The global blow molding market is experiencing robust growth, driven by rising demand for lightweight, cost-effective plastic packaging across industries such as automotive, consumer goods, and healthcare. According to Mordor Intelligence, the blow molding market was valued at USD 115.6 billion in 2023 and is projected to grow at a CAGR of 4.8% from 2024 to 2029. This expansion is further supported by technological advancements in multi-layer and injection blow molding processes, as well as increasing adoption of recycled materials to meet sustainability goals. As the industry scales to meet evolving production needs, manufacturers are investing heavily in automation and energy-efficient systems to maintain competitive advantage. In this dynamic landscape, a select group of blow molding companies are leading innovation, capacity, and global reach, shaping the future of plastic manufacturing. The following list highlights the top 10 blow molding manufacturers at the forefront of this growth trajectory.

Top 10 Blow Molding Companies Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 Custom

Domain Est. 1996

Website: custom-pak.com

Key Highlights: Custom-Pak is one of the world’s largest industrial blow molded parts manufacturers and a leading provider of advanced blow molding technology. Custom-Pak ……

#2 Custom Blow Molding & Contract Manufacturing

Domain Est. 1996

Website: flambeau.com

Key Highlights: Flambeau is a custom manufacturer of injection-molded and blow-molded parts, components and assemblies supplying a wide range of applications….

#3 Jomar Corporation

Domain Est. 1997

Website: jomarcorp.com

Key Highlights: Jomar is the world’s leading manufacturer of injection blow molding machinery for the pharmaceutical, health care, personal care, beauty, food, beverage and ……

#4 Blow Molded Specialties

Domain Est. 1998

Website: blowmolded.com

Key Highlights: We are a custom industrial blow molder serving customers across several industries. We specialize in the manufacturing and assembly of medium and large plastic ……

#5 Blow Molding Manufacturers

Domain Est. 2000

Website: blowmoldedplastic.com

Key Highlights: Conveniently access the leading blow molding manufacturers and suppliers in the USA, who utilize state-of-the-art equipment to produce high quality ……

#6 Flexcraft

Domain Est. 2005

Website: flexcraft.com

Key Highlights: Flexcraft specializes in custom blow molding and injection molding solutions with over 50 years of expertise. Partner with us to bring your product to life….

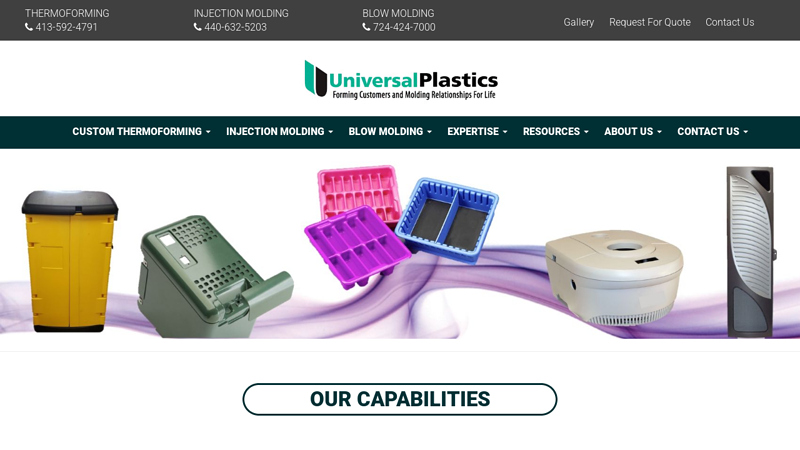

#7 Universal Plastics: Thermoforming

Domain Est. 1996

Website: universalplastics.com

Key Highlights: Universal Plastics offers many injection molding services, including structural foam and gas assist to offer the proper process, engineering support, global ……

#8 Innovative Molding Solutions –

Domain Est. 1997

Website: currierplastics.com

Key Highlights: Currier provides custom injection molding, custom blow molding, tooling, and design engineering for industries including: healthcare, packaging, and more!…

#9 N.E.W. Plastics Custom Blow Molding

Domain Est. 1999

Website: newplastics.com

Key Highlights: Custom Blow Molding Manufacturing. N.E.W. Plastics provides manufacturing solutions for companies that require high quality blow molded products and services….

#10 Plastic Blow Molding Machines

Domain Est. 2019

Website: parker-global.com

Key Highlights: As a blow molding machine supplier, Parker has over 30 years of experience and sells more than 3000 production lines in 102 nations….

Expert Sourcing Insights for Blow Molding Companies

H2: 2026 Market Trends for Blow Molding Companies

The global blow molding industry is poised for significant transformation by 2026, driven by evolving consumer demands, regulatory pressures, technological advancements, and sustainability imperatives. As a critical manufacturing process for plastic containers, packaging, and automotive components, blow molding companies must adapt to key market trends to remain competitive and capitalize on emerging opportunities.

-

Sustainability and Circular Economy Adoption

By 2026, environmental sustainability will be a dominant force shaping the blow molding sector. Governments and consumers are increasingly demanding reduced plastic waste and greater use of recycled materials. Blow molding companies are expected to invest heavily in post-consumer recycled (PCR) resins and lightweighting technologies to meet regulatory standards such as the EU’s Single-Use Plastics Directive and extended producer responsibility (EPR) laws. Closed-loop recycling systems and partnerships with waste management firms will become essential components of operational strategy. -

Growth in Lightweight and Multi-Layer Packaging

The demand for high-performance, lightweight containers—especially in food and beverage, pharmaceuticals, and personal care—will drive innovation in multi-layer blow molding. These advanced structures improve barrier properties (e.g., oxygen and moisture resistance) while using less material, aligning with both sustainability goals and cost-efficiency. Companies adopting co-extrusion and stretch blow molding technologies will gain a competitive edge. -

Expansion in Emerging Markets

Emerging economies in Asia-Pacific, Latin America, and Africa will be key growth drivers by 2026, fueled by rising middle-class populations and increasing demand for packaged goods. Blow molding companies are likely to establish regional production hubs to reduce logistics costs and comply with local content regulations. India, Vietnam, and Indonesia are expected to witness rapid capacity expansion in plastic packaging infrastructure. -

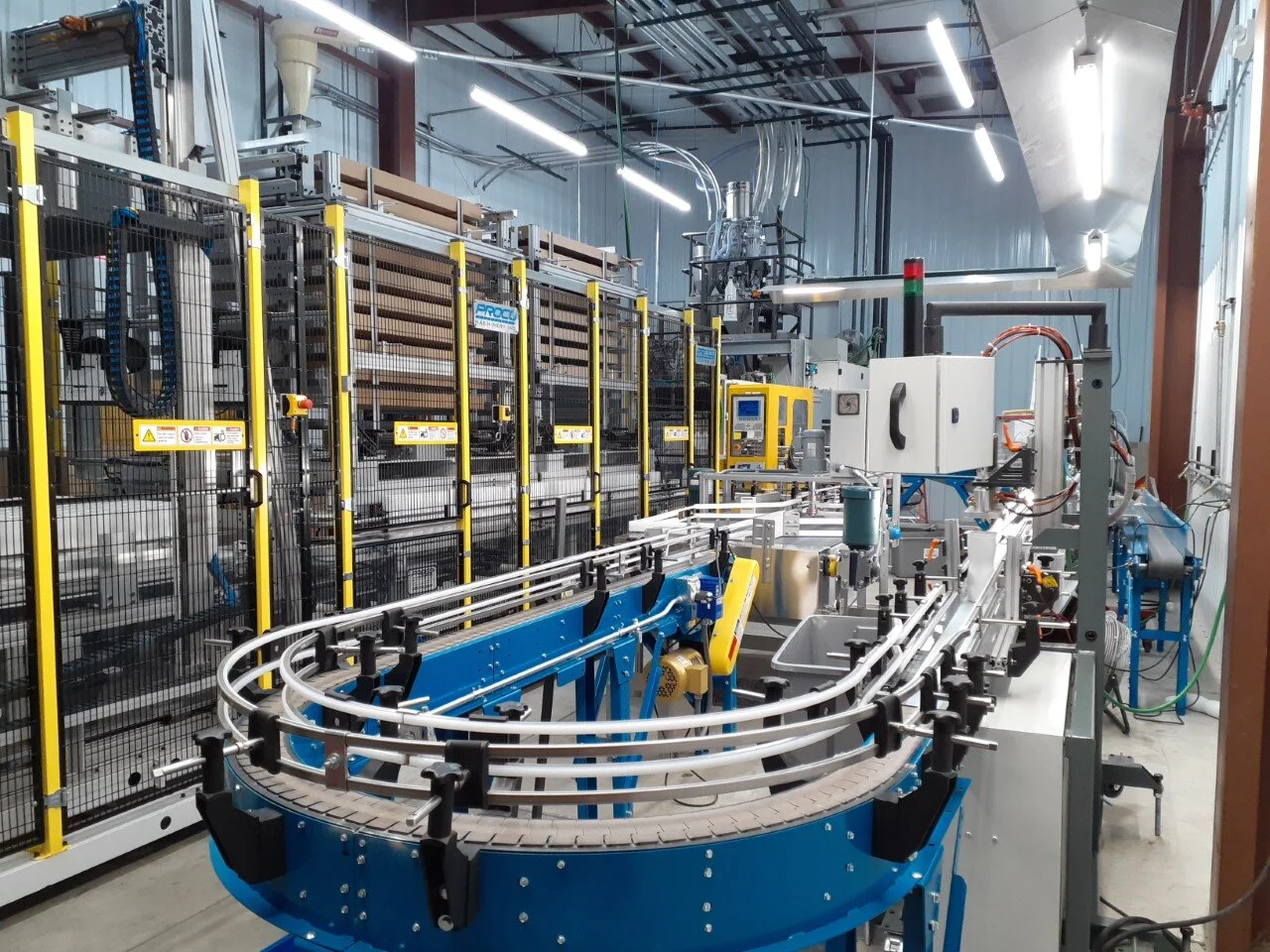

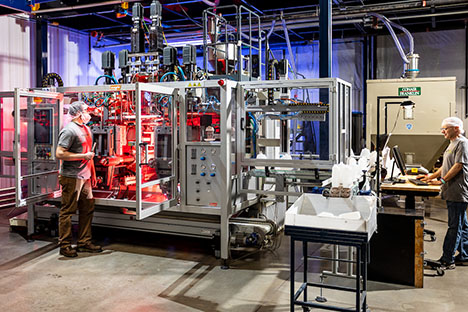

Automation and Industry 4.0 Integration

Digital transformation will accelerate in blow molding operations. By 2026, smart manufacturing technologies—including IoT-enabled machines, predictive maintenance, AI-driven process optimization, and real-time quality monitoring—are expected to become standard. These advancements will improve production efficiency, reduce downtime, and enable mass customization to meet diverse customer needs. -

Shift Toward Bio-Based and Compostable Materials

As bioplastics become more cost-competitive, blow molding companies are exploring alternatives to traditional petroleum-based resins. Polylactic acid (PLA), bio-PET, and other compostable polymers are gaining traction, particularly in short-life consumer products. While technical challenges remain—such as lower melt strength and barrier performance—R&D investments are expected to overcome these hurdles by 2026. -

Consolidation and Strategic Partnerships

Market consolidation will continue as larger players acquire niche innovators to expand capabilities in sustainable materials and advanced molding technologies. Strategic alliances between blow molders, resin suppliers, and brand owners will become more common to co-develop eco-friendly packaging solutions and secure supply chains. -

Regulatory and Compliance Pressures

Blow molding companies will face stricter global regulations on plastic usage, carbon emissions, and recyclability. The implementation of carbon taxes and plastic levies will influence production decisions and material selection. Proactive compliance and transparent reporting on environmental impact will be critical for maintaining brand reputation and customer relationships.

In summary, by 2026, blow molding companies that prioritize sustainability, embrace digitalization, innovate with materials, and expand strategically in high-growth regions will be best positioned for long-term success in an increasingly competitive and regulated market landscape.

Common Pitfalls When Sourcing Blow Molding Companies (Quality, IP)

Quality Inconsistencies and Lack of Process Control

One major pitfall when sourcing blow molding partners is encountering inconsistent product quality. Many suppliers, especially smaller or less experienced ones, may lack robust quality management systems, leading to variations in wall thickness, dimensional accuracy, or material integrity. Without standardized process controls and regular in-line inspections, defects such as weak seams, flash, or uneven surfaces can go undetected until final delivery. Buyers should verify that the supplier implements statistical process control (SPC), conducts regular mold maintenance, and adheres to ISO or other industry-specific quality standards.

Inadequate Material Verification and Traceability

Sourcing from blow molding companies that do not rigorously verify incoming resin or maintain material traceability can result in substandard end products. Some suppliers may substitute materials without notice or fail to test for compliance with food-grade, medical, or environmental regulations. This can lead to product failures, regulatory non-compliance, or customer recalls. Always confirm the supplier’s material sourcing protocols, request certificates of conformance (CoC), and ensure batch traceability throughout production.

Intellectual Property (IP) Risks and Lack of Legal Protections

Partnering with blow molding companies—especially overseas—can expose your designs and proprietary information to theft or unauthorized use. A common pitfall is failing to secure intellectual property through non-disclosure agreements (NDAs), clear ownership clauses in contracts, or registered design protections. Some suppliers may replicate molds or sell similar products to competitors if IP rights are not explicitly defined and enforced. Always conduct due diligence on the supplier’s reputation for IP protection and ensure legal agreements are in place before sharing sensitive data.

Poor Communication and Technical Misalignment

Miscommunication about design specifications, tolerances, or tooling requirements can lead to costly rework or rejected batches. Some blow molding companies may lack the engineering expertise to provide meaningful feedback during the design-for-manufacturability (DFM) stage, resulting in molds that don’t perform as expected. Establish clear communication channels, involve technical teams early, and request detailed mold flow analysis or prototype samples before full-scale production.

Hidden Costs and Tooling Ownership Issues

Suppliers may offer low per-unit pricing but retain ownership of molds or charge excessive fees for mold storage, modifications, or retrieval. This creates dependency and limits flexibility. Always clarify tooling ownership upfront and ensure it’s transferred to your company upon payment. Request a full breakdown of all costs—including setup, maintenance, and ejection fees—to avoid unexpected charges down the line.

Limited Scalability and Capacity Planning

Choosing a blow molding partner without assessing their production scalability can backfire during peak demand. Some companies may lack the capacity, backup equipment, or workforce to scale efficiently, leading to delays. Evaluate the supplier’s production capabilities, redundancy plans, and track record in meeting volume commitments before finalizing a contract.

Logistics & Compliance Guide for Blow Molding Companies

Understanding Regulatory Requirements

Blow molding companies must comply with a range of federal, state, and international regulations. Key areas include environmental compliance (e.g., EPA regulations on emissions and waste disposal), occupational safety (OSHA standards), and chemical handling (GHS labeling and SDS management). Additionally, if producing containers for food, pharmaceuticals, or medical devices, adherence to FDA, USDA, or ISO standards is mandatory. Regular audits and employee training are essential to maintain compliance.

Material Handling and Storage

Proper storage of raw materials—such as HDPE, LDPE, PP, and PET resins—is critical. Materials should be stored in a dry, temperature-controlled environment to prevent degradation. Reusable bulk totes and silos must be cleaned and maintained according to industry best practices. Implement a first-in, first-out (FIFO) inventory system to minimize material aging and ensure consistency in product quality.

Transportation and Shipping Logistics

Coordinate transportation of raw materials and finished goods with reliable carriers experienced in plastic product handling. Use protective packaging to prevent damage during transit, especially for fragile or custom-shaped containers. Optimize load configurations to reduce freight costs and carbon footprint. Maintain accurate shipping documentation, including bills of lading, packing lists, and export/import forms where applicable.

Customs and International Trade Compliance

For companies engaged in cross-border trade, understanding Harmonized System (HS) codes, country-of-origin rules, and import/export restrictions is vital. Ensure all plastic products meet destination country regulations, including packaging, labeling, and environmental directives (e.g., EU REACH, SCIP database). Utilize a licensed customs broker and maintain records for at least five years to support compliance audits.

Waste Management and Environmental Responsibility

Develop a comprehensive waste management plan addressing scrap plastic, spent molds, and process byproducts. Recycle post-industrial regrind whenever possible and partner with certified recyclers. Comply with local and federal regulations for hazardous waste disposal (e.g., used oils, cleaning solvents). Document waste streams and recycling rates to support sustainability reporting and regulatory submissions.

Quality Assurance and Traceability

Implement a robust quality management system (e.g., ISO 9001) to ensure product consistency and customer satisfaction. Maintain traceability of raw materials, production batches, and finished goods using lot numbering and digital tracking systems. Conduct regular in-process and final inspections to detect defects early and reduce returns or recalls.

Supplier and Customer Compliance

Verify that suppliers meet required certifications (e.g., ISO, FDA, SQF) and conduct periodic evaluations. Clearly communicate compliance expectations in contracts and purchase orders. For customers, provide necessary compliance documentation such as certificates of conformance (C of C), material safety data sheets (MSDS/SDS), and test reports upon request.

Emergency Preparedness and Incident Response

Develop and maintain an emergency response plan addressing chemical spills, fire hazards, equipment failure, and natural disasters. Train employees on spill containment, evacuation procedures, and reporting protocols. Keep spill kits, fire extinguishers, and personal protective equipment (PPE) readily available and inspected regularly.

Recordkeeping and Documentation

Maintain detailed records of compliance activities, including training logs, inspection reports, waste manifests, shipping documents, and audit results. Digitize records where possible to improve accessibility and reduce storage costs. Ensure data security and compliance with data retention regulations.

Continuous Improvement and Compliance Audits

Conduct regular internal audits to identify gaps in logistics and compliance processes. Use findings to update policies, enhance training programs, and invest in technology (e.g., ERP or compliance management software). Stay informed about changing regulations through industry associations and government alerts to ensure ongoing adherence.

Conclusion:

Sourcing blow molding companies requires a strategic and thorough approach to ensure quality, cost-efficiency, and reliability. After evaluating various suppliers based on factors such as manufacturing capabilities, material expertise, quality certifications, production capacity, lead times, and geographic location, it becomes evident that selecting the right partner is crucial for product success and supply chain efficiency.

Key considerations—such as the company’s experience in your specific industry (e.g., automotive, consumer goods, or medical), their ability to scale production, technological investment (e.g., advanced blow molding techniques like multi-layer or rotational molding), and track record for on-time delivery—should guide the final decision.

Ultimately, establishing a strong partnership with a reputable blow molding manufacturer not only ensures consistent product quality but also supports innovation, cost optimization, and long-term business growth. Conducting due diligence, requesting samples, and maintaining open communication throughout the sourcing process will significantly enhance the likelihood of a successful collaboration.