The global blister packaging market is experiencing robust growth, driven by increasing demand across pharmaceuticals, consumer goods, and healthcare sectors. According to Grand View Research, the global blister packaging market size was valued at USD 16.8 billion in 2022 and is projected to expand at a compound annual growth rate (CAGR) of 5.2% from 2023 to 2030. This growth is fueled by the rising need for tamper-evident, shelf-stable, and patient-friendly packaging solutions—particularly in the pharmaceutical industry, where product integrity and compliance are critical. Additionally, advancements in thermoforming technologies and the shift toward sustainable materials are reshaping manufacturing standards. As demand surges, a select group of manufacturers have emerged as leaders, combining innovation, scalability, and regulatory compliance to serve global markets. Based on production capacity, geographic reach, technological investment, and market presence, the following nine companies represent the top performers in the blisterpack manufacturing industry today.

Top 9 Blisterpack Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 Blister Pack Manufacturers: Your Custom Packaging Options

Domain Est. 1996

Website: indepak.com

Key Highlights: As blister pack manufacturers, we’ve created these packages for products such as school supplies, tools, office supplies, personal care items, pharmaceutical ……

#2 Blister Packaging – VisiPak

Domain Est. 2000

Website: visipak.com

Key Highlights: As one of the leading manufacturers of blister packaging in the United States, VisiPak works with companies of all sizes to develop a wide variety of blister ……

#3 Leading Blister Pack Manufacturers

Domain Est. 2000

Website: vacuumformedplastics.com

Key Highlights: Research Manufacturers: Use our comprehensive directory of blister pack manufacturers to compare companies based on their experience, industry certifications ( ……

#4 Blister Packaging

Domain Est. 2005

Website: mplusa.com

Key Highlights: MPL is a contract manufacturer and packager offering custom blister packaging for human/veterinary pharmaceuticals, nutritional supplements and natural health ……

#5 Medication Blister Pack Manufacturer & Supplier

Domain Est. 2009

Website: pharmapackagingsolutions.com

Key Highlights: Tjoapack US is a US based blister packaging supplier and manufacturer serving clients from design to delivery….

#6 Blister Packaging Manufacturers

Domain Est. 2024

Website: blister-pack.com

Key Highlights: We are blister packaging manufacturer offering custom design, bulk production, and wholesale supply. High-quality blister packs for ……

#7 Blister Pack Manufacturing for Pharmaceuticals

Domain Est. 1997

Website: cattycorp.com

Key Highlights: We first produced blister pack material for the Pharmaceutical industry in the 1980’s, since expanding our line to serve additional markets beyond pharma….

#8 Blister Packaging

Domain Est. 2013

Website: pharmatechlabs.com

Key Highlights: Our professional blister packaging is a sealed and individualized way to deliver encapsulated formulas for consumption….

#9 Top 10 Blister Pack Manufacturers for Quality Packaging

Domain Est. 2018

Website: sedpharma.com

Key Highlights: Blister packaging machines are useful in industries that require high security, attractive packaging, and visibility such as tablets, capsules, toothbrushes, ……

Expert Sourcing Insights for Blisterpack

H2: Market Trends for Blister Packaging in 2026

As we approach 2026, the blister packaging market is undergoing significant transformation driven by evolving consumer demands, regulatory pressures, technological advancements, and sustainability imperatives. This analysis explores key trends shaping the blisterpack industry during the second half of 2026 (H2), highlighting growth drivers, challenges, and strategic opportunities.

1. Sustainability and Eco-Friendly Materials Drive Innovation

Environmental concerns continue to be a major catalyst for change. By H2 2026, blister packaging manufacturers are increasingly adopting recyclable, biodegradable, and compostable materials such as paper-based blisters, mono-material thermoforms, and bio-PVC alternatives. Regulatory frameworks in the EU and North America—such as the Single-Use Plastics Directive and extended producer responsibility (EPR) schemes—are pushing companies to redesign packaging with end-of-life considerations. Leading pharmaceutical and consumer goods brands are partnering with packaging suppliers to launch fully recyclable blister solutions, setting new industry benchmarks.

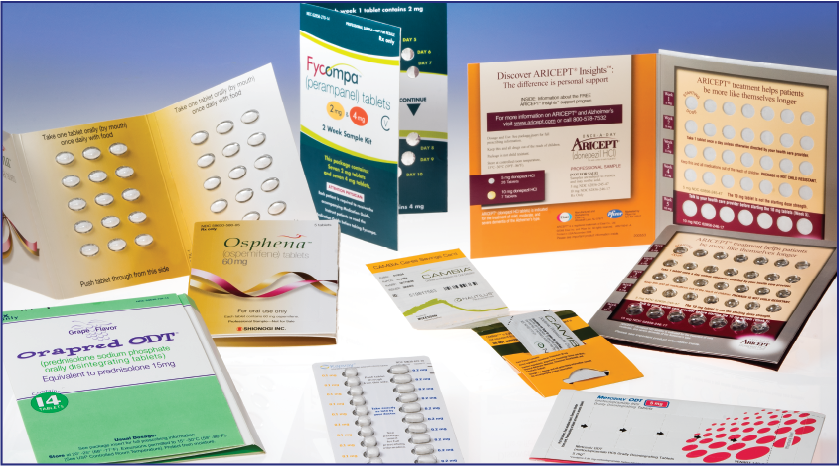

2. Growth in Pharmaceutical and Healthcare Applications

The pharmaceutical sector remains the dominant end-user of blister packaging, and demand is rising due to the global emphasis on medication safety, compliance, and tamper evidence. In H2 2026, smart blister packs embedded with NFC tags or QR codes are gaining traction, enabling dose tracking, anti-counterfeiting measures, and patient engagement via mobile apps. These innovations are particularly valuable in chronic disease management and adherence programs, supported by digital health initiatives and telemedicine expansion.

3. Automation and Digitalization in Manufacturing

Blisterpack production is becoming increasingly automated and data-driven. In H2 2026, manufacturers are leveraging Industry 4.0 technologies such as AI-powered quality control, real-time monitoring, and predictive maintenance to improve efficiency and reduce waste. Digital twin simulations allow for faster prototyping and customization, catering to the growing demand for small-batch, personalized packaging in niche markets like nutraceuticals and cosmetics.

4. Regional Market Diversification

While North America and Europe remain strong markets due to stringent regulations and high healthcare spending, Asia-Pacific is emerging as the fastest-growing region. Countries like India, China, and Vietnam are witnessing increased adoption of blister packaging in pharmaceuticals and FMCG sectors, driven by rising disposable incomes, urbanization, and modern retail expansion. Local manufacturers are investing in sustainable production capabilities to meet both domestic and export demand.

5. Lightweighting and Design Optimization

To reduce material usage and transportation costs, companies are focusing on lightweight blister designs without compromising protection or shelf appeal. Advanced thermoforming techniques and thinner gauge materials are being optimized to maintain structural integrity while minimizing environmental impact. This trend aligns with corporate sustainability goals and circular economy principles gaining momentum in H2 2026.

6. Challenges: Cost Pressures and Supply Chain Resilience

Despite innovation, the industry faces challenges. Volatility in raw material prices—especially for resins and aluminum—continues to pressure margins. Additionally, supply chain disruptions caused by geopolitical tensions and climate-related events emphasize the need for localized production and diversified sourcing strategies. Companies are investing in regional manufacturing hubs to enhance resilience and reduce lead times.

Conclusion

In H2 2026, the blister packaging market is characterized by a strong push toward sustainability, digital integration, and functional innovation. Success will depend on the ability of manufacturers to balance regulatory compliance, environmental responsibility, and cost-efficiency while meeting the evolving needs of healthcare and consumer markets. Companies that invest in green materials, smart packaging, and agile production systems are best positioned to lead in this dynamic landscape.

Common Pitfalls Sourcing Blisterpacks: Quality and Intellectual Property (IP) Concerns

Sourcing blisterpacks, especially from overseas suppliers, can introduce significant risks related to both quality consistency and intellectual property protection. Failing to address these pitfalls can lead to product recalls, legal disputes, reputational damage, and lost revenue.

Quality Control Challenges

Blisterpacks serve as both protective packaging and a critical component of product presentation and consumer safety. Poor quality can compromise both.

- Inconsistent Material Quality: Suppliers may use substandard plastic (e.g., incorrect thickness, poor clarity, or non-compliant resins), leading to brittleness, cracking, or failure during shipping and handling.

- Sealing Defects: Inadequate heat sealing can result in leaks, compromised sterility (for medical devices or pharmaceuticals), or premature product exposure, reducing shelf life.

- Dimensional Inaccuracies: Poor mold tolerances can cause misalignment with automated packaging lines or improper fit with the product, increasing waste and downtime.

- Lack of Regulatory Compliance: Blisterpacks for regulated industries (e.g., pharmaceuticals, medical devices) must meet standards such as ISO 11607 or FDA requirements. Sourcing from non-compliant suppliers risks regulatory rejection.

- Poor Print and Graphics Quality: Misregistration, fading, or low-resolution printing can damage brand image and fail to meet labeling requirements.

Intellectual Property (IP) Risks

Blisterpack designs—especially custom molds and unique packaging formats—represent valuable intellectual property that can be easily misappropriated when sourcing from third parties.

- Unauthorized Mold Replication: Suppliers may duplicate molds and sell identical or similar blisterpacks to your competitors, eroding your market advantage.

- Lack of IP Ownership Clauses: Contracts that fail to explicitly assign IP rights to the buyer leave the design ownership ambiguous, potentially allowing the supplier to claim rights.

- Reverse Engineering by Suppliers: Even with a trusted supplier, there’s a risk they or their subcontractors could analyze your product and packaging to develop competing offerings.

- Weak Legal Jurisdiction Enforcement: In some countries, IP laws are difficult to enforce, making it challenging to pursue legal action against infringement even with proper documentation.

- Design Leakage via Subcontractors: If the supplier outsources mold-making or production, your design could be exposed to additional third parties without adequate confidentiality safeguards.

Mitigation Strategies

To avoid these pitfalls, businesses should:

– Conduct thorough supplier audits and request material certifications.

– Implement clear, legally binding contracts that assign IP ownership and include non-compete and confidentiality clauses.

– Require samples and perform rigorous quality testing before full-scale production.

– Register designs and packaging trademarks where applicable.

– Use secure communication channels and limit design data access to essential personnel only.

Proactively addressing quality and IP concerns during the sourcing process is essential to protect your product, brand, and competitive position.

Logistics & Compliance Guide for Blisterpack

Blisterpacks—commonly used for pharmaceuticals, consumer goods, and electronics—require careful handling throughout the supply chain to ensure product integrity, regulatory compliance, and efficient logistics. This guide outlines key considerations for the transportation, storage, and regulatory adherence of blisterpack products.

Packaging and Product Protection

Blisterpacks are designed to protect individual items from moisture, contamination, and physical damage. Ensure that blisterpacks are:

- Sealed properly with tamper-evident features where required.

- Constructed from materials compatible with the product (e.g., PVC, PVDC, or eco-friendly alternatives).

- Packaged in secondary containers (e.g., cartons or trays) to prevent crushing during transit.

- Labeled clearly with batch numbers, expiry dates, and handling symbols (e.g., “Do Not Stack,” “Protect from Moisture”).

Storage Conditions

Maintain appropriate storage environments based on product sensitivity:

- Temperature: Store in a climate-controlled area if the product is temperature-sensitive (e.g., pharmaceuticals between 15–25°C).

- Humidity: Keep relative humidity below 60% to prevent moisture ingress, especially critical for hygroscopic products.

- Light Exposure: Protect from direct sunlight and UV radiation to avoid degradation of light-sensitive contents.

- Shelving: Store on clean, dry pallets or shelves; avoid floor contact to reduce contamination risk.

Transportation and Handling

Adhere to best practices during shipping:

- Use pallets with secure strapping or stretch wrapping to prevent shifting.

- Stack cartons according to manufacturer guidelines—do not exceed recommended load limits.

- Label shipments with appropriate hazard or handling labels (e.g., “Fragile,” “This Side Up”) when applicable.

- Monitor cold chain compliance if transporting temperature-sensitive blisterpacks (e.g., vaccines or biologics).

- Utilize track-and-trace systems for high-value or regulated products.

Regulatory Compliance

Blisterpacks, especially in regulated industries, must meet strict compliance standards:

Pharmaceuticals & Medical Devices

- Comply with Good Manufacturing Practice (GMP) and Good Distribution Practice (GDP) per FDA (21 CFR Part 211), EMA, or other regional authorities.

- Ensure packaging materials are approved under Drug Master Files (DMFs) or equivalent.

- Include necessary labeling such as lot numbers, expiration dates, and regulatory symbols (e.g., CE mark, Rx symbol).

Environmental Regulations

- Follow regional directives on packaging waste, such as the EU Packaging and Packaging Waste Directive (94/62/EC).

- Use recyclable or biodegradable blister materials where possible to meet sustainability goals.

- Comply with REACH and RoHS regulations for restricted substances in plastics.

Import/Export Requirements

- Provide accurate HS codes for blisterpack shipments (e.g., 3004.90 for pharmaceutical blister packs).

- Include necessary documentation: commercial invoice, packing list, certificate of conformity, and regulatory permits.

- Adhere to import regulations in destination countries (e.g., FDA Prior Notice for U.S. imports).

Quality Assurance & Traceability

- Implement batch traceability systems (e.g., barcode or RFID) to support recalls and audits.

- Conduct regular audits of packaging lines and logistics partners.

- Maintain records of storage conditions, shipping logs, and compliance certifications for at least the required retention period (e.g., 5 years for pharmaceuticals).

Conclusion

Effective logistics and compliance for blisterpacks require a holistic approach that balances protection, regulatory standards, and sustainability. By following this guide, companies can ensure product safety, minimize risks, and maintain compliance across global supply chains.

Conclusion for Sourcing Blister Packaging:

Sourcing blister packaging requires a strategic approach that balances cost, quality, functionality, and sustainability. By carefully evaluating suppliers based on material quality, production capabilities, regulatory compliance, and environmental practices, businesses can ensure reliable packaging that protects products, enhances shelf appeal, and meets consumer and regulatory expectations. It is essential to consider factors such as material selection (e.g., PVC, PET, eco-friendly alternatives), tooling and molding requirements, order volume, and lead times. Additionally, building strong relationships with experienced and responsive suppliers supports long-term efficiency and agility in the supply chain. Ultimately, effective blister pack sourcing contributes to product integrity, brand reputation, and operational success in competitive markets.