The global boat manufacturing industry is undergoing a significant transformation, driven by rising consumer demand for personalized watercraft and advancements in marine technology. According to Grand View Research, the global recreational boating market was valued at USD 42.7 billion in 2023 and is expected to grow at a compound annual growth rate (CAGR) of 5.3% from 2024 to 2030. This expansion is fueled by increasing disposable incomes, growing interest in leisure activities, and a surge in yacht and boat customization services. Mordor Intelligence further underscores this trend, projecting the marine and recreational boating market to grow at a CAGR of approximately 6.2% during the forecast period of 2023–2028. As customization becomes a key differentiator among manufacturers—spanning layout alterations, luxury finishes, advanced navigation systems, and eco-friendly propulsion—the following list highlights the top 10 boat manufacturers leading innovation and customer-centric design in this dynamic, fast-evolving sector.

Top 10 Boat Customized Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 Burger Boat Company – Custom Yachts

Domain Est. 1997

Website: burgerboat.com

Key Highlights: Creation starts here. Burger embraces innovation, state-of-the-art technology and exquisite craftsmanship to build the custom yacht of your dreams….

#2 Rabco Boats

Domain Est. 2020

Website: rabcomarine.com

Key Highlights: Rabco Boats is the leading skiff boat manufacturer in Florida. Over 47+ years of experience. High-quality, custom skiff boats. Get a free quote today!…

#3 DCB Performance Marine

Domain Est. 2023

Website: dcbperformancemarine.com

Key Highlights: DCB Performance Marine: Experience the thrill of high-performance boats. Explore custom designs and find your legacy on the water with DCB….

#4 Build & Price Your Customized Boat

Domain Est. 1995

Website: searay.com

Key Highlights: Create and customize your perfect Sea Ray® boat, or simply take a closer look at your favorite model. Choose a series and build your own boat….

#5 Custom Boat Configurator

Domain Est. 1997

Website: formulaboats.com

Key Highlights: Want to customize your own Formula Boat? Click here to select any of our boat models and pick out your own graphic and engine configurations!…

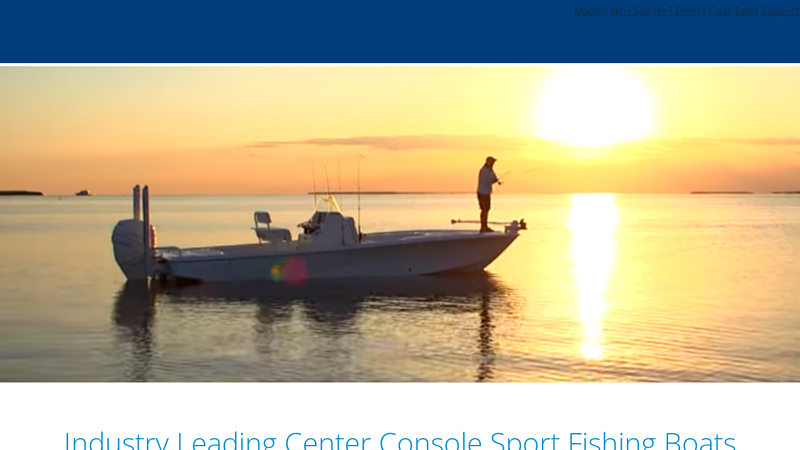

#6 SeaVee Boats

Domain Est. 1997

Website: seaveeboats.com

Key Highlights: Explore an industry leading line of high performance, built to order, sport fishing boats including bay boats, center consoles, and express fishing boats….

#7 Horizon Yachts

Domain Est. 1998

Website: horizonyacht.com

Key Highlights: A leading luxury yacht builder that has been setting the industry standard for nearly four decades. From pioneering new yacht designs to employing the latest ……

#8 Build Your 41

Domain Est. 1998

Website: regulatormarine.com

Key Highlights: Leisure Features. Note: Rendering and photos are intended to give you a more detailed look at your Regulator Ride. All specs and options are regularly updated; ……

#9 Contender Boats

Domain Est. 2004

Website: contenderboats.com

Key Highlights: We have over 40 years of experience building the world’s finest semi-custom sportfishing boats. Boats that are carefully engineered and meticulously ……

#10 Prodigy Boats

Domain Est. 2013

Website: prodigyboats.com

Key Highlights: We specialize in creating custom-built aluminum boats tailored to your unique lifestyle and preferences, from recreational adventures to professional endeavors….

Expert Sourcing Insights for Boat Customized

H2: 2026 Market Trends for Boat Customization

The boat customization market is poised for significant transformation by 2026, driven by technological advancements, evolving consumer preferences, and growing demand for personalized marine experiences. This analysis explores key trends shaping the industry under the H2 framework—highlighting innovations, sustainability, digital integration, and market expansion.

-

Personalization and Luxury Demand

By 2026, high-net-worth individuals and recreational boaters are increasingly seeking bespoke marine solutions. Customization is shifting beyond aesthetics to include tailored navigation systems, interior layouts, entertainment setups, and performance enhancements. The rise of luxury yachting and experiential tourism fuels demand for unique, one-of-a-kind vessels, positioning customization as a key differentiator in the premium segment. -

Integration of Smart Technology

Smart boat systems are becoming standard in customized builds. By 2026, expect widespread adoption of IoT-enabled dashboards, AI-assisted navigation, remote monitoring via mobile apps, and voice-activated controls. Boatbuilders are partnering with tech firms to embed advanced connectivity, predictive maintenance tools, and energy management systems, enhancing both safety and user experience. -

Sustainable and Eco-Friendly Materials

Environmental regulations and consumer awareness are pushing customization toward sustainability. Boat designers are incorporating recycled composites, low-VOC finishes, and eco-conscious upholstery. Additionally, hybrid and fully electric propulsion systems are being seamlessly integrated into custom designs, aligning with global decarbonization goals and appealing to environmentally conscious buyers. -

3D Printing and Advanced Manufacturing

Additive manufacturing is revolutionizing boat customization. By 2026, 3D printing enables rapid prototyping of custom parts, reducing lead times and enabling complex, lightweight designs. This technology allows for on-demand production of unique fittings, hull components, and interior elements, lowering costs and increasing design flexibility. -

Growth in Emerging Markets

Asia-Pacific and the Middle East are emerging as hotspots for customized boat demand. Expanding marinas, rising disposable incomes, and government investments in coastal tourism are driving growth. Local customization firms are partnering with European and North American designers to offer hybrid designs that blend regional aesthetics with global technology standards. -

Digital Design and Virtual Showrooms

Augmented Reality (AR) and virtual reality (VR) tools are transforming the customization process. By 2026, clients can use immersive platforms to visualize their custom boats in real-time, adjusting colors, materials, and layouts before production begins. This digital-first approach reduces errors, improves client satisfaction, and accelerates decision-making.

Conclusion

The 2026 boat customization market is characterized by a fusion of personalization, technology, and sustainability. As consumer expectations evolve and digital tools mature, customization is no longer a niche offering but a central pillar of competitive advantage in the marine industry. Companies that embrace innovation, agility, and eco-conscious design will lead the next wave of growth in this dynamic sector.

Common Pitfalls When Sourcing Customized Boats (Quality, IP)

Sourcing customized boats—whether for pleasure, commercial use, or specialized applications—can be a complex process fraught with risks, particularly concerning quality assurance and intellectual property (IP) protection. Recognizing these pitfalls early helps mitigate costly delays, disputes, or substandard outcomes.

Quality-Related Pitfalls

Inadequate Supplier Vetting

Failing to thoroughly assess a boatbuilder’s track record, certifications, and past projects can lead to poor craftsmanship. Many custom boat suppliers lack consistent quality control processes, especially in low-regulation markets. Always verify references, inspect completed vessels, and audit manufacturing facilities before signing contracts.

Unclear or Incomplete Specifications

Vague design requirements or incomplete technical drawings often result in deviations from the desired outcome. Without precise documentation covering materials, tolerances, systems integration, and finishing standards, the final product may fall short of expectations. Invest time in detailed specifications co-developed with naval architects or marine engineers.

Lack of Independent Quality Inspections

Relying solely on the supplier’s internal quality checks increases the risk of overlooked defects. Engaging a third-party marine surveyor at key production milestones (e.g., hull layup, engine installation, sea trials) ensures objective verification of workmanship and compliance.

Overlooking Material and Component Sourcing

Custom boats often incorporate third-party components (engines, electronics, fittings). If the builder sources substandard or counterfeit parts to cut costs, long-term reliability suffers. Specify approved brands and require material certifications (e.g., ISO, ABS, DNV) in the contract.

Intellectual Property Pitfalls

Ambiguous Ownership of Design IP

Without a clear agreement, the boatbuilder may retain rights to the custom design, limiting your ability to replicate or modify the vessel. Ensure contracts explicitly transfer IP ownership of bespoke elements (hull design, layouts, systems) to your organization upon full payment.

Risk of Design Replication by the Builder

Some boatyards use custom designs as templates for future clients without consent. Include non-compete or exclusivity clauses in the contract to prevent the supplier from replicating or marketing your design to competitors for a specified period.

Inadequate Protection of Technical Documentation

Design files, CAD models, and engineering reports are valuable assets. Ensure secure handling of digital assets and include confidentiality clauses that survive project completion. Use NDAs with all parties involved in the design and build process.

Failure to Register or Enforce IP Rights

In jurisdictions with weak IP enforcement, unauthorized use of unique design features may go unchallenged. Consider registering key design elements (e.g., design patents, copyrights) in relevant markets and establish legal recourse options in the supply agreement.

By proactively addressing these quality and IP-related pitfalls, buyers can ensure a smoother sourcing process, protect their investment, and achieve a truly customized boat that meets both performance and legal standards.

Logistics & Compliance Guide for Boat Customization

Understanding the Scope of Customization

Boat customization involves modifying a vessel’s structure, systems, or appearance beyond the manufacturer’s standard offerings. This may include changes to the hull, interior layout, navigation systems, propulsion, or aesthetic features. Each modification impacts logistics and regulatory compliance, making careful planning essential.

Pre-Customization Compliance Review

Before any work begins, verify that proposed modifications comply with maritime regulations from relevant authorities such as the U.S. Coast Guard (USCG), International Maritime Organization (IMO), or local maritime agencies. Obtain necessary permits and ensure the customization adheres to safety, environmental, and construction standards.

Material Sourcing and Import Regulations

Custom boat parts often come from international suppliers. Ensure all materials meet local and international standards (e.g., fire-resistant interiors, non-toxic paints). Be aware of import duties, customs documentation, and restrictions on hazardous or protected materials (e.g., certain wood types or electronic components).

Transport and Handling of Custom Components

Coordinate logistics for delivering large or delicate components (e.g., custom engines, electronics, or furnishings). Use specialized marine transport services where needed, and ensure secure packaging and climate control for sensitive items. Schedule deliveries to align with the shipyard’s workflow to avoid delays.

Shipyard Coordination and Workflow Management

Select a certified shipyard experienced in custom builds and compliance. Provide detailed blueprints and material specifications. Establish clear milestones and conduct regular progress inspections. Ensure all contractors follow local labor and safety regulations.

Regulatory Inspections and Certification

After customization, the boat must undergo inspection by a certified marine surveyor or classification society. This confirms compliance with stability, safety equipment, electrical systems, and environmental standards. Documentation such as an updated Certificate of Inspection or CE marking (for EU waters) may be required.

Documentation and Record Keeping

Maintain a comprehensive log of all modifications, including engineering drawings, material certifications, and inspection reports. This documentation is critical for insurance, resale, and future compliance audits.

Post-Completion Sea Trials and Testing

Conduct sea trials to verify performance, stability, and system functionality under real conditions. Address any issues before final delivery. Record trial data to demonstrate compliance and operational readiness.

Ongoing Compliance and Maintenance

Customized vessels require updated maintenance schedules reflecting new components. Stay informed about regulatory changes that may affect compliance, especially if operating in multiple jurisdictions. Schedule annual inspections to ensure continued adherence to standards.

Environmental and Waste Disposal Compliance

During customization, manage hazardous waste (e.g., paint solvents, old batteries) according to environmental regulations. Use certified disposal services and keep records of waste handling to avoid penalties and protect marine ecosystems.

Conclusion for Sourcing Customized Boats:

Sourcing a customized boat requires careful planning, clear communication of requirements, and collaboration with reputable manufacturers or boat builders. It offers the advantage of tailoring the vessel to specific needs—whether for leisure, commercial use, or specialized operations—ensuring optimal performance, comfort, and functionality. However, the process involves longer lead times, higher costs, and the need for detailed specifications to avoid misunderstandings.

Successful sourcing hinges on thorough research, due diligence in selecting the right partner, and ongoing project management throughout the build process. By establishing clear goals, budget parameters, and quality expectations from the outset, buyers can ensure a smooth customization experience and achieve a final product that meets or exceeds their expectations. Ultimately, investing in a customized boat can deliver long-term value, enhanced user satisfaction, and a unique maritime asset perfectly aligned with individual or organizational needs.