The global HVAC components market is experiencing robust expansion, driven by rising construction activities, increased demand for energy-efficient systems, and stringent indoor air quality regulations. According to Mordor Intelligence, the HVAC market is projected to grow at a CAGR of over 6.5% from 2023 to 2028, with components like box plenums playing a critical role in optimizing airflow distribution and system efficiency. Plenums, essential for connecting ductwork to air handlers, are witnessing increased demand in commercial and industrial applications due to their impact on HVAC performance and noise reduction. As sustainability and building automation gain traction, manufacturers are innovating with improved materials, modular designs, and acoustic enhancements. This growing market momentum underscores the importance of choosing reliable and technologically advanced box plenum manufacturers—players who combine engineering precision with compliance to global standards. Below are the top 9 box plenum manufacturers leading the industry in quality, innovation, and market presence.

Top 9 Box Plenum Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 Sid Harvey Duct Work Plenum Chamber

Domain Est. 1997

Website: sidharvey.com

Key Highlights: Gray Metal Products, Inc., is a family owned business started in 1906, is a full line manufacturer of heating and air conditioning products….

#2 Plenum Boxes

Domain Est. 2021

Website: daniaair.com

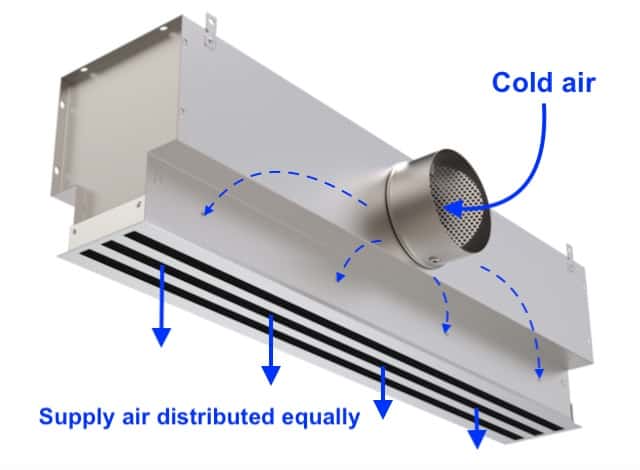

Key Highlights: Plenum Box PB is an essential component in HVAC air distribution systems, designed to ensure uniform airflow and balanced pressure across air outlets such ……

#3 4

Domain Est. 1995

#4 Universal Plenum

Domain Est. 1996

Website: priceindustries.com

Key Highlights: The Universal Plenum (UP) is designed to fit Price Custom Flow, Linear Slot Diffuser, and Linear Bar Grille products….

#5 Supply & Return Air Plenum Boxes

Domain Est. 1998

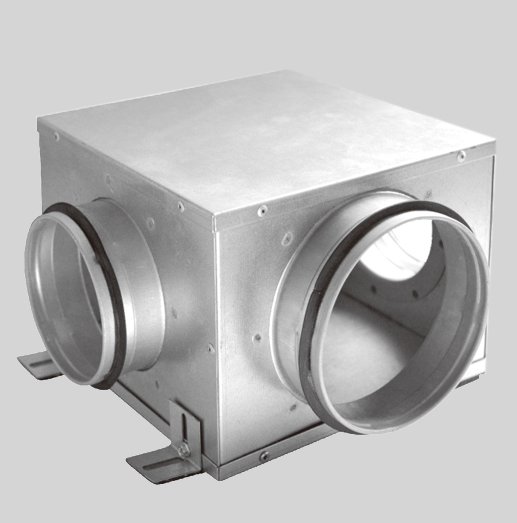

#6 PB plenum boxes

Domain Est. 1999

Website: h-v-c.com

Key Highlights: An essential component of any ventilation system, connecting air terminals to ductwork. HVC plenum boxes are available in a side or top entry variants….

#7 Peerless-AV® Plenum Box For CMJ450, 453, 455 and 500

Domain Est. 2009

Website: peerless-av.com

Key Highlights: This easy to install Plenum box is a universal solution for any false ceiling application. Featuring the only slide-on lid design in the industry….

#8 Air Conditioning Plenum boxes

Domain Est. 2017

Website: airconplenums.com

Key Highlights: Linwood Plenums is a market leader in the supply of air conditioning plenum boxes. Based in the UK, we supply air conditioning, refrigeration and HVAC ……

#9 EZ Plenum

Domain Est. 2023

Website: ezplenum.com

Key Highlights: Shop fiberglass & insulated plenum boxes (12″–72″), vent caps & duct fittings. EZ Plenum ships HVAC air distribution parts fast for contractors….

Expert Sourcing Insights for Box Plenum

H2: 2026 Market Trends for Box Plenum

As the demand for efficient, scalable, and compliant infrastructure solutions grows across commercial and data-centric environments, the market for Box Plenums—air distribution chambers used in HVAC systems, especially above drop ceilings in office buildings, data centers, and healthcare facilities—is poised for notable evolution by 2026. Driven by sustainability mandates, smart building integration, and stricter indoor air quality (IAQ) standards, several key trends are shaping the Box Plenum landscape.

1. Increased Adoption in Green Building Projects

With global emphasis on energy efficiency and sustainability, green building certifications such as LEED, WELL, and BREEAM are influencing HVAC design. Box plenums are being optimized for energy recovery and air mixing efficiency, enabling tighter integration with energy-efficient HVAC systems. By 2026, demand for insulated, airtight plenum boxes with low leakage rates is expected to surge, particularly in net-zero energy buildings.

2. Integration with Smart Building Technologies

The rise of IoT-enabled building management systems (BMS) is reshaping HVAC components. Smart box plenums equipped with embedded sensors for pressure, temperature, and airflow monitoring are gaining traction. These smart plenums allow real-time diagnostics, predictive maintenance, and dynamic airflow adjustments, improving system performance and reducing energy waste. By 2026, modular plenums with plug-and-play sensor compatibility are expected to become standard in new commercial developments.

3. Growth in Data Center and High-Density Computing Environments

Data centers require precise climate control to manage heat loads from high-performance computing. Raised floor and overhead plenum systems—especially box plenums designed for underfloor air distribution (UFAD) or ceiling-based air delivery—are being customized for better thermal management. Anticipated expansion in edge data centers and AI infrastructure will drive demand for compact, high-efficiency plenum solutions that support variable cooling loads.

4. Material Innovation and Fire Safety Compliance

Regulatory updates, particularly in fire safety (e.g., stricter adherence to NFPA 90A and IMC codes), are pushing manufacturers to adopt non-combustible, low-smoke materials in plenum construction. By 2026, expect wider use of galvanized steel, aluminum composites, and fire-retardant insulation. Additionally, modular, lightweight designs using recyclable materials will appeal to environmentally conscious developers.

5. Standardization and Prefabrication

To reduce on-site labor and installation errors, the industry is shifting toward prefabricated, modular plenum systems. Off-site manufacturing ensures precision, quality control, and faster deployment—critical in fast-track construction projects. By 2026, BIM-integrated plenum designs and standardized connection interfaces will dominate, enabling seamless integration with ductwork and air terminals.

6. Regional Market Expansion

While North America and Western Europe lead in advanced HVAC adoption, emerging markets in Asia-Pacific (particularly India, Southeast Asia) and the Middle East are investing heavily in commercial infrastructure. These regions will see increased deployment of box plenums in new office complexes, hospitals, and smart cities, supported by urbanization and rising HVAC standards.

Conclusion

By 2026, the box plenum market will be defined by intelligence, sustainability, and integration. Manufacturers who innovate in energy performance, digital connectivity, and compliance will capture significant market share. As buildings evolve into responsive, data-driven environments, the box plenum—once a passive component—will become a critical node in the intelligent HVAC ecosystem.

Common Pitfalls Sourcing Box Plenum (Quality, IP)

Sourcing Box Plenum components—critical for network infrastructure and data center environments—can present several challenges, especially concerning quality assurance and intellectual property (IP) protection. Being aware of these pitfalls helps organizations avoid operational risks, compliance issues, and long-term cost overruns.

Quality-Related Pitfalls

Inconsistent Manufacturing Standards

One of the most common quality issues arises from suppliers who do not adhere to recognized industry standards (e.g., ISO, TIA/EIA). Plenum-rated cables and enclosures must meet strict fire safety regulations (such as NFPA 90A and UL 910) due to their installation in air-handling spaces. Sourcing from manufacturers with inconsistent quality control can result in substandard materials that fail compliance testing or pose fire hazards.

Substandard Materials and Coatings

Low-cost suppliers may use inferior jacketing materials that do not meet true plenum ratings. For example, some cables labeled as “plenum-rated” may use polyvinyl chloride (PVC) blends instead of low-smoke zero-halogen (LSZH) compounds, increasing toxic fume risks during combustion. These materials may pass basic inspections but fail under real-world fire conditions.

Lack of Certification Documentation

Reputable plenum products should come with verifiable test reports and certifications (e.g., UL, ETL, CPR). A red flag arises when suppliers cannot provide up-to-date, third-party certification documents. Some resellers may falsely claim certifications, exposing buyers to liability and code violations.

Inadequate Testing and Validation

Even if a product appears compliant, insufficient batch testing or lack of performance validation under real environmental conditions (e.g., temperature fluctuations, humidity) can lead to premature failure. This is especially critical in data centers where reliability is paramount.

IP-Related Pitfalls

Counterfeit or Clone Products

The demand for cost-effective network infrastructure has led to a rise in counterfeit Box Plenum components that mimic branded products. These clones often replicate logos and packaging but lack the design integrity and IP protection of the original. Using such products risks warranty voidance, performance issues, and potential legal exposure.

Unauthorized Resellers and Gray Market Goods

Purchasing from unauthorized distributors increases the risk of receiving non-genuine or diverted products. These goods may not be covered under the manufacturer’s warranty and could infringe on the brand’s intellectual property rights. Additionally, gray market items might not meet regional safety or regulatory standards.

Lack of Traceability and Documentation

Legitimate IP-protected components include traceable manufacturing data, serial numbers, and anti-counterfeit features. Sourcing from vendors who cannot provide item-level traceability makes it difficult to verify authenticity and support compliance audits.

Risk of IP Infringement in Custom Solutions

When sourcing custom-designed plenum enclosures or integrated systems, there’s a risk that the supplier may use patented designs or technologies without proper licensing. Buyers may unknowingly become complicit in IP violations if due diligence on design origins is not conducted.

Mitigation Strategies

To avoid these pitfalls, organizations should:

– Source exclusively from authorized, certified suppliers.

– Request and verify test reports and certifications.

– Conduct periodic audits and product spot-checks.

– Use supply chain transparency tools to track origin and authenticity.

– Include IP indemnification clauses in procurement contracts.

Proactively addressing quality and IP concerns ensures that Box Plenum components perform safely and reliably while protecting the buyer from legal and operational risks.

Logistics & Compliance Guide for Box Plenum

This guide outlines the logistics handling and regulatory compliance requirements specific to Box Plenum products. Adherence to these guidelines ensures safe transportation, regulatory approval, and operational efficiency across the supply chain.

Product Overview

Box Plenum refers to fire-rated, plenum-safe enclosures designed for use in HVAC air circulation spaces (plenums) in commercial buildings. These enclosures are commonly used to house electrical, data, or low-voltage components and must meet strict safety standards due to their installation environment.

Regulatory Compliance Standards

All Box Plenum units must comply with the following standards to ensure regulatory acceptance:

- NFPA 90A: Standard for the Installation of Air-Conditioning and Ventilation Systems

- UL 2043: Test for Heat and Visible Smoke Release for Discrete Products and Their Components Installed in Air-Handling Spaces

- UL 1847: Standard for Outlet Boxes and Covers for Use in Plenum Areas

- NEC Article 300.22(C): National Electrical Code requirements for wiring in ducts, plenums, and other air-handling spaces

- RoHS & REACH: Compliance with hazardous substance restrictions in electrical equipment

Manufacturers and suppliers must provide certification documentation (e.g., UL listing, test reports) with each shipment.

Packaging & Labeling Requirements

To maintain compliance and ensure safe handling:

- Each Box Plenum unit must be packaged in recyclable, crush-resistant material.

- Outer packaging must display:

- UL Plenum-Rated label

- Lot or batch number

- “Plenum Rated – For Use in Air Handling Spaces Only”

- Handling symbols (e.g., “Do Not Stack,” “Fragile”)

- Include compliance documentation (e.g., certificate of compliance, safety data sheet) inside the shipping container.

Shipping & Transportation

- Mode of Transport: Suitable for ground, air, and sea freight. No special hazardous material designation required if compliant.

- Temperature & Humidity: Store and transport in dry environments; avoid prolonged exposure to temperatures above 60°C (140°F) or below -20°C (-4°F).

- Stacking Limits: Do not stack more than 5 standard cartons high unless palletized and secured.

- Palletization: Use 48” x 40” GMA pallets; secure loads with stretch wrap or banding. Maximum pallet weight: 1,500 lbs.

Import/Export Considerations

- Verify country-specific electrical safety certifications (e.g., CE for EU, RCM for Australia).

- Provide Harmonized System (HS) Code: 8538.90 (Parts suitable for use solely or principally with the apparatus of headings 8535, 8536, or 8537).

- Ensure export documentation includes:

- Commercial invoice

- Packing list

- Certificate of Origin

- Regulatory compliance certificates

Warehouse Handling & Storage

- Store indoors in a dry, well-ventilated area.

- Keep away from direct sunlight and sources of heat.

- Max storage duration: 24 months from manufacture date (verify material integrity beyond this period).

- Practice FIFO (First In, First Out) inventory rotation.

Installation & End-User Compliance

- Only qualified electricians or licensed installers may install Box Plenum units.

- Installation must follow manufacturer instructions and local building/electrical codes.

- Post-installation inspection may be required by AHJ (Authority Having Jurisdiction).

Environmental & Disposal Guidelines

- At end-of-life, Box Plenum units should be recycled through certified e-waste facilities.

- Materials typically include recyclable thermoplastics and metal components.

- Do not incinerate—combustion may release hazardous fumes.

Contact & Support

For compliance verification, technical documentation, or logistics support, contact:

Compliance Team

Email: [email protected]

Phone: +1 (800) 555-0198

Always consult the latest product-specific datasheet and regulatory updates before shipment or installation.

Conclusion for Sourcing Box Plenum

In conclusion, the sourcing of a box plenum is a critical step in ensuring the efficiency, performance, and longevity of HVAC systems. A properly selected and installed box plenum helps distribute airflow evenly, reduces system noise, and enhances overall energy efficiency. When sourcing a box plenum, key considerations such as material quality, dimensional accuracy, compatibility with existing ductwork, and compliance with industry standards must be prioritized.

Sourcing from reputable suppliers who offer durable materials—such as galvanized steel or insulated variants—and provide customization options ensures the plenum meets specific application requirements. Additionally, evaluating cost-effectiveness, lead times, and technical support from suppliers contributes to a successful integration within the HVAC system.

Ultimately, a well-sourced box plenum not only supports optimal system performance but also reduces maintenance issues and operational costs over time. Therefore, a strategic and informed sourcing approach is essential to achieving reliable and efficient air distribution in commercial and industrial building environments.