The global powder coatings market is experiencing robust growth, driven by increasing demand for durable, environmentally friendly finishes across automotive, industrial, and architectural applications. According to Grand View Research, the global powder coatings market size was valued at USD 13.4 billion in 2022 and is expected to expand at a compound annual growth rate (CAGR) of 6.5% from 2023 to 2030. This expansion is fueled by stringent environmental regulations limiting volatile organic compound (VOC) emissions and a shift toward sustainable coating solutions—factors that position black powder coated textures as a preferred choice for both aesthetic and protective performance.

With black accounting for the largest segment share due to its versatility, corrosion resistance, and aesthetic appeal, demand for high-quality textured finishes—particularly matte, wrinkled, and hammered effects—has surged. As industries prioritize durability and design, manufacturers specializing in black powder coated textures are at the forefront of innovation. The following list highlights the top four manufacturers excelling in this niche, selected based on production capacity, technological advancement, global footprint, and product performance data.

Top 4 Black Powder Coated Texture Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 Powder Coatings Manufacturer

Domain Est. 2001

Website: ifscoatings.com

Key Highlights: IFS Coatings is a leading powder coatings manufacturer for all applications. Find the perfect color and powder chemistry for your project with IFS….

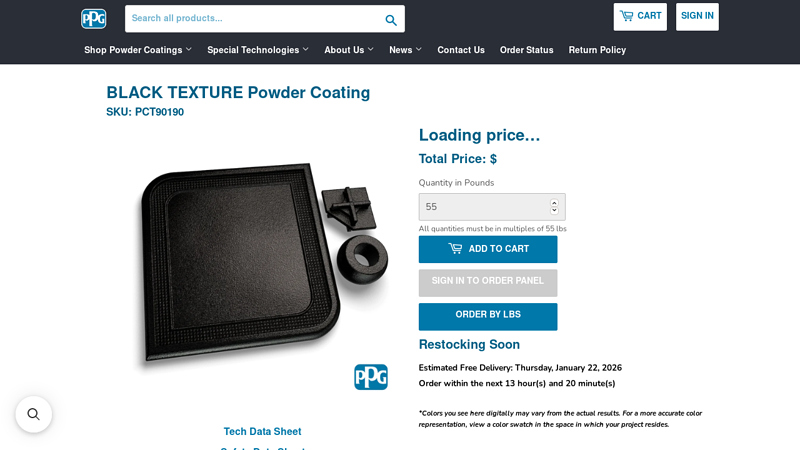

#2 BLACK TEXTURE Powder Coating Color

Domain Est. 1990

Website: powdercoatings.ppg.com

Key Highlights: Black Texture is a thermosetting powder coating resulting in a tough and resilient coating. This powder coating is specifically formulated to offer excellent ……

#3 Powder Coatings by AkzoNobel

Domain Est. 1997

Website: interpon.com

Key Highlights: Discover Interpon, AkzoNobel’s brand transforming powder coatings. Explore innovative solutions tailored to every need and join the powder revolution!…

#4 Fine Black Texture Powder Coating Paint

Domain Est. 2013

Expert Sourcing Insights for Black Powder Coated Texture

H2: Market Trends for Black Powder Coated Texture in 2026

The demand for black powder coated textures is poised for significant growth and transformation by 2026, driven by advancements in material science, evolving consumer preferences, and sustainability imperatives across key industries. This H2 analysis explores the major market trends shaping the trajectory of black powder coated finishes over the next few years.

-

Increased Adoption in Architectural and Construction Sectors

By 2026, the architectural industry is expected to favor black powder coated textures for both aesthetic and functional benefits. Matte black, textured finishes are becoming synonymous with modern design in residential, commercial, and infrastructure projects. These coatings offer enhanced durability, UV resistance, and low maintenance—critical for exterior applications such as façades, window frames, and roofing. Regulatory support for long-lasting, low-VOC materials further accelerates their adoption. -

Sustainability and Eco-Compliance Driving Innovation

Environmental regulations are tightening globally, pushing manufacturers toward solvent-free coating solutions. Powder coatings, including black textured variants, emit zero volatile organic compounds (VOCs), aligning with green building standards like LEED and BREEAM. By 2026, expect increased R&D in bio-based resins and recyclable powders, enhancing the eco-profile of black textured finishes and expanding their use in sustainable manufacturing. -

Expansion in Automotive and Transportation Applications

The automotive industry is shifting toward black textured powder coatings for under-the-hood components, chassis, wheels, and EV battery enclosures. These finishes provide superior corrosion resistance and heat tolerance, while the matte, non-reflective surface improves visual appeal and reduces glare. With the rise of electric vehicles, demand for durable, lightweight, and thermally efficient coatings will surge, positioning black powder coatings as a preferred solution. -

Growth in Consumer Durables and Appliance Markets

Home appliances, furniture, and outdoor equipment increasingly feature black textured powder coatings to meet consumer demand for sleek, modern, and fingerprint-resistant surfaces. By 2026, manufacturers will leverage advanced texturing techniques—such as wrinkled, hammered, or sand finishes—to differentiate products in competitive markets. The durability of these coatings also reduces lifecycle costs, appealing to both producers and end-users. -

Technological Advancements in Application and Curing

Innovations in electrostatic application systems and low-cure powder technologies will enhance the efficiency and versatility of black powder coated textures. By 2026, wider adoption of UV-curable and near-infrared (NIR) curing methods will reduce energy consumption and enable coating of heat-sensitive substrates, opening new application avenues in electronics and composite materials. -

Regional Market Shifts and Supply Chain Localization

Asia-Pacific, particularly China and India, will lead market growth due to rapid urbanization and industrialization. However, North America and Europe will emphasize high-performance, specialty-grade black textured powders with traceability and compliance certifications. Supply chain resilience will drive regional production, reducing dependence on global logistics and enabling faster customization. -

Customization and Premium Finishes

As brands seek differentiation, demand for custom black textures—ranging from soft-touch to high-grip surfaces—will rise. Digital color matching and AI-driven formulation tools will allow manufacturers to offer tailored solutions with shorter lead times. This trend will be prominent in luxury automotive, high-end appliances, and designer architectural elements.

In conclusion, the 2026 market for black powder coated texture is set for robust expansion, underpinned by sustainability, performance, and design innovation. Companies investing in R&D, circular economy models, and digital manufacturing will gain a competitive edge in this evolving landscape.

Common Pitfalls Sourcing Black Powder Coated Texture (Quality, IP)

Sourcing Black Powder Coated Texture materials—especially for high-performance or consumer-facing products—presents several critical pitfalls related to both quality consistency and intellectual property (IP) protection. Overlooking these can lead to production delays, compromised product integrity, legal disputes, and reputational damage.

Inconsistent Coating Quality and Finish

One of the most prevalent issues is variability in the final powder-coated finish. Factors such as inconsistent powder application thickness, improper curing temperatures, or substandard raw materials can result in:

- Color and Gloss Variation: Slight deviations in black hue (e.g., bluish vs. brownish undertones) or gloss levels across batches.

- Texture Inconsistency: The “texture” aspect—whether matte, rough, or patterned—may not replicate uniformly, affecting both aesthetics and tactile experience.

- Durability Deficiencies: Poor adhesion, chipping, or reduced UV/chemical resistance due to inadequate surface pre-treatment or low-grade powder.

These inconsistencies often stem from suppliers cutting corners or lacking robust quality control (QC) processes, especially when scaling production.

Lack of Standardized Specifications and Testing

Many suppliers do not adhere strictly to industry standards (e.g., ASTM D4258, AAMA 2604/2605), leading to ambiguous or incomplete product specifications. Without clear documentation on:

- Powder chemistry (epoxy, polyester, hybrid)

- Film thickness

- Accelerated weathering test results (QUV, salt spray)

- Adhesion and impact resistance

buyers risk receiving coatings that fail in real-world conditions. This is particularly critical for outdoor or high-wear applications.

Intellectual Property Risks and Reverse Engineering

Black Powder Coated Textures—especially proprietary finishes developed in-house or by specialty coating houses—can be vulnerable to IP theft. Common risks include:

- Reverse Engineering by Suppliers: A contract manufacturer may analyze the coating sample to replicate the formula, potentially using it for competing clients.

- Unprotected Formulations: Failure to patent or legally protect unique textures or color-matching processes leaves them exposed.

- Weak Contractual Safeguards: Supplier agreements without robust confidentiality clauses (NDAs), IP ownership terms, or usage restrictions increase the risk of unauthorized duplication.

This is especially problematic when sourcing from regions with weaker IP enforcement.

Supply Chain Opacity and Subcontracting

Suppliers may subcontract coating work to third-party facilities without disclosure, leading to:

- Loss of control over process parameters

- Inconsistent quality due to differing equipment or expertise

- Increased risk of IP exposure across multiple facilities

Without audit rights or transparency in the supply chain, ensuring consistency and security becomes nearly impossible.

Mitigation Strategies

To avoid these pitfalls:

- Require detailed technical data sheets and batch test reports.

- Conduct on-site audits of coating facilities to verify processes and QC.

- Establish clear IP clauses in contracts, specifying ownership and restricting reverse engineering.

- Use controlled samples and secure color standards (e.g., locked physical references) with limited distribution.

- Partner with reputable, certified coaters with proven track records in textured black finishes.

Proactive management of both quality and IP safeguards is essential to ensure reliable, protected, and high-performing black powder coated textures.

Logistics & Compliance Guide for Black Powder Coated Texture

Product Overview

Black Powder Coated Texture refers to a surface finish applied through an electrostatic process where dry powder paint is sprayed onto a substrate (typically metal) and then cured under heat to form a durable, textured, and protective coating. The black color provides a modern aesthetic, while the textured finish enhances scratch resistance, minimizes fingerprints, and adds grip. This guide outlines key logistics and compliance considerations for handling, transporting, storing, and using black powder-coated textured products.

Regulatory Compliance

Environmental Regulations

- VOC Emissions: Powder coating is solvent-free and contains no volatile organic compounds (VOCs), making it compliant with EPA, EU VOC Directive (2004/42/EC), and other regional air quality regulations.

- Waste Management: Overspray powder can often be recovered and reused. Non-recoverable waste must be disposed of in accordance with local hazardous waste regulations. Confirm whether spent powder is classified as hazardous based on composition and local jurisdiction.

- REACH & RoHS Compliance: Ensure the powder formulation complies with EU REACH (Registration, Evaluation, Authorisation, and Restriction of Chemicals) and RoHS (Restriction of Hazardous Substances) directives. Request Safety Data Sheets (SDS) and compliance certificates from suppliers.

Safety & Handling Standards

- OSHA & GHS: Follow OSHA Hazard Communication Standard (HCS) and GHS (Globally Harmonized System) labeling requirements. Provide SDS for the powder coating material to all handlers.

- Dust Control: Although cured coatings are inert, the uncured powder poses inhalation risks. Use local exhaust ventilation and personal protective equipment (PPE) during application.

- Combustibility: Powder coatings may be combustible in dust form. Follow NFPA 654 (Standard for the Prevention of Fire and Dust Explosions) for safe handling and storage of unused powder.

Packaging & Labeling

Packaging Requirements

- Use moisture-resistant, durable packaging to protect coated components during transit.

- Separate parts with non-abrasive materials (e.g., foam, bubble wrap) to prevent scratching of the textured surface.

- For bulk shipments, use pallets with edge protectors and stretch wrap to secure loads.

Labeling

- Clearly label packages with:

- Product description (e.g., “Black Powder Coated Metal Bracket – Textured Finish”)

- Batch/lot number for traceability

- Handling instructions (e.g., “Fragile,” “This Side Up,” “Protect from Moisture”)

- Compliance marks (e.g., CE, RoHS, REACH) if applicable

- Safety warnings for uncured powder, if included

Storage Guidelines

Ambient Conditions

- Store coated parts in a dry, temperature-controlled environment (10–30°C / 50–86°F).

- Avoid high humidity (>60%) to prevent potential corrosion of exposed metal edges or substrate.

- Keep away from direct sunlight and UV exposure to minimize long-term color fading.

Shelf Life

- Cured powder-coated parts have an indefinite shelf life if stored properly.

- Uncured powder should be stored in sealed containers and used within the manufacturer’s recommended shelf life (typically 6–12 months).

Handling

- Use clean gloves when handling to avoid oil transfer.

- Avoid stacking coated parts without protective layers to prevent surface damage.

Transportation

Domestic & International Shipping

- Comply with IMDG Code (for sea), IATA DGR (for air), or ADR (for road in Europe) if shipping uncured powder, as some formulations may be classified as hazardous (e.g., Division 4.1 Flammable Solid).

- For cured coated parts: generally non-hazardous; standard freight regulations apply.

- Secure loads to prevent shifting or impact during transit.

Documentation

- Include commercial invoice, packing list, and certificate of compliance.

- Provide SDS if uncured powder is being shipped.

- For exports, verify destination country’s import regulations (e.g., customs codes, labeling requirements).

Quality Assurance & Traceability

- Maintain batch traceability from raw powder to finished product.

- Conduct periodic adhesion, salt spray, and abrasion resistance tests per ASTM B117, ASTM D3359, or ISO 2409 standards.

- Audit suppliers regularly for compliance with environmental and safety standards.

Disposal & End-of-Life

- Powder-coated metal parts are recyclable. The coating burns off during high-temperature metal recycling.

- Do not incinerate isolated uncured powder waste without proper controls.

- Follow local regulations for disposal of non-recyclable coated waste.

Summary

Black powder coated textured products offer a durable, eco-friendly finish with broad regulatory acceptance. Success in logistics and compliance depends on proper handling of uncured materials, adherence to environmental and safety standards, correct packaging, and thorough documentation. Always work with certified suppliers and stay updated on evolving regional regulations to ensure uninterrupted supply chain operations.

Conclusion for Sourcing Black Powder Coated Texture:

Sourcing black powder coated textured finishes requires a strategic approach that balances quality, cost, durability, and supplier reliability. This finish offers superior aesthetic appeal, excellent corrosion and wear resistance, and enhanced durability compared to traditional painting methods, making it ideal for both industrial and consumer applications. When sourcing, it is critical to partner with experienced and certified powder coating providers who use high-quality materials and adhere to industry standards such as ISO or AAMA. Key considerations include substrate compatibility, required texture profile (e.g., wrinkled, hammered, matte), environmental regulations, and volume requirements.

Additionally, conducting sample testing, requesting material certifications, and evaluating lead times and logistics can help ensure consistency and performance. In conclusion, successful sourcing of black powder coated texture hinges on due diligence, clear specifications, and strong supplier relationships, ensuring a durable, visually consistent, and cost-effective finish for end-use applications.