The global carbon fiber market is experiencing robust growth, driven by increasing demand for lightweight materials in the automotive sector, particularly in high-performance vehicles like BMWs. According to Grand View Research, the global carbon fiber market was valued at USD 3.57 billion in 2022 and is projected to expand at a compound annual growth rate (CAGR) of 11.6% from 2023 to 2030. This surge is fueled by the automotive industry’s push for improved fuel efficiency, enhanced performance, and aesthetic customization—key factors influencing the rising adoption of carbon fiber hoods in premium models. As BMW enthusiasts seek both functional and visual upgrades, the aftermarket for high-quality carbon fiber hoods has expanded rapidly. This demand has given rise to a competitive manufacturing landscape, where performance, weight reduction, and OEM compatibility are critical differentiators. Based on market trends and product performance, we’ve identified the top 5 BMW carbon fiber hood manufacturers leading innovation and customer satisfaction in this growing niche.

Top 5 Bmw Carbon Fiber Hood Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 Seibon Carbon

Domain Est. 2003

Website: seiboncarbon.com

Key Highlights: Manufacturer of high-quality carbon fiber automotive body components such as hoods, trunks, fenders, and aerodynamic body additions such as rear spoilers ……

#2 Carbon fiber CS/GTS replica F30/31/32/33/35/36 hood

Domain Est. 2006

Website: f30.bimmerpost.com

Key Highlights: I found a carbon fiber manufacturer in China making (what appeared to be) really high quality CF CS/GTS replica hoods. This will fit F30, F31, F32, F33, F35 ……

#3 ADRO NOT FOR EVERYBODY

Domain Est. 1998

Website: adro.com

Key Highlights: At ADRO, we specialize in aerospace and Formula 1 aerodynamics, pushing the boundaries of speed and style. We don’t just optimize a vehicle’s aerodynamics—we ……

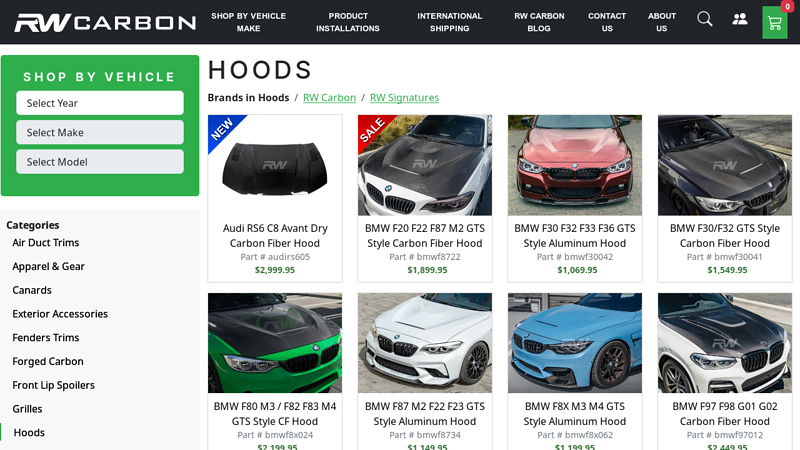

#4 Hoods

Domain Est. 2013

#5 bmw m3/m4 (f80 f82 f83) carbon fibre bonnet/hood

Domain Est. 2019

Website: ctcarbon.co

Key Highlights: In stock Rating 5.0 (1) CT Carbon brings this high-quality pre-preg carbon fibre GTS Style Bonnet/Hood for the BMW F80 M3 & F82 M4, made from ultra-lightweight materials with a ….

Expert Sourcing Insights for Bmw Carbon Fiber Hood

2026 Market Trends for BMW Carbon Fiber Hoods

The market for BMW carbon fiber hoods is poised for significant evolution by 2026, driven by shifting consumer preferences, technological advancements, and economic factors. Here’s a breakdown of the key trends shaping this niche automotive aftermarket segment:

1. Accelerated Demand from Performance and Luxury Enthusiasts

By 2026, the appetite for BMW carbon fiber hoods will continue to grow among performance-oriented and luxury-focused consumers. As BMW expands its M Performance and M Series lineup—including electrified models like the i4 M and iX M—the desire for lightweight, high-strength components will intensify. Carbon fiber hoods offer tangible weight reduction (typically 30–50% lighter than steel), improving handling, acceleration, and braking performance. This performance benefit, combined with the visual appeal of exposed carbon weave, will sustain demand across both ICE and electric BMW platforms.

2. Integration of Sustainable and Recycled Carbon Fiber

Environmental awareness will become a major trend influencing material sourcing. By 2026, manufacturers and consumers alike will increasingly prioritize sustainability. Expect a rise in carbon fiber hoods made from recycled or bio-based resins, with OEMs like BMW already investing in closed-loop recycling. Aftermarket suppliers will respond by offering eco-certified products, appealing to environmentally conscious buyers and aligning with global sustainability regulations.

3. Advancements in Manufacturing: RTM and 3D Weaving

Traditional hand-laid carbon fiber will face competition from advanced manufacturing techniques. Resin Transfer Molding (RTM) and automated 3D weaving will enable more consistent quality, reduced production times, and lower costs. By 2026, these methods will allow smaller aftermarket brands to enter the market with higher-quality, more affordable carbon hoods. Improved structural integrity and finish quality will also reduce warranty claims and increase consumer trust.

4. Rise of Premium Aftermarket and OEM-Style Fitment

Consumers will demand OEM-level precision and finish by 2026. The market will see a shift toward “plug-and-play” carbon hoods with factory-fit tolerances, pre-installed hardware, and paint-matching options. Brands offering seamless integration—especially those with BMW-specific certifications or partnerships—will gain competitive advantage. This trend will blur the line between OEM accessories and aftermarket upgrades.

5. Growth in Electric Vehicle (EV) Customization

As BMW’s EV fleet expands with models like the i5, i7, and next-gen iX, owners will seek personalized aesthetic upgrades despite fewer visible engine components. Carbon fiber hoods will serve as a key styling element, offering a high-tech, futuristic look that complements BMW’s electric design language. The lightweight advantage also contributes to extended range, making carbon hoods a performance and efficiency upgrade for EVs.

6. Price Stabilization and Market Segmentation

While carbon fiber remains premium-priced, economies of scale and improved production methods will moderate cost increases by 2026. The market will segment clearly: high-end OEM-supplied or boutique handcrafted hoods ($3,000–$6,000) versus mid-tier mass-produced options ($1,500–$2,500). Increased competition will pressure pricing, especially in the mid-range, making carbon fiber more accessible without sacrificing significant quality.

7. Digital Customization and AR Integration

E-commerce platforms will increasingly use augmented reality (AR) to let customers visualize how a carbon fiber hood looks on their specific BMW model. By 2026, configurators with real-time 3D rendering, finish options (gloss, matte, clear coat), and fitment guarantees will become standard. This digital experience will reduce hesitation in online purchases and drive conversion rates.

Conclusion

By 2026, the BMW carbon fiber hood market will be defined by performance enhancement, sustainability, and digital consumer engagement. Advances in materials and manufacturing will improve accessibility and quality, while the growing popularity of BMW’s performance and electric models will fuel demand. Brands that combine technical precision, environmental responsibility, and seamless digital integration will lead the market.

Common Pitfalls Sourcing BMW Carbon Fiber Hoods (Quality, IP)

Sourcing a carbon fiber hood for a BMW can enhance aesthetics and performance, but buyers often encounter significant pitfalls related to quality and intellectual property (IP). Being aware of these issues is crucial to avoid costly mistakes.

Substandard Material and Construction Quality

Many aftermarket carbon fiber hoods, especially budget options, use low-grade materials and poor manufacturing techniques. These hoods may employ fiberglass or plastic with a carbon fiber vinyl wrap instead of genuine woven carbon fiber. Real carbon fiber hoods use dry woven fabric cured with resin (pre-preg or wet layup), providing strength and a genuine weave appearance. Inferior products are often heavier, less durable, and prone to warping, cracking, or fading.

Misrepresentation of “Dry” vs. “Wet” Carbon Fiber

A common marketing trap involves exaggerating the use of “dry” carbon fiber, a high-end method typically reserved for OEM or race applications. Most aftermarket hoods use wet layup techniques, which are more affordable but can result in a less consistent finish and higher resin content. Sellers may falsely advertise wet carbon as dry carbon, misleading buyers about the product’s quality and value.

Poor Fitment and Finishing

Low-quality hoods frequently suffer from inaccurate dimensions and poor paint or gel coat finishes. This can lead to misalignment with factory panels, requiring extensive modification during installation. Additionally, inconsistent weave patterns, visible pinholes, or rough edges indicate subpar craftsmanship, detracting from the vehicle’s overall appearance.

Intellectual Property (IP) Infringement

Many carbon fiber hoods replicate BMW’s original design, which is protected under design patents and trademarks. Unauthorized reproduction of these designs constitutes IP infringement. Sourcing from manufacturers that ignore IP rights not only supports unethical practices but may also expose buyers to legal risks, particularly in regions with strict IP enforcement.

Lack of OEM Certification and Compliance

Genuine BMW or BMW-licensed parts meet specific safety, structural, and emissions standards. Aftermarket hoods from unverified suppliers often lack such certifications. This can affect vehicle insurance coverage, inspection compliance, and resale value. Moreover, non-OEM hoods may interfere with pedestrian safety systems or hood latch mechanisms if not engineered properly.

Inadequate Supplier Transparency

Reputable suppliers provide detailed information about material composition, manufacturing process, and compliance. Many problematic vendors offer vague descriptions, stock photos, or fake certifications. Without verifiable details, buyers cannot assess authenticity or quality, increasing the risk of receiving a counterfeit or defective product.

Avoiding these pitfalls requires due diligence—researching suppliers, verifying product claims, and prioritizing reputable brands with transparent manufacturing practices.

Logistics & Compliance Guide for BMW Carbon Fiber Hood

Overview

This guide outlines the essential logistics and compliance considerations for the transportation, import/export, and installation of an aftermarket BMW carbon fiber hood. Proper adherence to regulations ensures product safety, legal compliance, and smooth distribution across markets.

Packaging & Handling Requirements

Carbon fiber hoods are sensitive to impact, moisture, and improper storage. Ensure packaging includes:

– Custom-molded foam inserts or protective cradles

– Waterproof polyethylene wrapping to prevent moisture damage

– Reinforced outer corrugated cardboard or wooden crate for structural support

– Fragile and “This Side Up” labeling to prevent mishandling during transit

Handle with clean gloves to avoid surface contamination or resin degradation from skin oils.

Transportation Guidelines

- Use climate-controlled freight for long-distance or international shipments to avoid resin warping due to temperature fluctuations.

- Secure hoods upright in vehicles or containers to prevent flexing or edge damage.

- For air freight, comply with IATA Dangerous Goods Regulations if adhesives or resin remnants are present (rare but possible).

- Ground transport should minimize vibration; use padded suspension and avoid stacking heavy items on top.

Import/Export Compliance

Customs Documentation

- Provide a detailed commercial invoice specifying:

- Harmonized System (HS) Code: Typically 8708.29.50 (Body parts of vehicles, not elsewhere specified)

- Product description: “Aftermarket Carbon Fiber Hood for BMW [Model], Non-OEM”

- Country of manufacture

- Value in USD or local currency

- Include a packing list, bill of lading, and certificate of origin.

Regional Regulations

- United States (CBP & DOT): No federal safety certification required for hoods unless equipped with integrated lighting. However, ensure no interference with OEM safety systems (e.g., pedestrian impact sensors).

- European Union (EU): May require ECE R123 compliance if the hood affects pedestrian protection. Aftermarket parts generally need a Certificate of Conformity (CoC) or ABE (General Operating Permit) for street legality.

- Canada (Transport Canada): Follow Motor Vehicle Safety Act (MVSA); hoods must not compromise structural integrity or safety systems.

- Australia (DOTARS): Comply with ADR (Australian Design Rules); modifications may require engineering certification.

Environmental & Safety Compliance

- Carbon fiber production and disposal are subject to environmental regulations. Confirm supplier compliance with REACH (EU) and RoHS directives regarding hazardous substances.

- Packaging materials should be recyclable; avoid expanded polystyrene (EPS) where prohibited.

- Provide Safety Data Sheets (SDS) if resins or adhesives are included in the shipment.

Installation & Vehicle Compliance

- Installation must not disable or interfere with OEM safety systems (e.g., hood latch sensors, airbag triggers, or pedestrian impact mitigation).

- In regions with strict emissions or vehicle modification laws (e.g., California CARB), verify that hood replacement does not affect smog equipment access or engine bay ventilation.

- Recommend professional installation to prevent misalignment or water leakage.

Warranty & Liability Considerations

- Clearly state that installation of an aftermarket hood may void certain aspects of the manufacturer’s warranty, per the Magnuson-Moss Warranty Act (U.S.).

- Include disclaimers regarding fitment variance across BMW models and production years.

- Advise end-users to register modifications with local authorities if required (e.g., Japan’s Shaken inspection system).

Conclusion

Proper logistics planning and regulatory compliance are critical for distributing BMW carbon fiber hoods globally. Partner with certified freight forwarders, maintain accurate documentation, and stay informed on regional vehicle modification laws to ensure smooth operations and customer satisfaction.

In conclusion, sourcing a BMW carbon fiber hood requires careful consideration of quality, authenticity, compatibility, and budget. Opting for an OEM carbon fiber hood from BMW ensures the highest standards of fit, finish, and material integrity, though it comes at a premium price. Aftermarket alternatives offer a more affordable option, but it’s crucial to research reputable manufacturers known for using genuine or high-quality simulated carbon fiber with proper weave, UV protection, and clear coat finishes.

Additionally, verifying the hood’s compatibility with your specific BMW model and year is essential to avoid installation issues. Whether purchasing online or through authorized dealers, always assess warranty terms, return policies, and customer reviews to make an informed decision. Ultimately, a well-sourced carbon fiber hood not only enhances the vehicle’s aesthetic appeal and performance through potential weight reduction but also contributes to a more aggressive and sporty driving presence when properly selected and installed.