The global market for industrial control panels, including box control panels, has experienced steady expansion driven by increasing automation across manufacturing, energy, and infrastructure sectors. According to Mordor Intelligence, the Industrial Control Systems Market was valued at USD 19.62 billion in 2023 and is projected to reach USD 28.24 billion by 2029, growing at a CAGR of 6.27% during the forecast period. This growth is fueled by the rising adoption of smart manufacturing technologies, demand for energy-efficient systems, and the integration of IoT and Industry 4.0 solutions in industrial operations. As a critical component of automation infrastructure, box control panels play a pivotal role in ensuring operational efficiency, safety, and system reliability. With North America and Asia-Pacific leading in industrial automation investments, manufacturers are innovating to meet rigorous standards in durability, customization, and digital integration. In this competitive landscape, a select group of companies have emerged as leaders, combining engineering excellence with scalable production and global support networks—setting the benchmark in performance and reliability.

Top 10 Box Control Panel Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 Keystone EMC

Domain Est. 1995

Website: hubbell.com

Key Highlights: Keystone works directly with original equipment manufacturer (OEM) partners to design and manufacture low voltage electrical control panels, commonly used in ……

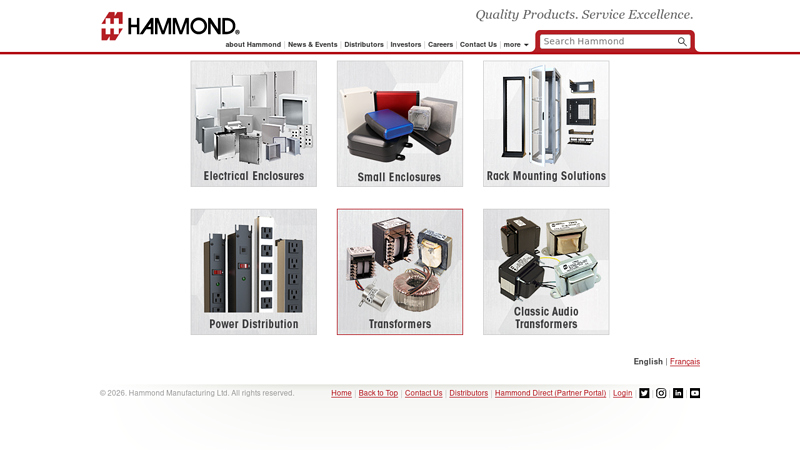

#2 Hammond Manufacturing

Domain Est. 1996

Website: hammfg.com

Key Highlights: Hammond Manufacturing is a leading manufacturer of industrial enclosures, electronic enclosures, racks & rack cabinets, transformers, outlet strips and ……

#3 Paneltronics

Domain Est. 1996 | Founded: 1979

Website: paneltronics.com

Key Highlights: Since 1979, Paneltronics has been the industry-leading manufacturer of high quality electrical control panels and assemblies….

#4 Control Panels

Domain Est. 2003 | Founded: 2001

Website: apx-enclosures.com

Key Highlights: APX Enclosures has manufactured these cabinets since 2001. Our NEMA enclosures protect housed electronics from rain, snow, dripping water and corrosion….

#5 EXM Manufacturing

Domain Est. 2007

Website: exmweb.com

Key Highlights: EXM Manufacturing Ltd, based in Canada, USA, and China, is a top-tier electrical enclosures manufacturer: Wallmount, Free standing, Pull Box….

#6 Control panels

Domain Est. 1990

Website: abb.com

Key Highlights: ABB’s CP600 range offers reliable, user-friendly control panels for everything from basic machines to advanced automation ‒ scalable, intuitive, ……

#7 Saginaw Control and Engineering

Domain Est. 1997

Website: saginawcontrol.com

Key Highlights: We’re now adding a weight distribution shelf, side panels, and pole mount kit. Each accessory provides durable and practical solutions for your unique needs….

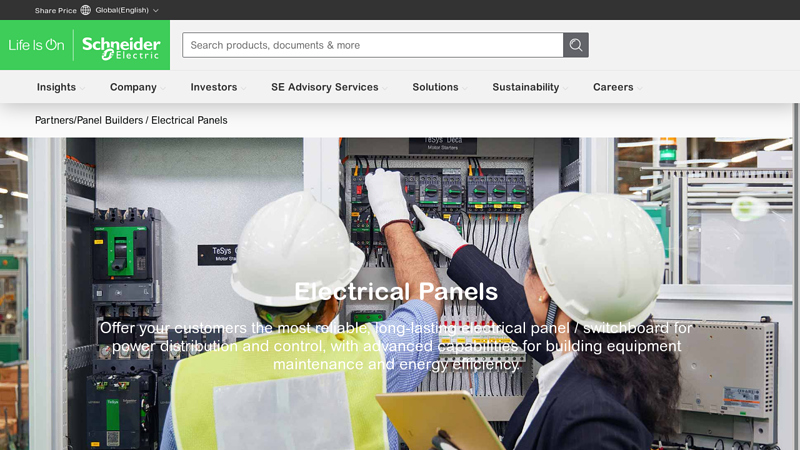

#8 Electrical Panels and Switchboards for Panel Builders

Domain Est. 1997

Website: se.com

Key Highlights: Schneider Electric electrical panels / switchboards provide industry-leading performance. Offering advanced protection, fault protection and seamless ……

#9

Domain Est. 2001

Website: nvent.com

Key Highlights: Choose from 12,000+ standard products with a large in-stock selection. All products are manufactured locally in multiple regions around the world, and meet ……

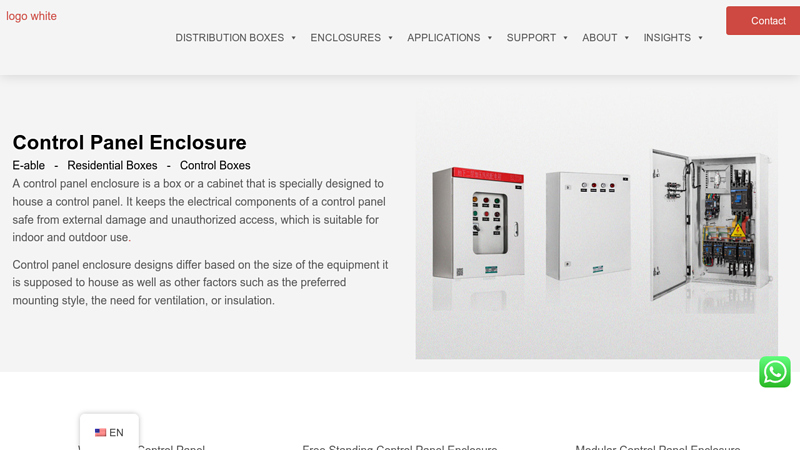

#10 Control Boxes

Domain Est. 2004

Website: eabel.com

Key Highlights: Made from durable materials such as stainless steel, aluminum, or polycarbonate, control panel enclosures help maintain system performance, meet industry ……

Expert Sourcing Insights for Box Control Panel

2026 Market Trends for Box Control Panels

The Box Control Panel market is poised for significant transformation by 2026, driven by technological innovation, evolving regulatory standards, and shifting industrial demands. As industries across manufacturing, energy, infrastructure, and smart buildings continue to digitize, control panels—central nervous systems for automation and monitoring—are adapting to meet new performance, connectivity, and sustainability expectations.

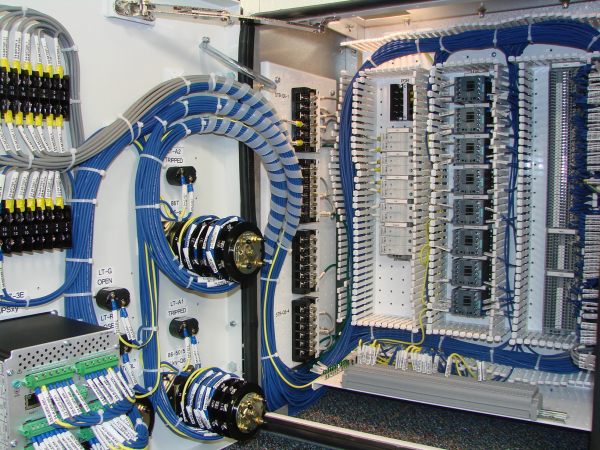

Growing Demand for Smart and Connected Panels

By 2026, the integration of Industrial Internet of Things (IIoT) technologies will be a defining trend in the Box Control Panel market. Manufacturers are increasingly embedding sensors, remote monitoring capabilities, and edge computing functions directly into control panels. This enables predictive maintenance, real-time diagnostics, and seamless integration with cloud-based platforms. Demand will rise for panels that support protocols like OPC UA, MQTT, and 5G connectivity, allowing for faster data exchange and improved operational efficiency in smart factories and utility grids.

Increased Focus on Cybersecurity and Compliance

With heightened connectivity comes greater exposure to cyber threats. In 2026, box control panels will be required to meet stringent cybersecurity standards such as IEC 62443 and NIST frameworks. Panel builders and OEMs will prioritize secure-by-design architectures, including encrypted communications, access controls, and firmware integrity checks. Regulatory bodies and end-users in critical infrastructure—such as water treatment and power distribution—will mandate robust security features, influencing panel design, certification, and lifecycle management.

Sustainability and Energy Efficiency as Key Drivers

Environmental regulations and corporate ESG goals will push the market toward energy-efficient and sustainable control panel solutions. Expect increased use of energy-saving components, eco-friendly materials, and modular designs that extend product lifecycles. Panels with integrated energy monitoring systems will gain favor, enabling businesses to track and optimize power consumption. Additionally, manufacturers may adopt circular design principles, focusing on recyclability and reduced carbon footprint during production.

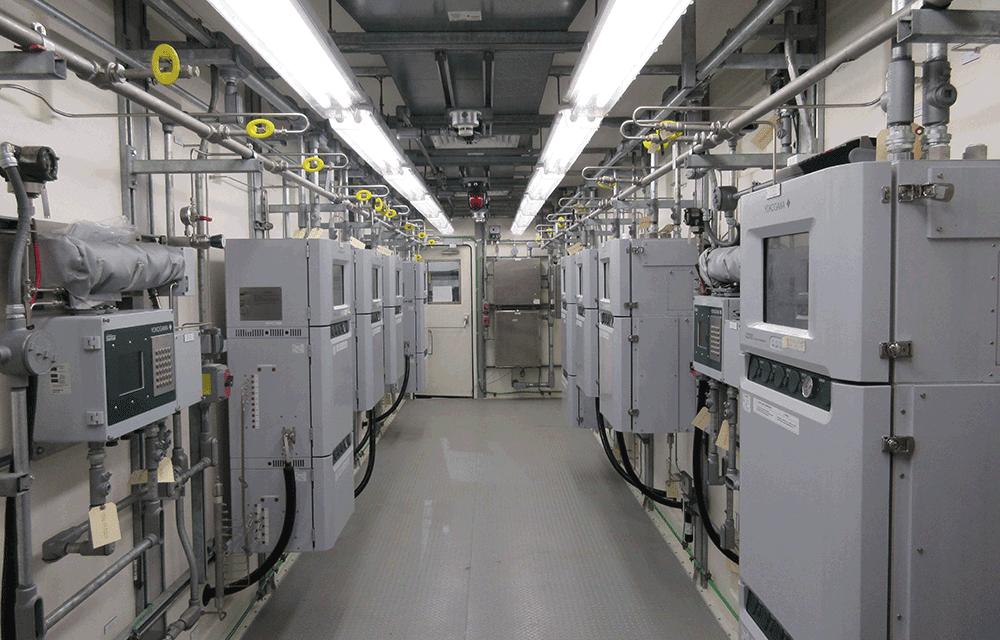

Rise of Modular and Customizable Solutions

Standardization will coexist with a growing demand for modular, scalable control panels. As industries face fluctuating production needs and rapid deployment requirements, plug-and-play modules and configurable enclosures will become essential. This trend supports faster installation, easier upgrades, and reduced downtime. Customization—especially for harsh environments (e.g., oil & gas, marine)—will also expand, with panels designed to meet specific environmental ratings (IP66, NEMA 4X) and operational demands.

Expansion in Emerging Markets and Renewable Energy Sectors

Geographically, growth will accelerate in Asia-Pacific, Latin America, and parts of Africa, where industrialization and infrastructure development are on the rise. Simultaneously, the renewable energy sector—particularly solar farms, wind turbines, and battery storage systems—will become a major end-user segment. Control panels tailored for distributed energy resources (DERs) and microgrids will see increased adoption, requiring robust, weather-resistant designs with advanced grid management capabilities.

Conclusion

By 2026, the Box Control Panel market will be characterized by intelligence, security, sustainability, and adaptability. Success will depend on manufacturers’ ability to innovate while meeting global standards and customer-specific needs. Companies that embrace digital integration, prioritize cybersecurity, and align with green initiatives will lead the evolving landscape of industrial control systems.

Common Pitfalls When Sourcing a Box Control Panel (Quality and IP Protection)

Logistics & Compliance Guide for Box Control Panel

This guide outlines the logistics processes and compliance requirements associated with the procurement, handling, transportation, and deployment of the Box Control Panel. Adherence to these guidelines ensures smooth operations, regulatory compliance, and product integrity.

Procurement and Supplier Management

All Box Control Panels must be sourced from approved suppliers who meet quality, environmental, and ethical standards. Purchase orders should include specifications for compliance certifications such as ISO 9001, ISO 14001, and RoHS. Supplier audits are conducted annually to verify ongoing adherence.

Import and Export Compliance

Box Control Panels shipped internationally must comply with applicable export control regulations, including EAR (Export Administration Regulations) and ITAR where relevant. Accurate Harmonized System (HS) codes must be used, and all documentation—including commercial invoices, packing lists, and certificates of origin—must be complete and retained for a minimum of five years.

Packaging and Labeling Standards

Each Box Control Panel must be packaged in ESD-safe materials and labeled with:

– Product name and model number

– Serial number and manufacturing date

– Regulatory compliance marks (CE, FCC, RoHS)

– Handling symbols (e.g., “Fragile,” “This Side Up”)

Transportation and Handling

Shipments must use carriers compliant with IATA and IMDG regulations if hazardous materials are involved (e.g., batteries). Temperature and humidity controls are required during transit to prevent damage. Handlers must be trained in proper lifting techniques and ESD precautions to avoid equipment damage.

Inventory Management and Traceability

Maintain a digital inventory system that tracks each Box Control Panel through its lifecycle using unique serial numbers. Records must include receipt date, storage location, calibration status, and deployment history to ensure full traceability for compliance audits.

Storage Conditions

Store Box Control Panels in a dry, climate-controlled environment (15°C–25°C, 30%–60% relative humidity). Avoid exposure to dust, direct sunlight, and corrosive substances. Stock rotation (FIFO—First In, First Out) should be strictly followed.

Installation and Deployment Compliance

Installation must be performed by certified technicians following manufacturer guidelines and local electrical codes. A compliance checklist must be completed and archived, including verification of grounding, power supply compatibility, and safety interlocks.

Documentation and Audit Readiness

All logistics and compliance documentation must be stored in a secure, accessible system. Regular internal audits will verify adherence to this guide. External auditors must be granted access upon request with 48 hours’ notice.

End-of-Life and Recycling

Decommissioned Box Control Panels must be disposed of in accordance with WEEE (Waste Electrical and Electronic Equipment) directives. Use certified e-waste recyclers and obtain disposal certificates. Data-bearing components must be securely wiped or destroyed before recycling.

Training and Responsibility

Personnel involved in logistics or handling must complete annual training on compliance policies, safety procedures, and environmental regulations. Responsibility for compliance rests with the Logistics Manager and Quality Assurance Officer, who must report any non-conformances immediately.

Conclusion for Sourcing a Box Control Panel

In conclusion, sourcing a box control panel requires a comprehensive evaluation of technical specifications, quality standards, supplier reliability, and cost-effectiveness. It is essential to ensure that the selected control panel meets the required electrical and environmental standards (such as IP rating, UL, CE, or NEMA compliance), aligns with the operational needs of the system, and integrates seamlessly with existing equipment. Engaging reputable suppliers with proven track records, robust after-sales support, and the ability to customize solutions when necessary will contribute significantly to long-term reliability and performance. Additionally, considering factors such as lead times, warranty, and lifecycle costs will help optimize the total cost of ownership. By adopting a strategic and informed approach to sourcing, organizations can ensure the acquisition of a durable, efficient, and safe control panel solution that supports uninterrupted operations and project success.