The global drywall market is experiencing steady expansion, driven by rising construction activities, urbanization, and demand for energy-efficient building materials. According to Grand View Research, the global drywall market size was valued at USD 35.1 billion in 2022 and is expected to grow at a compound annual growth rate (CAGR) of 5.8% from 2023 to 2030. This growth trajectory underscores the increasing reliance on high-performance wall systems, including specialized moisture- and mold-resistant solutions such as blue drywall—also known as greenboard or moisture-resistant gypsum board. Popular in high-humidity environments like bathrooms, kitchens, and basements, blue drywall offers enhanced durability without sacrificing ease of installation. As demand for resilient interior finishing materials rises across residential, commercial, and institutional sectors, manufacturers are innovating to improve moisture resistance, fire performance, and sustainability. In this evolving landscape, six key players have emerged as leaders in the production and distribution of blue drywall board, combining scale, product quality, and technological advancement to capture significant market share worldwide.

Top 6 Blue Drywall Board Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 USG

Domain Est. 1996

Website: usg.com

Key Highlights: USG Corporation remains a leading manufacturer of ceiling, wall, backerboard, underlyament, gypsum, roofing, sheathing, and industrial products….

#2 National Gypsum® Products & Brands

Domain Est. 1998

Website: nationalgypsum.com

Key Highlights: High-performance drywall, plaster and industrial products for commercial and residential use. Manufactured by Gold Bond Building Products, LLC. Visit Website….

#3 Product Catalog

Domain Est. 1995

Website: buildgp.com

Key Highlights: From gypsum panels, OSB, plywood, radiant barriers, WRB/AB to versatile Southern Yellow Pine, explore GP Building Products tailored for every project….

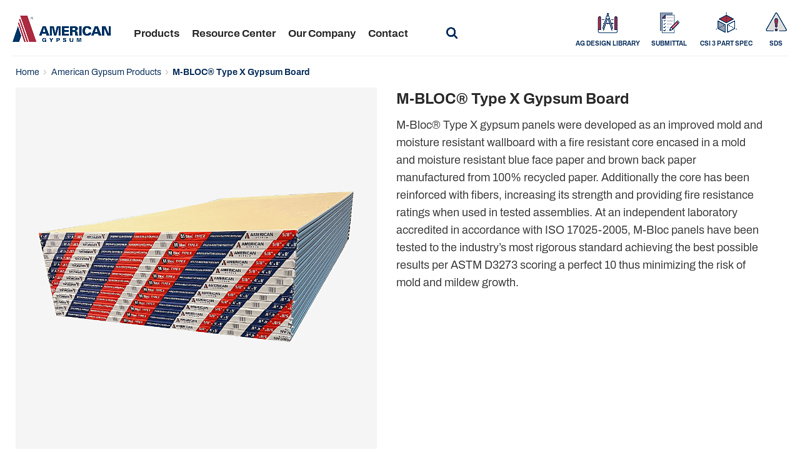

#4 M

Domain Est. 1998

Website: americangypsum.com

Key Highlights: M-Bloc® Type X gypsum panels were developed as an improved mold and moisture resistant wallboard with a fire-resistant core….

#5 Action Gypsum Supply

Domain Est. 2003

Website: actiongypsum.com

Key Highlights: Action Gypsum Supply is an independent materials supplier with more than 24 different locations throughout Texas, Arizona, and California….

#6 Gold Bond® Kal

Domain Est. 2020

Website: goldbondbuilding.com

Key Highlights: Suitable for walls and ceilings in non-fire-rated construction with framing members spaced 24” o.c.. Provides a smooth durable base for plaster….

Expert Sourcing Insights for Blue Drywall Board

H2: Projected 2026 Market Trends for Blue Drywall Board

The market for Blue Drywall Board (also known as moisture-resistant or green board) is expected to undergo significant evolution by 2026, driven by shifting construction priorities, technological advancements, and broader economic and environmental trends. Here’s an analysis of the key projected trends:

1. Sustained Demand in Key Applications, But Facing Substitution Pressure:

* Resilience in Moisture-Prone Areas: Demand will remain strong for traditional applications in bathrooms, kitchens, laundry rooms, and basements where moisture resistance is non-negotiable. Building codes will continue to mandate its use in these zones.

* Competition from Cement Board and Tile Backer Boards: The most significant trend is the increasing substitution of blue board by cementitious backer boards (like fiber cement board) and newer tile backer systems, especially for tile installations in wet areas (showers, tub surrounds). These alternatives offer superior water resistance, dimensional stability when saturated, and are often perceived as more durable and code-compliant for high-moisture applications. This trend will accelerate, particularly in high-end renovations and new construction focusing on longevity and reducing moisture-related failures (mold, rot).

* Focus Shift to Semi-Moisture Areas: Blue board’s primary market may consolidate towards areas with high humidity but not direct water exposure (e.g., behind vanities, ceilings in bathrooms, utility rooms), where its cost-effectiveness and ease of use still hold an advantage over cement board.

2. Integration with Sustainable Building Practices:

* Eco-Friendly Formulations: Manufacturers will increasingly focus on developing blue boards with reduced environmental impact. This includes:

* Recycled Content: Higher percentages of recycled gypsum and paper.

* Low-VOC Emissions: Enhanced formulations to meet stringent indoor air quality standards (e.g., UL GREENGUARD Gold, LEED).

* Sustainable Sourcing: Improved sourcing practices for raw materials.

* Lifecycle Assessment (LCA): Demand for boards with verified lower carbon footprints and better end-of-life recyclability will grow, driven by green building certifications (LEED, BREEAM) and corporate sustainability goals.

* Moisture Management = Sustainability: Proper moisture control prevents mold, structural damage, and costly repairs/replacements, aligning with the long-term sustainability and durability goals of modern construction.

3. Advancements in Product Performance and Technology:

* Enhanced Moisture Resistance: While not matching cement board, expect incremental improvements in the water-resistant core and paper facing to better withstand humidity and incidental moisture, potentially blurring the lines slightly with standard drywall but still falling short of true “wet area” performance.

* Mold and Mildew Resistance: Expect stronger claims and testing for mold and mildew resistance inhibitors within the core and facing, a key selling point for health and durability. This will be a major differentiator.

* Improved Dimensional Stability: Reducing the tendency to warp or swell slightly when exposed to high humidity will be a focus area.

* Digital Tools & BIM Integration: Wider adoption of Building Information Modeling (BIM) will require manufacturers to provide detailed digital product data (specifications, performance data, environmental impact) for seamless integration into design and construction planning.

4. Supply Chain and Economic Influences:

* Cost Volatility Management: The market will remain sensitive to fluctuations in raw material (gypsum, paper, chemicals) and energy costs. Manufacturers may focus on efficiency, regional sourcing, and long-term contracts to mitigate volatility. Consumers and contractors will remain cost-conscious.

* Supply Chain Resilience: Continued emphasis on diversified sourcing and robust distribution networks to avoid the disruptions experienced in recent years.

* Labor Availability & Productivity: Products that are easier and faster to install (e.g., optimized board sizes, improved handling characteristics, compatible joint compounds) will have a competitive advantage in a market facing skilled labor shortages.

5. Regional Variations:

* Climate-Driven Demand: Regions with high humidity (Southeast US, coastal areas globally) will see stronger sustained demand for moisture-resistant products, including blue board, compared to arid regions.

* Regulatory Differences: Building codes and green building mandates vary significantly by region/country. Markets with strict energy efficiency and moisture control codes (e.g., parts of Europe, California) will drive demand for higher-performance, sustainable solutions faster.

Conclusion:

By 2026, the Blue Drywall Board market will be characterized by consolidation in its core applications and increased competition from superior moisture barriers. While it will remain a staple for semi-moisture areas due to its cost and ease of use, its use in direct wet areas will continue to decline in favor of cementitious backer boards. Success for blue board manufacturers will hinge on enhancing performance (especially mold resistance), embracing sustainability (eco-formulations, recycled content, low carbon), and providing clear value propositions that differentiate it from both standard drywall and premium backer boards. The market will favor innovation, reliability, and alignment with the overarching trends of durability, health, and environmental responsibility in construction.

Common Pitfalls When Sourcing Blue Drywall Board (Quality, IP)

Sourcing Blue Drywall Board—often marketed for its moisture resistance and mold inhibition—can present several challenges related to quality assurance and intellectual property (IP) concerns. Being aware of these pitfalls helps ensure you receive a reliable, compliant product.

Inconsistent or Substandard Quality

One of the most prevalent issues when sourcing Blue Drywall Board is inconsistent product quality. Not all boards labeled “blue” meet the same performance standards. Some suppliers may use inferior gypsum cores, inadequate moisture-resistant paper facings, or insufficient mold-inhibiting additives. This can lead to premature deterioration in humid environments, reduced structural integrity, or failure to meet building code requirements.

Additionally, lack of standardized testing and certification can make it difficult to verify claims. Always demand third-party test reports (e.g., ASTM C1396 for gypsum board) and ensure compliance with regional building codes. Avoid suppliers who cannot provide material safety data sheets (MSDS) or performance documentation.

Misleading Branding and IP Infringement

“Blue Drywall Board” is often associated with specific branded products like USG’s Durock® Aqua Tough® or Mold Tough®, which are trademarked and protected by intellectual property rights. A common pitfall is sourcing generic boards that mimic the appearance and name of these branded products without authorization.

Suppliers may use names like “Blue Board” or “Aqua Blue” to imply equivalence, creating confusion and potentially infringing on trademarks. This not only raises legal risks but also misleads buyers about product performance. Always verify whether the product is an authorized version or a counterfeit imitation.

Lack of Technical Support and Warranty Coverage

Reputable branded Blue Drywall Boards typically come with technical backing, installation guidelines, and limited warranties. When sourcing generic or off-brand versions, these supports may be absent. In the event of product failure or moisture-related damage, lack of warranty can leave the project team financially exposed.

Ensure that the supplier provides clear installation instructions, compatibility information with other building materials, and access to technical expertise—especially critical in high-moisture applications like bathrooms or basements.

Supply Chain Transparency and Traceability Issues

Many low-cost Blue Drywall Boards originate from manufacturers with limited traceability and quality control. Without transparent supply chains, it’s difficult to verify the origin of raw materials, production practices, or environmental compliance. This opacity increases the risk of receiving subpar or non-compliant materials.

Prioritize suppliers who offer full traceability, factory audit access, and adherence to international quality standards (e.g., ISO 9001). Request batch numbers and certificates of conformance to ensure accountability.

Regulatory and Code Compliance Gaps

Depending on the region, Blue Drywall Boards may need to meet specific fire, moisture, and emission standards (e.g., LEED, California 01350, or EU CE marking). Generic or imported boards might not comply with local regulations, leading to failed inspections or costly rework.

Always confirm that the sourced product meets the required codes for the project’s jurisdiction. Do not rely solely on the supplier’s claims—verify through independent certifications or local authority approvals.

By recognizing these common pitfalls—quality inconsistencies, IP risks, lack of support, supply chain opacity, and compliance gaps—buyers can make informed decisions and mitigate risks when sourcing Blue Drywall Board.

Logistics & Compliance Guide for Blue Drywall Board

Overview

Blue Drywall Board, commonly known as moisture-resistant or mold-resistant drywall, is designed for use in high-humidity areas such as bathrooms, laundry rooms, and basements. Due to its specialized composition and applications, proper logistics handling and adherence to compliance standards are critical to maintaining product integrity and ensuring safe, code-compliant installations.

Storage and Handling

Store Blue Drywall Boards in a dry, well-ventilated area, elevated off the ground on pallets or skids to prevent moisture absorption. Cover with breathable tarps to protect from dust and precipitation while allowing airflow. Avoid direct exposure to rain, snow, or standing water. Handle boards vertically when possible and use mechanical lifting equipment (e.g., drywall lifts or forklifts) to prevent bending, cracking, or edge damage during transport and installation.

Transportation Requirements

Secure drywall stacks firmly on flatbed or enclosed trucks to prevent shifting during transit. Use edge protectors and banding to stabilize bundles. Ensure that transport vehicles are free from leaks and excess moisture. Avoid stacking other construction materials on top of drywall to prevent crushing. In humid or rainy climates, use waterproof tarps—ensuring they do not trap moisture against the boards.

Regulatory Compliance

Blue Drywall Board must meet relevant building code and safety standards, including but not limited to:

– ASTM C1396/C1396M: Standard Specification for Gypsum Board

– ICC-ES Evaluation Reports: Confirming code compliance for moisture resistance

– International Building Code (IBC) and International Residential Code (IRC): For approved use in specific moisture-prone areas

Verify that product labeling includes compliance markings and manufacturer certifications. Some jurisdictions may require third-party testing documentation for commercial projects.

Environmental and Safety Considerations

Blue Drywall may contain mold inhibitors and moisture-resistant facers (typically green or blue paper). While generally safe during handling, use PPE such as gloves, safety glasses, and dust masks when cutting or sanding to minimize exposure to gypsum dust. Dispose of waste in accordance with local environmental regulations—gypsum board should not be mixed with general landfill waste in some regions due to decomposition concerns.

Installation Compliance

Install Blue Drywall only in areas permitted by local building codes (e.g., walls in bathrooms, not ceilings unless specifically rated). Use appropriate moisture-resistant joint compounds and mold-resistant tape. Fasteners must be corrosion-resistant (e.g., coated screws). Ensure proper spacing, backing, and seam treatment per manufacturer guidelines and ASTM standards.

Documentation and Traceability

Maintain records of product batch numbers, delivery receipts, and compliance certificates. This ensures traceability in case of recalls or inspections. Contractors and builders should verify that the supplied Blue Drywall Board matches project specifications and is installed per approved plans.

Conclusion

Proper logistics and compliance practices for Blue Drywall Board help ensure structural integrity, longevity, and adherence to safety standards. Always consult manufacturer guidelines, local building codes, and project specifications to guarantee correct handling, storage, and installation.

Conclusion for Sourcing Blue Drywall Board

In conclusion, sourcing blue drywall board requires a strategic approach that balances quality, availability, cost, and project-specific requirements. Blue drywall, commonly known for its moisture-resistant properties, is ideal for high-humidity environments such as bathrooms, basements, and utility areas. When sourcing this material, it is essential to partner with reputable suppliers or manufacturers that provide certified products meeting industry standards (such as ASTM C1396).

Key considerations include verifying the board’s moisture and mold resistance, ensuring compatibility with local building codes, and evaluating lead times and logistics for timely delivery. Additionally, comparing pricing across multiple vendors and exploring bulk purchasing options can lead to significant cost savings without compromising quality.

Sustainability and environmental impact should also be factored in, favoring suppliers with eco-friendly manufacturing practices. Ultimately, successful sourcing of blue drywall board contributes to the durability, performance, and longevity of building projects, supporting both structural integrity and indoor air quality. A well-planned procurement process ensures reliability, efficiency, and value throughout the construction lifecycle.