The global building materials market is undergoing a transformative shift driven by sustainability demands, urbanization, and rising construction activity—trends that are fueling innovation among niche manufacturers like those specializing in bison-based or Bison-branded products. While “Bison” may refer to a brand (such as Bison Wallboard or Bison Manufacturing in construction sectors) rather than the animal in this context, companies under the Bison umbrella have emerged as key players in specialty building materials, particularly in wall systems and insulation solutions. According to Grand View Research, the global building materials market was valued at USD 1.4 trillion in 2023 and is projected to grow at a compound annual growth rate (CAGR) of 6.3% from 2024 to 2030. Mordor Intelligence further supports this trajectory, estimating a CAGR of over 5.8% during the forecast period of 2024–2029. This growth is propelled by increased infrastructure spending, energy efficiency regulations, and demand for durable, non-combustible materials—areas where Bison-affiliated manufacturers have strategically positioned themselves. In this data-driven landscape, we highlight the top 8 Bison-associated building materials manufacturers that are leveraging market momentum, technological innovation, and sustainable practices to lead in performance and market reach.

Top 8 Bison Building Materials Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 Trusted sports & athletic equipment manufacturer

Domain Est. 1996

Website: bisoninc.com

Key Highlights: Bison Inc. delivers durable athletic equipment and sporting goods for schools, gyms, and parks. Explore our lineup and connect with a dealer near you….

#2 Bison Panel: Buy Sound Proof Board

Domain Est. 2002

Website: bisonpanel.com

Key Highlights: Building Board Manufacturer. Home · About Us; Products. Bison Panel Plain Board · Bison Lam · Bison Designer Board · Bison Plank. Applications….

#3 Bison

Domain Est. 1996

Website: bison.net

Key Highlights: To glue or seal all kinds of materials, Bison products offer the best solution. At home, in the office, at school and of course when doing odd jobs….

#4 Bison Steel Buildings

Domain Est. 2003

Website: bisonsteel.com

Key Highlights: Bison Steel Buildings are 100% manufactured in the United States, with a 50 year structural warranty. Recognized as the industry leader….

#5 Bison Innovative Products

Domain Est. 2009

Website: bisonip.com

Key Highlights: Bison Innovative Products leads the industry in designing & manufacturing pedestals, pavers, and site furnishings used to create unique rooftop decks….

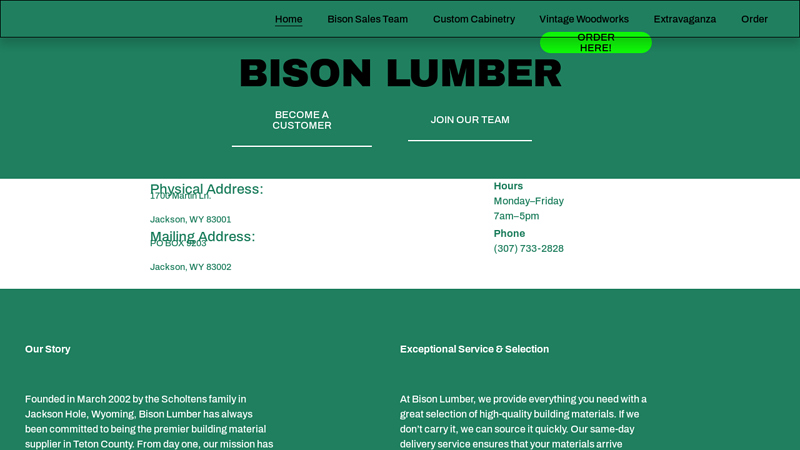

#6 Bison Lumber

Domain Est. 2009

Website: bisonlumber.net

Key Highlights: Founded in March 2002 by the Scholtens family in Jackson Hole, Wyoming, Bison Lumber has always been committed to being the premier building material supplier ……

#7 Bison Building Solutions

Domain Est. 2016

Website: bisonbuildingsolutions.com

Key Highlights: Bison Building Solutions provides a wide array of finish materials from cabinetry and flooring to fireplaces and decking nationwide….

#8 Bison Biocomposites: Sustainable Building Materials

Domain Est. 2024

Website: bisonbiocomposites.com

Key Highlights: Bison Biocomposites is on a mission to become the leader in developing sustainable building materials for the construction industry….

Expert Sourcing Insights for Bison Building Materials

H2: 2026 Market Trends Outlook for Bison Building Materials

As the global construction and building materials sector evolves through 2026, Bison Building Materials is poised to navigate a dynamic landscape shaped by technological innovation, sustainability mandates, shifting consumer preferences, and evolving supply chain dynamics. The following analysis outlines key market trends expected to influence Bison Building Materials’ strategic positioning and performance in 2026.

1. Accelerated Demand for Sustainable and Low-Carbon Materials

Environmental regulations and green building certifications (e.g., LEED, BREEAM) are driving demand for eco-conscious construction solutions. By 2026, Bison is expected to face increased pressure—and opportunity—to expand its portfolio of low-carbon concrete and recycled-content products. With governments enforcing stricter emissions standards (e.g., EU Green Deal, U.S. Buy Clean Initiative), Bison’s investments in carbon capture, alternative binders (like geopolymers), and energy-efficient production will be critical differentiators.

2. Growth in Residential and Infrastructure Spending

Global infrastructure modernization programs—particularly in North America and emerging markets—are expected to boost demand for durable building materials. The U.S. Infrastructure Investment and Jobs Act and similar initiatives in Canada and Europe will stimulate public-sector construction, benefiting Bison’s precast concrete and masonry product lines. Additionally, housing shortages in urban centers will continue to fuel residential development, supporting steady demand for Bison’s ready-mix and wall systems.

3. Digitalization and Smart Construction Integration

By 2026, digital tools such as Building Information Modeling (BIM), IoT-enabled materials tracking, and AI-driven supply chain optimization will be standard in construction. Bison can leverage these technologies to improve project coordination, reduce waste, and offer value-added services like just-in-time delivery and performance data transparency. Customers will increasingly favor suppliers that integrate digital workflows, giving Bison a competitive edge if it enhances its tech-enabled service offerings.

4. Supply Chain Resilience and Localization

Ongoing geopolitical tensions and logistical disruptions have underscored the need for resilient, localized supply chains. By 2026, Bison is likely to see greater emphasis on regional manufacturing hubs to reduce dependency on imported raw materials and mitigate transportation costs. Strengthening local sourcing of aggregates and cementitious materials will enhance Bison’s agility and responsiveness to regional market fluctuations.

5. Labor Shortages and Demand for Prefabrication

The construction industry continues to grapple with skilled labor shortages. This trend is accelerating the adoption of off-site prefabrication and modular construction—areas where Bison’s precast concrete solutions excel. In 2026, Bison is well-positioned to capitalize on this shift by marketing its products as labor-efficient, quality-controlled, and faster to install, aligning with developers’ needs for speed-to-market.

6. Competitive Pressure and Market Consolidation

The building materials sector is experiencing consolidation, with larger players acquiring niche innovators to expand sustainable portfolios. Bison may face intensified competition from both multinational firms and agile startups offering alternative materials (e.g., mass timber, 3D-printed concrete). To maintain market share, Bison should consider strategic partnerships, innovation in product design, and brand positioning around durability and lifecycle value.

Conclusion

In 2026, Bison Building Materials will operate in a market defined by sustainability, digital transformation, and operational efficiency. Success will depend on its ability to innovate sustainably, adapt to regulatory changes, leverage technology, and meet the growing demand for resilient and efficient construction solutions. By proactively aligning with these macro trends, Bison can strengthen its market leadership and deliver long-term value across residential, commercial, and infrastructure sectors.

Common Pitfalls When Sourcing Bison Building Materials (Quality, IP)

Sourcing Bison building materials—whether referring to products from the brand Bison (such as Bison Wallboard, Bison Board, or related construction materials) or metaphorically to robust, heavy-duty materials—can present several challenges, particularly concerning quality control and intellectual property (IP) risks. Being aware of these pitfalls helps ensure reliable supply chains and legal compliance.

Quality Inconsistencies

One of the most frequent issues when sourcing Bison building materials is inconsistent product quality. This can stem from:

- Unverified Suppliers: Third-party vendors may claim to offer genuine Bison products but deliver substandard or counterfeit materials that do not meet required fire, moisture, or structural resistance standards.

- Batch Variability: Even authorized distributors may supply materials with inconsistent density, thickness, or bonding integrity, especially if inventory comes from different manufacturing batches or regions.

- Lack of Certifications: Failure to provide valid CE marking, BBA (British Board of Agrément) certification, or fire safety test reports can indicate poor quality control.

To mitigate this, always verify supplier credentials, request material test reports, and conduct on-site or third-party quality inspections.

Intellectual Property Infringement Risks

Sourcing Bison materials also carries potential IP concerns, particularly when dealing with off-brand or generic alternatives:

- Counterfeit Products: Some suppliers may imitate the branding, packaging, or product names of Bison materials (e.g., “Bison-style” boards) to mislead buyers. This violates trademark laws and can expose the buyer to legal liability.

- Unauthorized Manufacturing: Certain overseas manufacturers produce look-alike products using similar compositions, potentially infringing on patented formulations or registered designs protected by Bison’s IP portfolio.

- Grey Market Goods: Importing genuine Bison products through unauthorized channels may violate distribution agreements and void warranties, raising IP and contractual issues.

To avoid IP pitfalls, ensure suppliers are authorized distributors, conduct due diligence on product provenance, and include IP indemnity clauses in procurement contracts.

Conclusion

Sourcing Bison building materials requires careful vetting to avoid quality defects and IP violations. Partnering with certified suppliers, demanding compliance documentation, and staying informed about trademark and patent protections are essential steps for risk mitigation.

Logistics & Compliance Guide for Bison Building Materials

This guide outlines the essential logistics and compliance protocols for Bison Building Materials to ensure efficient operations, regulatory adherence, and product integrity across the supply chain.

Order Processing & Documentation

All orders must be entered into the Bison Logistics Management System (BLMS) within one business day of receipt. Required documentation includes a completed purchase order, customer account verification, and approved credit terms. Export orders require additional documentation, including commercial invoices, packing lists, and certificates of origin, all compliant with destination country regulations.

Transportation & Carrier Management

Shipments must be dispatched via approved carriers with verifiable safety records and appropriate equipment for building materials (e.g., flatbeds for lumber, enclosed trailers for drywall). Temperature-sensitive products must be handled per manufacturer specifications. Real-time tracking is mandatory for all shipments exceeding $10,000 in value. Carriers must comply with FMCSA regulations and provide proof of insurance.

Inventory Management & Warehousing

Inventory must be stored in designated, weather-protected areas with proper stacking and labeling per OSHA standards. High-turnover items should be placed in easily accessible zones to minimize handling time. Weekly cycle counts are required, with a full physical inventory audit conducted quarterly. Any discrepancies must be reported to the Logistics Manager within 24 hours.

Health, Safety, and Environmental Compliance

All warehouse and yard personnel must complete OSHA 10-Hour General Industry training annually. Personal protective equipment (PPE), including hard hats, safety vests, and steel-toed boots, is mandatory in operational areas. Spill response kits must be available and inspected monthly. Hazardous materials (e.g., adhesives, sealants) must be stored in compliant containment areas with SDS documentation readily accessible.

Regulatory Compliance

Bison Building Materials must adhere to all applicable federal, state, and local regulations, including but not limited to:

– DOT regulations for hazardous materials transport (49 CFR)

– EPA guidelines for waste disposal and emissions

– Customs-Trade Partnership Against Terrorism (C-TPAT) standards for international shipments

– ADA compliance for facility access

Compliance audits are conducted biannually by the Legal & Risk team.

Import/Export Procedures

For international shipments, all documentation must be verified by the Trade Compliance Officer prior to dispatch. Products must meet destination country building codes and labeling requirements (e.g., CE marking, NIST compliance). Restricted party screening is mandatory for all foreign entities. Incoterms must be clearly defined in all contracts (e.g., FOB, EXW).

Customer Delivery & Proof of Delivery

Drivers must inspect loads before departure and obtain a signed Proof of Delivery (POD) upon completion. PODs must be uploaded to BLMS within 24 hours. Deliveries to construction sites require coordination with site supervisors to ensure safe unloading and compliance with site-specific safety rules.

Incident Reporting & Corrective Actions

All incidents—including damage, delays, safety violations, or compliance breaches—must be reported via the Incident Reporting Portal within four hours. A root cause analysis will be conducted within 48 hours, and corrective actions implemented within one week. Records must be retained for a minimum of seven years.

Training & Continuous Improvement

All logistics and warehouse staff must complete compliance training annually. Quarterly reviews of logistics performance metrics (on-time delivery rate, damage rate, inventory accuracy) will inform process improvements. Feedback from customers and carriers is collected semi-annually to refine service delivery.

In conclusion, sourcing bison-based building materials—while not common in modern construction—can refer either to historical or niche sustainable practices involving bison hides, bones, or byproducts, or more likely reflects a misunderstanding or metaphor related to natural, locally sourced, or alternative eco-friendly materials. If interpreted symbolically, it underscores the broader principle of using regionally available, renewable, and low-impact resources in construction. However, in practical contemporary building, materials like timber, bamboo, rammed earth, or recycled composites are more viable and ethical options. Ultimately, sustainable sourcing should prioritize environmental responsibility, durability, and respect for ecological balance—principles that align with the historical resourcefulness of utilizing natural materials, without relying on non-traditional or potentially unethical sources like bison. Future efforts should focus on innovation in green building materials that honor sustainability without compromising conservation or animal welfare.