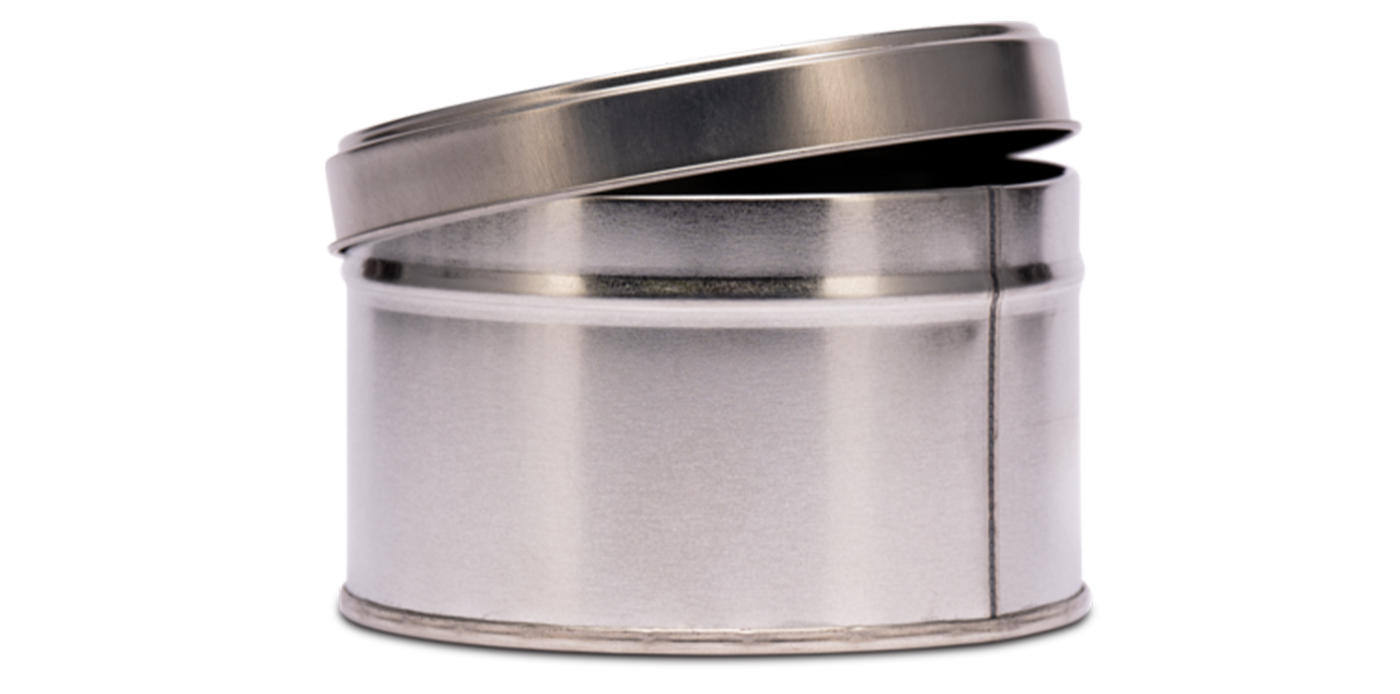

The global market for metal packaging, including blank tin cans, has seen steady expansion driven by rising demand across food & beverage, paint, and chemical industries. According to Grand View Research, the global metal packaging market was valued at USD 136.5 billion in 2023 and is projected to grow at a compound annual growth rate (CAGR) of 4.3% from 2024 to 2030. This growth is fueled by the sustainability advantage of tin-plated steel—its recyclability, durability, and excellent barrier properties—making it a preferred choice for product preservation. Mordor Intelligence further highlights that increasing consumer preference for packaged food and beverages, especially in emerging economies, is accelerating the need for high-quality, customizable blank tin cans. As demand rises, manufacturers are investing in advanced coating technologies and scalable production to meet evolving industry standards. In this competitive landscape, identifying the top 10 blank tin can manufacturers becomes crucial for brands seeking reliable, efficient, and eco-conscious packaging solutions.

Top 10 Blank Tin Cans Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 Tin Box Manufacturer, Buy Custom Tins Wholesale, Decorative tin …

Domain Est. 2003

Website: tinpak.com

Key Highlights: We are ISO 22000 Certified Tin Factory. Deals with decorative & custom Tin Boxes, We are the Manufacturer& Wholesaler for Tins & Containers….

#2 Allstate Can Corporation

Domain Est. 1998

Website: allstatecan.com

Key Highlights: Leading U.S. manufacturer of metal packaging for toiletries, food, home & leisure. Custom and stock tins including seamless tins, coffee cans, cookie tins….

#3 Tin Containers

Domain Est. 2017

Website: ucan-packaging.com

Key Highlights: uCan-Packaging offers a wide selection of empty tin containers for sale. All metal tins are produced in China by carefully selected manufacturers….

#4 Beverage Cans

Domain Est. 1991

Website: ball.com

Key Highlights: Whether it’s beer, water, or soda, Ball cans offer visually appealing, crowd-pleasing packaging in various styles and sizes….

#5 Metal Food Cans

Domain Est. 1995

Website: sonoco.com

Key Highlights: Sonoco manufactures two-piece and three-piece steel food cans and components across our 12 world-class manufacturing facilities in the United States….

#6 Metal Tin Cans and Containers

Domain Est. 1998

Website: specialtybottle.com

Key Highlights: $12.68 delivery · 30-day returnsShop our silver and gold Metal Tin Containers ideal for tea, candles, cosmetics, candies, and other dry products—available for wholesale and bulk o…

#7 Metal Cans

Domain Est. 2000

Website: silgancontainers.com

Key Highlights: Silgan metal cans include 3-Piece Welded Cans, 2-Piece Draw Redraw (DRD) Steel and Aluminum Cans, 2-Piece Draw and Ironed (D&I) Steel, and Hybrid Packages….

#8 CanSource

Domain Est. 2003

Website: cansource.com

Key Highlights: Your one-stop shop for aluminum cans and packaging supplies. Unbeatable turnaround times on brites, sleeved, and printed cans! Order now….

#9 Tin plate Products

Domain Est. 2006

Website: northamerica.arcelormittal.com

Key Highlights: We provide products for the full range of 3-piece welded can applications and 2-piece cans including drawn and ironed and draw-redraw….

#10 Cans

Domain Est. 2018

Website: mauserpackaging.com

Key Highlights: Mauser has produced high-quality cans for over 145 years and is trusted by some of the largest brands and household-names….

Expert Sourcing Insights for Blank Tin Cans

H2: 2026 Market Trends for Blank Tin Cans

The global market for blank tin cans is poised for steady growth and transformation by 2026, driven by evolving consumer preferences, sustainability mandates, and advancements in manufacturing technologies. As a critical component in food and beverage packaging, industrial aerosols, and specialty chemical containment, blank tin cans—unprinted or unprocessed metal cans made primarily from tin-coated steel—are undergoing significant shifts influenced by macroeconomic and industry-specific dynamics.

-

Sustainability and Circular Economy Push

By 2026, environmental regulations and consumer demand for eco-friendly packaging are accelerating the adoption of recyclable and lightweight tinplate materials. Blank tin cans, already highly recyclable, are benefiting from innovations in low-tin coatings and alternative steel substrates that reduce environmental impact. Governments in Europe and North America are enforcing stricter packaging waste directives, prompting manufacturers to invest in closed-loop recycling systems. This trend is expected to increase demand for high-purity blank tin cans designed for multiple recycling cycles. -

Growth in Food and Beverage Packaging

The food and beverage sector remains the largest consumer of blank tin cans. Rising demand for shelf-stable, ready-to-eat meals, canned seafood, vegetables, and beverages—especially in emerging markets like India, Southeast Asia, and Africa—is fueling production. By 2026, the trend toward convenience and extended shelf life will drive continued investment in high-barrier tin can solutions, boosting the blank can market as a foundational input. -

Technological Advancements in Manufacturing

Automation, digital printing integration, and precision stamping technologies are enhancing the efficiency of converting blank tin cans into finished products. By 2026, manufacturers are increasingly adopting Industry 4.0 principles, such as real-time monitoring and AI-driven quality control, to reduce waste and improve throughput. This shift increases the need for standardized, high-quality blank cans compatible with advanced production lines. -

Raw Material Cost Volatility and Supply Chain Adjustments

Tin and steel prices remain subject to geopolitical and mining output fluctuations. By 2026, producers are likely to adopt hedging strategies and vertical integration to mitigate risks. Additionally, regionalization of supply chains—especially in response to trade tensions and pandemic-era disruptions—will favor localized production of blank tin cans, reducing lead times and import dependencies. -

Competition from Alternative Packaging

While aluminum and plastic packaging continue to compete in lightweight and cost-sensitive applications, tin cans maintain a strong foothold in sectors requiring superior barrier protection and durability. Innovations such as thinner gauges and improved internal lacquers are helping blank tin cans remain competitive. However, market players must continue to innovate to justify higher costs in price-sensitive markets. -

Emerging Markets Driving Demand

Developing economies are expected to be the primary growth engines for blank tin cans by 2026. Urbanization, rising disposable incomes, and expanding retail infrastructure are increasing packaged food consumption. Local can manufacturing capacity is expanding in countries like Vietnam, Indonesia, and Nigeria, creating new opportunities for blank tin can suppliers.

In conclusion, the 2026 outlook for blank tin cans is characterized by resilience, innovation, and strategic adaptation. While challenges such as material costs and competition persist, the sector is well-positioned for growth due to enduring demand for safe, sustainable, and functional metal packaging. Companies that invest in green technologies, supply chain agility, and emerging market expansion are likely to capture significant market share in the coming years.

Common Pitfalls When Sourcing Blank Tin Cans: Quality and Intellectual Property Risks

Poor Material Quality and Thickness Inconsistencies

One of the most frequent issues when sourcing blank tin cans is inconsistent or substandard material quality. Suppliers may use tinplate with inadequate steel base thickness or insufficient tin coating, leading to corrosion, leakage, or structural failure. Buyers often overlook detailed material specifications—such as temper (e.g., T2, T3), coating weight (e.g., 2.8 g/m²), and surface finish—resulting in cans that fail performance or shelf-life requirements. Always verify material certifications and conduct third-party lab testing to avoid underperforming products.

Inadequate Quality Control During Manufacturing

Many suppliers, especially low-cost manufacturers, lack rigorous in-line quality control processes. This can result in defects like seam irregularities, scoring, uneven trimming, or oil contamination on the tin surface. These flaws may not be visible during initial inspection but can cause issues during filling, sealing, or storage. Implementing a formal QC protocol with AQL (Acceptable Quality Level) standards and on-site audits is essential to mitigate these risks.

Misrepresentation of Tin Coating Specifications

Some suppliers mislabel or exaggerate tin coating weights or fail to distinguish between electroplated tinplate (ETP) and hot-dipped tinplate (HTP). Using the wrong type can affect weldability, corrosion resistance, and food safety compliance. Ensure suppliers provide mill test certificates and conduct independent verification to confirm coating specifications match contractual agreements.

Intellectual Property (IP) Infringement Risks

Sourcing blank tin cans—especially those designed for specific machinery or proprietary formats—can inadvertently lead to IP violations. Some suppliers replicate patented can designs, closure systems, or tooling without authorization. Buyers may become liable if these counterfeit or cloned components are integrated into their products. Conduct due diligence on supplier design rights and require IP indemnification clauses in contracts to protect against legal exposure.

Lack of Traceability and Compliance Documentation

Blank tin cans used in food, pharmaceutical, or cosmetic applications must comply with regulations such as FDA 21 CFR, EU Framework Regulation (EC) No 1935/2004, or BRCGS standards. A common pitfall is sourcing from suppliers who cannot provide full traceability, including raw material origin, coating details, and compliance certifications. This can lead to product recalls or import denials. Insist on full documentation packages and audit supplier compliance history before placing orders.

Overlooking Tooling and Compatibility Issues

Blank tin cans must be compatible with the buyer’s can-making or filling equipment. Sourcing blanks with incorrect diameters, heights, or curl specifications can cause machine downtime or defective final products. Suppliers may offer “standard” sizes that aren’t truly standardized across regions. Always validate dimensional tolerances and conduct fit-testing with actual production lines before mass ordering.

Logistics & Compliance Guide for Blank Tin Cans

Overview

Blank tin cans, typically made of tinplate steel or tin-coated steel, are widely used in food packaging, industrial applications, and consumer goods. Proper logistics and compliance handling are essential to ensure product integrity, regulatory adherence, and efficient supply chain operations.

Classification & HS Code

Blank tin cans fall under specific Harmonized System (HS) codes depending on their form, material composition, and intended use. Common classifications include:

– HS 7310.29: Containers of iron or steel, of a kind used for the conveyance or packing of goods, not elsewhere specified.

– HS 7210.70: Tinplate steel (flat-rolled products, coated or plated).

Accurate classification is critical for customs clearance, duty calculation, and import/export compliance.

Packaging & Palletization

To prevent damage during transit:

– Blank tin cans should be securely stacked and wrapped in moisture-resistant materials.

– Use reinforced pallets (e.g., wooden or plastic) with edge protectors to avoid deformation.

– Load within humidity-controlled containers to prevent corrosion.

– Clearly label each pallet with product details, batch numbers, and handling instructions (e.g., “Fragile,” “Do Not Stack”).

Transportation Requirements

- Mode of Transport: Suitable for road, rail, sea, and air freight. Sea freight is most common for bulk shipments.

- Container Type: Use dry freight containers; desiccants recommended for long sea voyages to control moisture.

- Temperature & Humidity: Store and transport in dry conditions (relative humidity <60%) to prevent rusting. Avoid exposure to extreme temperatures.

- Stacking Limits: Observe manufacturer’s stacking guidelines to prevent crushing or deformation.

Regulatory Compliance

International Standards

- ISO 9001: Quality management systems for manufacturing and supply.

- ISO 22000: Applicable if cans are intended for food contact (ensures safety in packaging).

- REACH & RoHS: Comply with restrictions on hazardous substances (e.g., lead, cadmium) in metal components, especially for EU markets.

Food Contact Compliance (if applicable)

- FDA 21 CFR Part 175–176: U.S. regulations for indirect food additives and coatings.

- EU Framework Regulation (EC) No 1935/2004: Ensures materials are safe for food contact.

- Require supplier declarations and test reports confirming compliance with migration limits.

Import/Export Documentation

Essential paperwork includes:

– Commercial Invoice

– Packing List

– Bill of Lading or Air Waybill

– Certificate of Origin

– Material Compliance Certificate (REACH, RoHS, FDA, etc.)

– Phytosanitary Certificate (if required by destination country for wooden pallets)

Customs Clearance

- Provide accurate product descriptions (e.g., “Blank Tin Cans for Food Packaging, Unprinted, Tin-Coated Steel”).

- Declare correct HTS/HS code and country of origin.

- Be prepared for inspections, particularly for food-grade or regulated shipments.

Environmental & Safety Considerations

- Tinplate is recyclable; comply with local waste and recycling regulations.

- Handle with care to avoid cuts from sharp edges; use protective gloves.

- Follow OSHA or local safety standards during loading/unloading.

Labeling & Traceability

- Each shipment must include:

- Product name and specifications

- Batch/lot number

- Manufacturer details

- Net weight and quantity

- Maintain traceability records for at least 5 years (especially for food-grade applications).

Storage Guidelines

- Store indoors on raised pallets in a dry, ventilated area.

- Avoid direct contact with concrete floors to limit moisture absorption.

- Rotate stock using FIFO (First In, First Out) method to minimize aging risks.

Conclusion

Effective logistics and compliance management for blank tin cans ensure product quality, regulatory adherence, and customer satisfaction. Partner with certified suppliers and stay updated on regional regulations to maintain smooth international trade operations.

In conclusion, sourcing blank tin cans requires a thorough evaluation of suppliers based on factors such as material quality, production capacity, pricing, compliance with industry standards, and geographic location. Establishing strong partnerships with reliable manufacturers—whether domestic or international—ensures consistent supply, cost efficiency, and product reliability. Additionally, considering sustainability practices and customization options can further enhance the value and environmental impact of the final product. A well-structured sourcing strategy not only supports operational efficiency but also contributes to the overall competitiveness and scalability of your packaging or manufacturing business.