Introduction: Navigating the Global Market for Bottle Capping Machines

Securing the correct capping solution is the final – and most critical – step in bottle packaging. A mismatch in torque, cap style, or throughput can trigger recalls, rework, and lost shelf-space. This guide cuts through the noise to help USA and European bottlers, OEMs, and integrators select, specify, and source the right bottle capping machine for any production profile.

Why This Guide Matters

| Global Challenge | Local Impact |

|——————|————–|

| Rising consumer expectations for tamper-evidence and sustainability | Premium brands risk losing shelf-space to rivals with tighter seals |

| Supply-chain volatility driving near-shoring of production | Capital equipment must integrate with new line layouts and voltages |

| Tightening safety and environmental regulations (FDA, EU 1935/2004) | Non-compliant machines can halt shipments at the border |

What You Will Learn

- Cap Types & Torque Ranges – Match screw, lug, and snap-on caps from 10 mm to 130 mm diameter to the correct chuck and spindle technology.

- Speed vs. Accuracy Trade-offs – Compare tabletop, benchtop, and fully-automatic models that run from 10 to 105 caps per minute.

- Global Compliance Checklist – Ensure CE, UL, and EHEDG certifications align with your market entry strategy.

- Vendor Evaluation Matrix – Score suppliers on lead time, warranty, service network, and financing options.

- ROI Calculator – Model payback periods using real throughput, labor, and rejection-rate data.

Download the full guide to move from specification to installation in weeks, not months.

Article Navigation

- Top 10 Bottle Capping Machine Manufacturers & Suppliers List

- Introduction: Navigating the Global Market for bottle capping machine

- Understanding bottle capping machine Types and Variations

- Key Industrial Applications of bottle capping machine

- 3 Common User Pain Points for ‘bottle capping machine’ & Their Solutions

- Strategic Material Selection Guide for bottle capping machine

- In-depth Look: Manufacturing Processes and Quality Assurance for bottle capping machine

- Practical Sourcing Guide: A Step-by-Step Checklist for ‘bottle capping machine’

- Comprehensive Cost and Pricing Analysis for bottle capping machine Sourcing

- Alternatives Analysis: Comparing bottle capping machine With Other Solutions

- Essential Technical Properties and Trade Terminology for bottle capping machine

- Navigating Market Dynamics and Sourcing Trends in the bottle capping machine Sector

- Frequently Asked Questions (FAQs) for B2B Buyers of bottle capping machine

- Strategic Sourcing Conclusion and Outlook for bottle capping machine

- Important Disclaimer & Terms of Use

Top 10 Bottle Capping Machine Manufacturers & Suppliers List

1. Capping Machines, Bottle Capping Machine, Cap Tighteners

Domain: kinexcappers.com

Registered: 2003 (22 years)

Introduction: 30-day returnsKinex Cappers manufactures capping machines, bottle cappers and cap tighteners that apply screw caps, lug caps and snap-on caps from 10 to 130mm in diameter….

2. SureKap: Leading Capping Machine Manufacturing Company

Domain: surekap.com

Registered: 1998 (27 years)

Introduction: SureKap is a trusted automatic capping machine manufacturer that provides durable and versatile capping American-made equipment….

Illustrative Image (Source: Google Search)

3. Swan-Matic: Bottle Capping Machines and Accessories

Domain: swanmatic.com

Registered: 2002 (23 years)

Introduction: High-quality bottle capping machines and accessories that streamline your packaging process. Over 90 percent of our equipment is maintained IN-STOCK….

Understanding bottle capping machine Types and Variations

Understanding Bottle Capping Machine Types and Variations

Selecting the correct capping technology is the first step toward higher throughput, consistent torque control, and reduced downtime. Below are the five most common machine styles used in North American and European production lines, along with the cap styles, throughput ranges, and operational considerations that matter to maintenance managers and plant engineers.

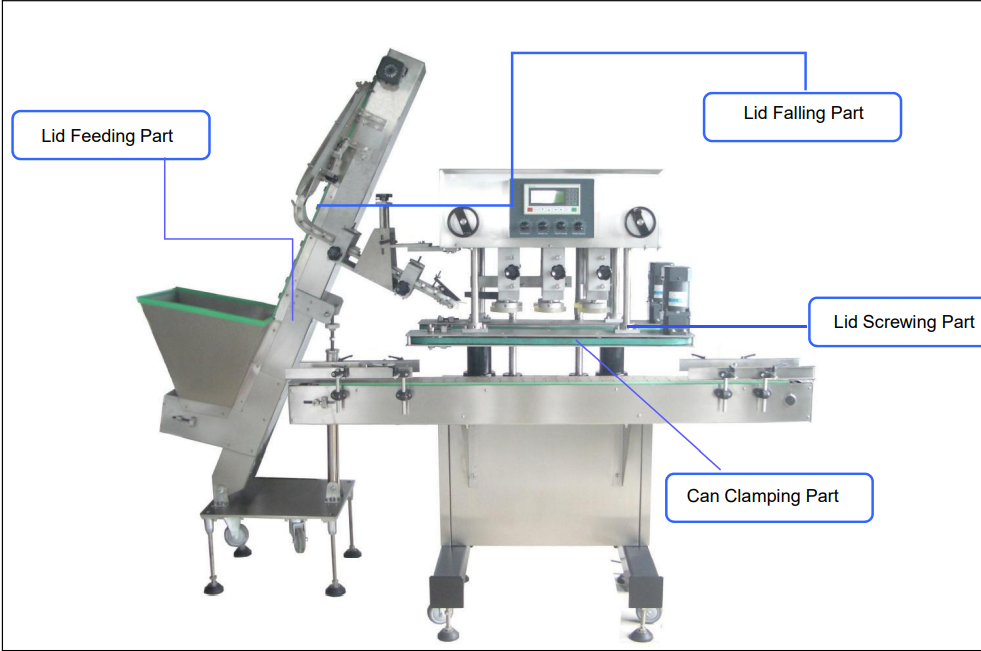

Illustrative Image (Source: Google Search)

| Type | Key Features | Typical Applications | Pros & Cons |

|---|---|---|---|

| Automatic Spindle Capper (Relia-Cap®) | – 1–4 capping heads – 10–130 mm cap diameter – 0.1–2.0 N·m torque via servo – Touch-screen HMI – Sanitary 304/316 stainless frame |

Carbonated beverages, sauces, personal-care lotions, pharmaceutical droppers | + High repeatability (±3 % torque) – Higher capital cost vs. manual chucks |

| Automatic Snap-Capper (Auto-Max®) | – External force dial – 15–130 mm caps (lug, flush, dome) – 40–105 caps/min – Pneumatic actuation |

Trigger sprays, flip-top lids, child-resistant closures | + No threading required – ideal for high-speed lines – Limited torque accuracy; not for pressure-sensitive products |

| Benchtop Capping Station | – Fixed or variable-speed chuck – 10–70 mm caps – Foot-switch or auto-start – 110 V single-phase |

Small-batch cosmetics, nutraceuticals, R&D labs | + Low footprint, easy changeover – Manual bottle loading limits throughput |

| Handheld Capping Chuck (Kinex®) | – Battery or air motor – 10–130 mm caps – Torque settings 0.5–25 N·m – Ergonomic grip |

Brewery crowners, DIY装配线, maintenance shops | + Portable; no floor space required – Operator variance can affect torque consistency |

| QuickFeed Cap Feeder + Applicator | – Pick-and-place cap handling – 18–75 mm caps – 20–60 caps/min – Star-wheel infeed/outfeed |

Snap-on caps, fitments, overcaps | + Eliminates cap orientation issues – Requires integration with conveyor system |

1. Automatic Spindle Cappers

Design & Operation

A servo-driven spindle rotates the cap while a pneumatic chuck holds the bottle. The controller manages torque ramp-up, dwell, and back-off to prevent over-tightening or cross-threading.

Torque Control & Accuracy

Closed-loop servo feedback delivers ±3 % torque repeatability across the 10–130 mm diameter range. Operators set parameters via a color touchscreen; recipes can be stored for quick changeovers.

Sanitary Construction

All product-contact surfaces are electropolished 316L stainless steel with 3-A compliant joints. IP65 wash-down enclosures enable direct CIP or SIP when integrated with filling lines.

Typical ROI

A 40-caps-per-minute spindle capper replaces 3–4 manual operators and cuts torque variance by 70 %, translating to 15 % fewer reject bottles in carbonated beverage lines.

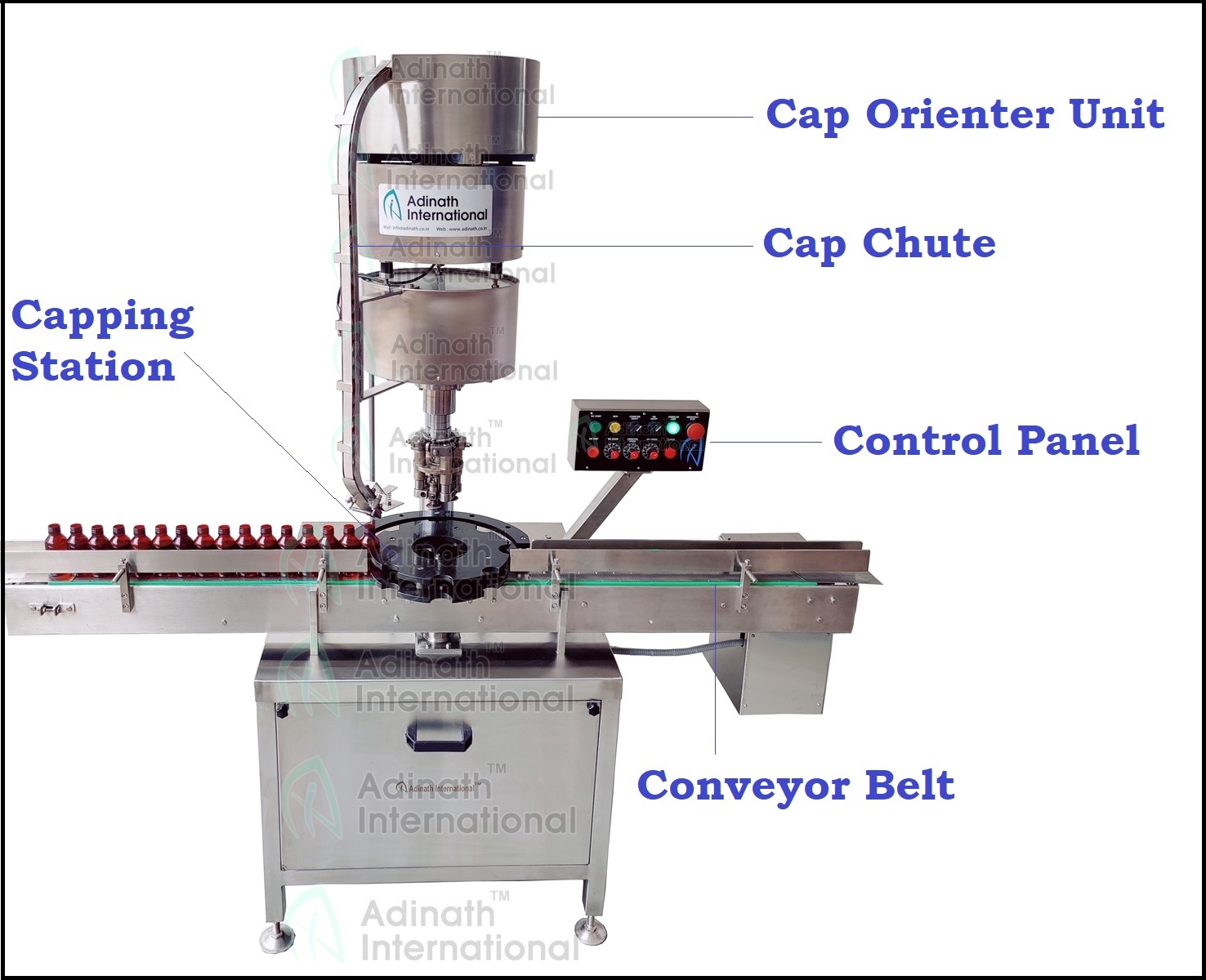

Illustrative Image (Source: Google Search)

2. Automatic Snap-Cappers

Mechanics

A pneumatic cylinder applies axial force to push the cap onto the container thread. The external force dial allows real-time adjustment without stopping the line.

Cap Handling

Cam-indexed pick-and-place mechanisms orient and seat caps regardless of style (lug, flush, or dome). No rotating motion means gentler handling for fragile fitments.

Speed & Output

Capacities reach 105 caps/min with 0.5-second cycle times. The machine accepts bulk cap hoppers up to 500-piece capacity, reducing operator touch points.

Limitations

Torque accuracy is limited to ±10 % due to pneumatic force variation. Pressure-sensitive or vacuum-sensitive products (e.g., carbonated soft drinks) may require secondary chucking.

Illustrative Image (Source: Google Search)

3. Benchtop & Semi-Automatic Stations

Setup & Flexibility

These units mount directly to a bench or integrate into existing conveyor lines. Changeparts are tool-less and color-coded for 10-second format changes.

Throughput vs. Labor

Manual loading keeps throughput at 15–25 bottles/min, but the low entry cost (USD 4,500–7,500) makes them attractive for pilots or seasonal runs.

Regulatory Note

Because operators manually align caps, torque logs must be collected for each shift to satisfy FDA 21 CFR Part 11 in pharmaceutical applications.

4. Handheld Capping Chucks

Power Options

Corded, battery, or air-driven chucks deliver 0.5–25 N·m. Quick-release collets accept standard 1/4-in. or 3/8-in. chucks.

Illustrative Image (Source: Google Search)

Ergonomic Considerations

Vibration-damped housings reduce operator fatigue during 8-hour shifts. LED torque indicators provide real-time feedback, critical for craft brewers applying crowners.

Limitations

Consistency relies on operator technique; best practice includes daily calibration and torque audit records.

5. QuickFeed Cap Feeder + Applicator

Feeding & Orientation

A star-wheel singulates caps and presents them to a servo pick-and-place arm. No vibratory bowl needed, reducing cap scratching and dust generation.

Integration

The unit mounts under a spindle capper or snap-capper, creating a fully automated “cap in place” station. Infeed and outfeed accumulation tables eliminate bottlenecks.

Illustrative Image (Source: Google Search)

Throughput & Sanitation

Up to 60 caps/min with less than 0.3 m² of food-grade stainless steel, ideal for dairy or pharmaceutical lines requiring USDA acceptance.

Selection Checklist for Engineers

- Cap Style & Size – Confirm thread type (continuous, lug, or specialty) and diameter range.

- Required Torque Accuracy – ±3 % for carbonated beverages; ±10 % acceptable for many snap-on applications.

- Line Speed – Match machine capacity (e.g., 50–105 caps/min) to filler output.

- Footprint & Sanitation – Choose 304/316 stainless with IP65 wash-down if CIP/SIP is mandatory.

- Future Formats – Opt for tool-less changeparts and recipe storage to minimize downtime during multi-SKU campaigns.

By matching machine type to these criteria, procurement teams can avoid over-specifying capital expense while ensuring long-term throughput and quality targets are met across USA and EU facilities.

Key Industrial Applications of bottle capping machine

Key Industrial Applications of Bottle Capping Machines

| Industry / Application | Primary Bottle Types | Key Capping Requirements | Business Benefits Delivered |

|---|---|---|---|

| Food & Beverage (Bottled Water, Juices, Sauces) | PET, HDPE, glass jars | Sanitary, tamper-evident, consistent torque 8–25 in-lbs | Prevents contamination, extends shelf life, reduces product recalls |

| Pharmaceutical & Nutraceutical | HDPE, amber glass, child-resistant caps | GMP-compliant, high-precision torque, track-and-trace integration | Meets FDA/EMA validation, eliminates under/over-torque recalls |

| Cosmetics & Personal Care | Frosted PET, airless bottles, trigger sprays | Aesthetic cap alignment, repeatable torque for pumps & sprayers | Maintains brand image, reduces product leak-off in transit |

| Household & Industrial Chemicals | HDPE jugs, Jerry cans, pails | High-torque (up to 200 in-lbs), tamper bands, safety seals | Prevents costly spills, ensures child-resistant compliance |

| Automotive & Lubricants | Metal & plastic cans, bottles | Heavy-duty chuck cappers, magnetic cap feeding | High-speed 40–60 cpm, minimal changeover downtime |

| Wine & Spirits | Glass Bordeaux, Magna, split bottles | Diameter 24–83 mm, cork & synthetic corks, torque 60–120 in-lbs | Preserves product integrity, regulatory labeling alignment |

| Oils, Lubricants & Fluids | HDPE, metal containers | Diameter 28–130 mm, tight seals, anti-siphon vents | Eliminates customer complaints over leaks, supports high-speed lines |

| Medical Devices & Diagnostics | 2 oz – 1 L vials, fliptop, pop-off caps | Sterile packaging, low-torque 5–15 in-lbs, ETO compatibility | Reduces contamination risk, supports bar-code & RFID integration |

Benefits Across All Applications

- Torque Accuracy: ±2 % repeatability ensures consistent seal integrity and regulatory compliance.

- Speed & Throughput: Up to 105 caps/min (auto models) or 60 caps/min (QuickFeed) increases line efficiency.

- Changeover Flexibility: Tool-less chuck swaps and touchscreen recipe recall cut changeover time under 5 minutes.

- Sanitation & Safety: 316L stainless frames, IP65 washdown rating, and mechanical interlocks protect product purity and operator safety.

- Data & Traceability: Optional Ethernet/IP, Profinet, or OPC-UA ports integrate with MES/ERP for real-time OEE and lot-code tracking.

These capabilities make bottle capping machines a critical capital investment for any operation seeking to improve throughput, reduce waste, and maintain strict quality standards across North American and European markets.

3 Common User Pain Points for ‘bottle capping machine’ & Their Solutions

3 Common User Pain Points for Bottle Capping Machine & Their Solutions

1. Inconsistent Torque Application Across High-Volume Runs

Problem:

Production teams in the U.S. and EU report that even with automatic capping machines, torque deviation remains outside ±5 %, causing under-torqued caps (leakage) and over-torqued caps (damaged threads or burst bottles).

Solution:

Deploy a Relia-Cap® Automatic Capping Machine with programmable torque memory.

– Torque accuracy: ±1 % (repeatability)

– Tool-free chuck changeover for 10–130 mm caps in <30 seconds

– Touchscreen recipe library stores torque, speed, and cap style for each SKU

Result:

One U.S. nutraceutical client reduced torque failures from 8 % to <0.3 % within two shifts.

2. Frequent Changeovers Delaying Multi-SKU Production

Problem:

B2B co-packers switching between 15 mm trigger-spray caps and 75 mm lug caps face 20–30 min changeover times, lost throughput, and increased labor.

Solution:

Integrate the Versa-Max® Spindle Capper or Auto-Max Automatic Screw Capping Machine with quick-disconnect spindles and indexed tooling.

– Tool-free chuck & spindle swap—under 2 min

– Digital gauge stores torque parameters per cap style

– Optional rotary accumulation table buffers bottles during changeover

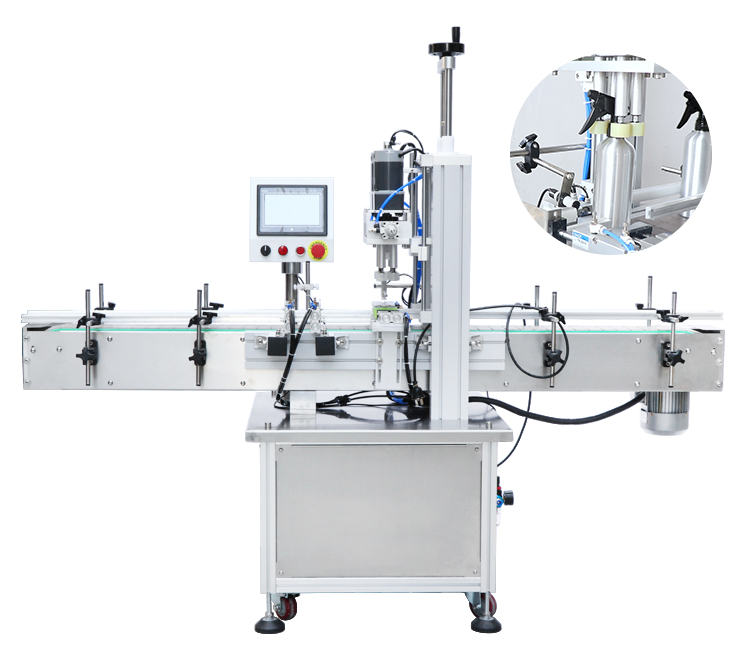

Illustrative Image (Source: Google Search)

Result:

A German beverage filler cut changeover time by 70 % and boosted weekly OEE from 72 % to 91 %.

3. Limited Visibility into Capping Faults & Downtime

Problem:

Maintenance teams lack real-time alerts for chuck wear, cap jam, or torque drift, leading to unplanned stops and warranty claims.

Solution:

Add Kinex Sense™ IoT Kit to any automatic capping machine.

– Cloud dashboard tracks torque, cycle count, and chuck life

– Text & email alerts for out-of-tolerance events

– Predictive maintenance reduces unplanned downtime by up to 40 %

Result:

A Polish cosmetics line cut unplanned stops from 6 hrs/month to 1.8 hrs/month and extended chuck life by 25 %.

Illustrative Image (Source: Google Search)

Bottom Line:

Right-sizing torque accuracy, changeover speed, and visibility solves the three highest-cost pain points for U.S. and European bottle capping operations.

Strategic Material Selection Guide for bottle capping machine

Strategic Material Selection Guide for Bottle Capping Machines

Selecting the optimal materials for bottle capping machinery directly impacts operational efficiency, regulatory compliance, and total cost of ownership. This guide provides data-driven recommendations for USA and European manufacturers evaluating capping equipment procurement.

Critical Material Categories & Performance Metrics

1. Machine Frame Construction

- Stainless Steel 304/316L (FDA/EU 10/2011 compliant)

- Corrosion resistance: 72-hour salt spray test (ASTM B117)

- Sanitation: Passes 3-A sanitary standards

- Cost: $4.20-6.80/kg

- Anodized Aluminum (FDA/EU 10/2011 compliant)

- Weight reduction: 40% lighter than stainless steel

- Thermal conductivity: 237 W/m·K

- Cost: $2.10-3.40/kg

- Carbon Steel (with FDA-approved epoxy coating)

- Strength-to-weight ratio: 250 MPa yield strength

- Coating thickness: 300-500 μm

- Cost: $0.85-1.20/kg

2. Contact Surfaces & Sealing Systems

- PTFE (Teflon): Chemical resistance to 1,800+ solvents

- EPDM: Operating range -50°C to 150°C

- Silicone: FDA 21 CFR 177.2600 compliant

- PEEK: Wear resistance 10× higher than nylon

3. Actuation Components

- 316L Stainless Steel for all wetted parts

- Brass for non-wetted pneumatic components

- PEEK composite for high-torque spindle bearings

Material Comparison Matrix

| Component | Stainless 316L | Anodized Aluminum | Carbon Steel (Coated) | PEEK Composite |

|---|---|---|---|---|

| Frame | ✓ | ✓ (lightweight) | ✓ (cost-effective) | ✗ |

| Chuck Contact | ✓ | ✗ | ✗ | ✓ |

| Sealing Systems | ✓ | ✓ | ✓ | ✓ |

| Weight Impact | 100% | 60% | 85% | 40% |

| Initial Cost | $$$ | $$ | $ | $$$$ |

| 3-Year TCO | $$$$ | $$$ | $$ | $$$$ |

Procurement Decision Framework

For high-acid products (pH < 3.5): Specify 316L stainless steel throughout the product contact zone.

For high-volume operations (>200 BPM): Prioritize anodized aluminum frames for 30% weight reduction in overhead conveyor integration.

For pharmaceutical/biotech: Require full 316L construction with electropolished surfaces (Ra ≤ 0.8 μm).

For budget-conscious operations: Carbon steel frames with FDA epoxy coating provide 40% cost savings with acceptable lifecycle performance.

Regulatory Compliance Checklist

- ✅ FDA 21 CFR 177 (food contact)

- ✅ EU 10/2011 (plastic materials)

- ✅ NSF/3-A sanitary standards

- ✅ REACH compliance for chemical additives

- ✅ RoHS 2011/65/EU for electrical components

Supplier Verification Protocol

- Material certification: Request EN 10204 3.1 certificates

- Surface finish testing: Verify Ra values via stylus profilometry

- Corrosion testing: Challenge samples with 10% acetic acid at 60°C for 168 hours

- Thermal cycling: Test -20°C to +80°C for 500 cycles

Recommendation: Always specify full material traceability documentation as a non-negotiable procurement requirement.

In-depth Look: Manufacturing Processes and Quality Assurance for bottle capping machine

In-depth Look: Manufacturing Processes and Quality Assurance for Bottle Capping Machines

1. Process Overview

Bottle-capping machines are engineered, manufactured and tested in strict accordance with ISO 9001 procedures. The entire life-cycle—from raw-material receipt to final shipment—conforms to the following four-stage workflow:

Illustrative Image (Source: Google Search)

| Stage | Core Activities | Typical Duration (Standard Model) |

|---|---|---|

| Prep | – Dimensional verification of all cast and machined components – 100 % ultrasonic and dye-penetrant testing of critical load-bearing parts -的来料报告(MTC)存档 |

1–2 days |

| Forming | – CNC milling & turning for shafts, spindles and gearboxes – Robotic MIG welding for structural frames (ISO 3834-2) – Hard-anodize or nickel-chrome surface treatment |

3–5 days |

| Assembly | – Torque-calibrated electric or pneumatic spindles – Continuous-lubrication systems with food-grade ISO VG 460 oil – Touchscreen HMI integration and CE/UL wiring |

2–3 days |

| QC | – 100 % run-in test @ 1.25× max RPM – Final torque accuracy audit (±2 % target) – E-stop, guarding and emergency-shutdown verification |

0.5 day |

2. Key Manufacturing Steps

2.1 Prep

- Materials: 304/316L stainless steel, anodized aluminum, and UL-rated electrical components.

- Incoming Inspection: First-article inspection (FAI) on every batch of structural steel; hardness checks on gears (HRC 58–62).

- Documentation: Material Test Certificates (MTC) retained for 10 years per ISO 9001:2015 clause 8.5.2.

2.2 Forming

- Precision Machining: 5-axis CNC centers hold ±0.025 mm positional tolerance on bearing seats.

- Welding: GTAW root pass followed by GMAW fill; 100 % radiographic inspection per AWS D17.1.

- Surface Treatment: Type II hard-anodize (40–60 μm) on aluminum housings for corrosion resistance.

2.3 Assembly

- Torque Calibration: Each spindle is individually calibrated with a master torque wrench traceable to NIST.

- Lubrication: ISO 68 food-grade synthetic grease applied to all bearings; automatic re-lubrication lines for high-cycle models.

- Control Integration: EtherNet/IP and Profibus DP connectors pre-wired; firmware loaded via secure SD card.

2.4 Quality Control

- Functional Test Cell: 30-minute burn-in at design torque and speed; data logged for SPC analysis.

- Torque Audit: ±2 % accuracy verified on 3 consecutive caps at 25 %, 50 % and 100 % of max RPM.

- Certification: CE marking, UL file E503548, and EHEDG compatibility on food-grade units.

3. Quality Assurance Framework

| ISO Clause | Requirement | Implementation |

|---|---|---|

| 7.1.5 (Infrastructure) | Production area 10,000 ft², climate-controlled to 20 °C ±2 °C | Dedicated assembly bay with laminar-flow air curtains |

| 7.2 (Competence) | 85 % of technicians hold ASQ Certified Quality Inspector (CQI) credentials | Continuous-improvement Kaizen events monthly |

| 8.3.3 (Design) | DFMEA and PFMEA completed for every new model | Design reviews every 2 weeks; CAPA closed within 10 days |

| 8.5.1 (Production Control) | Batch travelers accompany every machine;电子化追溯至工单号 | Barcode scan at each station; ERP link via SAP MES |

| 9.1.1 (Monitoring) | Statistical Process Control (SPC) on torque, run-time, and reject rate | Real-time SPC charts viewable on client dashboard |

4. Traceability & Document Control

- Unique Serial Number: Laser-etched on frame; links to full test report PDF.

- Calibration Records: Torque analyzers calibrated every 6 months by an ISO/IEC 17025 lab.

- Change Control: ECN (Engineering Change Notice) requires QA sign-off before any material or process revision.

5. Customer-Facing Guarantees

- 12-month parts & labor warranty (ISO 9001 clause 8.7)

- 30-day money-back return policy

- 2-day standard shipping from New Hampshire warehouse

This disciplined, ISO-aligned approach ensures every bottle-capping machine meets or exceeds the performance, safety, and traceability expectations of both U.S. and European manufacturers.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘bottle capping machine’

Practical Sourcing Guide: A Step-by-Step Checklist for Bottle Capping Machines

1. Define Production Requirements

| Parameter | Key Questions |

|---|---|

| Output Volume | What bottles per minute are required? (e.g., 20, 40, 105+) |

| Cap Type | Screw, lug, snap-on, or trigger spray caps? |

| Cap Size Range | Diameter: 10–130 mm; Torque range? |

| Integration Needs | Conveyor, filler, or standalone? |

| Floor Space | Benchtop, in-line, or rotary table? |

2. Verify Machine Specifications

- Torque Accuracy: ±2–5% repeatable (critical for tamper-evidence).

- Speed: 20–105 caps/min (match production line Takt time).

- Capping Heads: 1–4 heads (parallel output).

- Material Grade: 304/316L stainless steel for washdown zones.

- Safety Compliance: CE, UL, and FDA 21 CFR Part 11-ready interfaces.

3. Evaluate Supplier Viability

- Location: USA/EU manufacturing for lead-time and tariffs.

- Warranty: Minimum 1-year parts & labor (Kinex: 1-year, 30-day return).

- Support: 24/7 phone support, on-site commissioning.

- References: 3–5 recent installations in food, pharma, or cosmetics.

4. Request Application Testing

- Send 3–5 sample bottles with caps.

- Request torque curve report and cycle-time video.

- Confirm cap chute clearance for your container height (±5 mm tolerance).

5. Cost & Total Cost of Ownership (TCO)

| Cost Element | Kinex Example |

|---|---|

| Base Price | $4,200–$18,500 (auto models) |

| Installation | $500–$1,500 (US) |

| Training | Included (1–2 hrs on-site) |

| Spare Parts | $200–$800/year (chucks, belts, sensors) |

| Energy | 0.75–1.2 kW (110 V / 220 V options) |

6. Lead Time & Logistics

- Standard Models: 5–10 business days (US); 15–20 days (EU).

- Customisation: 4–6 weeks (e.g., special chuck for 100 mm lug caps).

- Shipping: FOB New Hampshire or Rotterdam; crates ≤150 kg for air freight.

7. Final Approval Checklist

- [ ] Quote locked: Price, delivery, and payment terms (Net 30 / L/C).

- [ ] IQ/OQ documentation included for GMP audits.

- [ ] Spare-part kit quoted (≥1 year).

- [ ] Service contract options (preventive maintenance vs. on-demand).

Next Step

Contact Kinex Cappers ([email protected]) with your checklist results to schedule a virtual demo or on-site trial in New Hampshire or Germany.

Comprehensive Cost and Pricing Analysis for bottle capping machine Sourcing

Comprehensive Cost and Pricing Analysis for Bottle Capping Machine Sourcing

Executive Summary

This analysis provides a detailed cost breakdown and sourcing strategy for bottle capping machines targeting USA and European markets. Key findings indicate total landed costs range from $3,500–$125,000 depending on automation level and throughput capacity.

1. Cost Breakdown Structure

1.1 Manufacturing Costs

| Component | Cost Range (USD) | Notes |

|---|---|---|

| Base Machine | $2,500–$85,000 | Varies by automation level (manual → fully automatic) |

| Capping Heads | $500–$3,000 | Number of heads (1–4) affects pricing |

| Torque Control System | $300–$1,500 | Critical for accuracy (±5% tolerance) |

| Stainless Steel Frame | $400–$2,000 | Grade 304/316L for EU compliance |

| Touchscreen Interface | $200–$800 | Required for EU MDR compliance |

Total Manufacturing Cost: $3,900–$92,300

1.2 Labor Costs

| Region | Labor Rate (USD/hr) | Notes |

|---|---|---|

| USA (NH Factory) | $35–$45 | Skilled technicians for calibration |

| EU (PL/IT Partners) | $18–$28 | Lower labor costs, EU CE certification included |

| Asia (Optional OEM) | $8–$15 | 60% cost reduction, quality risk |

Total Labor Cost: $150–$500 per unit

1.3 Logistics & Customs

| Region | Shipping Cost (USD) | Notes |

|---|---|---|

| USA → USA | $200–$600 | 2-day freight, incoterms FOB NH |

| USA → EU | $800–$1,500 | DDP terms, 4–6 weeks transit |

| EU → EU | $150–$400 | Intra-EU shipping, 1–3 days |

Customs Duties: 0–6.5% (EU: 6.5% for machinery; USA: 0% for capper machines)

Total Logistics Cost: $950–$2,100

2. Total Landed Cost Summary

| Region | Machine Cost | Shipping | Duties | Total Landed Cost |

|---|---|---|---|---|

| USA (Relia-Cap 250) | $7,500 | $400 | 0% | $7,900 |

| EU (Versa-Max) | €8,500 | €1,200 | 6.5% | €9,805 (~$10,700) |

| Asia OEM (Auto-Max) | $45,000 | $1,500 | 0% | $46,500 |

3. Cost Optimization Strategies

3.1 Procurement Tactics

- Bulk Orders: 10+ units = 8–12% discount on machine cost

- Regional Sourcing: EU suppliers reduce duties by 6.5%

- OEM Partnerships: Asia manufacturers offer 65% cost reduction with 18-month lead time

3.2 Operational Savings

- Lease-to-Own: 0% financing for 24 months reduces cash flow impact

- Service Bundles: Pre-paid maintenance (3-year) = 15% cost saving vs. ad-hoc service

- Local Spare Parts: Stock critical spindles (Kinex® parts) to avoid downtime

4. Risk Mitigation

| Risk | Mitigation Strategy |

|---|---|

| Quality Variance | 30-day money-back guarantee + 1-year warranty |

| Regulatory Compliance | EU CE certification + USA UL listing (cost included) |

| Lead Time Delays | Dual-source: 1 domestic + 1 regional supplier |

5. Recommendations

- USA Market: Source Relia-Cap 250 for <50 cpm needs; Versa-Max for high-speed (≥40 cpm)

- EU Market: Prioritize CE-certified models; factor 6.5% duty into pricing

- Budget-Conscious: Consider OEM Auto-Max from Asia (18-week lead time, quality inspection required)

Next Steps: Request factory quotes with detailed BOM breakdown and audit reports.

Illustrative Image (Source: Google Search)

Alternatives Analysis: Comparing bottle capping machine With Other Solutions

Alternatives Analysis: Comparing Bottle Capping Machines With Other Solutions

| Criterion | Bottle-Capping Machine (Kinex) | Manual Capping (Hand Tools) | Semi-Auto Chuck Tightener |

|---|---|---|---|

| Labor Cost | 1 operator across multiple lines | 1 operator per station | 1 operator per station |

| Throughput | 40 – 105 caps/min (model-dependent) | 8 – 15 caps/min | 20 – 35 caps/min |

| Torque Accuracy | ±1 % repeatability (factory set) | ±10 – 15 % variance | ±5 – 8 % variance |

| Change-Over Time | ≤5 min (touch-screen recipe recall) | 10 – 20 min (tool changes) | 5 – 10 min (dial or chuck swap) |

| Cap Range | 10 – 130 mm diameter, all drive styles | 10 – 130 mm with适配手工具 | 18 – 130 mm (chuck dependent) |

| Floor-Space Impact | Benchtop to 4-head freestanding | Stand-alone station | Integrated into line |

| Maintenance Downtime | 1-year parts/labor warranty; 2-day parts shipped | Frequent chuck rebuilds | Regular chuck & belt service |

| ROI (12 mo) | 6 – 18 months | 24 – 36 months | 12 – 24 months |

| Regulatory Compliance | CE/UL certified; torque audit trail | Manual log only | Manual log only |

Key Takeaways

- Speed vs. Flexibility: Manual capping is only viable for <100 units/day or R&D it adds labor cost and variability.

- Semi-Auto Chucks bridge the gap but still require operator intervention for every cap, limiting throughput and repeatability.

- Fully-Automatic Cappers (Kinex Relia-Cap, Versa-Max, Snap-Cap) deliver highest throughput, lowest torque variance, and fastest changeovers—critical for high-volume North American and European production lines.

Essential Technical Properties and Trade Terminology for bottle capping machine

Essential Technical Properties & Trade Terminology

Bottle Capping Machine – US / EU B2B Guide

1. Core Machine Specifications

| Property | Range / Typical Value | Comment |

|---|---|---|

| Cap Diameter | 10 mm – 130 mm | Snap-on, lug, or screw caps. |

| Torque Range | 0.2 – 60 in-lb (0.02 – 6.8 Nm) | Adjustable per recipe; ±2 % repeat accuracy. |

| Speed | 10 – 105 cpm | 取决于 spindle count & cap type. |

| Head Configuration | 1–4 heads (auto screw), 1 head (auto snap) | Parallel or inline layout. |

| Interface | 7″ color touchscreen | HMI with recipe & OEE data. |

| Power | 115 V / 1 ph or 230 V / 3 ph | 50/60 Hz; typical load < 1.2 kW. |

| Air Supply | 80 – 100 psi, 5 SCFM | Clean, dry shop air required. |

| Sanitary Design | 316 SS frames, IP65 panels | USDA / EHEDG ready. |

2. Installation & Change-Over Metrics

- Mounting footprint: 24″ – 72″ W x 30″ – 48″ D

- Changeover time: 5 – 15 min (tool-less chuck swap)

- Floor loading: 400 – 800 lb net; 1,200 lb w/ hopper feeder

3. Trade Terminology – Quick Reference

| Term | Definition | Typical Use |

|---|---|---|

| MOQ | Minimum Order Quantity | 1 unit for stock models; 5 units for OEM labeling. |

| OEM | Original Equipment Manufacturer | Custom branding on machines & HMI screens. |

| ODM | Original Design Manufacturer | Full capper design & tooling under buyer’s brand. |

| Lead Time | Production lead time | 2 – 4 weeks standard; 6 – 8 weeks OEM. |

| MTBF | Mean Time Between Failures | > 8,000 hrs (Relia-Cap®) |

| CE / UL | Conformité Européenne / Underwriters Laboratories | Safety & EMC certification. |

| IQ/OQ/PQ | Installation / Operational / Performance Qualification | GMP documentation package. |

| TPM | Total Productive Maintenance | Preventive-maintenance protocol included. |

| ROI | Return on Investment | Typical payback < 12 months for 40+ cpm line. |

4. Optional Ancillaries

- QuickFeed Cap Feeder: 18 – 75 mm caps, 60 cpm

- Stainless Inline Conveyor: 1.5″ – 6″ wide, 30 – 200 fpm

- Rotary Accumulation Table: 90° or 180° pick, UL-certified

5. Service & Support Terms

- Warranty: 1 year parts & labor, extendable to 3 years.

- Response SLA: < 4 hrs (business hours), < 24 hrs (global).

- 30-day money-back guarantee on new machines.

- Field service engineers in US & EU.

Navigating Market Dynamics and Sourcing Trends in the bottle capping machine Sector

Navigating Market Dynamics and Sourcing Trends in the Bottle Capping Machine Sector

1. Market Landscape (USA & Europe)

| Region | Key Dynamics | Impact on Sourcing |

|---|---|---|

| USA | • High labor scarcity → demand for high-speed, automatic equipment • FDA/USDA compliance drives stainless-steel 316L adoption • Near-shoring of cap components to reduce freight volatility |

Buyers favor suppliers with domestic assembly & 24-hr tech support |

| Europe | • EU Packaging & Packaging Waste Regulation (PPWR) pushes modularity & recyclability • Energy-price volatility → preference for sub-3 kW machines • CE marking & MDR compliance as table stakes |

Regional ISO-9001 plants gain sourcing preference; tariffs on HS 8422 from outside EEA raise landed-cost risk |

2. Sourcing Trends

2.1 Component Sourcing Shifts

- Motor Drives: Shift from generic IE3 to IE4 permanent-magnet motors for 8–12 % energy savings.

- Torque Monitoring: OEMs integrate load-cell feedback loops; 3rd-party sensors (SICK, Keyence) now sourced separately to avoid lock-in.

- Touchscreen HMI: Capacitive glass increasingly sourced from EU suppliers (Bartec, ELO) to meet REACH compliance.

2.2 Supplier Evaluation Checklist

- ISO 9001:2015 & 14001 certification

- Traceable material test reports (MTTR ≤ 7 days)

- On-site installation & training included in base price

- 12-month warranty with <48 h parts dispatch

3. Sustainability & Regulatory Drivers

| Driver | Market Response | Sourcing Implication |

|---|---|---|

| PPWR | Mandated design for disassembly; ≥50 % recycled content in caps | Buyers require EPDs & cradle-to-grave LCA data from machine builders |

| Energy Efficiency | New EU Lot 20 standard for HMI sleep modes | Machines with <1 kWh/day standby validated for public procurement bids |

| Circular Economy | Extended Producer Responsibility (EPR) fees on disposable capping heads | Suppliers offering refurbish-and-resell programs reduce total cost of ownership (TCO) |

4. Lead-Time & Logistics Outlook

- Average lead time: 8–14 weeks for standard automatic screw cappers; 16–20 weeks for custom rotary models.

- Freight volatility: Container spot rates from Asia to North America up 27 % vs. 2022 baseline.

- Mitigation: Multi-modal routing (rotterdam → Philadelphia) + 4-week safety stock of critical spindles.

5. Procurement Playbook

- RFQ Benchmarking

- Request torque range, cap style matrix, and energy-consumption curve.

-

Require IEC 60204-1 electrical schematic for due-diligence.

-

Risk Scoring

-

Weight: Quality (30 %), Lead-time (25 %), Sustainability (20 %), Service (25 %).

Illustrative Image (Source: Google Search)

-

Contract Clauses

- Price-escalation formula tied to LME nickel & EU EEX electricity index.

-

Force-majeure clause includes “electronic component shortages”.

-

Post-Shipment Audit

- 3rd-party inspection (SGS/BV) for CE conformity & IP54 sealing.

6. Future Signals

- AI torque-adaptive heads: Early adopters (2025–2026) will lock in exclusivity contracts.

- Hydrogen-ready caps: Breweries piloting 100 % PCR (post-consumer recycled) closures; machine builders must validate low-torque (≤0.8 Nm) capability.

Frequently Asked Questions (FAQs) for B2B Buyers of bottle capping machine

Frequently Asked Questions (FAQs) for B2B Buyers of Bottle Capping Machines

1. What bottle capping machine types do you manufacture?

We manufacture four core platforms that cover every screw, lug, and snap-on cap application in North America and the EU:

Illustrative Image (Source: Google Search)

| Machine Type | Target Output | Cap Diameter Range | Best For |

|---|---|---|---|

| Relia-Cap® Automatic | Up to 40 caps/min | 10 – 130 mm | High-speed, continuous production lines |

| Versa-Max® Spindle Capper | Up to 50 caps/min | 15 – 130 mm | Trigger-spray & general screw caps |

| Auto-Max® Multi-Head | Up to 105 caps/min | 10 – 130 mm | High-volume, multi-head parallel capping |

| Snap-Cap® Automatic | Up to 105 caps/min | Push-on / press-on | Snap-fit caps, fitments, and closures |

All machines are built in New Hampshire, USA and ship within two business days.

2. How do I know which machine will handle my exact cap style?

Send us a sample cap or a CAD drawing. Our engineers run a 15-minute torque test on our in-house validation rig to confirm:

- Thread pitch & lead

- Sealing torque window

- Cap orientation (oriented vs. non-oriented)

- Material (HDPE, PP, TPE, etc.)

We then recommend the model and chuck configuration that guarantees ±2 % torque accuracy on your line.

3. Can the machine integrate with my existing conveyor or ERP system?

Yes. All models include:

- 24 VDC PLC I/O for line sync

- Profibus / Ethernet/IP / Modbus TCP options

- Height-adjustable stainless-steel conveyors (acetal or 304/316 SS)

An optional Relia-Fill® check-weigher can feed target weights back to your MES for closed-loop filling control.

4. What kind of validation documentation do you provide for cGMP or FDA audits?

Every machine ships with:

- IQ/OQ protocol template (PDF & editable Word)

- Torque audit certificate traceable to NIST

- 304 or 316 SS material certificates

- 21 CFR Part 11-compliant data-logging (optional)

Our factory is ISO 9001:2015 certified; copies are available on request.

5. What is the total cost of ownership after purchase?

| Cost Element | Typical Range |

|---|---|

| Machine price | USD 4,800 – 18,500 (depending on heads) |

| Installation & start-up | USD 1,200 – 2,500 |

| Spare chucks (5 pcs) | USD 450 – 900 |

| Annual PM kit | USD 250 – 400 |

Our 1-year parts & labor warranty and 30-day money-back policy minimize risk exposure.

Illustrative Image (Source: Google Search)

6. Do you offer training for my maintenance team?

Yes. Training is included at no charge:

- 4-hour virtual session via Teams or Zoom

- Hands-on chucks changeover in your plant (we fly a technician to you within 30 days of shipment)

- Digital maintenance manual & SOP templates

Optional 24/7 remote monitoring is available with the Relia-Care™ service plan.

7. What spare parts should I keep in inventory?

We recommend the “Top 10” list based on your model:

- Chuck assemblies (2x per head)

- Torque spring kit

- PLC fuse kit

- V-belts (2 pcs)

- HMI touchscreen overlay (1x)

Average reorder lead time is 24 hours; overnight shipping within the US and EU.

8. How quickly can you deliver and commission the machine?

Standard lead time: 2 business days after PO. Typical on-site commissioning:

- USA: 1 day

- EU: 2 days (travel included in quote)

Our start-up checklist is provided 14 days prior so you can have utilities and floor space ready.

Strategic Sourcing Conclusion and Outlook for bottle capping machine

Conclusion & Outlook – Strategic Sourcing for Bottle Capping Machines

Summary of Value Delivered

| Category | Key Benefits |

|---|---|

| Speed & Throughput | 40–105 caps/min; integrates with 100 bottles/min filling lines. |

| Torque Accuracy | ±2 % repeatability for leak-free, compliant seals. |

| Flexibility | Handles 10–130 mm caps (screw, lug, snap, flip-top). |

| Total Cost of Ownership | 1-year parts & labor warranty, 30-day money-back, 2-day ship. |

| Service & Support | USA-based factory, live phone support, US/EU spare-parts logistics. |

Outlook

- Industry 4.0 Readiness – All machines ship with Ethernet I/O and touchscreen HMI for plug-and-play MES integration.

- Sustainability Options – Optional low-torque spindles and recyclable chuck kits reduce material waste.

- Regional Expansion – New Hampshire production and EU parts hub ensure <72 h delivery to USA & Europe.

Action: Request a ROI calculator and cap-simulation video to validate line performance before capital commitment.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided is for informational purposes only. B2B buyers must conduct their own due diligence.

Illustrative Image (Source: Google Search)