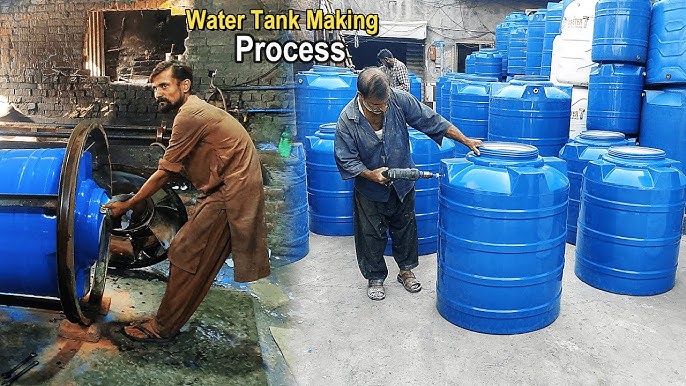

The global water storage tank market is experiencing robust growth, driven by rising urbanization, increasing demand for clean water, and expanding infrastructure development. According to a report by Mordor Intelligence, the global water storage tanks market was valued at USD 31.4 billion in 2023 and is projected to grow at a CAGR of 5.8% from 2024 to 2029. This growth is further fueled by the shift toward sustainable water management and the adoption of durable, corrosion-resistant materials such as polyethylene and fiberglass—hallmarks of blue water tanks widely used in residential, commercial, and agricultural applications. As demand surges, manufacturers are ramping up innovation in design, capacity, and UV resistance to meet stringent quality standards and environmental conditions. In this competitive landscape, six key players have emerged as leaders in the production of blue water tanks, combining technological advancement, scalability, and reliability to dominate regional and international markets.

Top 6 Blue Water Tank Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 Bluewater

Domain Est. 2014

Website: bluewaterstoragesystems.com

Key Highlights: Bluewater is Michigan’s choice for building liquid storage tanks, with decades of municipal and industrial experience across the state….

#2 Blu Technology RV Water Filtration Systems

Domain Est. 2021

Website: goblutech.com

Key Highlights: Free delivery over $250 · 30-day returnsPortable Systems for RV & Campground Water · Off-Grid Filtration Systems · Permanently Mounted Systems · Purification Systems….

#3 Bulk Water Delivery Services

Domain Est. 2007

Website: bluewatertrucking.net

Key Highlights: Blue Water Trucking supplies non-potable bulk water for pools, spas, ponds, construction sites, and emergencies with 6500-gallon tankers….

#4

Domain Est. 2010

Website: blue-tank.net

Key Highlights: Blue Tank manufactures and installs bolted metal tanks in galvanised, powder coated or thermoplastic steel. Our tanks are easily transportable….

#5

Domain Est. 2010

Website: bluewaterbaitsystems.com

Key Highlights: HOW TO GET ONE FOR YOUR BOAT · Visit the Bait Tanks page to choose your model based on shape and size. Next visit the Accessories page to choose your add-ons….

#6 Water Treatment

Domain Est. 2017

Website: bluetankandpump.com

Key Highlights: Water Treatment Accessories. Blue Tank and Pump Rental is more than just your rental company but your engineered solution. Facebook Instagram Linkedin ……

Expert Sourcing Insights for Blue Water Tank

H2: Market Trends for Blue Water Tanks in 2026

By 2026, the market for blue water tanks—large-scale storage solutions used primarily for potable water, irrigation, and industrial applications—is expected to undergo significant transformation driven by technological innovation, environmental concerns, urbanization, and shifting regulatory landscapes. Key trends shaping the blue water tank market in 2026 include:

-

Increased Demand from Urbanization and Infrastructure Development

Rapid urban expansion, particularly in emerging economies across Asia, Africa, and Latin America, is driving the need for reliable water storage infrastructure. Governments are investing heavily in resilient water management systems, boosting demand for durable, high-capacity blue water tanks in municipal and residential projects. -

Sustainability and Eco-Friendly Materials

Environmental regulations and consumer preferences are pushing manufacturers toward sustainable materials, such as recycled polyethylene and UV-stabilized polymers. Blue water tanks with lower carbon footprints, recyclability, and energy-efficient production methods will gain market share. Green building certifications (e.g., LEED, BREEAM) are incentivizing the use of eco-conscious water storage solutions. -

Smart Water Management Integration

The integration of IoT (Internet of Things) sensors and smart monitoring systems into blue water tanks is a growing trend. By 2026, tanks equipped with real-time level monitoring, leak detection, and remote management capabilities will become standard in both commercial and industrial applications. This enables predictive maintenance, reduces water loss, and improves resource efficiency. -

Growth in Decentralized Water Systems

With climate change increasing water scarcity and strain on centralized systems, decentralized water storage and harvesting are gaining traction. Blue water tanks are increasingly used in rainwater harvesting and off-grid systems, especially in drought-prone regions. Government incentives and awareness campaigns are supporting this shift. -

Advancements in Tank Design and Durability

Innovations in material science are leading to lighter, corrosion-resistant, and longer-lasting tanks. Modular and collapsible designs are emerging for easier transport and installation in remote or disaster-prone areas. Blue tanks with improved thermal insulation will also be in demand to maintain water quality in extreme climates. -

Regulatory Compliance and Health Standards

Stricter regulations around drinking water safety are prompting manufacturers to meet higher standards (e.g., NSF/ANSI 61 certification). Blue water tanks that ensure contamination-free storage will be preferred in both public health and private sector applications. -

Regional Market Growth

The Asia-Pacific region is expected to lead market growth due to population density and infrastructure development in countries like India, Indonesia, and Vietnam. Meanwhile, North America and Europe will see steady demand driven by aging infrastructure replacement and sustainability mandates.

In conclusion, the 2026 blue water tank market will be defined by smarter, greener, and more resilient solutions. Companies that invest in innovation, sustainability, and digital integration will be best positioned to capitalize on these evolving trends.

Common Pitfalls When Sourcing Blue Water Tanks (Quality & IP)

Sourcing blue water tanks—typically used for potable water storage—requires careful attention to both product quality and intellectual property (IP) rights. Overlooking these aspects can lead to significant operational, legal, and reputational risks. Below are key pitfalls to avoid:

Poor Material Quality and Non-Compliance

One of the most frequent issues is receiving tanks made from substandard or non-compliant materials. Blue water tanks must meet strict health and safety standards for drinking water storage (e.g., NSF/ANSI 61, WRAS, or local potable water regulations). Pitfalls include:

- Use of recycled or contaminated plastics that leach harmful chemicals into water.

- UV degradation due to inadequate UV stabilization, leading to brittleness and cracking over time.

- Incorrect resin type, such as using non-food-grade polyethylene, which can compromise water safety.

Always request material certifications and verify compliance with regional potable water standards before procurement.

Inadequate Structural Design and Manufacturing Defects

Low-quality tanks may have design flaws or manufacturing inconsistencies that reduce lifespan and performance:

- Thin wall thickness or uneven molding, increasing the risk of leaks or structural failure.

- Poorly welded seams or joints, especially in larger tanks, which are prone to splitting.

- Lack of baffles or structural reinforcements in large-capacity tanks, leading to deformation under load.

Conduct factory audits or request third-party inspection reports (e.g., ISO 9001 certification) to assess manufacturing consistency and design integrity.

Misrepresentation of Intellectual Property (IP) Rights

Many reputable blue water tank designs are protected by patents, trademarks, or industrial designs. Common IP-related pitfalls include:

- Sourcing counterfeit or cloned products that mimic branded tanks (e.g., imitation of Rotoplas, JoJo Tanks, or National Tank Company designs) without authorization.

- Lack of design patent verification, leading to potential infringement claims when importing or selling.

- Unauthorized use of logos, colors, or branding, particularly the distinctive “blue” color scheme associated with certain brands, which may be trademarked.

Always verify the supplier’s right to produce and sell the design. Request IP documentation and conduct due diligence to avoid legal disputes or shipment seizures.

Inconsistent Product Labeling and Traceability

Non-compliant or missing labeling can signal poor quality control and create compliance risks:

- Absence of batch numbers, manufacturing dates, or material grades.

- Missing certification marks (e.g., NSF, ISO, WRAS).

- Vague or falsified origin information.

Ensure tanks are properly labeled and traceable to facilitate quality tracking and regulatory compliance.

Supply Chain and Warranty Risks

Sourcing from unreliable suppliers can lead to:

- Lack of after-sales support or warranty coverage.

- Inconsistent delivery timelines or product availability.

- No technical support for installation or maintenance.

Engage suppliers with established track records, clear warranty terms, and accessible customer service.

Conclusion

To avoid these pitfalls, conduct thorough due diligence: verify material certifications, inspect manufacturing quality, confirm IP legitimacy, and choose suppliers with transparent, compliant practices. Investing time upfront minimizes risks related to water safety, structural integrity, and legal exposure.

Logistics & Compliance Guide for Blue Water Tank

Overview

This guide outlines the essential logistics and compliance considerations for the transportation, handling, storage, and regulatory adherence related to Blue Water Tank products. Adhering to these guidelines ensures safe operations, legal compliance, and product integrity throughout the supply chain.

Product Specifications

Blue Water Tanks are high-density polyethylene (HDPE) or polypropylene storage units designed for potable water, wastewater, and chemical storage. Standard models range in capacity from 500 to 50,000 liters and are UV-stabilized for outdoor use. Confirm model-specific details before shipping or installation.

Transportation Guidelines

Loading and Securing

- Use flatbed or enclosed trucks with non-slip surfaces.

- Secure tanks with ratchet straps or chains at multiple anchor points to prevent shifting.

- Stack only if designed for vertical stacking and within manufacturer limits.

- Protect tank walls from sharp edges or abrasive materials during transit.

Handling Equipment

- Use forklifts with wide, padded forks or cranes with lifting slings rated for the tank’s weight.

- Never lift by manholes, fittings, or sidewalls unless specified by the manufacturer.

- Avoid dragging or rolling tanks on the ground.

Environmental Conditions

- Avoid transporting in extreme temperatures (below -20°C or above 50°C) to prevent material stress.

- Cover tanks during transit to avoid debris accumulation or UV exposure on prolonged trips.

Storage Requirements

Indoor Storage

- Store in a dry, ventilated area away from direct sunlight.

- Place on level, stable surfaces with support across the entire base.

- Keep away from heat sources, open flames, or incompatible chemicals.

Outdoor Storage

- Elevate tanks on a sand or gravel bed or concrete pad to prevent moisture absorption and deformation.

- Cover with UV-protective tarpaulins if stored for extended periods.

- Ensure proper drainage to avoid water pooling under the tank.

Regulatory Compliance

International Standards

- Comply with ISO 9001 (Quality Management) and ISO 14001 (Environmental Management) where applicable.

- Confirm adherence to ISO 8317 (child-resistant packaging) if relevant for chemical storage models.

Regional Regulations

- United States: Meets NSF/ANSI 61 standards for drinking water system components.

- European Union: Conforms to REACH and RoHS directives; CE marking applied where required.

- Australia/New Zealand: Complies with AS/NZS 4766 for polyethylene water tanks.

Customs & Import Documentation

- Provide Material Safety Data Sheets (MSDS) and Certificate of Conformity (CoC) for cross-border shipments.

- Include Harmonized System (HS) Code: 3926.10 (Plastic tanks and cisterns).

- Declare country of origin and material composition accurately.

Installation & Site Compliance

Foundation Requirements

- Construct foundations per engineering guidelines (e.g., compacted soil with sand layer or concrete slab).

- Ensure foundation is level within 5 mm over the tank’s footprint.

Safety Clearances

- Maintain minimum 60 cm clearance around the tank for inspection and maintenance.

- Locate away from vehicular traffic, drainage systems, or septic tanks as per local codes.

Permits & Approvals

- Verify local building, plumbing, and environmental permits prior to installation.

- Register large-capacity tanks (e.g., over 10,000L) with municipal water authorities where required.

Environmental & Safety Compliance

Spill Prevention

- Install secondary containment for chemical storage models per EPA Spill Prevention, Control, and Countermeasure (SPCC) rules.

- Equip tanks with overflow protection and secure venting.

Waste Disposal

- Dispose of damaged tanks through certified plastic recyclers. HDPE is recyclable under resin code #2.

- Do not incinerate without proper emission controls.

Documentation & Recordkeeping

Required Records

- Retain shipping manifests, inspection reports, and compliance certificates for a minimum of five years.

- Log installation dates, maintenance activities, and compliance audits.

Traceability

- Use batch numbers and QR codes (if available) to track manufacturing origin and distribution history.

Conclusion

Proper logistics and compliance management ensure the longevity, safety, and regulatory acceptance of Blue Water Tanks. Always refer to the manufacturer’s technical manual and consult local authorities for region-specific requirements.

Conclusion for Sourcing Blue Water Tank:

After a comprehensive evaluation of suppliers, product quality, cost, delivery timelines, and after-sales support, sourcing the blue water tank from the selected vendor presents a reliable and cost-effective solution for safe and durable water storage. The chosen supplier meets all technical specifications, including UV resistance, food-grade materials, and structural integrity, ensuring compliance with health and safety standards. Additionally, their proven track record, timely delivery, and competitive pricing make them a preferred partner. Moving forward, establishing a long-term procurement agreement can enhance supply chain efficiency and support scalability for future projects. Overall, the sourcing decision aligns with operational requirements and sustainability goals, ensuring a consistent and secure water storage capacity.