The global demand for respiratory protection, particularly in high-risk environments involving biological contaminants like black mold (Stachybotrys chartarum), has significantly increased in recent years. According to a 2023 report by Mordor Intelligence, the global respirator mask market was valued at USD 4.2 billion in 2022 and is projected to grow at a compound annual growth rate (CAGR) of 6.8% from 2023 to 2028. This growth is driven by rising awareness of indoor air quality, stricter occupational safety regulations, and increased remediation activities in the residential and commercial construction sectors. As mold-related health concerns—ranging from allergic reactions to respiratory complications—gain broader recognition, the need for high-efficiency particulate air (HEPA)-rated and N95 or higher-grade protective masks has become critical for professionals in restoration, HVAC, and industrial hygiene. In response, several manufacturers have emerged as leaders in producing specialized respiratory protection designed to filter out mold spores effectively. The following list highlights the top 7 black mold mask manufacturers known for their technical performance, certification standards, and reliability in hazardous environments.

Top 7 Black Mold Mask Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 3M Half Mask Respirators

Domain Est. 1988

Website: 3m.com

Key Highlights: Respirators which cover the nose and mouth of the wearer and have one or two replaceable filter compartments to filter contaminants from the surrounding air ……

#2 Moldex

Domain Est. 1995

Website: moldex.com

Key Highlights: Moldex-Metric is an industry leader in innovative respiratory and hearing protection. We make quality products for safety and comfort….

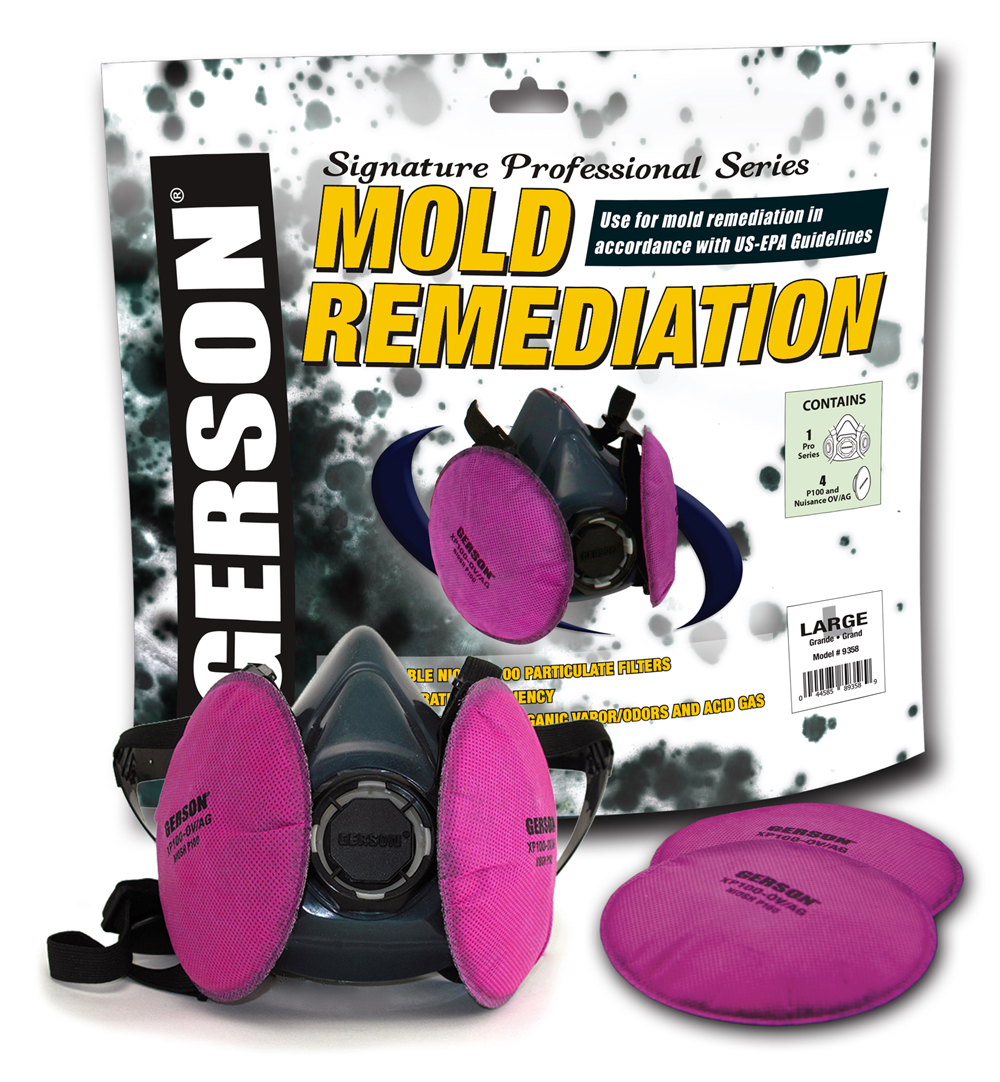

#3 Gerson

Domain Est. 1996

Website: gersonco.com

Key Highlights: For over 60 years, Gerson has integrated new technologies, excellence in product design and manufacturing innovation to provide essential products….

#4 Top Respirators from 3M, Honeywell & More

Domain Est. 1997

Website: pksafety.com

Key Highlights: Free deliveryMany of our respirators protect against a range of hazardous substances, while others are designed for specific threats, such as the 3M Mold Remediation ……

#5 JSP

Domain Est. 2003

Website: jspsafety.com

Key Highlights: JSP produce a vast range of moulded and fold flat Disposable Masks. Suitable for a wide array of working environments and hazards, these Disposable Masks ……

#6 Armbrust American

Domain Est. 2020

Website: armbrustusa.com

Key Highlights: Free delivery over $60 30-day returnsUnparalleled quality. Our surgical, KN95, and N95 masks are all crafted to the highest possible standards, right here on American soil….

#7 Respirators & Gas Masks You Can Trust

Domain Est. 2020

Website: parcilsafety.com

Key Highlights: Free delivery Free 30-day returnsProtect your health with our respirators and gear that filter out harmful particles like dust, mold spores, chemicals, and fumes….

Expert Sourcing Insights for Black Mold Mask

H2: Projected Market Trends for Black Mold Masks in 2026

The global market for black mold masks is poised for significant evolution by 2026, driven by rising awareness of indoor air quality, increasing incidence of mold-related health issues, and advancements in respiratory protection technology. As urbanization and climate change contribute to higher humidity levels and building dampness—key factors in mold proliferation—demand for effective personal protective equipment (PPE), particularly specialized masks targeting mold spores, is expected to surge.

One of the key trends shaping the 2026 landscape is the growing consumer preference for N95 and higher-rated respirators with activated carbon layers, which are especially effective against mold spores and associated volatile organic compounds (VOCs). These hybrid black mold masks combine particulate filtration with odor and chemical absorption, making them ideal for remediation workers, homeowners, and allergy sufferers. Major PPE manufacturers are investing in ergonomic designs, improved breathability, and antimicrobial coatings to enhance user comfort and safety.

Another significant driver is the expansion of residential and commercial mold remediation services, particularly in regions prone to flooding and high humidity such as Southeast Asia, the southeastern United States, and parts of Europe. Regulatory bodies are also tightening indoor air quality standards, indirectly boosting demand for certified mold protection gear. By 2026, compliance with standards like NIOSH, CE, and GB2626 will likely become a baseline requirement in professional settings, further segmenting the market toward certified black mold masks.

E-commerce platforms are expected to play a pivotal role in market penetration, with direct-to-consumer sales rising due to increased online health awareness and home improvement trends. Smart marketing strategies emphasizing product differentiation—such as reusable silicone masks with replaceable filters or eco-friendly disposable options—are gaining traction among environmentally conscious consumers.

In conclusion, the black mold mask market in 2026 will be characterized by technological innovation, regulatory influence, and heightened public health awareness. As mold exposure becomes a more recognized environmental health risk, the demand for reliable, high-performance black mold masks will continue to grow across both professional and consumer segments.

Common Pitfalls Sourcing Black Mold Masks (Quality, IP)

Sourcing black mold masks—whether referring to protective equipment for mold remediation or fashion/costume items—presents specific challenges related to quality assurance and intellectual property (IP) risks. Being aware of these pitfalls is essential to avoid legal, safety, and reputational issues.

Poor Material Quality and Safety Standards

One of the most critical pitfalls is receiving masks made from substandard materials. Inadequate filtration (e.g., non-NIOSH-approved filters), poor seal integrity, or use of toxic dyes and adhesives can compromise user safety, especially in industrial or health-related applications. Suppliers may cut corners to reduce costs, resulting in masks that fail to protect against mold spores or irritants.

Misrepresentation of Certification and Compliance

Many suppliers falsely claim compliance with safety standards such as NIOSH N95, FFP2, or ASTM. Without proper verification, buyers risk importing masks that do not meet regulatory requirements, leading to legal liability and potential harm. Always request and validate test reports, certification documents, and batch-specific compliance data.

Inconsistent Manufacturing and Lack of Quality Control

Low-cost suppliers, especially in unverified overseas markets, may lack robust quality control systems. This results in inconsistent product batches—varying strap strength, fit, or filtration efficiency—making it difficult to ensure reliable performance. Regular on-site audits or third-party inspections are crucial to mitigate this risk.

Intellectual Property Infringement

Sourcing masks that resemble branded designs (e.g., popular fashion or tactical masks) can lead to IP violations. Unauthorized use of logos, patented shapes, or distinctive design elements may result in customs seizures, legal action, or forced product recalls. Always conduct a design freedom-to-operate (FTO) analysis and avoid suppliers offering “inspired by” or “replica” versions of protected products.

Counterfeit or Grey Market Goods

Some suppliers offer branded black mold masks at suspiciously low prices, indicating counterfeit or grey market items. These products often lack authenticity, traceability, and after-sales support. They also expose buyers to IP liability and damage brand reputation if distributed unknowingly.

Inadequate Documentation and Traceability

Missing or falsified documentation—such as material safety data sheets (MSDS), certificates of origin, or batch tracking—hampers regulatory compliance and recall readiness. Ensure suppliers provide complete, verifiable records to support product legitimacy and safety claims.

Supplier Reliability and Hidden Costs

Unverified suppliers may offer attractive upfront pricing but lack reliability in delivery, after-sales service, or responsiveness to quality issues. Hidden costs such as retesting, customs delays due to compliance gaps, or product rejection can significantly impact total cost of ownership.

Conclusion

To avoid these pitfalls, conduct thorough due diligence: verify certifications, audit suppliers, perform product testing, and consult legal experts on IP matters. Prioritizing quality and compliance from the outset protects end-users and safeguards your business from liability.

Logistics & Compliance Guide for Black Mold Mask

Overview

This guide outlines the essential logistics and compliance considerations for the distribution, handling, and sale of the Black Mold Mask, a protective face mask designed for environments with potential mold exposure. Adherence to these guidelines ensures product safety, regulatory compliance, and supply chain efficiency.

Regulatory Compliance

FDA and Medical Device Classification

The Black Mold Mask is classified as a non-surgical, general-use particulate respirator and is not intended for use as a medical device. It does not require FDA 510(k) clearance unless marketed with medical claims. Ensure marketing materials do not imply surgical use, infection prevention, or treatment of disease to remain outside medical device regulations.

NIOSH Certification (If Applicable)

If the mask is intended to provide protection against airborne particles—including mold spores—and is marketed as such, it may require NIOSH (National Institute for Occupational Safety and Health) certification as an N95 respirator. Only NIOSH-approved respirators can legally claim filtration efficiency of at least 95% against non-oil-based particles. Verify NIOSH approval status and include the TC number and approval label on packaging if applicable.

OSHA Respiratory Protection Standard (29 CFR 1910.134)

In occupational settings, if employers require the use of respirators like the Black Mold Mask for mold remediation, compliance with OSHA’s respiratory protection standard is mandatory. This includes fit testing, training, and medical evaluation for users. The product should be accompanied by a user manual clarifying employer responsibilities under OSHA.

Labeling and Product Claims

All labeling must comply with FTC and FDA advertising guidelines. Avoid unsubstantiated claims such as “eliminates mold toxins” or “prevents respiratory illness.” Use accurate language: e.g., “filters out 95% of non-oil-based airborne particles, including mold spores, when properly fitted.”

Consumer Product Safety Commission (CPSC)

Ensure the product meets flammability and material safety standards under CPSC regulations, particularly for textiles and components in direct facial contact. Report any defects or hazards immediately under the Consumer Product Safety Act.

Logistics and Distribution

Storage Conditions

Store Black Mold Masks in a dry, cool environment between 50°F and 85°F (10°C to 29°C). Protect from direct sunlight, moisture, and contaminants to preserve filtration material integrity. Avoid compression during storage to prevent deformation of the mask structure.

Packaging Requirements

Each mask should be individually sealed in tamper-evident packaging. Bulk packaging must be sturdy and moisture-resistant, clearly labeled with product name, model number, NIOSH approval (if applicable), lot number, and expiration date. Include multilingual instructions for use where required.

Transportation

Ship via ground or air freight using climate-controlled transport when possible. Ensure packages are stacked securely to avoid crushing. For international shipments, comply with IATA dangerous goods regulations only if components are classified as hazardous (typically not applicable for standard masks).

Inventory Management

Implement a FIFO (First In, First Out) inventory system to prevent distribution of expired units. Monitor shelf life—typically 3 to 5 years from manufacture date—and remove expired stock from circulation.

International Compliance

CE Marking and EU Regulations

For distribution in the European Union, the Black Mold Mask must comply with EU Personal Protective Equipment (PPE) Regulation (EU) 2016/425. It must undergo conformity assessment, be manufactured under a quality management system, and bear the CE mark. Classification under Category II or III depends on claimed protection levels.

Health Canada and Other Jurisdictions

In Canada, respirators are regulated under the Medical Devices Regulations if making health claims. Otherwise, ensure compliance with the Canadian General Standards Board (CGSB) for respirator performance. For other markets (e.g., Australia, UK, Japan), verify local PPE or consumer safety standards prior to import.

Documentation and Recordkeeping

Certifications and Test Reports

Maintain accessible copies of:

– NIOSH approval (if applicable)

– ISO 13485 (if applicable)

– Third-party filtration efficiency test results (e.g., NaCl aerosol testing per ISO 22609 or NIOSH 42 CFR Part 84)

– Biocompatibility reports (skin contact safety)

– Declaration of Conformity (CE Marking)

Batch Traceability

Assign unique lot numbers to each production batch. Record manufacturing dates, raw material sources, and quality control results. This enables efficient recall management if needed.

Recall and Incident Response

Establish a recall protocol in accordance with FDA, CPSC, or equivalent international bodies. In the event of product defects, contamination, or non-compliance, notify regulatory agencies within required timeframes (e.g., 10 days for CPSC). Provide clear instructions to distributors and consumers for returning affected units.

Conclusion

Proper logistics and regulatory compliance are critical for the safe and legal distribution of the Black Mold Mask. Regular audits, staff training, and staying updated on evolving regulations (e.g., EPA mold guidelines, OSHA updates) will ensure ongoing compliance and consumer trust.

Conclusion: Sourcing a Black Mold Mask

In conclusion, sourcing an appropriate mask for protection against black mold is a critical step in ensuring health and safety during mold remediation or exposure-prone environments. Not all masks offer sufficient protection—standard surgical or cloth masks are ineffective against mold spores. Instead, it is essential to source a respirator rated N95 or higher (such as N99, N100, P100) from NIOSH-approved manufacturers to effectively filter out hazardous mold particles. For prolonged or severe exposure, a full-face respirator with P100 filters may be necessary.

When sourcing, prioritize quality, certification, and proper fit. Purchase from reputable suppliers or safety equipment providers to avoid counterfeit products. Additionally, ensure the mask is used in conjunction with other protective gear—such as gloves, goggles, and protective clothing—for comprehensive protection.

Ultimately, investing in a high-quality, properly rated black mold mask is a crucial preventative measure that safeguards respiratory health and minimizes the risks associated with mold exposure.