The global stainless steel fasteners market, including specialized products such as black stainless steel screws, is experiencing steady growth driven by rising demand across construction, automotive, and industrial sectors. According to Mordor Intelligence, the stainless steel fasteners market was valued at approximately USD 6.3 billion in 2023 and is projected to grow at a CAGR of over 5.2% from 2024 to 2029. This expansion is fueled by the increasing need for corrosion-resistant, durable, and aesthetically pleasing fastening solutions—qualities that black stainless screws deliver through their unique combination of performance and modern visual appeal. As architectural and engineering specifications place greater emphasis on both longevity and design integration, manufacturers are responding with advanced surface treatments and proprietary coatings to meet evolving demands. Against this backdrop, identifying the leading producers of black stainless steel screws becomes essential for sourcing high-performance components in a competitive and innovation-driven market.

Top 10 Black Stainless Screws Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 Stainless Steel Screw Manufacturers

Domain Est. 2017

Website: sstls.com

Key Highlights: stainless steel screw manufacturers, 21 years stainless steel wire manufacturers, guarantee stainless steel screw quality from the source….

#2 ARP

Domain Est. 1997

Website: arp-bolts.com

Key Highlights: Fastener Tech • ARP Ultra-Torque • Find Your Kit Instructions • Fastener Installation Overview • Torque Value Lookup • Fastener Installation FAQs…

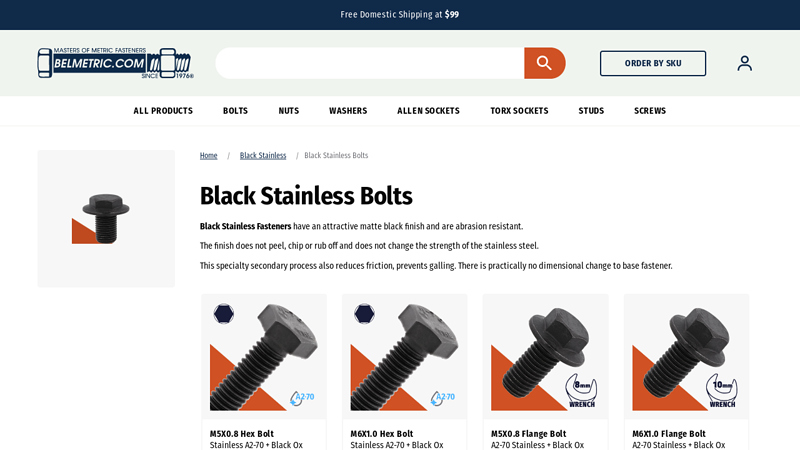

#3 Black Stainless Bolts

Domain Est. 1998

#4 Wholesale Stainless Steel Products

Domain Est. 1998

Website: starstainless.com

Key Highlights: Star Stainless is a wholesale distributor specializing in Stainless Steel products. For over 70 years our STAR Service, Off-the-Shelf Inventory Programs and ……

#5 Black Stainless Steel Screws

Domain Est. 2000

Website: tremontnail.com

Key Highlights: Black Stainless 1-1/4 x 12 Pyramid Head Wood Screw, Box 15. $20.00. Add to Cart Add to Wish List Add to Compare….

#6 Marsh Fasteners

Domain Est. 2003

Website: marshfasteners.com

Key Highlights: As top fastener suppliers, our extensive inventory of quality fasteners includes stainless steel fasteners in 18-8, 304 & 316 Stainless Steel….

#7 Black Oxide Stainless Steel Sheet Metal Screws

Domain Est. 2007

Website: albanycountyfasteners.com

Key Highlights: 1–2 day delivery · 60-day returns…

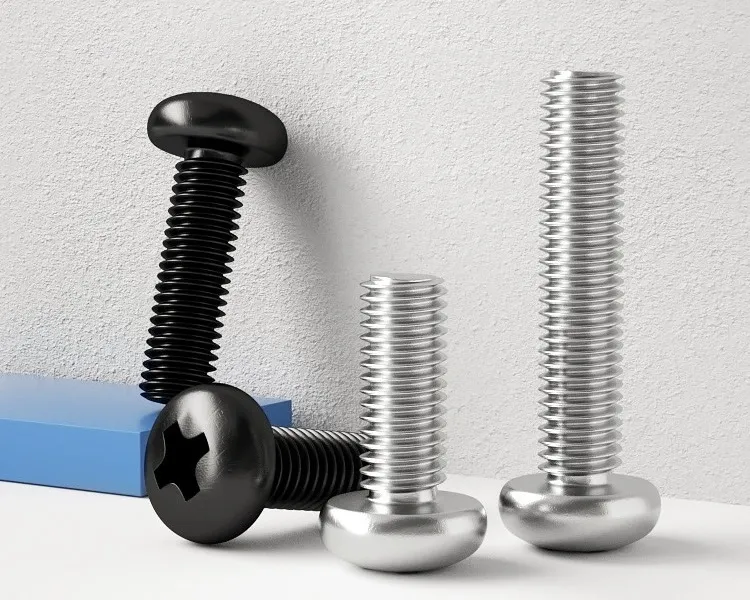

#8 Black Stainless Steel Bolts Screws and Studs

Domain Est. 2014

#9 What Is AccuBlack? The Benefits Of Choosing Chemi Black Screws …

Domain Est. 2020

Website: accu-components.com

Key Highlights: AccuBlack is a chemical blackening process that converts the finish of stainless steel components from natural to matte black….

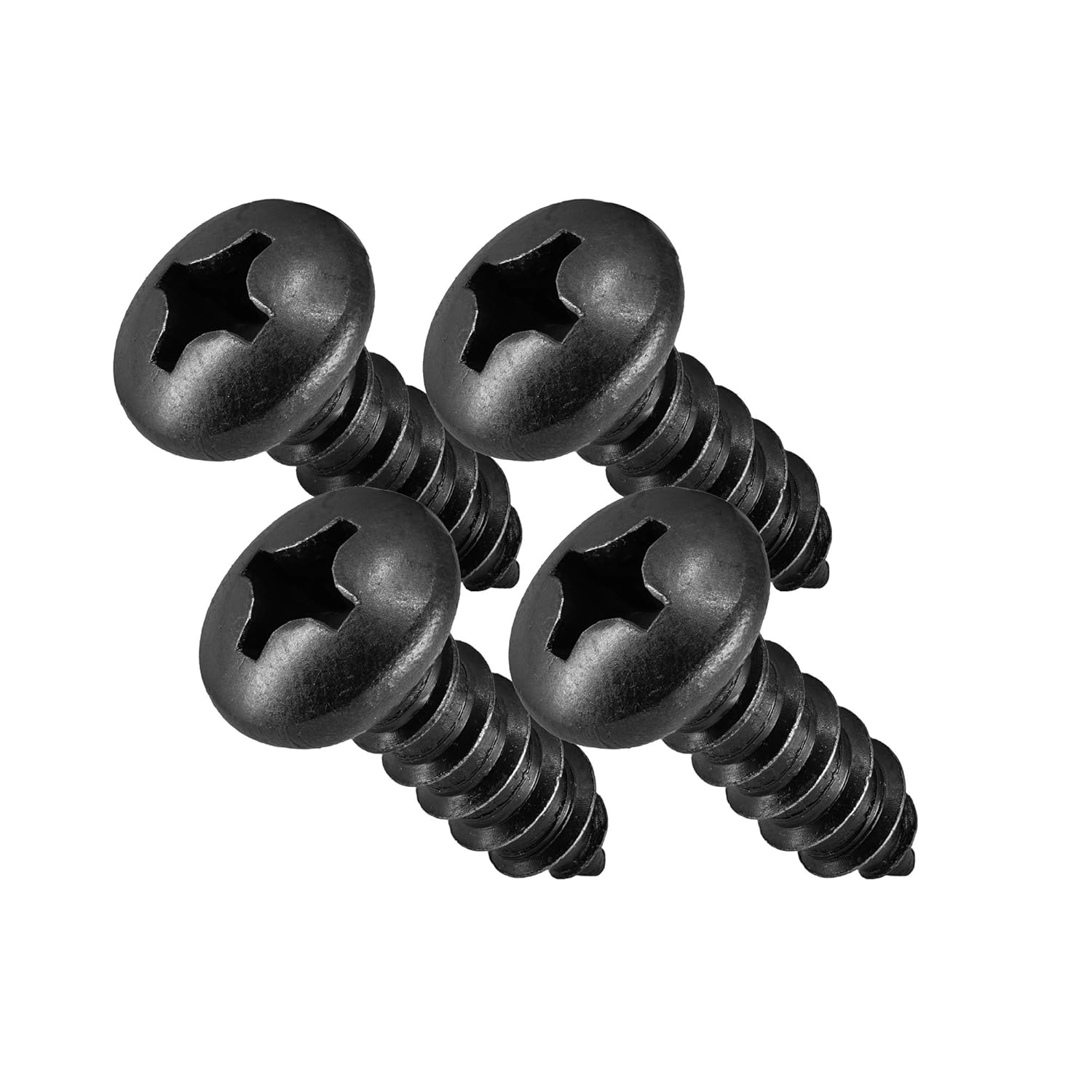

#10 What are Black Stainless Steel Screws ? A2 A4 Black Screws

Domain Est. 2021

Website: a2fasteners.com

Key Highlights: Black stainless steel screws are a surface treatment of stainless steel 304 and 316 screws, after treatment, the formation of a black film on the surface of ……

Expert Sourcing Insights for Black Stainless Screws

H2: 2026 Market Trends for Black Stainless Steel Screws

The global market for black stainless steel screws is poised for steady growth and transformation by 2026, shaped by evolving industrial demands, aesthetic preferences, and advancements in material technology. These fasteners—known for their corrosion resistance, durability, and sleek, modern appearance—are increasingly favored in both residential and commercial applications. Below are the key trends expected to influence the black stainless steel screw market in 2026:

-

Rising Demand in Construction and Architecture

The construction industry, particularly in high-end residential and commercial developments, is driving demand for black stainless steel screws due to their dual functionality and visual appeal. Their matte black finish complements modern architectural designs featuring black metalwork, glass, and minimalist fixtures. As urbanization continues and design trends favor darker, cohesive aesthetics, this demand is projected to grow significantly through 2026. -

Expansion in Appliance Manufacturing

Major appliance manufacturers are increasingly incorporating black stainless steel screws into the assembly of premium kitchen appliances. These screws provide a seamless look when used in visible joints and panels, aligning with the growing consumer preference for black stainless steel finishes in refrigerators, ovens, and dishwashers. This integration supports brand consistency and enhances perceived product quality. -

Growth in DIY and Home Improvement Markets

The surge in do-it-yourself (DIY) culture, accelerated by online tutorials and home renovation platforms, is boosting retail sales of specialty fasteners. Black stainless steel screws are becoming a popular choice among homeowners seeking durable and visually appealing solutions for outdoor decking, fencing, and interior projects. E-commerce platforms are expected to play a crucial role in making these products more accessible by 2026. -

Technological Advancements in Coating and Finishing

Innovations in PVD (Physical Vapor Deposition) and other coating technologies are improving the durability and scratch resistance of the black finish on stainless steel screws. Enhanced coatings ensure that the screws maintain their appearance under UV exposure, moisture, and mechanical stress—critical for outdoor and high-wear applications. These improvements will support broader adoption across industries. -

Sustainability and Recyclability Factors

Stainless steel is inherently recyclable, and as environmental regulations tighten globally, manufacturers and end-users are prioritizing sustainable materials. Black stainless steel screws offer a long service life and reduced need for replacement, contributing to lower lifecycle environmental impact. This eco-friendly profile will become a stronger selling point by 2026, especially in green building certifications like LEED. -

Regional Market Dynamics

North America and Western Europe are expected to lead market growth due to high construction activity and consumer preference for premium finishes. Meanwhile, Asia-Pacific—particularly China and India—will experience rapid expansion due to industrialization and rising disposable incomes. Localized manufacturing and supply chain optimization will be critical for companies aiming to capitalize on these regional opportunities. -

Competitive Landscape and Brand Differentiation

As the market matures, competition among fastener manufacturers will intensify. Companies are likely to differentiate through product quality, specialized coatings, custom sizing, and technical support. Branding and marketing efforts will increasingly highlight the aesthetic and functional advantages of black stainless steel screws over standard alternatives.

In conclusion, the 2026 outlook for black stainless steel screws is positive, with growth driven by design trends, technological improvements, and expanding applications across construction, appliances, and consumer markets. Stakeholders who invest in innovation, sustainability, and market-specific strategies will be best positioned to thrive in this evolving landscape.

Common Pitfalls When Sourcing Black Stainless Steel Screws (Quality & IP)

Sourcing black stainless steel screws may seem straightforward, but several pitfalls related to quality and intellectual property (IP) can compromise performance, compliance, and brand reputation. Being aware of these risks is crucial for making informed procurement decisions.

Inconsistent or Substandard Black Coating Quality

One of the most frequent issues is variability in the black finish. Many suppliers apply coatings like PVD (Physical Vapor Deposition), powder coating, or black oxide, but without strict quality control, these coatings may lack durability. Poor adhesion, uneven color, chipping, or premature fading can occur—especially in harsh environments. This not only affects aesthetics but can expose the underlying stainless steel to corrosion, defeating the purpose of using stainless material.

Misrepresentation of Base Material

Some suppliers may claim the screws are made from stainless steel, but in reality, they use inferior base materials such as carbon steel with a black plating. These imitations are prone to rust and fail under stress or in corrosive conditions. Without proper material certifications (e.g., mill test reports), it’s difficult to verify compliance with standards like AISI 304 or 316.

Lack of IP Due Diligence

Black stainless screws—particularly those with proprietary finishes or specialized thread designs—may be protected by patents or trademarks. Sourcing from unauthorized manufacturers or copying branded products can lead to intellectual property infringement. This exposes your business to legal action, shipment seizures, and reputational damage, especially in regulated markets like the EU or North America.

Inadequate Testing and Certification

Reliable black stainless screws should undergo performance testing for corrosion resistance (e.g., salt spray tests), torque strength, and coating adhesion. Many low-cost suppliers skip these tests or provide falsified reports. Without verifiable certifications (such as ISO or ASTM compliance), there’s no assurance the product meets required specifications.

Supply Chain Transparency Issues

Opaque supply chains make it difficult to trace the origin of materials and manufacturing processes. This increases the risk of receiving counterfeit or non-compliant products. It also complicates efforts to ensure ethical sourcing and regulatory compliance, particularly under sustainability and conflict minerals regulations.

Overlooking Finish Compatibility

The black coating must be compatible with the intended application. For example, in high-temperature or chemically aggressive environments, some coatings degrade quickly. Selecting the wrong type of finish due to insufficient technical data can result in field failures and costly replacements.

Avoiding these pitfalls requires thorough supplier vetting, demand for material and test certifications, and legal review when sourcing proprietary designs. Partnering with reputable, transparent manufacturers is key to ensuring both quality and IP compliance.

Logistics & Compliance Guide for Black Stainless Steel Screws

Overview

Black stainless steel screws combine the corrosion resistance of stainless steel with a durable, aesthetically pleasing black coating. Proper logistics and compliance management are essential to ensure product integrity, regulatory adherence, and customer satisfaction. This guide outlines key considerations for the transportation, storage, documentation, and regulatory compliance of black stainless steel screws.

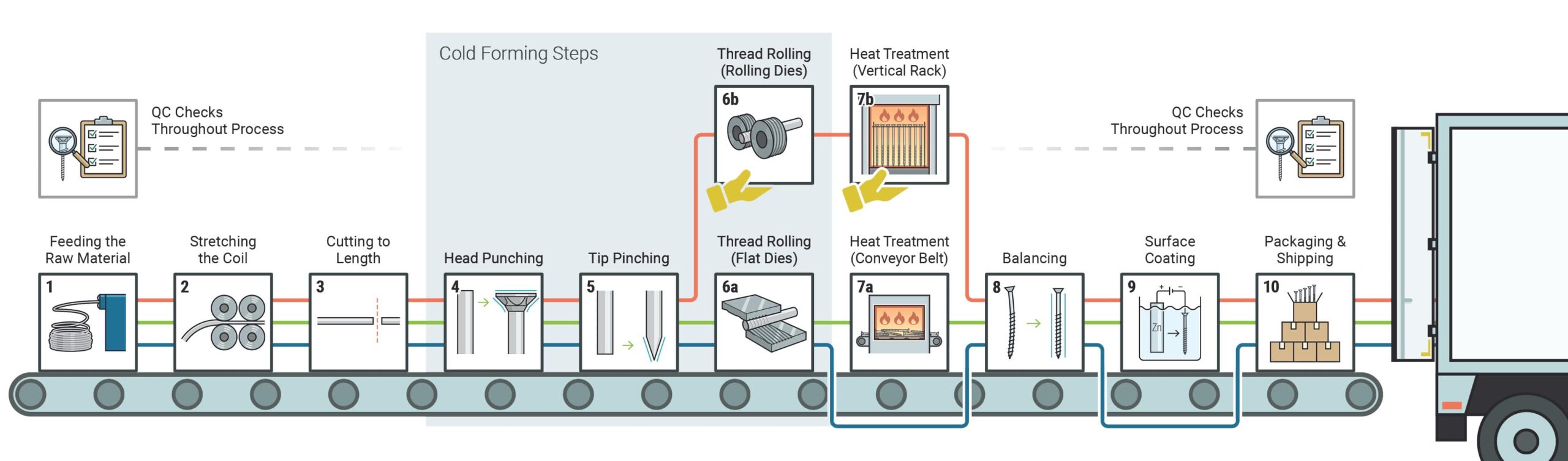

Material & Coating Specifications

Ensure all black stainless steel screws meet specified material standards (e.g., ASTM A320 for low-temperature applications or ISO 3506 for mechanical properties of stainless steel fasteners). The black finish is typically achieved via physical vapor deposition (PVD), black oxide, or electroplating. Confirm coating durability and resistance to chipping, fading, and corrosion per ASTM B117 (salt spray testing) where applicable.

Packaging Requirements

Use anti-static, moisture-resistant packaging to prevent surface damage and corrosion during transit. Screws should be packaged in sealed polybags with desiccants, especially for maritime shipping. Larger quantities must be palletized with edge protectors and stretch-wrapped. Clearly label each package with product description, part number, quantity, batch/lot number, and handling instructions (e.g., “Fragile,” “Keep Dry”).

Storage Conditions

Store black stainless steel screws in a climate-controlled environment with temperatures between 10°C and 30°C and relative humidity below 60%. Avoid direct sunlight to prevent coating degradation. Keep materials off the floor on pallets or shelving to minimize moisture exposure. Implement a first-in, first-out (FIFO) inventory system to prevent aging-related quality issues.

Transportation Guidelines

Use enclosed, dry vehicles for transport. Protect loads from vibration and shock using dunnage and secure strapping. For international shipments, comply with International Safe Transit Association (ISTA) standards. Monitor shipments with temperature and humidity data loggers when necessary, particularly for long-haul or cross-climate zone deliveries.

Regulatory Compliance

Ensure compliance with relevant regional and international regulations:

– REACH (EU): Confirm no restricted substances (e.g., lead, cadmium) exceed allowable limits in the coating or base material.

– RoHS (EU/UK): Verify compliance for screws used in electrical or electronic equipment.

– California Proposition 65: Provide warnings if applicable chemical components are present.

– Customs & Tariff Codes: Classify under correct HS Code (e.g., 7318.15 for stainless steel screws). Maintain accurate commercial invoices, packing lists, and certificates of origin.

Certification & Documentation

Provide the following documentation with shipments:

– Certificate of Compliance (CoC)

– Material Test Report (MTR) confirming stainless steel grade (e.g., 304, 316)

– Coating specification and test results (e.g., salt spray resistance)

– RoHS/REACH compliance statement

– SDS (Safety Data Sheet) if coating involves chemical treatments

Traceability & Quality Control

Maintain full batch traceability from raw material sourcing to final shipment. Implement quality control checks at inbound, in-process, and outbound stages. Use barcode or QR code labeling for lot tracking. Address non-conformances through documented corrective and preventive actions (CAPA).

Environmental & Sustainability Considerations

Dispose of packaging materials in accordance with local recycling regulations. Minimize waste through efficient packaging design. Source materials from suppliers with ISO 14001 environmental management certification where possible.

Conclusion

Effective logistics and compliance for black stainless steel screws require attention to packaging, environmental controls, regulatory standards, and documentation. Adhering to this guide ensures product performance, legal compliance, and customer trust across global supply chains.

In conclusion, sourcing black stainless steel screws requires a careful balance of evaluating material quality, supplier reliability, and cost-effectiveness. While black stainless screws offer both aesthetic appeal and corrosion resistance, it is essential to verify that the black finish is achieved through durable methods such as PVD coating or electrophoretic deposition rather than cosmetic plating that may wear over time. Partnering with reputable suppliers who provide certification for material composition and finish durability ensures long-term performance and compliance with project specifications. Additionally, considering minimum order quantities, lead times, and customization options will help streamline procurement and support project timelines. Overall, thorough due diligence in supplier selection and product verification is key to successfully integrating black stainless steel screws into high-quality, long-lasting applications.