The global demand for blocking diodes has seen steady growth, driven by expanding applications in solar power systems, automotive electronics, and industrial power supplies. According to a 2023 report by Mordor Intelligence, the global diode market is projected to grow at a CAGR of over 6.8% from 2023 to 2028, with increasing adoption of renewable energy systems serving as a key growth catalyst. Blocking diodes, specifically, are witnessing heightened demand due to their critical role in preventing reverse current flow in photovoltaic installations — a segment expected to dominate diode consumption in the coming decade. Grand View Research further supports this trajectory, noting in its 2022 analysis that the power diode market alone was valued at USD 4.7 billion and is anticipated to expand at a CAGR of 6.2% through 2030, driven by advancements in energy-efficient power management across sectors. As demand escalates, a select group of manufacturers have emerged as industry leaders, combining innovation, scale, and reliability to serve a rapidly evolving electronics landscape. Here are the top 9 blocking diode manufacturers shaping the future of power electronics.

Top 9 Blocking Diode Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

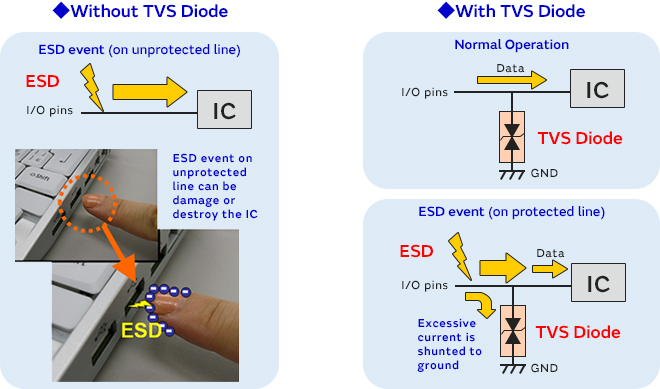

#1 TVS Diodes (ESD Protection Devices)

Domain Est. 1994

Website: murata.com

Key Highlights: TVS diodes (ESD protection devices) are used to prevent electronic equipment from breakdown or malfunctioning due to ESD. Here, we introduce product lineups ……

#2 Diodes Incorporated

Domain Est. 1995

Website: diodes.com

Key Highlights: Diodes Incorporated is a leading global manufacturer and supplier of high-quality application specific standard products….

#3 Vishay Intertechnology

Domain Est. 1995

Website: vishay.com

Key Highlights: Vishay electronic component solutions – MOSFETs, ICs, Diodes & Rectifiers, Optoelectronics, Resistors, Sensors, Inductors, Custom Magnetics, and Capacitors….

#4 Integrated Blocking Diode – Hardware Option

Domain Est. 1998

Website: magna-power.com

Key Highlights: The Integrated Blocking Diode Option (+BD) provides an internally heat-sunk protection diode on the positive output terminal of a MagnaDC programmable DC power ……

#5 Rectifier diodes

Domain Est. 1999

Website: infineon.com

Key Highlights: We offer rectifier diodes in disc housings with a blocking voltage range of 400 V to 9000 V and average currents from 120 A up to 8400 A….

#6 MCC Diodes

Domain Est. 2000

Website: mccsemi.com

Key Highlights: Our portfolio contains five core discrete semiconductor types—offering a full range of diodes, rectifiers, transistors, MOSFETs, voltage regulators and ……

#7 Blocking Diode for Industries for Sale

Domain Est. 2020

Website: secompower.com

Key Highlights: SECOM has a wide range of blocking diodes for photovoltaic systems, which maximise solar energy plant performance, preventing the return current issue….

#8 High Voltage Resistance Blocking Diode DKA40BA300

Website: sansha.co.jp

Key Highlights: We have developed a low loss backflow prevention diode module with an ultra-high breakdown voltage of 3000V for DC 1500V strings….

#9 Blocking diodes

Website: bz-elektronik.ch

Key Highlights: Our space saving blocking diodes (T-rail-versions) in an overview. The devices are only 22.5mm wide and mountable on a common T-rail….

Expert Sourcing Insights for Blocking Diode

H2: 2026 Market Trends for Blocking Diodes

The global blocking diode market is poised for steady growth through 2026, driven by rising demand in renewable energy systems, electric vehicles (EVs), and industrial electronics. As a critical component in power management circuits, blocking diodes prevent reverse current flow, ensuring system efficiency and reliability—particularly in solar photovoltaic (PV) installations and battery-powered applications.

Key trends shaping the blocking diode market in 2026 include:

-

Expansion of Solar Energy Infrastructure: The continued global push toward decarbonization is accelerating solar PV deployment. Blocking diodes are essential in solar panel arrays to mitigate power losses caused by shading or panel failure. With countries enhancing renewable energy targets under climate initiatives, demand for high-efficiency blocking diodes—especially Schottky and ultra-fast recovery types—is expected to rise significantly.

-

Integration in Electric Vehicles and Charging Systems: The EV market’s rapid expansion is increasing the need for reliable power components. Blocking diodes are used in onboard chargers, DC-DC converters, and battery management systems (BMS) to prevent backflow and protect sensitive electronics. As EV adoption grows, particularly in North America, Europe, and Asia-Pacific, demand for compact, thermally efficient diodes will increase.

-

Advancements in Semiconductor Materials: There is a growing shift from traditional silicon-based diodes to wide-bandgap semiconductors such as silicon carbide (SiC) and gallium nitride (GaN). These materials offer lower forward voltage drop, faster switching speeds, and improved thermal performance, making them ideal for next-generation blocking diodes. By 2026, SiC diodes are expected to gain significant market share in high-power applications due to their efficiency and reliability.

-

Miniaturization and High-Power Density Designs: As electronic systems become more compact and power-dense, blocking diodes are being engineered for smaller footprints without compromising performance. Surface-mount technology (SMT) diodes are gaining preference in consumer electronics and telecom infrastructure, driving innovation in packaging and thermal management.

-

Supply Chain Resilience and Regional Manufacturing: Post-pandemic supply chain disruptions have prompted companies to localize production. In 2026, we expect increased investment in semiconductor fabrication in North America and Europe, reducing dependency on Asian suppliers. This shift could impact pricing and availability but enhance supply stability.

-

Stringent Efficiency Standards and Regulations: Governments and regulatory bodies are enforcing stricter energy efficiency standards for power electronics. This is pushing manufacturers to adopt higher-performance blocking diodes that reduce energy losses. Compliance with standards such as Energy Star and EU Ecodesign is influencing product development and market positioning.

In summary, the 2026 blocking diode market will be characterized by technological innovation, strong renewable energy tailwinds, and expanding applications in electrified transportation. Companies that invest in advanced materials, scalable manufacturing, and application-specific designs are likely to gain a competitive edge in this evolving landscape.

Common Pitfalls When Sourcing Blocking Diodes (Quality, IP)

When selecting and sourcing blocking diodes for power systems—especially in solar, battery, and DC power applications—engineers and procurement teams often encounter several critical pitfalls. Overlooking these can compromise system reliability, efficiency, and long-term performance. Below are key issues related to quality and intellectual property (IP) that must be addressed.

Poor Quality Components and Counterfeit Parts

One of the most significant risks in sourcing blocking diodes is receiving substandard or counterfeit components. Low-cost suppliers, particularly from unverified sources, may offer diodes that fail to meet datasheet specifications. These can include:

- Lower current and voltage ratings than advertised, leading to premature failure under load.

- Inconsistent thermal performance, causing overheating and potential thermal runaway.

- Poor packaging and material quality, increasing susceptibility to environmental stress.

Counterfeit diodes may be reclaimed, remarked, or made from inferior materials, posing serious reliability and safety risks. Always source from authorized distributors or reputable manufacturers and verify lot traceability.

Inadequate IP Protection and Design Infringement

Using blocking diodes without proper attention to intellectual property (IP) considerations can expose companies to legal risks, especially in competitive or regulated markets. Pitfalls include:

- Unlicensed use of patented circuit designs where the blocking diode is part of an integrated patented power management solution.

- Reverse-engineered components that mimic protected designs, potentially infringing on patents related to efficiency, thermal management, or integration.

- Design copying in custom modules, where third-party diode integration may inadvertently violate existing IP.

To mitigate IP risks, conduct thorough due diligence on both the diode components and the broader circuit architecture. Consult legal counsel when integrating diodes into proprietary systems, and ensure suppliers provide freedom-to-operate assurances.

Lack of Compliance and Certification

Many applications—particularly in automotive, industrial, and renewable energy—require components to meet specific standards (e.g., AEC-Q101, ISO/TS 16949, UL). Sourcing diodes without proper certifications can lead to:

- System-level compliance failure, delaying product certification.

- Voided warranties or liability issues in case of field failures.

Ensure that the blocking diodes are certified for the target application and that documentation (test reports, reliability data) is provided by the supplier.

Insufficient Supplier Qualification

Relying on suppliers without a proven track record in power electronics can result in inconsistent quality and poor technical support. Key red flags include:

- No documented quality management system (e.g., ISO 9001).

- Limited or no field failure data.

- Inadequate responsiveness to technical queries or failure analysis requests.

Always audit or pre-qualify suppliers, especially for high-reliability applications.

Conclusion

To avoid these pitfalls, prioritize sourcing blocking diodes from reputable, authorized suppliers, verify both component quality and IP compliance, and ensure alignment with industry standards. Proactive due diligence safeguards system performance and reduces legal and operational risks.

Logistics & Compliance Guide for Blocking Diodes

Overview

Blocking diodes are essential components in electrical systems, particularly in photovoltaic (PV) and battery applications, where they prevent reverse current flow and protect equipment. Due to their use in energy systems and electronic circuits, shipping and handling these components involve specific logistics considerations and regulatory compliance requirements. This guide outlines key procedures and standards relevant to the international and domestic movement of blocking diodes.

Classification and Harmonized System (HS) Code

Blocking diodes are typically classified under the Harmonized System (HS) for international trade. The most common HS code is:

– 8541.10 – Diodes, other than photosensitive or light-emitting diodes (LEDs).

Note: If the blocking diode is part of a solar charge controller or integrated module, classification may vary. Confirm based on product specifications and country-specific tariff schedules.

Export Controls and Regulatory Compliance

- Dual-Use Items: Most standard blocking diodes are not subject to export controls under regimes like the Wassenaar Arrangement or EU Dual-Use Regulation. However, if the diodes are designed for military, aerospace, or high-reliability applications (e.g., space-grade components), review ITAR (U.S.) or similar national regulations.

- EAR (Export Administration Regulations): Generally, commercial-grade blocking diodes fall under ECCN 3A999 (items not specifically listed) and may be eligible for export under License Exception NLR (No License Required) for most destinations.

- REACH & RoHS Compliance: Blocking diodes intended for the EU market must comply with:

- RoHS Directive (2011/65/EU): Restricts hazardous substances such as lead, cadmium, and mercury.

- REACH (EC 1907/2006): Requires declaration of Substances of Very High Concern (SVHC).

- Conflict Minerals: If supplying to U.S. or EU markets, ensure supply chain due diligence under the Dodd-Frank Act (Section 1502) or EU Conflict Minerals Regulation (Regulation (EU) 2017/821).

Packaging and Handling

- ESD Protection: Blocking diodes are sensitive electronic components. Use anti-static packaging (e.g., conductive foam, static-shielding bags) to prevent electrostatic discharge damage.

- Moisture Sensitivity: If the diodes are classified as Moisture Sensitivity Level (MSL) 3 or higher, use moisture-barrier bags with desiccant and humidity indicator cards. Label with MSL level and floor life.

- Packaging Standards: Follow ISTA 3A or similar standards for unitized loads to ensure integrity during transit. Secure components to prevent movement.

Shipping and Transportation

- Mode of Transport: Suitable for air, sea, or ground freight. Air freight is preferred for high-value or time-sensitive shipments.

- Labeling Requirements:

- Product name and part number

- Quantity and weight

- ESD-sensitive label

- Manufacturer and country of origin

- RoHS and REACH compliance marks (as applicable)

- Battery-Related Shipments: If blocking diodes are shipped with batteries or within solar kits, comply with IATA DGR (air) or IMDG Code (sea) for any associated lithium batteries.

Import Requirements by Region

- United States: No special import license required for standard diodes. Ensure correct HS code declaration and provide a commercial invoice, packing list, and bill of lading/air waybill.

- European Union: Validate CE marking (if applicable), and ensure RoHS and REACH compliance documentation is available upon request.

- China: Requires CCC certification only if the diode is part of a regulated end-product. Standalone components typically do not require CCC.

- Canada: Subject to CBSA import requirements; use HS code 8541.10. No additional certification unless part of a regulated system.

Documentation Checklist

Ensure the following documents accompany shipments:

– Commercial Invoice (with detailed description, value, and HS code)

– Packing List

– Certificate of Origin (preferably Form A for preferential tariffs)

– RoHS and REACH Compliance Declaration

– ESD Handling Instructions (internal use)

– SDS (Safety Data Sheet) – if requested (generally not required for passive components)

Best Practices

- Supplier Qualification: Source from manufacturers with certified quality systems (ISO 9001, IATF 16949 if automotive-grade).

- Traceability: Maintain lot/batch traceability for quality and compliance audits.

- Customs Broker Coordination: Engage a licensed customs broker familiar with electronics components to ensure smooth clearance.

- Updates: Regularly monitor changes in trade regulations, especially in response to geopolitical factors or environmental legislation.

Conclusion

Proper logistics and compliance management for blocking diodes ensures timely delivery, avoids customs delays, and maintains market access. By adhering to classification standards, packaging best practices, and regional regulatory requirements, businesses can mitigate risks and support reliable supply chain operations.

Conclusion for Sourcing a Blocking Diode:

After evaluating the technical requirements, application environment, and supplier options, sourcing a suitable blocking diode involves balancing performance, reliability, cost, and availability. It is essential to select a diode with appropriate voltage and current ratings, low forward voltage drop, fast switching capability (if applicable), and adequate thermal performance to ensure efficient operation and longevity in the target system—particularly in solar, power supply, or battery applications where reverse current prevention is critical.

Priority should be given to reputable manufacturers offering certified components with traceable quality standards. Additionally, considerations such as lead time, packaging type, and long-term supply chain stability are crucial for both prototyping and volume production. By carefully aligning the diode specifications with system needs and ensuring supply chain resilience, the sourced blocking diode will effectively enhance system efficiency and reliability while minimizing risks of failure or downtime.