductive toxins.

Packaging and Labeling Requirements

Use packaging materials that are recyclable or sustainably sourced. Labels must include:

– Product composition (e.g., “Stainless Steel,” “Recycled PET Cord”)

– Country of origin

– Compliance marks (e.g., CE, UKCA)

– Care instructions

– Supplier or manufacturer identification

Import and Export Documentation

Prepare accurate customs documentation including:

– Commercial invoice

– Packing list

– Certificate of Origin

– Material Safety Data Sheets (MSDS), if applicable

Ensure Harmonized System (HS) codes are correctly classified (e.g., 7113.19 for imitation jewelry) to avoid delays or penalties.

Transportation and Storage

Use secure, climate-appropriate packaging to prevent damage during transit. Store materials in dry, temperature-controlled environments to prevent corrosion or degradation. Implement inventory tracking systems to monitor stock levels and shelf life, especially for organic or sensitive materials (e.g., wood, leather).

Environmental and Ethical Standards

Follow sustainability best practices by minimizing waste, reusing scrap materials, and recycling where possible. Verify labor practices across the supply chain to comply with ethical standards such as SA8000 or the UN Guiding Principles on Business and Human Rights.

Quality Control and Testing

Conduct regular third-party testing for compliance with chemical, durability, and safety standards. Maintain records of test results and certifications for audit readiness. Implement batch tracking to trace materials from source to finished product.

Recordkeeping and Audits

Maintain comprehensive records for a minimum of five years, including supplier certifications, test reports, shipping documents, and compliance declarations. Schedule periodic internal and external audits to ensure ongoing adherence to logistics and regulatory requirements.

In conclusion, sourcing bracelet materials requires a strategic balance between quality, cost, sustainability, and ethical considerations. By carefully evaluating suppliers, prioritizing durable and safe materials—such as hypoallergenic metals, natural gemstones, recycled components, or eco-friendly alternatives—businesses can create products that meet customer expectations while aligning with environmental and social values. Building strong relationships with reliable suppliers, staying informed about material trends and regulations, and incorporating sustainable practices into the sourcing process not only enhances product integrity but also strengthens brand reputation and long-term success in the competitive jewelry market.