The global lithium iron phosphate (LiFePO4) battery market is experiencing robust expansion, driven by increasing demand for safer, longer-lasting energy storage solutions in electric vehicles, renewable energy systems, and industrial applications. According to Mordor Intelligence, the LiFePO4 battery market was valued at approximately USD 11.5 billion in 2023 and is projected to grow at a CAGR of over 18% from 2024 to 2029. This growth is fueled by the rising adoption of energy storage systems and the shift toward sustainable transportation. As market demand intensifies, a select group of manufacturers has emerged as leaders in battery performance, production capacity, and technological innovation. Below are the top 9 BMS-integrated LiFePO4 battery manufacturers shaping the future of energy storage.

Top 9 Bms Lifepo4 Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1

Domain Est. 2019

Website: jkbms.com

Key Highlights: We are the leading manufacturer & designer for active battery balancer and active balancer BMS. We Make Batteries Work Better And Longer….

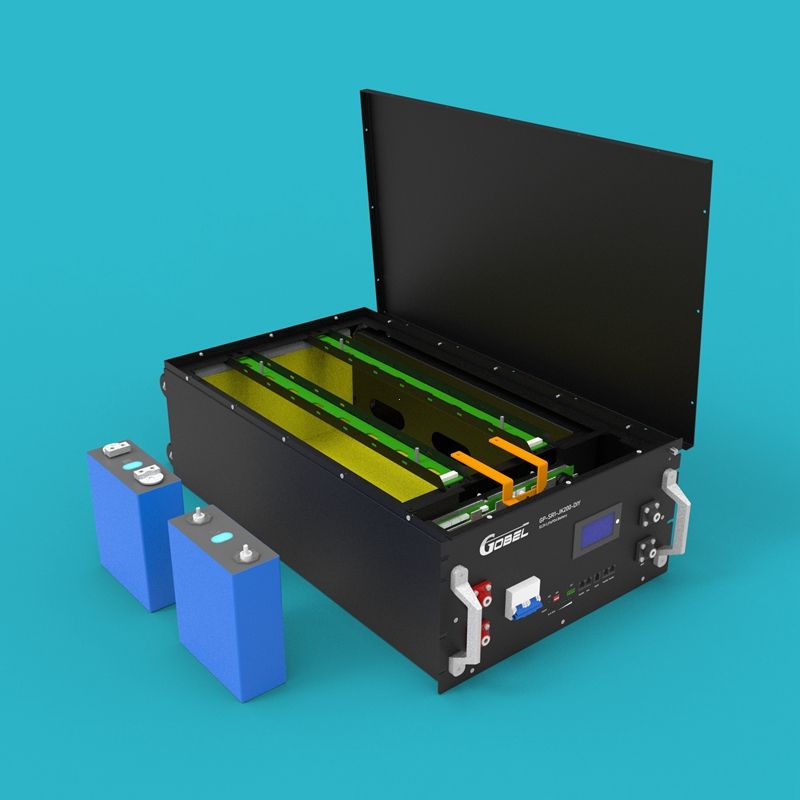

#2 Gobel Power

Domain Est. 2021

Website: gobelpower.com

Key Highlights: Gobel Power offers wholesale lithium iron phosphate (LiFePO4) battery cells, as primary agent of several lithium battery cell manufacturers in China….

#3 Jiabaida BMS: Battery Management System

Domain Est. 2024

Website: jiabaida-bms.com

Key Highlights: Free deliveryAs the best Lithium-ion/LiFePO4 Battery management system(BMS) manufacturer in China, with more than 30 R&D engineers, 40 sales elites, JiaBaiDa BMS adhere ……

#4 Lithium Battery Management Systems (BMS)

Domain Est. 2007

Website: lithiumbalance.com

Key Highlights: Advanced monitoring of battery packs: Maximise safety, performance, and longevity for your lithium battery with our LiBAL Battery Management Systems (BMS)….

#5

Domain Est. 2020

Website: lithionbattery.com

Key Highlights: Every Valence system includes the Lithion XB BMS—our advanced battery management system that monitors temperature, voltage, current, and state of charge. It ……

#6 DALY BMS: LifePO4 BMS

Domain Est. 2021

Website: dalybms.com

Key Highlights: DALY BMS specializes in the manufacturing, distribution, design, research, and servicing of cutting-edge Lithium Battery Management Systems (BMS)….

#7 daly

Domain Est. 2022

#8 TDT BMS

Domain Est. 2022

Website: tdtbms.com

Key Highlights: Protect all-scenario safety of lithium batteries for electric tricycles. Deeply adapted to the heavy-load working conditions of cargo tricycles….

#9 JIKONG BMS

Domain Est. 2023

Expert Sourcing Insights for Bms Lifepo4

H2: 2026 Market Trends for BMS LiFePO4

As the global shift toward clean energy and electrification accelerates, Battery Management Systems (BMS) tailored for Lithium Iron Phosphate (LiFePO4) batteries are expected to experience significant growth and transformation by 2026. The LiFePO4 chemistry, known for its safety, long cycle life, and thermal stability, is increasingly being adopted across multiple sectors—including electric vehicles (EVs), renewable energy storage, and industrial applications. In this context, BMS technology plays a critical role in optimizing performance, ensuring safety, and extending battery lifespan. The following analysis outlines the key market trends expected to shape the BMS LiFePO4 landscape by 2026.

-

Growing Demand in Energy Storage Systems (ESS)

The expansion of renewable energy infrastructure—especially solar and wind—is driving demand for reliable and scalable energy storage. LiFePO4 batteries, paired with advanced BMS, are becoming the preferred solution for residential, commercial, and utility-scale energy storage due to their safety and cycle durability. By 2026, analysts project that BMS-equipped LiFePO4 systems will dominate new ESS installations, particularly in markets with strong policy support for renewables, such as Europe, China, and North America. -

Electric Vehicle (EV) and E-Mobility Adoption

While NMC batteries still dominate high-performance EVs, LiFePO4 is gaining traction in entry-level electric cars, buses, and e-mobility solutions (e.g., e-scooters, e-bikes) due to lower cost and enhanced safety. Leading automakers like Tesla (in standard-range models), BYD, and others are increasingly using LiFePO4 batteries, necessitating sophisticated BMS to manage cell balancing, temperature control, and state-of-charge (SOC) accuracy. The integration of smart BMS with Vehicle-to-Grid (V2G) capabilities is also expected to increase by 2026, enabling bidirectional energy flow and grid support. -

Advancements in BMS Intelligence and Connectivity

By 2026, BMS for LiFePO4 batteries will increasingly feature embedded AI, IoT connectivity, and cloud-based monitoring. These technologies enable predictive maintenance, real-time performance analytics, and remote diagnostics, improving system reliability and reducing downtime. Edge computing within BMS units will allow faster decision-making, particularly in mission-critical applications such as telecom backup power and medical devices. -

Standardization and Regulatory Push

Global safety and performance standards for battery systems—such as UL 1973, IEC 62619, and UN 38.3—are becoming more stringent. Regulatory bodies are emphasizing the need for robust BMS to prevent thermal runaway and ensure safe operation. In parallel, industry consortia are working toward BMS interoperability and modular design, which will streamline integration and reduce costs. These developments are expected to drive consolidation and innovation among BMS providers. -

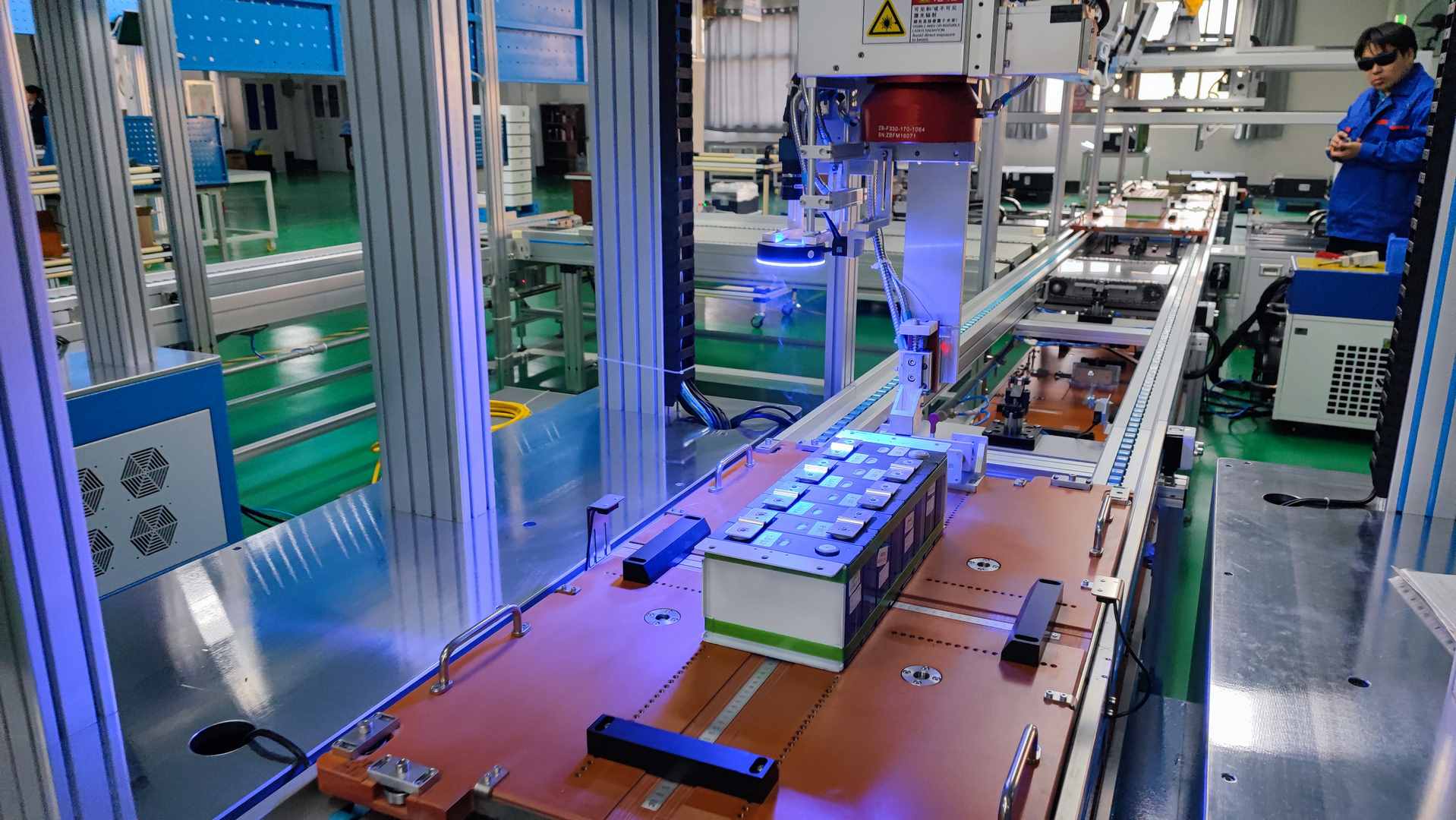

Cost Reduction and Scalability

Manufacturing scale, particularly in China, is driving down the cost of both LiFePO4 cells and integrated BMS solutions. By 2026, economies of scale, combined with advancements in semiconductor technology (e.g., low-power microcontrollers, integrated sensor chips), will make high-performance BMS more accessible across price-sensitive markets. This trend supports broader adoption in emerging economies and off-grid applications. -

Second-Life and Recycling Applications

As early LiFePO4 batteries from EVs reach end-of-life, the market for repurposed batteries in less demanding applications (e.g., stationary storage) is expected to grow. Advanced BMS solutions will be critical in assessing battery health, managing heterogeneous cell packs, and ensuring safety in second-life use. This circular economy model will create new demand for adaptive and flexible BMS platforms.

Conclusion:

By 2026, the BMS LiFePO4 market will be shaped by the convergence of technological innovation, regulatory developments, and rising demand from energy storage and electrified transport. Companies that invest in intelligent, scalable, and compliant BMS solutions will be well-positioned to capture value in this rapidly expanding sector. The LiFePO4-BMS ecosystem is poised to become a cornerstone of the global energy transition.

Common Pitfalls When Sourcing BMS for LiFePO4 Batteries (Quality & IP)

Sourcing Battery Management Systems (BMS) for LiFePO4 (Lithium Iron Phosphate) batteries is critical to ensuring performance, safety, and longevity. However, buyers often encounter significant pitfalls related to quality and intellectual property (IP). Recognizing and avoiding these issues is essential for reliable and legally compliant integration.

Poor Manufacturing Quality and Component Sourcing

Many low-cost BMS units, especially from less reputable suppliers, use substandard components such as low-grade MOSFETs, inaccurate current sensors, or inferior PCB materials. This leads to premature failure, inconsistent performance, and increased risk of thermal runaway. Poor soldering, lack of conformal coating, and inadequate heat dissipation design exacerbate reliability issues in demanding environments.

Inaccurate Cell Monitoring and Balancing

A common quality issue is inaccurate voltage measurement across cells, which can result in overcharging or deep discharging—both of which degrade LiFePO4 cells and create safety hazards. Additionally, passive balancing circuits that are either too slow or poorly calibrated fail to maintain cell voltage balance over time, reducing battery pack capacity and lifespan.

Lack of Robust Protection Features

Some BMS units omit or inadequately implement key protection mechanisms such as over-voltage, under-voltage, over-current, short-circuit, and temperature protection. Even when present, poorly tuned thresholds or slow response times can fail to prevent damage during fault conditions, undermining the safety benefits of LiFePO4 chemistry.

Inadequate Communication and Integration

Many BMS solutions offer limited or non-standard communication protocols (e.g., custom UART, non-compliant CAN), making integration with inverters, battery monitors, or energy management systems difficult. Lack of clear documentation or API support further complicates system development and troubleshooting.

IP Infringement and Counterfeit Designs

A significant IP-related pitfall is sourcing BMS units that copy patented circuit designs, firmware algorithms, or communication protocols from established manufacturers. These counterfeit or cloned products not only pose legal risks but often lack proper testing, updates, and technical support. Using such BMS can expose integrators to liability, especially in commercial or industrial applications.

Absence of Certification and Compliance

Many generic BMS units lack essential certifications such as CE, UL, UN38.3, or ISO standards. This absence indicates that the product may not have undergone rigorous safety and electromagnetic compatibility (EMC) testing, increasing the risk of failure and non-compliance with regional regulations.

Insufficient Firmware Support and Updates

Firmware bugs in BMS can lead to erratic behavior, incorrect state-of-charge (SOC) estimation, or communication failures. Some suppliers do not provide firmware updates or source code access, leaving users with no recourse when issues arise. This also raises concerns about long-term support and product lifecycle.

Hidden Costs from Integration Challenges

While some BMS units appear cost-effective upfront, hidden costs emerge from compatibility issues, integration effort, debugging time, and potential field failures. These costs often outweigh initial savings, especially when the BMS lacks documentation, technical support, or debugging tools.

By carefully evaluating suppliers for manufacturing quality, design authenticity, compliance, and long-term support, buyers can avoid these common pitfalls and ensure a safe, reliable, and legally sound BMS solution for their LiFePO4 battery systems.

Logistics & Compliance Guide for BMS LiFePO4 Batteries

Overview of BMS LiFePO4 Batteries

Battery Management System (BMS)-integrated Lithium Iron Phosphate (LiFePO4) batteries are widely used in renewable energy storage, electric vehicles, and backup power systems due to their safety, long cycle life, and thermal stability. However, their transport and handling are subject to strict international regulations due to their classification as hazardous materials. This guide outlines key logistics and compliance requirements to ensure safe and legal shipment of BMS LiFePO4 batteries.

Classification & Regulatory Framework

BMS LiFePO4 batteries are classified under the United Nations (UN) Model Regulations as Class 9 hazardous materials (Miscellaneous Dangerous Goods) due to the risk of fire or explosion if damaged, improperly handled, or short-circuited. Key regulatory bodies include:

– IMDG Code – For international maritime transport

– IATA DGR – For air transport

– 49 CFR – For ground transportation in the United States

– ADR – For road transport in Europe

All shipments must comply with the applicable regulations based on transport mode and destination.

Packaging Requirements

Proper packaging is essential to prevent short circuits, damage, and thermal runaway:

– Use non-conductive, rigid outer packaging that fully encloses the battery.

– Protect terminals with insulating caps or tape to prevent short circuits.

– Secure batteries to prevent movement within the package.

– Use packaging tested and certified to UN 38.3 standards for lithium batteries.

– For air transport, packages must pass vibration, pressure differential, and impact tests.

Marking and Labeling

Correct labeling ensures safe handling throughout the supply chain:

– Affix Class 9 Miscellaneous Dangerous Goods labels.

– Display the proper shipping name: “LITHIUM ION BATTERIES, CONTAINED IN EQUIPMENT” (UN 3481) or “LITHIUM ION BATTERIES PACKED WITH EQUIPMENT” if applicable.

– Include the UN number, shipper/consignee information, and orientation markings if required.

– For air freight, add a “Cargo Aircraft Only” label if the battery exceeds watt-hour limits for passenger aircraft.

Documentation

Accurate documentation is mandatory:

– Shipper’s Declaration for Dangerous Goods – Required for air and sea freight.

– Safety Data Sheet (SDS) – Must accompany shipments per GHS standards.

– UN 38.3 Test Summary – Required for most lithium battery shipments; confirms compliance with safety testing.

– Commercial invoices and packing lists should clearly describe the contents as lithium batteries.

Transportation Restrictions

- Air Transport: IATA DGR limits state that batteries over 100Wh require approval; those over 160Wh are typically restricted to cargo aircraft only. State of charge (SOC) must not exceed 30% unless authorized.

- Sea Transport: Must comply with IMDG Code packing, segregation, and stowage rules. Batteries must be properly secured to avoid shifting.

- Ground Transport: ADR (Europe) and 49 CFR (U.S.) require placarding for larger shipments and trained personnel.

State of Charge (SOC) Limits

To reduce risk during transport, BMS LiFePO4 batteries should be shipped at no more than 30% state of charge, unless specific exemptions apply. Pre-charging beyond this level increases the risk of thermal events.

Training and Certification

Personnel involved in handling, packaging, or shipping BMS LiFePO4 batteries must be trained and certified in hazardous materials handling according to:

– IATA’s Dangerous Goods Regulations (for air)

– IMDG Code (for sea)

– 49 CFR HazMat training (for U.S. ground transport)

– ADR training (for European road transport)

Training must be refreshed every 1–2 years depending on the regulation.

Incident Response & Emergency Procedures

In the event of damage, overheating, or leakage:

– Isolate the battery in a well-ventilated, fire-resistant area.

– Do not use water on lithium battery fires; use Class D fire extinguishers or sand.

– Notify emergency responders and follow local hazardous material protocols.

– Report incidents to regulatory authorities as required (e.g., FAA, DOT, or national agencies).

Compliance with Environmental Regulations

LiFePO4 batteries are subject to environmental regulations such as:

– REACH and RoHS (EU) – For chemical content and restricted substances.

– WEEE Directive – Requires proper recycling and disposal at end-of-life.

– Battery Directive 2006/66/EC – Governs labeling, collection, and recycling.

Ensure suppliers provide compliance documentation and support end-of-life recycling.

Best Practices for Safe Logistics

- Conduct internal audits of packaging and labeling procedures.

- Partner with certified dangerous goods freight forwarders.

- Use tracking systems to monitor shipments in real time.

- Maintain records of training, test summaries, and shipment documentation for at least two years.

Conclusion

Shipping BMS LiFePO4 batteries requires strict adherence to international hazardous materials regulations. By following proper classification, packaging, labeling, and documentation procedures, companies can ensure compliance, enhance safety, and avoid costly delays or penalties. Regular training and staying updated with regulatory changes are critical for ongoing compliance.

Conclusion for Sourcing LiFePO4 BMS (Battery Management System):

Sourcing the right Battery Management System (BMS) for LiFePO4 (Lithium Iron Phosphate) batteries is critical to ensuring safety, performance, longevity, and reliability of the overall battery system. After evaluating various suppliers, technical specifications, and quality standards, it is evident that a high-quality, appropriately matched BMS enhances cell balance, prevents overcharging, over-discharging, overheating, and short circuits—all of which are essential for maintaining the stability of LiFePO4 chemistry.

Key considerations when sourcing include compatibility with voltage and current ratings, cell count configuration, communication protocols (e.g., CAN bus, RS485), environmental durability, and certifications (e.g., CE, UL, UN38.3). While cost is a factor, prioritizing reliability and robust protection features over price alone helps avoid potential safety hazards and long-term operational issues.

Ultimately, partnering with reputable manufacturers or suppliers that offer proven product performance, technical support, and warranty coverage ensures optimal system integration and peace of mind. Whether for renewable energy storage, electric vehicles, or backup power systems, investing in a well-engineered BMS tailored to LiFePO4 batteries is a fundamental step toward achieving efficient, safe, and sustainable energy solutions.