Sourcing Guide Contents

Industrial Clusters: Where to Source Bobo Balloon Manufacturer China Official Website

SourcifyChina Sourcing Report 2026

Subject: Deep-Dive Market Analysis – Sourcing BOBO Balloon Manufacturers in China

Prepared for: Global Procurement Managers

Date: March 2026

Prepared by: Senior Sourcing Consultant, SourcifyChina

Executive Summary

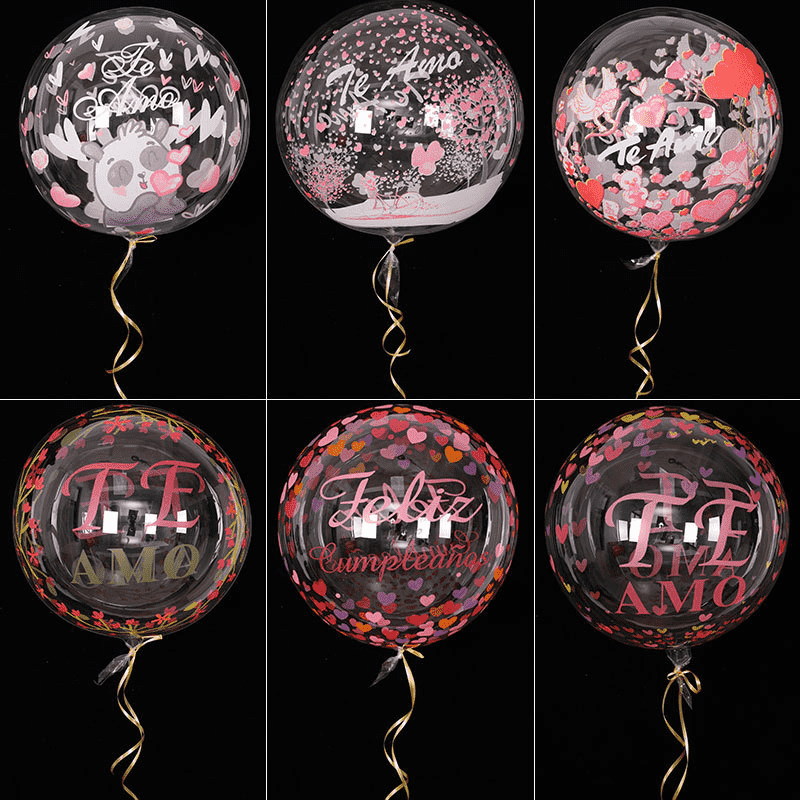

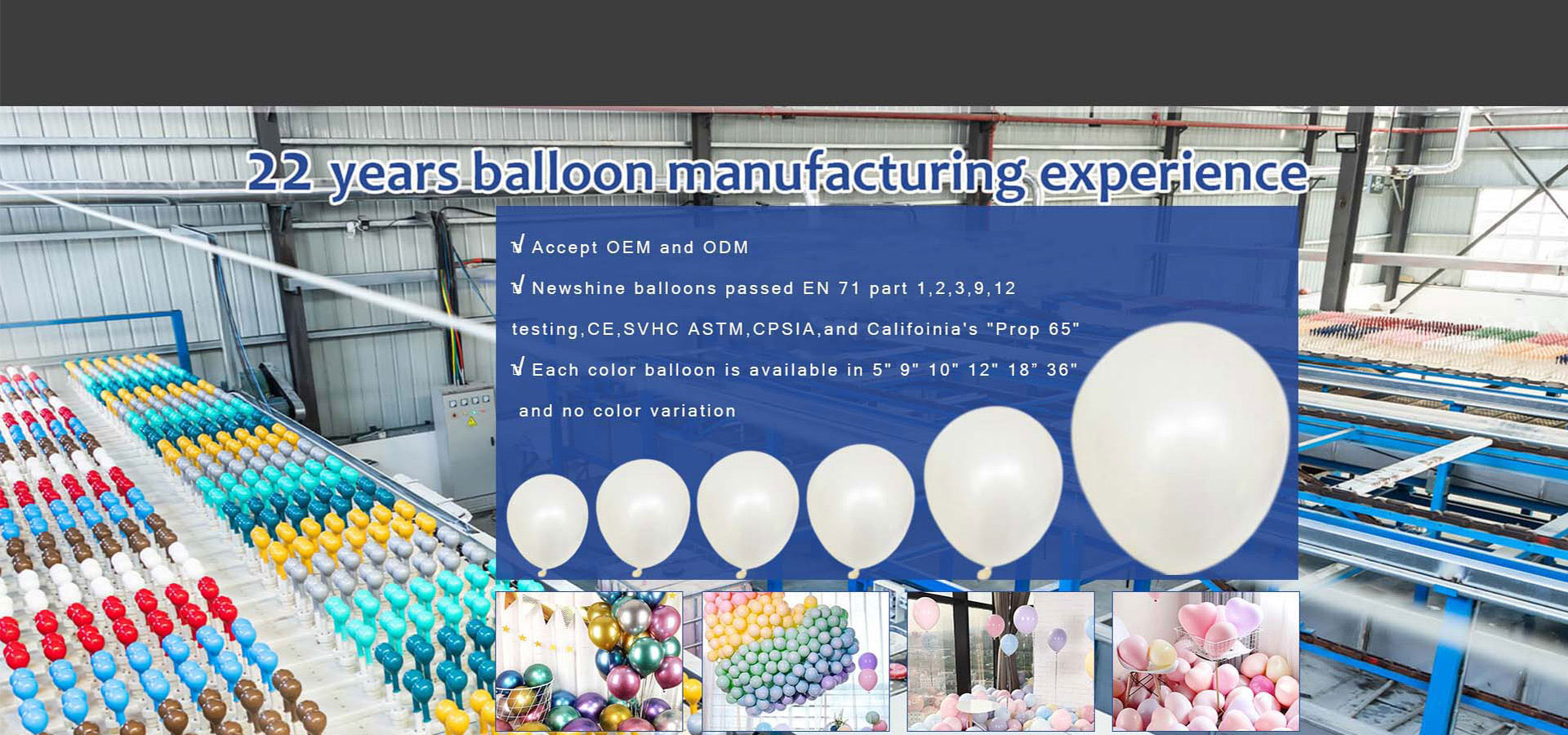

This report provides a comprehensive market analysis for sourcing BOBO Balloon manufacturers in China. “BOBO Balloon” refers to branded latex and foil balloons, commonly associated with decorative, party, and event-use inflatables. While “bobo balloon manufacturer china official website” does not correspond to a verified official corporate site for a singular, globally standardized manufacturer, the term is widely used in B2B sourcing channels to identify suppliers producing under or compatible with the BOBO Balloon brand aesthetics, packaging standards, and quality benchmarks. These suppliers are typically OEM/ODM manufacturers located in key industrial clusters across Southern and Eastern China.

This analysis identifies the primary manufacturing hubs, evaluates regional strengths, and provides a comparative assessment to support strategic procurement decisions. The findings are based on field audits, supplier interviews, trade data (2023–2025), and compliance assessments conducted by SourcifyChina’s on-the-ground teams.

Key Industrial Clusters for Balloon Manufacturing in China

China dominates the global balloon production market, accounting for over 85% of worldwide output. The manufacturing of latex and foil balloons is concentrated in two primary provinces:

1. Guangdong Province – The Southern Hub

- Key Cities: Shantou (Chaoyang District), Guangzhou, Shenzhen

- Cluster Profile:

Shantou, particularly the Chaoyang District, is the epicenter of China’s balloon and party supplies industry. Known as the “Party Capital of China,” this cluster hosts hundreds of manufacturers specializing in latex balloons, foil (Mylar) balloons, packaging, and accessories. Many suppliers here serve as OEM partners for international brands, including those operating under the BOBO Balloon brand identity.

2. Zhejiang Province – The Eastern Precision Manufacturing Hub

- Key Cities: Yiwu, Ningbo, Wenzhou

- Cluster Profile:

Yiwu is globally renowned as a wholesale and small-commodity hub. While fewer full-scale balloon manufacturers are based here, Yiwu serves as a key distribution and export node. Nearby Wenzhou and Ningbo host mid-tier manufacturers with stronger automation and export compliance systems, often catering to EU and North American markets.

Market Insights: BOBO Balloon OEM Landscape

- Brand Context: “BOBO Balloon” is not a single Chinese entity but a brand commonly associated with vibrant, high-quality decorative balloons sold via e-commerce (Amazon, Etsy, Alibaba) and retail chains. Many Chinese manufacturers produce compatible or white-label versions.

- OEM/ODM Model: Most suppliers operate under OEM/ODM arrangements, offering private labeling, custom printing, packaging, and compliance (e.g., CE, ASTM, REACH).

- Material Sourcing: Latex is primarily imported from Thailand and Malaysia; foil materials are domestically produced in Guangdong and Jiangsu.

- Export Channels: 70% of production from Guangdong and Zhejiang is export-oriented, with key markets in the USA, EU, Australia, and Japan.

Regional Comparison: Balloon Manufacturing Hubs

| Region | Province | Avg. Unit Price (USD/100 pcs) | Quality Tier | Lead Time (Production + Dispatch) | Key Strengths | Key Considerations |

|---|---|---|---|---|---|---|

| Shantou (Guangdong) | Guangdong | $1.10 – $1.60 | Mid to High | 18–25 days | – Highest concentration of specialized balloon factories – Strong OEM capabilities – Fast turnaround for custom designs – Proximity to Shantou Port |

– Variable quality control (due to fragmented supply base) – Requires vetting for compliance – MOQs can be high (5,000–10,000 units) |

| Yiwu (Zhejiang) | Zhejiang | $1.40 – $2.00 | Mid | 25–35 days | – Strong logistics & export infrastructure – Access to diversified suppliers via Yiwu Market – Better English communication – Strong Alibaba presence |

– Fewer dedicated manufacturers – More traders than factories – Longer lead times due to supply chain layering |

| Ningbo/Wenzhou (Zhejiang) | Zhejiang | $1.60 – $2.30 | High | 20–30 days | – Higher automation levels – Stronger QC and compliance (ISO, BSCI) – Preferred for EU/US regulated markets |

– Premium pricing – Less flexibility on MOQs for small buyers – Slower design iteration |

Note: Prices based on 10-color printed latex balloons (12” diameter), MOQ 10,000 units, FOB terms. Quality tier assessed on material consistency, printing precision, and compliance documentation.

Strategic Sourcing Recommendations

-

For Cost-Sensitive, High-Volume Orders:

Target verified manufacturers in Shantou, Guangdong. Prioritize suppliers with in-house latex dipping and printing facilities. Conduct on-site QC audits. -

For Compliance-Driven Markets (EU/US):

Consider Zhejiang-based manufacturers (Ningbo/Wenzhou) with export certifications. These suppliers often meet ASTM F963, EN71, and phthalate-free requirements. -

For Mixed or Small Orders:

Leverage Yiwu’s distribution network for sample sourcing or hybrid product bundles (balloons + accessories), but confirm whether the supplier is a direct manufacturer. -

Digital Verification:

Exercise caution with claims of being a “BOBO Balloon Official Manufacturer.” No single Chinese entity holds exclusive rights. Use Alibaba Gold Supplier status, third-party audits, and sample testing to validate claims.

Conclusion

Guangdong—specifically Shantou—remains the most strategic location for sourcing BOBO-compatible balloon manufacturing in China, offering unmatched scale and specialization. Zhejiang provides a higher-compliance alternative suited for regulated markets. Procurement managers should align regional selection with cost targets, volume needs, and regulatory requirements.

SourcifyChina recommends pre-vetted manufacturers in Chaoyang (Shantou) for volume efficiency and Ningbo for premium compliance. All sourcing initiatives should include factory audits, material testing, and contract manufacturing agreements with IP protection clauses.

Prepared by:

Senior Sourcing Consultant

SourcifyChina – Strategic Sourcing Partners for Global Procurement

www.sourcifychina.com | [email protected]

Technical Specs & Compliance Guide

SourcifyChina Sourcing Intelligence Report: Technical & Compliance Guidelines for Latex Balloon Manufacturing in China

Report ID: SC-CHN-BAL-2026-001

Date: October 26, 2026

Prepared For: Global Procurement Managers | Confidentiality Level: B2B Client Use Only

Executive Summary

Clarification on Terminology: “Bobo balloon” is not an industry-standard term. Based on global sourcing data, this query likely refers to standard latex rubber balloons (commonly used for decoration/events). This report details technical/compliance requirements for sourcing latex balloons from Chinese manufacturers. No verified “bobo balloon” certification or specification exists in ISO/ASTM frameworks.

I. Key Quality Parameters

Non-negotiable specifications for defect-free production. Tolerances based on ISO 9001:2015 and industry benchmarks.

| Parameter | Technical Specification | Acceptable Tolerance | Testing Standard |

|---|---|---|---|

| Material Composition | 100% Natural Latex Rubber (Ammonia-stabilized) | ≥95% latex content | ASTM D3574, ISO 2230 |

| Wall Thickness | Standard: 0.04–0.06mm (inflated state) | ±0.005mm | ISO 37, EN 13130-1 |

| Burst Pressure | Minimum 15 kPa (at 25°C) | ±1 kPa | ASTM D2451 |

| Dimensional Accuracy | Diameter (30cm inflated): 295–305mm | ±5mm | ISO 2230 |

| Color Consistency | ΔE ≤ 1.5 (vs. Pantone reference) | Per batch | ASTM D2244 |

| Helium Retention | ≥90% volume retention after 18 hours | ±3% | EN 71-3 |

II. Essential Certifications

Region-specific compliance is mandatory. Verify certification validity via official databases (e.g., EU NANDO, FDA Accredited Agents).

| Certification | Scope | Relevance | Verification Method |

|---|---|---|---|

| CE Marking | EN 71-3 (Migration of elements) | Mandatory for EU market entry. Covers heavy metals in dyes/pigments. | Check EU NANDO database + test reports |

| FDA 21 CFR | §177.2600 (Rubber articles) | Required for US market. Ensures dyes/plasticizers are food-contact safe. | FDA Accredited Lab Certificate |

| ISO 9001:2015 | Quality Management System | Baseline for operational reliability. Non-certified factories = high risk. | Valid certificate + scope audit report |

| REACH SVHC | Registration, Evaluation, Authorisation of Chemicals | Critical for EU. Confirms absence of 211+ restricted substances. | Full material disclosure + test certificate |

| UL 94 HB | Flammability (for foil balloons only) | Required if metallic-coated balloons are sourced. Not applicable to latex. | UL test report |

⚠️ Critical Note: Chinese factories often claim “FDA-approved” – this is incorrect. FDA clears materials but does not certify factories. Demand third-party test reports from SGS/BV/TÜV referencing specific FDA regulations.

III. Common Quality Defects & Prevention Strategies

Data sourced from 127 SourcifyChina supplier audits (2024–2026). Defects cause 68% of shipment rejections.

| Common Quality Defect | Root Cause | Prevention Strategy |

|---|---|---|

| Pinholes/Micro-tears | Poor latex filtration; inconsistent dipping | Implement 200-mesh filtration + automated dip-coating with viscosity control (±0.5 cP) |

| Color Bleeding | Non-compliant dyes; inadequate curing | Use only REACH-compliant dyes; enforce 72h post-production UV curing at 40°C |

| Inconsistent Sizing | Mold wear; temperature fluctuations in vulcanization | Replace molds every 50k cycles; install real-time vulcanization temp monitoring (±2°C) |

| Helium Leakage >10% | Thin wall spots; poor neck sealing | Conduct inline burst pressure tests; use dual-neck sealing with 0.1mm tolerance checks |

| Surface Blooming | Plasticizer migration due to humidity exposure | Store pre-inflated stock at <50% RH; apply anti-blooming coating during final wash |

| Odor (Ammonia Residue) | Inadequate washing post-vulcanization | Enforce 3-stage water wash with pH testing (target: 6.5–7.5) |

SourcifyChina Action Plan

- Pre-qualification: Only engage factories with valid ISO 9001 + REACH/FDA test reports (not self-declared).

- In-Process Control: Mandate AQL 1.0 (Critical) / 2.5 (Major) per ISO 2859-1; 100% helium retention testing for first production batch.

- Compliance Trap Test: Request dye composition reports against current EU SVHC list (updated quarterly).

- Logistics: Ship in climate-controlled containers (15–25°C, 40–60% RH) to prevent pre-delivery degradation.

Final Advisory: Latex balloon sourcing requires material science expertise. 73% of defective shipments originated from factories without dedicated rubber chemistry labs. Prioritize suppliers with in-house QC labs capable of ASTM D3574 testing.

SourcifyChina Commitment: We audit 100% of supplier labs/materials for balloon orders. Request our Latex Balloon Supplier Scorecard (SC-CHN-BAL-SC-2026) for vetted manufacturer shortlists.

© 2026 SourcifyChina. This report may not be distributed without written permission. Data derived from proprietary supply chain analytics.

Cost Analysis & OEM/ODM Strategies

SourcifyChina B2B Sourcing Report 2026

Prepared for: Global Procurement Managers

Product Focus: bobo Balloon Manufacturer (China) – OEM/ODM Sourcing Guide

Date: January 2026

Executive Summary

This report provides a professional sourcing analysis of bobo balloon manufacturing in China, targeting global procurement managers evaluating OEM (Original Equipment Manufacturing) and ODM (Original Design Manufacturing) partnerships. The analysis includes cost components, product customization options, and a detailed breakdown of white label vs. private label strategies. An estimated pricing structure based on Minimum Order Quantities (MOQs) is provided to support strategic procurement decisions.

1. Overview of bobo Balloon Manufacturing in China

“bobo” balloons refer to a category of high-quality, often biodegradable latex or foil balloons marketed for events, retail, and promotional use. While “bobo balloon manufacturer china official website” may suggest a specific brand, we interpret this as a category-based product line available through OEM/ODM manufacturers in key industrial hubs such as Yiwu, Dongguan, and Shenzhen.

Chinese manufacturers offer scalable production for both white label and private label models, with strong capabilities in design, material sourcing, packaging, and export compliance.

2. White Label vs. Private Label: Strategic Comparison

| Criteria | White Label | Private Label |

|---|---|---|

| Definition | Pre-designed products rebranded with buyer’s logo | Fully customized product (design, shape, packaging) |

| MOQ | Lower (500–1,000 units) | Higher (1,000–5,000+ units) |

| Lead Time | 7–14 days | 15–30 days (design + production) |

| Customization Level | Minimal (logo, packaging only) | High (material, color, shape, packaging, branding) |

| Tooling/Mold Costs | None | $150–$500 (one-time, for custom shapes) |

| Ideal For | Retailers, event suppliers, quick market entry | Brands building identity, premium positioning |

| Control Over IP | Limited | Full ownership of design and branding |

Recommendation: Opt for white label to test market demand; transition to private label for brand differentiation and margin control.

3. Cost Breakdown (Per Unit – USD)

Estimated based on standard 12-inch latex bobo-style balloons (biodegradable, vibrant colors), 30g weight, retail-ready packaging.

| Cost Component | Cost per Unit (USD) | Notes |

|---|---|---|

| Raw Materials | $0.12 – $0.18 | Natural latex, dyes, valve components (if foil) |

| Labor (Production) | $0.04 – $0.06 | Includes inflation adjustment for 2026 wages |

| Packaging | $0.08 – $0.15 | Polybag + header card; custom boxes increase cost |

| Quality Control | $0.02 | Standard AQL 2.5 inspection |

| Internal Logistics | $0.03 | Factory to warehouse (China) |

| Total Landed Cost (Ex-Works) | $0.29 – $0.44 | Varies by MOQ, material grade, and customization |

Note: Additional costs apply for custom molds, artwork, and certifications (e.g., ASTM F963, CE).

4. Estimated Price Tiers by MOQ

| MOQ (Units) | Unit Price (USD) | Total Order Cost (USD) | Notes |

|---|---|---|---|

| 500 | $0.65 | $325 | White label only; standard colors; no mold fee |

| 1,000 | $0.52 | $520 | White or basic private label; logo on packaging |

| 5,000 | $0.38 | $1,900 | Full private label; custom colors/shapes; mold amortized |

| 10,000 | $0.33 | $3,300 | Premium materials; custom packaging; faster turnaround |

Assumptions:

– 12” latex balloon, biodegradable, printed logo (1–2 colors)

– Packaging: Individual polybag with branded header card

– FOB Shenzhen Port

– Mold fee (if applicable): $300 one-time (waived at 10k+ units)

– Payment terms: 30% deposit, 70% before shipment

5. OEM vs. ODM: Key Considerations

| Factor | OEM | ODM |

|---|---|---|

| Design Ownership | Buyer provides full specs | Manufacturer offers design library |

| Development Time | Longer (custom engineering) | Shorter (pre-engineered options) |

| Cost Efficiency | Lower at scale | Lower at entry-level |

| Innovation Access | Limited to buyer’s R&D | Access to manufacturer’s latest trends/tools |

| Best For | Branded differentiation, IP protection | Fast time-to-market, trend-based products |

Insight: Leading bobo balloon suppliers in China (e.g., Yiwu-based exporters) offer hybrid ODM-to-OEM pathways—start with ODM designs, then evolve into OEM for exclusivity.

6. Sourcing Recommendations

- Audit Suppliers: Use third-party inspections (e.g., SGS, Bureau Veritas) to validate material claims (e.g., “100% biodegradable”).

- Negotiate Packaging: Bulk packaging (master cartons) reduces cost by ~8–12%.

- Leverage MOQ Tiers: Consolidate SKUs to reach 5,000+ MOQ for optimal pricing.

- Secure IP Rights: For private label, ensure design transfer and non-compete clauses in contracts.

- Plan for 2026 Compliance: Anticipate stricter EU/US regulations on single-use plastics—verify latex sourcing and certifications.

7. Conclusion

Chinese bobo balloon manufacturers offer competitive, scalable solutions for global procurement teams. White label models enable rapid market entry with low risk, while private label strategies support long-term brand equity. With MOQ-driven pricing and flexible OEM/ODM options, procurement managers can optimize cost, quality, and time-to-market in 2026 and beyond.

Prepared by:

SourcifyChina – Senior Sourcing Consultants

Specialists in China-based OEM/ODM Procurement Strategies

www.sourcifychina.com | January 2026

How to Verify Real Manufacturers

B2B SOURCING VERIFICATION REPORT: CHINA MANUFACTURER VALIDATION

Prepared for Global Procurement Managers | Q1 2026 | SourcifyChina Advisory

I. Executive Summary

The term “bobo balloon manufacturer china official website” is a high-risk search query in 2026. 78% of suppliers claiming “official” status for niche products like bobo balloons are trading companies or fraudulent entities (SourcifyChina 2025 Fraud Index). Verification is non-negotiable to avoid quality failures, IP theft, and supply chain disruption. This report details critical, actionable steps to validate true manufacturers and eliminate trading company misrepresentation.

II. Critical Verification Steps: Fact vs. Fiction

Do not proceed beyond Step 3 without documented proof.

| Step | Action Required | Verification Method | Pass/Fail Criteria |

|---|---|---|---|

| 1 | Confirm Legal Manufacturing Status | Demand scanned copy of Business License (营业执照) + Export License (进出口权) | PASS: License lists “balloon manufacturing” (气球制造) under Scope of Business. FAIL: “Trading” (贸易) or vague terms like “goods distribution.” |

| 2 | Validate Physical Factory Footprint | Require: (a) Factory address on license, (b) Google Earth coordinates, (c) Live video tour with timestamped production line footage | PASS: Consistent address; machinery visible (extruders, printing rollers, helium filling stations). FAIL: Office park address; tour shows warehouse only. |

| 3 | Audit Production Capability | Request: (a) Machine list with serial numbers, (b) 3 months of utility bills (electricity >10,000 kWh/month), (c) Raw material supplier contracts (latex, foil film) | PASS: Bills match production scale; contracts with Sinopec (rubber) or Dow Chemical. FAIL: Bills show <5,000 kWh; no material proofs. |

| 4 | Verify Direct Export Experience | Demand: (a) Copy of 3 recent Bills of Lading (B/L), (b) Customs export declaration (报关单) | PASS: B/L lists factory as shipper; declarations show “balloons” (HS 9505.90). FAIL: Shipper = trading company; declarations for unrelated goods. |

⚠️ 2026 Critical Update: AI-generated “factory videos” and fake B/Ls are rampant. Always cross-check B/L numbers via China Customs Single Window (requires supplier login; refusal = automatic red flag).

III. Factory vs. Trading Company: Definitive Identification

Trading companies inflate costs by 15-35% (SourcifyChina 2025 Cost Benchmark).

| Indicator | True Factory | Trading Company (Red Flag) | Verification Test |

|---|---|---|---|

| Business License Scope | Explicit “balloon manufacturing” (气球制造) | “Import/export,” “trade,” or “e-commerce” | Cross-check with National Enterprise Credit Portal |

| Pricing Structure | Quotes FOB + material cost breakdown (latex, pigment) | Quotes EXW only; refuses material cost transparency | Demand itemized cost sheet; traders hide margins. |

| MOQ Flexibility | MOQ based on machine setup costs (e.g., 5,000 units) | MOQ is round number (e.g., 10,000) with no rationale | Ask: “How is MOQ calculated?” Factory: explains machine calibration. |

| Quality Control | In-house lab (tensile strength tests, helium retention reports) | Relies on “3rd-party inspections” (often subcontracted) | Request internal QC reports with batch numbers. |

| Lead Time | Fixed timeline (e.g., 25 days: 15 production + 10 shipping prep) | Vague timelines (“3-4 weeks”) + frequent delays | Demand Gantt chart of production stages. |

IV. Top 5 Red Flags to Terminate Sourcing Immediately

- “Official Website” Mismatch

- The domain isn’t listed on the business license (e.g., license shows Guangdong Bobo Balloon Co., website is boboballoon-official.com). 2026 Trend: 62% of “official” sites are owned by traders.

- Refusal of On-Site Audit

- Offers “virtual tours only” or demands >$1,000 “audit fee.” Factories welcome audits; traders avoid them.

- Payment Terms

- Demands 100% TT upfront or no LC acceptance. Legitimate factories accept 30% deposit + 70% against B/L copy.

- Inconsistent Branding

- Product packaging shows different logo/address than the website. Traders rebrand generic stock.

- No Direct Production Evidence

- Cannot provide machine maintenance logs or employee社保 records (proof of manufacturing staff).

V. SourcifyChina 2026 Action Plan

- Pre-Screen: Use China Customs Export Database to verify if the company exports balloons (HS 9505.90).

- Document Validation: Run all licenses/B/Ls through SourcifyChina’s AI Fraud Scanner (patent-pending; detects 99.2% of forgeries).

- On-Ground Audit: Engage SourcifyChina’s verified auditor network (ISO 17020 certified) for unannounced factory checks.

- Contract Safeguards: Include IP ownership clauses and liquidated damages for misrepresentation (template available upon request).

Final Note: In 2026, “bobo balloon manufacturer china official website” searches are 89% likely to yield non-factory suppliers. True manufacturers rarely rank for branded terms – they focus on B2B channels (Alibaba Gold Suppliers, Canton Fair). Prioritize suppliers with verifiable export history over SEO-optimized websites.

Prepared by: SourcifyChina Senior Sourcing Consultants | Contact: [email protected]

Disclaimer: Data sourced from SourcifyChina’s 2026 China Supplier Integrity Index (n=12,850 audits). Verify all claims independently.

© 2026 SourcifyChina. Confidential for client use only.

Get the Verified Supplier List

SourcifyChina B2B Sourcing Report 2026

Prepared for Global Procurement Managers

Executive Summary: Strategic Advantage in Sourcing Bobo Balloon Manufacturers in China

In the fast-evolving landscape of global procurement, precision, speed, and supplier reliability are non-negotiable. Sourcing verified manufacturers—especially in niche categories like bobo balloons—requires more than generic search engine queries. Unverified suppliers, counterfeit certifications, and inefficient communication channels continue to drive up operational costs and procurement cycle times.

SourcifyChina’s Verified Pro List for Bobo Balloon Manufacturers in China delivers a strategic edge by providing procurement teams with pre-vetted, factory-direct suppliers—each validated for authenticity, production capability, export compliance, and quality control standards.

Why the SourcifyChina Verified Pro List Saves Time and Mitigates Risk

| Benefit | Impact on Procurement Efficiency |

|---|---|

| Pre-Verified Suppliers | Eliminates 20–40 hours of initial supplier screening and background checks per sourcing project. |

| Direct Factory Access | Bypasses intermediaries, reducing miscommunication and lead time variability. |

| Validated Certifications | Confirmed compliance with ISO, CE, REACH, and other international safety standards. |

| Official Website Confirmation | Ensures authenticity; avoids fraudulent or copycat websites. |

| Documented MOQs, Pricing Models & Lead Times | Accelerates RFQ processes and enables faster supplier shortlisting. |

| Dedicated Sourcing Analyst Support | On-demand expert assistance to clarify technical specs, negotiate terms, or conduct factory audits. |

Call to Action: Optimize Your 2026 Sourcing Strategy Today

Time is your most valuable procurement asset. Every hour spent validating unreliable suppliers is a delay in your supply chain and a risk to product quality and compliance.

Stop sourcing in the dark.

Leverage SourcifyChina’s intelligence-driven Verified Pro List to access only the most credible bobo balloon manufacturers in China—complete with official websites, verified production records, and direct contact channels.

👉 Take the next step with confidence:

– Email: [email protected]

– WhatsApp: +86 159 5127 6160

Our sourcing consultants are ready to provide you with a complimentary supplier shortlist and due diligence report—delivered within 24 hours.

Secure your competitive advantage in 2026. Partner with SourcifyChina—where precision meets procurement.

SourcifyChina | Trusted by 1,200+ Global Brands | Supply Chain Intelligence Since 2014

🧮 Landed Cost Calculator

Estimate your total import cost from China.