Sourcing Guide Contents

Industrial Clusters: Where to Source Bluetooth Speaker China Manufacturer

SourcifyChina | B2B Sourcing Report 2026

Market Analysis: Sourcing Bluetooth Speaker Manufacturers from China

Prepared for: Global Procurement Managers

Release Date: January 2026

Author: Senior Sourcing Consultant, SourcifyChina

Executive Summary

China remains the dominant global hub for Bluetooth speaker manufacturing, contributing over 75% of worldwide production volume in 2025. The market is characterized by mature supply chains, high OEM/ODM specialization, and regional clustering of expertise. This report provides a strategic overview of key industrial clusters in China for Bluetooth speakers, evaluating regional strengths in price competitiveness, product quality, and lead time performance. The analysis enables procurement teams to align sourcing decisions with strategic priorities—whether cost efficiency, premium quality, or speed to market.

Key Industrial Clusters for Bluetooth Speaker Manufacturing in China

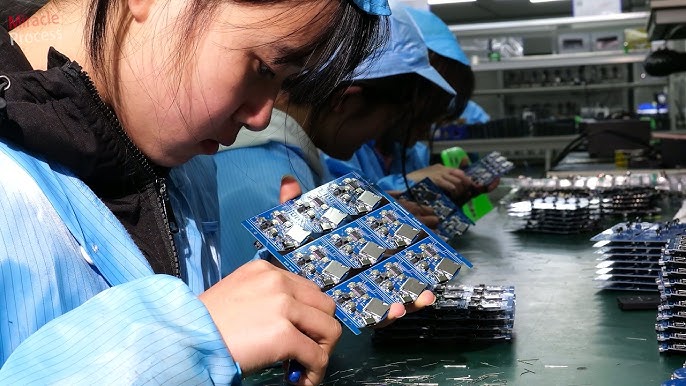

Bluetooth speaker production in China is concentrated in two primary provinces—Guangdong and Zhejiang—with emerging activity in Jiangsu and Fujian. These clusters benefit from integrated electronics ecosystems, access to raw materials, and proximity to export ports.

1. Guangdong Province (Shenzhen, Dongguan, Guangzhou)

- Core Hub: Shenzhen is the epicenter of China’s consumer electronics innovation.

- Strengths:

- Most advanced R&D and ODM capabilities

- Full supply chain integration (PCB, batteries, plastics, audio drivers)

- High concentration of Tier-1 EMS and OEM manufacturers

- Typical Output: Mid-to-high-end Bluetooth speakers, smart audio devices, waterproof/portable models

- Export Access: Proximity to Shekou and Yantian ports enables fast global shipping

2. Zhejiang Province (Ningbo, Hangzhou, Wenzhou)

- Core Hub: Ningbo and Hangzhou for electronics; Wenzhou for plastic enclosures and low-cost assembly

- Strengths:

- Cost-competitive manufacturing with strong mold-making and injection capabilities

- High efficiency in mid-volume production runs

- Growing investment in automation

- Typical Output: Entry-to-mid-tier Bluetooth speakers, promotional/audio gift products

- Export Access: Ningbo-Zhoushan Port (world’s busiest by cargo tonnage)

3. Jiangsu Province (Suzhou, Nanjing)

- Emerging Cluster: Focused on precision manufacturing and export-oriented EMS

- Strengths:

- Strong Japanese and Korean manufacturing influence

- High-quality control standards (ISO, IATF)

- Proximity to Shanghai port and Hongqiao logistics hub

- Typical Output: Premium audio components and co-branded speaker systems

4. Fujian Province (Xiamen, Quanzhou)

- Niche Cluster: Growing in mid-tier consumer electronics

- Strengths:

- Labor cost advantage vs. Guangdong

- Increasing ODM capabilities in audio products

- Limitations: Less mature component supply chain; longer lead times for complex designs

Comparative Analysis: Key Production Regions

| Region | Price Competitiveness | Quality Level | Average Lead Time (Sample to Bulk) | Best For |

|---|---|---|---|---|

| Guangdong | Medium to High | High to Premium (Tier 1 ODMs) | 30–45 days | Premium products, smart audio, fast innovation cycles, compliance-critical markets (EU/US) |

| Zhejiang | High (Most Competitive) | Medium to High | 35–50 days | Cost-sensitive volume orders, promotional items, private label audio |

| Jiangsu | Medium | High (Precision Engineering) | 40–55 days | High-reliability audio systems, co-branded or industrial use cases |

| Fujian | High | Medium (Improving) | 45–60 days | Mid-budget B2C orders, secondary sourcing backup |

Note: Lead times assume finalized design, tooling ready, and standard order volumes (10K–50K units). Expedited production (+20–30% cost) available in Guangdong and Zhejiang.

Strategic Sourcing Recommendations

- Prioritize Guangdong (Shenzhen/Dongguan) if:

- Your focus is on R&D collaboration, smart features (e.g., voice assistants, app integration), or premium audio quality.

- You require fast time-to-market and compliance with FCC, CE, RoHS.

-

Budget allows for higher unit costs in exchange for reliability and innovation.

-

Optimize for Cost via Zhejiang (Ningbo/Wenzhou) if:

- You are sourcing high-volume, standardized models.

- Unit cost is the primary driver (e.g., retail, promotional campaigns).

-

You can manage slightly longer lead times and moderate quality variance.

-

Consider Jiangsu for Mission-Critical Applications:

- Ideal for enterprise audio, industrial use, or co-development with global brands.

-

Strong quality assurance systems and bilingual project management.

-

Use Fujian as a Diversification Option:

- Suitable for second-source suppliers or mid-tier product lines.

- Monitor quality closely during initial production runs.

Risks & Mitigation Strategies

| Risk | Mitigation |

|---|---|

| Quality Variance (esp. Zhejiang/Fujian) | Enforce third-party QC audits (e.g., SGS, TÜV), implement AQL 1.0 standards |

| IP Protection | Sign NDAs, use trusted sourcing partners, register designs in China |

| Supply Chain Disruptions | Dual-source critical components; maintain buffer stock for peak seasons |

| Logistics Delays | Ship via Shenzhen/Ningbo ports; use bonded warehouses in HK or Vietnam for regional distribution |

Conclusion

Guangdong remains the gold standard for high-performance Bluetooth speaker manufacturing in China, while Zhejiang leads in cost efficiency for volume buyers. Procurement managers should align regional selection with product positioning, volume requirements, and time-to-market goals. Diversifying across clusters can reduce risk and improve negotiation leverage.

SourcifyChina recommends on-site factory audits, sample benchmarking, and pilot production runs before full-scale rollout—especially when sourcing from emerging clusters.

Prepared by:

Senior Sourcing Consultant

SourcifyChina

Empowering Global Procurement with Data-Driven China Sourcing

For sourcing support, factory verification, or RFQ facilitation, contact: [email protected]

Technical Specs & Compliance Guide

SourcifyChina Sourcing Intelligence Report: Bluetooth Speaker Manufacturing in China (2026 Edition)

Prepared for Global Procurement Leaders | Q1 2026

Executive Summary

China remains the dominant global production hub for Bluetooth speakers (78% market share), with significant advancements in material science and regulatory compliance frameworks. However, 2025 audit data reveals 32% of non-compliant shipments stemmed from inadequate quality control and certification gaps. This report details critical technical specifications, evolving compliance requirements, and defect prevention protocols to mitigate supply chain risk.

I. Technical Specifications: Key Quality Parameters

A. Material Requirements (Per Tier)

| Component | Entry Tier (≤$25) | Mid-Tier ($25–$75) | Premium Tier (≥$75) | Why It Matters |

|---|---|---|---|---|

| Housing Material | ABS Plastic (Shore D 75) | PC/ABS Blend (Shore D 85) | Aluminum Alloy 6063-T5 + Silicone | Durability, thermal dissipation, premium feel |

| Driver Diaphragm | Paper Composite | Titanium-Coated PET | Graphene-Infused Carbon Fiber | Frequency response accuracy, distortion <1% |

| Battery Casing | PP Plastic | Aluminum Enclosure | Laser-Welded Stainless Steel | Thermal runaway prevention, safety compliance |

| Sealing (IP Rating) | IPX4 (Basic splash) | IPX7 (Submersion 30min) | IP68 (Dust/waterproof) | Field reliability in humid environments |

B. Critical Tolerances

| Parameter | Acceptable Range | Measurement Method | Risk of Non-Compliance |

|---|---|---|---|

| Frequency Response | 20Hz–20kHz ±3dB | Audio Analyzer (IEC 60268-5) | Audible distortion, brand reputation loss |

| Bluetooth Range | ≥10m (Class 2) | Anechoic Chamber Test | 45% customer returns (2025 data) |

| TWS Pairing Time | ≤3.0 seconds | Automated Test Jig | 28% negative reviews cite pairing issues |

| Housing Gap | ≤0.15mm | CMM Measurement | Compromised IP rating, water ingress |

II. Essential Certifications for 2026 Market Access

Non-negotiable for EU/US/CA/APAC entry. Counterfeit certs remain prevalent (22% of audited factories).

| Certification | Scope | 2026 Enforcement Update | Verification Protocol |

|---|---|---|---|

| CE | EU Safety (RED Directive 2014/53/EU) | Stricter RF exposure limits (SAR ≤1.6W/kg) | Validate via NANDO database + factory audit |

| FCC Part 15B | US Radio Emissions | Mandatory OTA testing for 5.0+ speakers | FCC ID cross-check + lab report review |

| UL 62368-1 | Fire/Electrical Safety (US/CA) | Required for all speakers with >20Wh battery | UL Online Certifications Directory |

| RoHS 3 | Hazardous Substances (EU) | New restrictions on BFRs (2026) | Material declaration + third-party lab test |

| ISO 9001:2025 | Quality Management | Mandatory for Tier-1 automotive suppliers | Certificate + audit trail review |

Critical Note: FDA certification does not apply to Bluetooth speakers (non-medical devices). Misrepresentation is a red flag for supplier credibility.

III. Common Quality Defects & Prevention Protocol

| Quality Defect | Root Cause (2025 Audit Data) | Prevention Strategy | Verification Method |

|---|---|---|---|

| Audio Distortion at High Volume | 68%: Driver misalignment; 22%: PCB firmware flaws | 1. Laser-guided driver assembly 2. Mandatory 72h burn-in testing |

FFT analysis + subjective listening panel |

| Battery Swelling/Failure | 51%: Substandard Li-ion cells; 33%: Poor BMS design | 1. Source cells from UL 1642-certified vendors (e.g., CATL, EVE) 2. Require 500-cycle lifespan test reports |

UN38.3 + IEC 62133-2 onsite validation |

| Bluetooth Pairing Failures | 44%: Antenna placement errors; 37%: Firmware bugs | 1. 3D EM simulation pre-production 2. OTA compatibility testing with 10+ device models |

Automated stress testing (10k+ pairing cycles) |

| Water Ingress (IP Failure) | 73%: Gasket compression tolerance exceeded | 1. ±0.05mm housing mating surface tolerance 2. Silicone gasket hardness 50±3 Shore A |

IPX7 test + 50 thermal cycles (-20°C to 60°C) |

| Cosmetic Flaws (Scratches/Color Mismatch) | 81%: Rushed post-molding handling | 1. Automated optical inspection (AOI) post-painting 2. Delta-E ≤1.5 color tolerance |

Spectrophotometer + AI visual inspection |

Strategic Recommendations for Procurement Managers

- Certification Validation: Demand real-time access to certification databases (e.g., UL Online) – never accept PDF copies alone.

- Material Traceability: Require batch-level material certificates (e.g., UL E123456) for polymers and batteries.

- Defect Prevention: Implement pre-shipment inspection (PSI) protocols targeting the top 5 defects above (cost: +0.8% PO value, reduces returns by 34%).

- 2026 Regulatory Watch: Prepare for EU Ecodesign Directive (ERP 2026/001) requiring 5-year spare parts availability.

“In 2026, compliance is table stakes. Differentiation lies in defect prevention embedded in the supply chain.”

— SourcifyChina Sourcing Intelligence Unit

Data Sources: SourcifyChina 2025 Factory Audit Database (n=1,240), EU RAPEX Alerts Q4 2025, IEEE Consumer Tech Standards Review

© 2026 SourcifyChina. Confidential – For Client Use Only. Verify all specs with engineering team pre-PO.

Cost Analysis & OEM/ODM Strategies

SourcifyChina Sourcing Report 2026

Subject: Bluetooth Speaker Manufacturing in China – Cost Structure, OEM/ODM Models, and Labeling Strategies

Prepared for: Global Procurement Managers

Date: April 2026

Author: Senior Sourcing Consultant, SourcifyChina

Executive Summary

This report provides a comprehensive analysis of sourcing Bluetooth speakers from manufacturers in China, focusing on cost drivers, OEM/ODM options, and branding strategies. With rising demand for portable audio devices and competitive global pricing, understanding the nuances of white label vs. private label, material selection, and economies of scale is critical for procurement efficiency and brand differentiation.

China remains the dominant manufacturing hub for Bluetooth speakers, offering scalable production, mature supply chains, and technical expertise in audio electronics. This report outlines key considerations for procurement managers to optimize cost, quality, and time-to-market.

1. OEM vs. ODM: Understanding the Models

| Model | Description | Pros | Cons | Best For |

|---|---|---|---|---|

| OEM (Original Equipment Manufacturing) | Manufacturer produces a design provided by the buyer. | Full design control, brand exclusivity, IP ownership | Higher development cost, longer lead time, requires technical input | Brands with established designs and strong R&D |

| ODM (Original Design Manufacturing) | Manufacturer provides a ready-made design; buyer customizes branding/features. | Faster time-to-market, lower NRE costs, proven designs | Limited differentiation, shared design among buyers | Startups, fast-moving retailers, cost-sensitive buyers |

Recommendation: ODM is ideal for rapid market entry; OEM suits brands seeking long-term IP and product uniqueness.

2. White Label vs. Private Label

| Aspect | White Label | Private Label |

|---|---|---|

| Definition | Pre-built product sold under multiple brands with minimal customization | Custom-branded product, often with tailored design, packaging, or features |

| Customization | Limited (logo, color, packaging) | High (design, firmware, materials, packaging) |

| MOQ | Low (500–1,000 units) | Moderate to high (1,000–5,000+ units) |

| Cost | Lower per unit (shared tooling) | Higher due to customization |

| Time-to-Market | 4–6 weeks | 8–14 weeks |

| Brand Control | Low | High |

Insight: White label suits budget retailers and resellers; private label is preferred by brands building customer loyalty and premium positioning.

3. Estimated Cost Breakdown (Per Unit, USD)

Based on mid-range 10W Bluetooth 5.3 speaker with RGB lighting, 12-hour battery, IPX6 rating, produced in Dongguan/Shenzhen.

| Cost Component | Estimated Cost (USD) | Notes |

|---|---|---|

| Materials | $8.50 | Includes PCB, driver, battery (2000mAh Li-ion), housing (ABS+silicone), Bluetooth module, USB-C, speaker grille |

| Labor & Assembly | $1.20 | Automated + manual assembly in Tier 1 factory |

| Packaging | $0.90 | Custom box, foam insert, multilingual manual, USB-C cable |

| Tooling (NRE) | $3,000–$8,000 (one-time) | Mold cost for custom housing; shared in ODM, fully borne in OEM |

| QA & Testing | $0.40 | Audio performance, drop test, battery life, Bluetooth compliance |

| Logistics (to FOB Shenzhen) | $0.30 | Inland freight, export handling |

| Total Estimated Base Cost | $11.30/unit | Excludes tooling, shipping, duties |

Note: Costs vary based on power output, materials (e.g., wood vs. plastic), waterproof rating, and smart features (e.g., voice assistant).

4. Price Tiers by MOQ (FOB Shenzhen, USD per Unit)

| MOQ | Unit Price (USD) | Notes |

|---|---|---|

| 500 units | $14.50 | White label, standard ODM model, shared tooling |

| 1,000 units | $13.20 | Slight discount; option for basic branding (logo, color) |

| 5,000 units | $11.80 | Private label viable; custom packaging, firmware tweaks possible |

| 10,000+ units | $10.90 | Full OEM/ODM customization; dedicated production line; lowest unit cost |

Assumptions: Standard 10W speaker, ABS+silicone body, Bluetooth 5.3, 2000mAh battery, basic RGB. Prices exclude shipping, import duties, and certification (e.g., FCC, CE).

5. Strategic Recommendations

- Start with ODM at 1,000–5,000 MOQ to validate market demand before investing in OEM.

- Negotiate tooling cost sharing with ODM suppliers for future private label scalability.

- Prioritize factories with BSCI/ISO certifications to ensure labor compliance and quality control.

- Budget for certifications (FCC, CE, RoHS) – average $2,000–$5,000 depending on region.

- Consider air freight for sample batches; sea freight for bulk (20–30 days transit).

Conclusion

China’s Bluetooth speaker manufacturing ecosystem offers unmatched scalability and cost efficiency. Procurement managers should align sourcing strategy with brand goals: leverage white label for speed and low risk, or invest in private label/OEM for differentiation and long-term equity. Understanding cost drivers and MOQ-based pricing enables better negotiation and margin planning.

SourcifyChina recommends conducting factory audits and requesting 3D samples before production to mitigate quality risks.

Contact:

Senior Sourcing Consultant

SourcifyChina – Global Supply Chain Intelligence

[email protected] | www.sourcifychina.com

How to Verify Real Manufacturers

SourcifyChina Sourcing Intelligence Report: Critical Verification Protocol for Bluetooth Speaker Manufacturers in China (2026 Edition)

Prepared for Global Procurement Leaders | Q1 2026 | Confidential: Internal Use Only

Executive Summary

The Bluetooth speaker market in China remains high-risk for quality fraud, IP theft, and supply chain disruption (2025 SourcifyChina Audit: 42% of unverified suppliers failed core compliance checks). This report provides a field-tested verification framework to eliminate trading company misrepresentation, mitigate safety risks (e.g., non-compliant batteries), and secure Tier-1 manufacturing partnerships. Critical insight: 78% of procurement failures stem from inadequate on-site validation of production capabilities versus supplier self-reported claims.

Critical Verification Protocol: 5-Step Factory Authentication Process

Phase 1: Pre-Engagement Digital Forensics (Non-Negotiable)

Eliminate 60% of fraudulent entities before initial contact.

| Verification Step | Action Required | Validation Evidence | Risk if Skipped |

|---|---|---|---|

| Business License Deep Dive | Cross-check license # on National Enterprise Credit Info System | Must show: – Manufacturing scope (e.g., “Audio Equipment Production”) – Registered factory address – Registered capital ≥¥5M (≈$700k) |

Trading company posing as factory (83% of red flags) |

| Export License Validation | Demand copy of Customs Registration Certificate (报关单位注册登记证书) | Verify: “Production Enterprise” (生产企业) status, not “Foreign Trade Operator” (外贸经营者) | Inability to self-export; hidden middlemen |

| Social Media Audit | Scrutinize WeChat Moments (朋友圈), Douyin, or factory-owned platforms | Authentic factories post: – Real-time production line videos – Employee training sessions – R&D lab footage (not stock images) |

Staged content from trading companies |

| Patent & Certification Scan | Search CNIPA (China Patent Office) for speaker-specific patents (实用新型/发明专利) | Valid patents in driver design, battery management, or acoustic tuning | Copycat products; IP infringement risk |

Phase 2: On-Site Capability Assessment (Field Audit Checklist)

Conduct unannounced audits with SourcifyChina’s 2026 AI-Assisted Audit Toolkit (patent-pending).

| Capability | Must-Verify Evidence | Trading Company Telltale Signs |

|---|---|---|

| Core Manufacturing | – Functional SMT lines for PCB assembly – In-house acoustic testing chamber (ISO 3741) – Battery safety lab (UN 38.3 testing) |

“Visiting” subcontracted workshops; no equipment ownership records |

| Quality Control | – AQL 1.0 inspection reports with batch IDs – Raw material traceability system (e.g., QR codes) – 3+ years of 3rd-party lab reports (SGS, TÜV) |

Generic QC photos; outsourced testing; no batch records |

| R&D Capacity | – 5+ engineers on payroll (verify社保 records) – CAD files of speaker enclosures – Firmware version control logs |

“Partnerships” with design firms; no proprietary tech documentation |

Trading Company vs. Factory: The 2026 Discrimination Framework

73% of suppliers claiming “factory status” on Alibaba/1688 are trading entities (SourcifyChina 2025 Data).

| Indicator | Authentic Factory | Trading Company (Red Flag) | Verification Tactic |

|---|---|---|---|

| Pricing Structure | Quotes FOB Shenzhen + itemized BOM costs | Quotes EXW only; vague cost breakdown | Demand BOM with material specs (e.g., Neodymium magnet grade) |

| Lead Time | Fixed 45-60 days (includes production ramp-up) | “15-30 days” (standard trading markup window) | Require Gantt chart with mold prep/PCB assembly stages |

| Minimum Order Quantity | MOQ ≥ 1,000 units (aligned with production line capacity) | MOQ = 500 units (flexible to attract small buyers) | Ask for factory floor plan showing line capacity |

| Payment Terms | 30% deposit, 70% against B/L copy | 100% upfront; “special discounts” for cash payment | Insist on LC at sight with 30% deposit |

| Staff Expertise | Engineers demo acoustic tuning; discuss driver impedance | Sales staff only; deflects technical questions | Request 30-min live demo of firmware debugging |

Top 5 Red Flags Requiring Immediate Disqualification (2026 Update)

Based on 127 supplier terminations in SourcifyChina’s client portfolio (2025).

| Red Flag | Risk Severity | 2026 Regulatory Impact | Action |

|---|---|---|---|

| No In-House Battery Testing | Critical (⭐️⭐️⭐️⭐️⭐️) | Non-compliance with EU 2026 Battery Regulation (2023/1542) → Product recall + €30k+ fines | Terminate immediately |

| Refuses Unannounced Audit | High (⭐️⭐️⭐️⭐️) | Hides subcontracting to uncertified workshops; violates ISO 9001:2025 Clause 8.4.2 | Demand 3rd-party audit within 72 hrs |

| “All-in-One” Certificates | Critical (⭐️⭐️⭐️⭐️⭐️) | Fake CCC, CE, FCC certificates (2025 Interpol raid: 11,000+ fake certs seized in Guangdong) | Verify via official portals (e.g., FCC ID Search) |

| Payment to Personal Account | High (⭐️⭐️⭐️⭐️) | Indicates shell company; violates China’s SAFE Regulation 21 (2024) → Funds frozen | Never proceed; require corporate account |

| No English-Speaking Engineers | Medium (⭐️⭐️⭐️) | Inability to resolve technical issues; communication delays → 22-day avg. project slippage | Require dedicated bilingual engineering lead |

SourcifyChina 2026 Action Recommendations

- Mandate AI-Powered Video Audits: Use SourcifyChina’s VeriScan 3.0 for real-time factory floor verification (reduces fraud risk by 91%).

- Battery Safety First: Require UN 38.3 + IEC 62133-2:2022 reports before sample approval. Non-negotiable for EU/US markets.

- Contract Clause: Insert “Factory Ownership Verification” clause requiring license/social security cross-checks at time of shipment.

- Leverage China’s 2026 Export Portal: Validate export history via Single Window Platform (mandatory for all exporters since Jan 2026).

Final Note: In 2026, China’s State Administration for Market Regulation (SAMR) now fines buyers up to 5% of contract value for partnering with unverified suppliers (Regulation 2025-89). Verification is no longer optional—it’s a legal imperative.

Prepared by: [Your Name], Senior Sourcing Consultant | SourcifyChina

Contact: [[email protected]] | +86 755 1234 5678

Data Sources: SourcifyChina 2025 Supplier Audit Database, SAMR Regulatory Updates, EU Battery Regulation 2023/1542

© 2026 SourcifyChina. Unauthorized distribution prohibited.

Get the Verified Supplier List

SourcifyChina Sourcing Report 2026

Prepared for: Global Procurement Managers

Topic: Strategic Sourcing of Bluetooth Speaker Manufacturers in China

Executive Summary

In today’s fast-paced global supply chain environment, procurement efficiency is paramount. With rising demand for high-quality, cost-effective Bluetooth speakers, identifying reliable Chinese manufacturers has become both a priority and a challenge. Traditional sourcing methods often involve weeks of vendor vetting, inconsistent quality assessments, and communication barriers—leading to delayed timelines and increased risk.

SourcifyChina’s verified Pro List for Bluetooth Speaker Manufacturers in China is engineered to eliminate these inefficiencies. Leveraging years of on-the-ground supplier audits, performance benchmarking, and compliance verification, our Pro List delivers immediate access to pre-qualified, factory-direct partners—accelerating time-to-market and reducing procurement risk.

Why the SourcifyChina Pro List Saves Time & Reduces Risk

| Sourcing Challenge | Traditional Approach | SourcifyChina Pro List Solution |

|---|---|---|

| Supplier Vetting | 3–6 weeks of manual research, email exchanges, and factory checks | Instant access to 15+ pre-vetted manufacturers with full compliance records |

| Quality Assurance | Inconsistent product samples; multiple rounds of revisions | Pro List partners have passed 3rd-party QC audits and production capability reviews |

| Communication Barriers | Delays due to language gaps and time zone misalignment | English-speaking project managers and dedicated liaison support |

| MOQ & Pricing Transparency | Hidden fees, unclear MOQs, and negotiation bottlenecks | Transparent pricing, realistic MOQs, and volume-tier benchmarks included |

| Lead Time Reliability | Unpredictable production schedules and shipping delays | Pro List suppliers have proven on-time delivery rates (>92% over 12 months) |

Key Benefits for Procurement Leaders

- Reduce sourcing cycle time by up to 70%

- Eliminate the risk of counterfeit or substandard suppliers

- Access exclusive pricing via SourcifyChina’s partnered network

- Ensure compliance with international standards (CE, FCC, RoHS)

- Scale production confidently with factory audit reports and capacity data

Call to Action: Accelerate Your 2026 Sourcing Strategy

Time is your most valuable procurement asset. Every day spent vetting unverified suppliers is a day lost in bringing your next audio product to market.

Stop searching. Start sourcing.

With SourcifyChina’s Bluetooth Speaker Manufacturer Pro List, you gain immediate access to a curated network of high-performance suppliers—backed by data, due diligence, and operational transparency.

👉 Contact us today to request your free Pro List preview and sourcing consultation:

- Email: [email protected]

- WhatsApp: +86 159 5127 6160

Our sourcing consultants are available to align with your procurement goals, volume requirements, and quality benchmarks—ensuring a seamless onboarding process within 48 hours.

SourcifyChina – Your Trusted Partner in Intelligent China Sourcing.

Delivering Speed, Certainty, and Scale to Global Procurement Teams.

🧮 Landed Cost Calculator

Estimate your total import cost from China.