The global air compressor market is experiencing robust expansion, driven by rising industrial automation, infrastructure development, and increasing demand across manufacturing, automotive, and construction sectors. According to Mordor Intelligence, the market was valued at USD 35.1 billion in 2023 and is projected to grow at a CAGR of 4.5% from 2024 to 2029. This growth trajectory underscores the critical importance of high-quality compressor components—especially for widely recognized models like the Black Max air compressor. As demand for reliable, efficient, and durable parts rises, a select group of manufacturers has emerged as leaders in producing compatible and original equipment components. These companies combine precision engineering, adherence to industry standards, and scalable production capabilities to meet the evolving needs of both OEMs and aftermarket suppliers. The following list highlights the top 8 manufacturers excelling in this niche, backed by innovation, supply chain resilience, and strong market presence.

Top 8 Black Max Air Compressor Parts Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 Compressor Parts – Authentic OEM Parts

Domain Est. 1995

Website: fix.com

Key Highlights: $12.99 delivery 365-day returnsShop for Compressor parts today! Find genuine OEM replacement parts along with expert repair help, video tutorials, and same–day shipping on Fix.com….

#2 WPI

Domain Est. 1996

Website: wpi.com

Key Highlights: We focus on selling and servicing compression and onshore drilling support equipment from leading manufacturers in the industry….

#3 Compressor Parts

Domain Est. 2004

Website: ereplacementparts.com

Key Highlights: 1–2 day deliveryShop for Compressor parts today! Find genuine OEM replacement parts along with expert repair help, video tutorials, and same–day shipping on ……

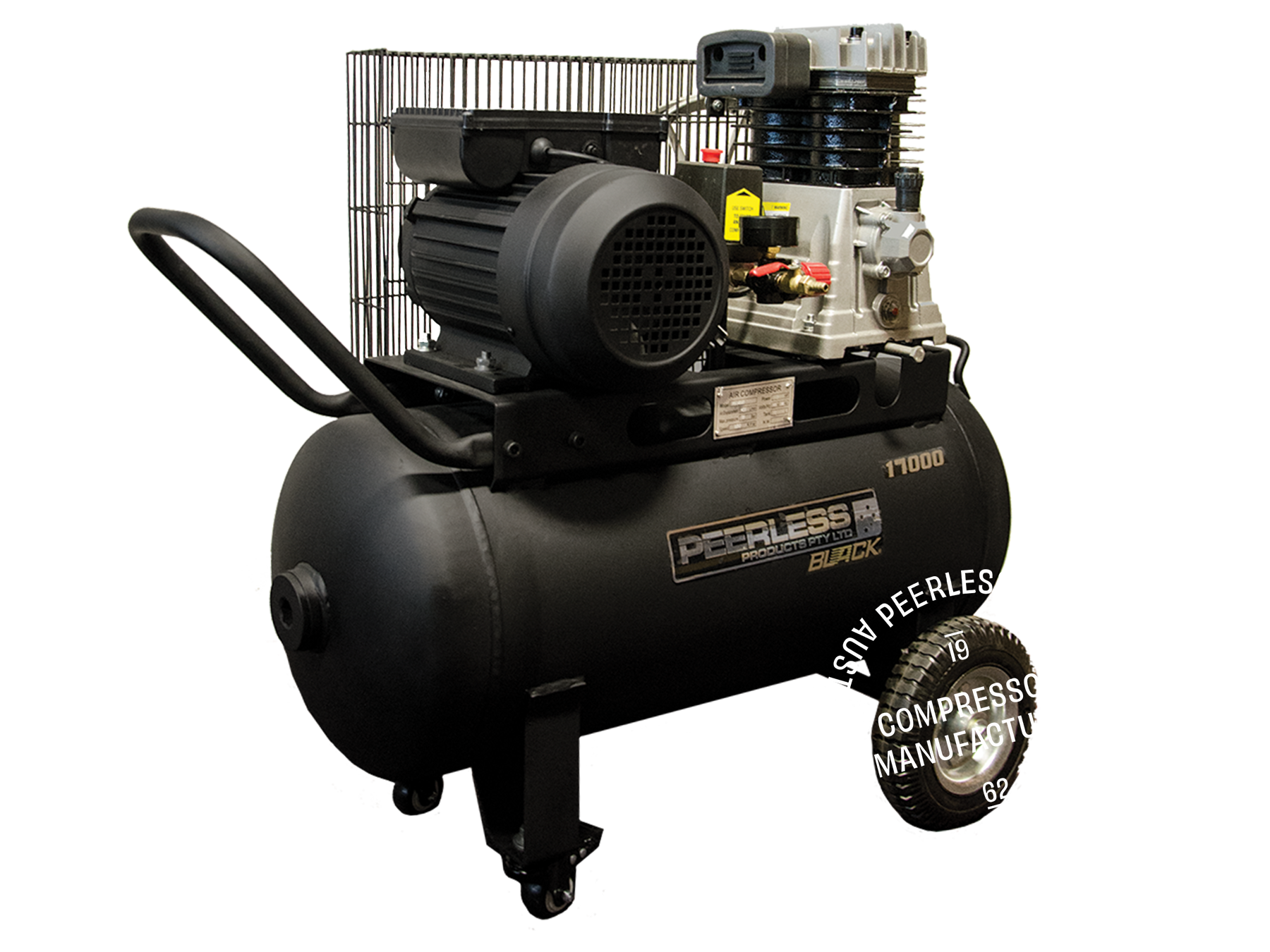

#4 Peerless Products

Website: peerlessproducts.com.au

Key Highlights: Australia’s leading compressor manufacturer. We Are Air. We never stop – and neither do our compressors. Buy online now….

#5 PowerMate Formerly Coleman Air Compressor Parts at Jack’s

Domain Est. 1997

Website: jackssmallengines.com

Key Highlights: Find all the PowerMate Formerly Coleman Air Compressor Parts and Accessories you need, with fast shipping and low prices!…

#6 Sanborn and Black Max Air Compressor Parts

Domain Est. 1999

Website: mastertoolrepair.com

Key Highlights: Shop Sanborn and Black Max air compressor parts at Master Tool Repair. Get pumps, gaskets, filters, schematics, repair tips, and how-to videos online….

#7 Air Compressors Direct

Domain Est. 2003

Website: aircompressorsdirect.com

Key Highlights: Air Compressors Direct is an online store, specializing in air compressors. Buy direct from an air compressor dealer. Free Shipping….

#8 SANBORN AIR COMPRESSOR PARTS

Website: arkansas-outdoor-power-equipment.myshopify.com

Key Highlights: We offer parts for Coleman Powermate air compressors built by Sanborn. We have a list of older Coleman Powermate air compressor parts manuals with parts ……

Expert Sourcing Insights for Black Max Air Compressor Parts

H2: 2026 Market Trends for Black Max Air Compressor Parts

The market for Black Max air compressor parts in 2026 is poised for notable transformation driven by evolving industrial demands, technological advancements, and shifting consumer preferences. As a recognized brand in the air compressor accessories and replacement components sector, Black Max is expected to encounter both opportunities and challenges in the coming years. Below are the key trends shaping the 2026 landscape:

-

Increased Demand for Durable, High-Performance Components

Industrial and commercial users continue to prioritize reliability and longevity in air compressor systems. Black Max parts—known for their robust construction—are anticipated to see rising demand, especially in manufacturing, automotive repair, and construction industries. As operational downtime becomes more costly, businesses are investing in premium-grade replacement parts, positioning Black Max favorably in the mid-to-high-end segment. -

Growth in E-Commerce and Direct-to-Consumer Sales

By 2026, online distribution channels are expected to dominate the sale of compressor parts. Black Max is likely to expand its presence on major e-commerce platforms (e.g., Amazon, eBay, and industrial supply websites) and enhance its direct-to-consumer website with improved product visualization, compatibility tools, and fast shipping. This shift caters to both DIY users and small businesses seeking convenience and competitive pricing. -

Focus on Compatibility and Universal Fit Solutions

With a fragmented market of compressor brands and models, Black Max is expected to emphasize universal-fit and cross-compatible parts—such as connectors, hoses, regulators, and pressure switches. This strategy reduces inventory complexity for distributors and increases accessibility for end-users, supporting broader market penetration. -

Rising Emphasis on Energy Efficiency and Sustainability

Regulatory pressures and environmental awareness are pushing industries toward energy-efficient operations. In response, Black Max may innovate parts that improve compressor efficiency—such as low-leakage fittings, precision pressure controls, and thermally efficient valves. While not a complete system manufacturer, enhancing part performance can contribute to overall system optimization. -

Expansion in Emerging Markets

Developing regions in Asia-Pacific, Latin America, and Africa are witnessing industrial growth and infrastructure development. This creates new demand for affordable yet reliable compressor components. Black Max could leverage cost-effective manufacturing and strategic partnerships to expand distribution in these markets by 2026. -

Competition from Generic and Private-Label Brands

The market faces growing competition from generic OEM alternatives and retailer-exclusive brands offering lower prices. To maintain its position, Black Max will need to reinforce its value proposition through quality assurance, warranties, and strong brand reputation. -

Integration with Smart Maintenance Systems

As predictive maintenance and IoT adoption grow, compressor parts with embedded sensors or compatibility with monitoring systems may become more prevalent. Although Black Max currently focuses on mechanical components, future iterations could include smart-ready parts that interface with digital maintenance platforms.

In conclusion, the 2026 market for Black Max air compressor parts will be shaped by a blend of performance expectations, digital sales transformation, and global market dynamics. By focusing on quality, compatibility, and strategic distribution, Black Max can strengthen its foothold in an increasingly competitive and tech-driven industry.

Common Pitfalls When Sourcing Black Max Air Compressor Parts: Quality and Intellectual Property Concerns

Logistics & Compliance Guide for Black Max Air Compressor Parts

This guide outlines the essential logistics and compliance considerations for the distribution, handling, and sale of Black Max Air Compressor Parts. Adhering to these guidelines ensures efficient operations, regulatory adherence, and customer satisfaction.

Product Classification and Identification

All Black Max Air Compressor Parts must be accurately classified using standardized nomenclature and identification systems. Each part should have a unique SKU or part number clearly labeled on packaging and in inventory systems. Ensure compatibility information (e.g., model numbers supported, dimensions, materials) is documented and readily accessible. Classify parts under appropriate Harmonized System (HS) codes for international trade purposes to facilitate customs clearance.

Packaging and Labeling Standards

Parts must be packaged to prevent damage during transit, using materials appropriate to weight, fragility, and environmental exposure. Inner packaging should prevent movement, while outer packaging must be durable. Labels must include the Black Max part number, product description, quantity, batch/lot number (if applicable), country of origin, and handling symbols (e.g., “Fragile,” “This Side Up”). For hazardous components (e.g., lubricants, adhesives), labeling must comply with GHS standards, including hazard pictograms and precautionary statements.

Shipping and Distribution Protocols

Shipments must be coordinated through approved carriers with proven reliability and tracking capabilities. Choose transport modes (ground, air, or sea) based on delivery timelines, cost, and part sensitivity. Maintain temperature control if required for certain components. Provide customers with tracking information and estimated delivery times. Implement a returns management process for defective or incorrect parts, including Return Merchandise Authorization (RMA) procedures and clear return shipping instructions.

Import and Export Compliance

Ensure all international shipments comply with destination country regulations. Verify export controls, especially if components contain dual-use technologies. Complete accurate commercial invoices, packing lists, and certificates of origin. Screen all parties (suppliers, distributors, end-customers) against denied persons lists (e.g., U.S. OFAC, EU Sanctions List). Obtain necessary export licenses where required. Retain all shipping and compliance documentation for a minimum of five years.

Regulatory and Safety Compliance

Black Max parts must meet applicable safety and performance standards in target markets, including but not limited to: CE marking (EU), UL or CSA certification (North America), and RoHS/REACH compliance for restricted substances. Maintain technical documentation and conformity assessments. Ensure that replacement parts meet or exceed OEM specifications to maintain equipment safety and performance. Any electrical or pressure-rated components must be validated by accredited testing bodies.

Inventory Management and Traceability

Implement a robust inventory management system to track stock levels, turnover rates, and shelf life (if applicable). Use barcode or RFID technology for accurate tracking from warehouse to delivery. Maintain traceability records linking parts to batch numbers, suppliers, and distribution points to support recalls or quality investigations. Conduct regular cycle counts and audits to ensure data accuracy.

Environmental and Sustainability Practices

Adopt environmentally responsible logistics practices, including minimizing packaging waste, using recyclable materials, and optimizing shipping routes to reduce carbon emissions. Comply with WEEE (Waste Electrical and Electronic Equipment) directives where applicable for end-of-life part disposal. Partner with certified e-waste recyclers for returned or obsolete components.

Training and Documentation

Provide regular training for logistics and warehouse staff on handling procedures, safety protocols, and compliance requirements. Maintain up-to-date Standard Operating Procedures (SOPs) for all logistics activities. Ensure all compliance documentation, including safety data sheets (SDS), certificates of conformity, and audit reports, is centralized and accessible to authorized personnel.

Audit and Continuous Improvement

Conduct periodic internal audits of logistics and compliance processes. Address non-conformances promptly and implement corrective actions. Solicit feedback from customers and partners to improve service and adherence to compliance standards. Stay informed on changes in trade regulations, environmental laws, and industry best practices to ensure ongoing compliance.

In conclusion, sourcing parts for a Black Max air compressor requires careful consideration of compatibility, quality, and reliability. Due to the fact that Black Max is often associated with compressor components rather than a standalone brand, it’s essential to identify the correct manufacturer or model specifications—such as pancake or hot dog-style compressors—often branded by companies like Campbell Hausfeld or sold under store labels. To ensure proper fit and function, cross-referencing part numbers, consulting OEM manuals, and purchasing from reputable suppliers or authorized dealers is highly recommended. Online marketplaces, specialty tool retailers, and manufacturer support channels can be valuable resources. Ultimately, selecting high-quality, compatible parts not only extends the lifespan of the compressor but also ensures safe and efficient operation, making informed sourcing a critical step in maintaining peak performance.