The global industrial fasteners market, a critical segment underpinning automotive, construction, and manufacturing sectors, was valued at approximately USD 98.8 billion in 2022 and is projected to grow at a CAGR of around 4.6% from 2023 to 2030, according to Grand View Research. With tightening regulatory standards and rising demand for high-performance materials, precision bolt specifications have become increasingly vital. This growth is further driven by advancements in aerospace, renewable energy infrastructure, and electric vehicle production—sectors that require strictly defined bolt tolerances, strength ratings, and corrosion resistance. As industries demand greater traceability and compliance with ISO, DIN, and ASTM standards, manufacturers specializing in high-specification bolts are emerging as key enablers of reliability and safety. Within this expanding landscape, the following ten companies stand out for their technical capabilities, global reach, and innovation in bolt specifications and materials engineering.

Top 10 Bolt Specs Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 Valley Forge & Bolt

Domain Est. 1997

Website: vfbolts.com

Key Highlights: Valley Forge & Bolt manufactures hot forged fasteners with real-time load monitoring for better performance….

#2 Portland Bolt

Domain Est. 1998 | Founded: 1912

Website: portlandbolt.com

Key Highlights: Portland Bolt has manufactured and distributed the highest-quality anchor bolts and nonstandard construction fasteners since 1912….

#3 Custom Fasteners Manufacturer

Domain Est. 1999

Website: nationalbolt.com

Key Highlights: National Bolt and Nut Corporation is a ISO Certified Nationwide custom fasteners manufacturer of nuts, washers, bolts and fasteners. Contact us today!…

#4 U

Domain Est. 1999

Website: uboltit.com

Key Highlights: At U-Bolt-It, we custom manufacture bolts and fasteners made to meet all your requirements and in all materials from stainless steel and exotic materials….

#5 The New 2027 Bolt

Domain Est. 1994

Website: chevrolet.com

Key Highlights: The Chevy Bolt is back and better than ever with its fast charging, comfort-focused interior, enhanced tech, and updated safety features….

#6

Domain Est. 1997

Website: arp-bolts.com

Key Highlights: ARP was the first company to design and engineer fasteners specifically for racing. We developed many patented process for manufacturing high strength ……

#7 2025 BOLT R-SPEC – Specifications

Domain Est. 2001

Website: yamahamotorsports.com

Key Highlights: Engine Type, 58-cubic-inch (942cc) air-cooled SOHC V-twin; 4 valves. Bore x Stroke, 85.0mm x 83.0mm. Compression Ratio, 9.0:1. Fuel Delivery, Fuel injection….

#8 Bolt-Spec

Domain Est. 2009

Website: bolt-spec.com

Key Highlights: With over 35 years of industry experience combined with the PASSION and DRIVE to always perform at a top notch level, Bolt-Spec is ready to become the next ……

#9 Extreme Bolt

Domain Est. 2012

Website: extreme-bolt.com

Key Highlights: We focus solely on ENGINEERED POLYMER, ADVANCED CERAMIC and SPECIALTY METAL fasteners for the most challenging applications….

#10 Bolt Graphics

Website: bolt.graphics

Key Highlights: We built a completely new graphics processor to enable faster renderings and simulations for users in the creative, gaming, and research industries….

Expert Sourcing Insights for Bolt Specs

H2: Market Trends for Bolt Specs in 2026

As we approach 2026, the market for bolt specifications (bolt specs) is undergoing significant transformation driven by advancements in materials science, sustainability mandates, digitalization in manufacturing, and evolving regulatory standards across key industries such as automotive, aerospace, construction, and renewable energy. Below is an analysis of the key market trends shaping the demand, development, and application of bolt specs in 2026.

-

Increased Demand for High-Performance Materials

The demand for bolts made from advanced materials—such as high-strength alloy steels, titanium, and corrosion-resistant stainless steels—is rising. Industries like aerospace and electric vehicle (EV) manufacturing require fasteners that offer superior strength-to-weight ratios and resistance to extreme conditions. Bolt specs are being revised to accommodate tighter tolerances and enhanced mechanical properties, particularly for applications in lightweight vehicle frames and aircraft components. -

Standardization and Global Harmonization

In 2026, there is a growing push toward global harmonization of bolt specifications, driven by international supply chains and trade agreements. Organizations such as ISO (International Organization for Standardization) and ASTM International are updating bolt standards (e.g., ISO 898, ISO 3506) to ensure compatibility and safety across regions. This trend enhances interoperability and reduces manufacturing complexity for multinational companies. -

Digital Integration and Smart Fastening Systems

The integration of digital technologies into bolt manufacturing and quality control is accelerating. In 2026, smart bolts equipped with embedded sensors (measuring torque, tension, and temperature) are gaining traction in critical infrastructure and industrial machinery. These innovations require updated bolt specs that define not only mechanical properties but also data interface protocols and digital traceability, aligning with Industry 4.0 practices. -

Sustainability and Circular Economy Pressures

Environmental regulations and corporate ESG (Environmental, Social, and Governance) goals are influencing bolt design and material selection. Bolt specs increasingly emphasize recyclability, reduced carbon footprint in production (e.g., via green steel), and longer service life to minimize replacement frequency. Reusable and non-toxic surface coatings (e.g., zinc-nickel, ceramic-based) are becoming standard in updated specifications. -

Growth in Renewable Energy Infrastructure

The expansion of wind, solar, and hydrogen infrastructure is creating strong demand for specialized bolt specs. For example, offshore wind turbines require large-diameter, high-tensile bolts with exceptional fatigue resistance and anti-corrosion properties. Bolt standards are being adapted to specify performance under dynamic loading and harsh marine environments, driving innovation in testing and certification protocols. -

Automation and Precision Manufacturing

Automated assembly lines, particularly in automotive and robotics, demand bolts with highly consistent dimensions and threading. Bolt specs in 2026 reflect tighter geometric tolerances and stricter quality control metrics to support robotic handling and precision fastening. This trend is pushing manufacturers to adopt AI-driven quality assurance systems aligned with updated spec requirements. -

Geopolitical and Supply Chain Resilience

Ongoing supply chain disruptions and regional trade policies are prompting companies to localize fastener production. Bolt specs are being tailored to regional material availability and manufacturing capabilities, while still maintaining compliance with international performance benchmarks. This localization trend supports faster delivery and reduces dependency on global logistics.

Conclusion:

By 2026, bolt specifications are no longer static mechanical guidelines but dynamic standards shaped by technological innovation, environmental imperatives, and global industrial needs. Stakeholders—from manufacturers to engineers and regulators—must stay aligned with evolving specs to ensure safety, efficiency, and competitiveness in a rapidly changing market landscape.

Common Pitfalls Sourcing Bolt Specs (Quality, IP)

Sourcing bolts based on specifications—especially concerning quality and International Protection (IP) ratings—can be deceptively complex. Overlooking key details often leads to performance issues, safety hazards, or compliance failures. Below are common pitfalls to avoid:

Misunderstanding Quality Grades and Standards

Confusing or misapplying quality grades (e.g., Grade 5 vs. Grade 8, or ISO 898-1 property classes like 8.8, 10.9) is a frequent error. Each grade indicates specific mechanical properties such as tensile strength and yield strength. Using a lower-grade bolt in a high-stress application can result in joint failure. Always verify that the bolt meets the required standard (ASTM, ISO, DIN, etc.) and that certification (e.g., mill test reports) is provided.

Assuming IP Ratings Apply to Bolts

A major misconception is applying IP (Ingress Protection) ratings directly to bolts. IP ratings classify the degree of protection provided by electrical enclosures against solids and liquids—but bolts themselves are not IP-rated. Instead, bolts contribute to maintaining the IP rating of an assembly by ensuring tight, corrosion-resistant joints in enclosures. Using bolts that corrode or loosen over time can compromise the overall IP integrity of a housing.

Neglecting Environmental and Corrosion Resistance

Bolts used in outdoor, marine, or chemically aggressive environments require appropriate material selection (e.g., stainless steel, galvanized, or coated variants). Sourcing standard carbon steel bolts without considering corrosion resistance can lead to premature degradation, especially when paired with dissimilar metals causing galvanic corrosion.

Overlooking Traceability and Certification

In regulated industries (e.g., aerospace, automotive, construction), full traceability and material certifications are mandatory. Failing to obtain proper documentation—such as 3.1 or 3.2 mill certificates—can result in rejected shipments or non-compliance during audits.

Confusing Metric and Imperial Specifications

Mixing up metric and imperial bolt dimensions, thread pitches, or strength classes can lead to improper fit and reduced load capacity. Always confirm whether the design calls for metric (ISO) or imperial (SAE/ASTM) specifications and ensure compatibility with mating components.

Ignoring Installation Requirements

Even high-quality bolts can fail if installation torque, lubrication, or tightening sequence is ignored. Under-torquing leads to loosening; over-torquing can cause thread stripping or bolt fracture. Always refer to the engineered specifications for correct installation practices.

Avoiding these pitfalls ensures bolts perform reliably in their intended application, maintain structural integrity, and support the required environmental protection of the overall system.

Logistics & Compliance Guide for Bolt Specifications

This guide outlines the logistics and compliance requirements associated with the manufacturing, distribution, and use of bolt specifications, ensuring adherence to industry standards, safety regulations, and international trade laws.

Scope and Applicability

This document applies to all entities involved in the production, supply, import/export, and installation of bolts, including manufacturers, distributors, procurement teams, and end-users. It covers mechanical fasteners defined by standardized bolt specs such as ISO, ASTM, DIN, and SAE.

Standardized Bolt Specifications

Bolts must conform to recognized international or national standards. Key specifications include:

- ISO 4014/4017: Hexagon head bolts (coarse/fine thread)

- ASTM A325/A490: High-strength structural bolts (U.S.)

- DIN 931/933: German industrial hex bolts

- SAE J429: Mechanical and material requirements for U.S. bolts

Each bolt must be clearly marked with grade, manufacturer ID, and compliance symbol as required by the applicable standard.

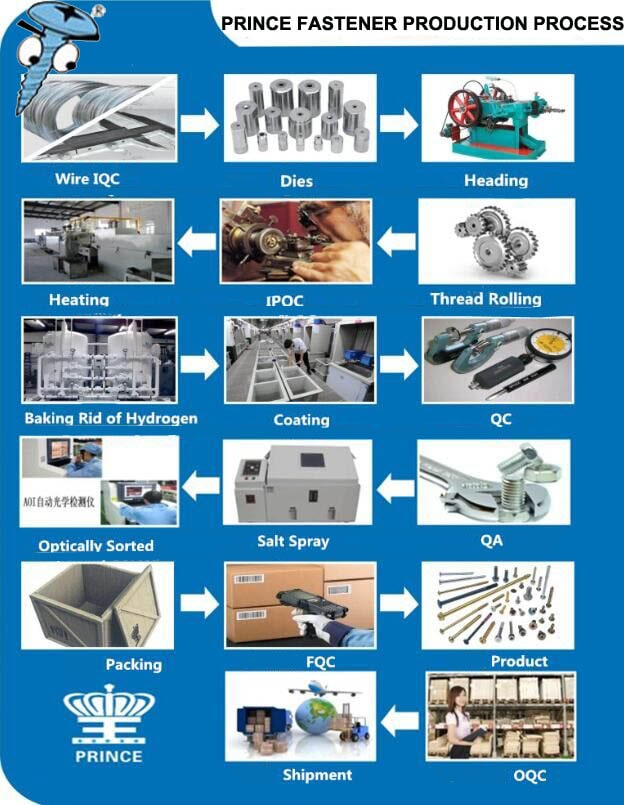

Material and Manufacturing Compliance

- Bolts must be manufactured using materials specified in the relevant standard (e.g., alloy steel, stainless steel, carbon steel).

- Heat treatment processes (quenching and tempering) must meet tensile and hardness requirements.

- Third-party certification (e.g., ISO 9001, ISO/IEC 17025) is required for manufacturing facilities supplying critical applications (aerospace, construction, automotive).

Testing and Quality Assurance

- Tensile Testing: Must verify ultimate tensile strength, yield strength, and elongation.

- Hardness Testing: Rockwell or Brinell methods per ASTM E18 or ISO 6508.

- Chemical Analysis: Verified via spectrographic analysis to ensure material composition.

- Torque and Clamping Tests: Required for performance-critical joints.

- Certificates of Conformity (CoC) or Mill Test Reports (MTRs) must accompany all shipments.

Packaging and Labeling Requirements

- Bolts must be packaged to prevent corrosion, mechanical damage, and contamination.

- Inner packaging: Anti-corrosion paper or VCI (Vapor Corrosion Inhibitor) bags.

- Outer packaging: Sturdy cardboard or wooden crates labeled with:

- Part number and bolt specification

- Quantity and net weight

- Manufacturer name and batch/lot number

- Compliance marks (e.g., CE, UKCA, RoHS if applicable)

Logistics and Transportation

- Transport must comply with IATA, IMDG (for maritime), or ADR (for road) when applicable, especially if packaged with hazardous inhibitors.

- Climate-controlled storage recommended for stainless and high-tensile bolts in humid environments.

- Traceability: Each batch must be trackable via lot number throughout the supply chain.

Import/Export Compliance

- HS Codes: Classify bolts correctly (e.g., 7318.15 for hex bolts) for customs clearance.

- Trade Restrictions: Verify compliance with sanctions, anti-dumping duties (e.g., U.S. Section 232 on steel), and country-specific regulations.

- Documentation: Commercial invoice, packing list, CoC, and origin certificate (e.g., Form A for GSP) as required.

Environmental and Safety Regulations

- RoHS (EU): Restricts hazardous substances (Pb, Cd, Hg, etc.) in electrical and electronic equipment.

- REACH (EU): Requires registration of chemical substances used in coatings or plating.

- California Prop 65: Warning labels required if bolts contain listed chemicals (e.g., lead in plating).

- OSHA & ANSI (U.S.): Workplace safety guidelines for handling and installation.

Traceability and Recordkeeping

- Maintain records of material sourcing, test results, and distribution for a minimum of 10 years for critical applications.

- Digital traceability systems (e.g., blockchain or ERP logs) recommended for high-volume or safety-critical industries.

Non-Conformance and Corrective Actions

- Non-compliant bolts must be quarantined and reported to relevant authorities if safety is compromised.

- Root cause analysis and corrective action plans (CAPA) required for recurring quality issues.

- Recall procedures must be documented and communicated to downstream partners.

Conclusion

Adherence to standardized bolt specifications and compliance protocols ensures structural integrity, regulatory conformity, and supply chain reliability. Regular audits, staff training, and certification maintenance are essential for ongoing compliance.

Conclusion on Sourcing Bolt Specifications:

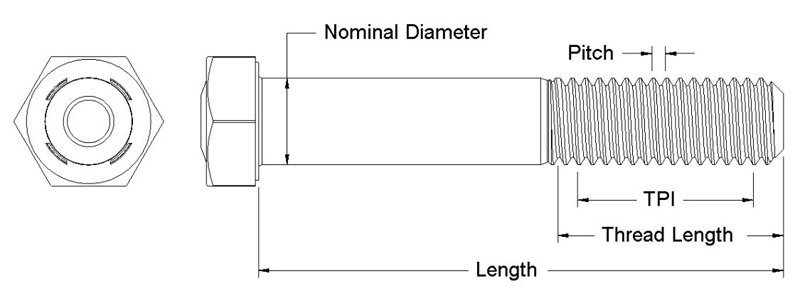

Sourcing accurate and reliable bolt specifications is a critical step in ensuring structural integrity, safety, and compliance in engineering and construction applications. Through careful evaluation of industry standards (such as ISO, ASTM, SAE, and DIN), material properties, load requirements, and environmental conditions, appropriate bolt specifications can be identified. It is essential to obtain detailed specifications—including diameter, length, thread pitch, grade, strength class, and coating—from reputable suppliers or manufacturers and to verify conformance through certification and testing where necessary. Effective communication with suppliers, access to technical datasheets, and adherence to project-specific requirements further support successful sourcing. Ultimately, diligent attention to bolt specifications minimizes risk, enhances performance, and ensures long-term reliability of assembled systems.