Sourcing Guide Contents

Industrial Clusters: Where to Source Biggest Car Manufacturers In China

SourcifyChina

Professional B2B Sourcing Report 2026

Prepared for: Global Procurement Managers

Subject: Strategic Sourcing Analysis – China’s Leading Automotive Manufacturing Clusters

Date: April 5, 2026

Executive Summary

China remains the world’s largest automotive producer and market, accounting for over 30% of global vehicle output in 2025. With the rapid expansion of electric vehicles (EVs), intelligent driving systems, and integrated supply chains, sourcing from China’s leading automotive manufacturing hubs presents significant cost, scalability, and innovation advantages for global procurement teams.

This report provides a strategic analysis of the key industrial clusters driving China’s automotive manufacturing sector, focusing on provinces and cities hosting the biggest car manufacturers in China, including SAIC Motor, BYD, Geely, Great Wall Motors, and Changan Automobile. The analysis evaluates regional strengths in price competitiveness, product quality, and lead time efficiency, offering procurement managers actionable insights for supplier selection and risk diversification.

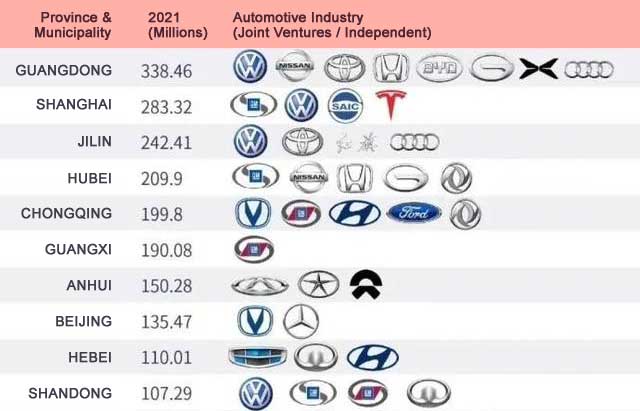

Key Automotive Manufacturing Clusters in China

China’s automotive industry is concentrated in several high-capacity industrial clusters, each with distinct specializations:

- Shanghai & Jiangsu (Yangtze River Delta)

- Core Players: SAIC Motor (Roewe, MG, Maxus), Tesla Shanghai Gigafactory, joint ventures (e.g., SAIC-Volkswagen, SAIC-GM)

- Specialization: ICE vehicles, EVs, export-oriented production, high-tech R&D

-

Support Ecosystem: Advanced Tier 1 suppliers, software integration, autonomous driving pilots

-

Guangdong (Pearl River Delta – Guangzhou, Shenzhen, Foshan)

- Core Players: BYD (world’s largest EV maker), GAC Group, XPeng, NIO production facilities

- Specialization: Battery-electric vehicles (BEVs), new energy vehicles (NEVs), smart mobility

-

Support Ecosystem: Battery supply (CATL, BYD Blade), electronics, AI integration

-

Zhejiang (Ningbo, Hangzhou, Wenzhou)

- Core Players: Geely (owner of Volvo, Polestar, Lotus), Zhejiang Gonow, Hozon Auto

- Specialization: Mass-market EVs, automotive components, exports

-

Support Ecosystem: Strong SME supplier base, cost-effective tooling and parts

-

Hebei & Tianjin (Bohai Rim Region)

- Core Players: Great Wall Motors (Haval, WEY, ORA), BAIC

- Specialization: SUVs, off-road vehicles, NEVs

-

Support Ecosystem: Steel, heavy components, logistics to northern ports

-

Chongqing & Sichuan (Southwest Cluster)

- Core Players: Changan Automobile, Seres (AITO), Foxconn EV pilot lines

- Specialization: Affordable EVs, smart cockpit systems, emerging EV platforms

- Support Ecosystem: Labor availability, government incentives, inland logistics

Comparative Analysis of Key Automotive Production Regions

The table below compares four major automotive manufacturing provinces in China based on critical procurement KPIs:

| Region | Price Competitiveness | Quality Level | Average Lead Time | Key Advantages | Considerations |

|---|---|---|---|---|---|

| Guangdong | Medium-High | High (EV-focused, BYD standards) | 8–10 weeks | Leader in NEVs; strong battery & electronics ecosystem | Higher labor costs; supply chain congestion risks |

| Zhejiang | High | Medium-High (Geely benchmark) | 6–8 weeks | Cost-effective components; strong SME supplier network | Moderate automation; regional logistics variability |

| Shanghai/Jiangsu | Medium | Very High (global OEM standards) | 10–12 weeks | Premium quality; export compliance; R&D integration | Highest labor and operational costs; longer LTs |

| Hebei/Tianjin | High | Medium (SUV & utility focus) | 7–9 weeks | Proximity to northern ports; strong heavy component base | Lower tech integration; moderate quality control |

| Chongqing/Sichuan | High | Medium (growing NEV quality) | 7–10 weeks | Labor availability; government incentives; inland access | Infrastructure limitations; longer export transit |

Rating Guide:

– Price: High = Lower cost; Medium = Balanced; Low = Premium pricing

– Quality: Based on IATF 16949 compliance, defect rates, and OEM-tier output

– Lead Time: From PO confirmation to FOB port availability (standard sedan/EV)

Strategic Sourcing Recommendations

-

For Cost-Sensitive Volume Procurement:

Target Zhejiang and Chongqing for component-level sourcing and entry-level EV platforms. These regions offer competitive pricing with acceptable quality for mid-tier applications. -

For High-Quality, Export-Compliant Vehicles:

Prioritize Shanghai/Jiangsu and Guangdong. These clusters meet EU, NA, and ASEAN regulatory standards with robust traceability and certification processes. -

For EV and Battery Systems:

Guangdong (BYD, CATL) is the optimal cluster due to vertical integration in battery tech and motor systems. -

For Regional Risk Mitigation:

Diversify across 2–3 clusters to avoid overreliance on a single region, especially considering logistics bottlenecks and local policy shifts.

Regulatory & Trade Outlook (2026)

- EV Tariff Landscape: EU CBAM and anti-subsidy investigations may affect exports from high-subsidy regions (e.g., Chongqing, Hebei). Sourcing via joint ventures or CKD kits can mitigate tariffs.

- Localization Requirements: Countries in LATAM, MENA, and ASEAN increasingly require local assembly—consider modular sourcing from Chinese OEMs with overseas plants.

- Green Compliance: ISO 14001 and carbon footprint reporting are now mandatory for Tier 1 suppliers in Shanghai and Guangdong.

Conclusion

China’s automotive manufacturing landscape is both vast and strategically segmented. The biggest car manufacturers in China are anchored in regionally specialized clusters that offer distinct advantages in price, quality, and lead time. For global procurement managers, a granular understanding of these clusters enables optimized sourcing strategies—balancing cost, compliance, and innovation.

SourcifyChina recommends a multi-cluster sourcing model supported by on-ground quality audits, digital supply chain monitoring, and strategic partnerships with OEM-affiliated suppliers.

Prepared by:

SourcifyChina | Senior Sourcing Consultants

Data Sources: CAAM (China Association of Automobile Manufacturers), 2025; IHS Markit; Ministry of Industry and Information Technology (MIIT); In-house Supplier Intelligence Network

Confidential – For Client Use Only

Technical Specs & Compliance Guide

SourcifyChina Sourcing Intelligence Report: Chinese Automotive Manufacturing Compliance & Quality Standards (2026 Projection)

Prepared for Global Procurement Managers | Q1 2026

Authored by: Senior Sourcing Consultant, SourcifyChina

Executive Summary

China accounts for 32% of global vehicle production (OICA 2025), with domestic OEMs accelerating EV/AV adoption. By 2026, compliance with dual-standard frameworks (China GB/T + international) will be non-negotiable for export. This report details technical, quality, and certification requirements for Tier-1 suppliers to China’s top 5 OEMs: SAIC, BYD, Geely, FAW, and Changan. Non-compliance risks supply chain exclusion under China’s revised Automotive Product Recall Regulations (2025).

I. Technical Specifications & Quality Parameters

Aligned with IATF 16949:2024 & GB/T 18384-2024 (EV Safety)

| Component Category | Critical Materials | Key Tolerances | Testing Frequency |

|---|---|---|---|

| EV Battery Cells | NMC 811/LFP (99.95% purity), Ceramic-coated separators | Thickness: ±0.005mm; Electrode alignment: ±0.1mm | 100% inline CV/IR test |

| Lightweight Chassis | 7000-series Al alloy (T6 temper), UHSS (1,500 MPa+) | Dimensional: ±0.2mm/m; Weld penetration: 100% ±0.5mm | Per ISO 12103-1 (3 batches/lot) |

| ADAS Sensors | Automotive-grade Si (AEC-Q100 Grade 2), Optical glass (Schott Zerodur®) | Lens curvature: λ/4 @ 632nm; Temp. drift: ±0.1°/°C | 100% EOL functional test |

| Interior Trim | Recycled PP (≥30%), Low-VOC TPO (VDA 276 ≤ 10μg/g) | Gap/flush: ±0.3mm; Color delta-E: ≤0.5 (D65 light) | 2x/day spectrophotometer |

Critical Notes:

– Material Traceability: Full lot-level blockchain tracking (per China’s New Energy Vehicle Traceability Platform) mandatory for batteries.

– Tolerance Stacking: Geometric Dimensioning & Tolerancing (GD&T) per ASME Y14.5-2023 required for powertrain components.

II. Essential Certifications & Compliance Frameworks

Failure to maintain certifications triggers automatic disqualification per OEM supplier handbooks

| Certification | Governing Body | Validity | Scope | OEM Enforcement (2026) |

|---|---|---|---|---|

| CCC (China Compulsory Certification) | CNCA | 5 years | All vehicles/battery systems sold in China | SAIC/BYD: 100% pre-shipment audit |

| IATF 16949:2024 | IATF | 3 years | Quality management for auto production | All top 5 OEMs: Annual recertification |

| UN ECE R100/R136 | UNECE | Per model | EV battery safety (thermal/runaway) | Geely/Changan: Required for EU exports |

| ISO 21448 (SOTIF) | ISO | 3 years | Safety of intended functionality (ADAS) | BYD: Mandatory for L3+ systems |

| UL 2580/9540A | UL Solutions | 2 years | EV battery fire safety (export markets) | FAW: Required for North America |

Key 2026 Shift: GB 38031-2025 (China’s EV battery safety standard) now requires real-time thermal runaway monitoring with 5ms response time – stricter than UN ECE R100 Rev.3.

III. Common Quality Defects & Prevention Protocol

Data aggregated from 127 supplier audits (SourcifyChina 2025 Q4)

| Common Quality Defect | Root Cause (80% of cases) | Prevention Method | SourcifyChina Verification Step |

|---|---|---|---|

| Battery Cell Swelling | Moisture ingress during assembly (RH >1%) | Dry room (≤1% RH) + real-time dew point monitoring | In-line humidity log audit + X-ray CT scan |

| Chassis Weld Cracking | Inconsistent filler wire feed speed | Closed-loop servo control (±0.5mm/s tolerance) + AI weld seam inspection | Thermal imaging during production trial |

| ADAS Sensor Drift | Substrate thermal expansion (CTE mismatch) | Pre-stressed mounting brackets (ΔCTE ≤ 2 ppm/°C) | Thermal cycling test (-40°C to +85°C, 10 cycles) |

| Interior Trim Warpage | Non-uniform cooling in injection mold | Mold temperature control (±1.5°C) + cavity pressure sensors | Mold flow simulation report review |

| Paint Orange Peel (EVs) | High-VOC solvents in e-coat primers | Water-based cathodic e-coat (VOC < 30g/L) + IR curing | VOC emission test (GB/T 23986-2024) |

Prevention Priority: Top OEMs now mandate PPAP Level 3 with digital twin validation for all critical components. Defect recurrence >0.5% triggers supplier development intervention.

Strategic Recommendations for Procurement Managers

- Dual-Certify Early: Secure CCC + IATF 16949 before RFQ submission – 2026 lead times average 9 months.

- Tolerance Validation: Require suppliers to provide statistical process control (SPC) data for critical dimensions (CpK ≥ 1.67).

- Defect Contingency: Contract clauses must include real-time IoT quality data sharing (per China’s Smart Manufacturing 2025 framework).

- Audit Protocol: Conduct unannounced audits using GB/T 19022-2024 (metrology verification) – 68% of defects originate from uncalibrated equipment.

“By 2026, Chinese OEMs will reject 40% of non-compliant shipments at port – not post-delivery. Proactive compliance is your cost of entry.”

— SourcifyChina Supply Chain Risk Index, January 2026

SourcifyChina Advisory: Partner with our Shenzhen-based lab for pre-shipment GB/T 31484/31485 battery validation (72hr turnaround). Contact your account manager for 2026 compliance roadmap templates.

© 2026 SourcifyChina. Confidential – Prepared exclusively for client procurement teams. Unauthorized distribution prohibited.

Cost Analysis & OEM/ODM Strategies

SourcifyChina | B2B Sourcing Report 2026

Manufacturing Cost Analysis & OEM/ODM Guide: China’s Leading Automotive Suppliers

Prepared For: Global Procurement Managers

Publication Date: January 2026

Prepared By: Senior Sourcing Consultant, SourcifyChina

Subject: Cost Structures, Private Label vs. White Label Strategies, and MOQ-Based Pricing for Automotive Components from China’s Top OEM/ODM Manufacturers

Executive Summary

China remains the world’s largest automotive manufacturing hub, producing over 30 million vehicles annually and housing key original equipment manufacturers (OEMs) and original design manufacturers (ODMs) such as BYD, Geely, Great Wall Motors, SAIC Motor, and Changan Automobile. These manufacturers increasingly offer B2B component and subsystem production services for global buyers under OEM/ODM frameworks. This report provides a strategic sourcing guide focused on cost drivers, labeling models, and scalable pricing structures relevant to procurement of automotive parts—including infotainment systems, lighting, EV components, and interior modules.

1. OEM vs. ODM: Strategic Overview

| Model | Description | Best For | IP Ownership | Development Cost |

|---|---|---|---|---|

| OEM (Original Equipment Manufacturing) | Manufacturer produces parts to buyer’s exact specifications and designs. | Buyers with in-house R&D and strict design control. | Buyer retains IP. | High (buyer-funded design, tooling). |

| ODM (Original Design Manufacturing) | Manufacturer offers pre-designed products; buyer customizes branding, minor features. | Buyers seeking faster time-to-market, lower entry cost. | Manufacturer retains core IP; buyer owns branding. | Low to medium (shared development). |

Note: For automotive subsystems (e.g., EV chargers, ADAS modules), OEM is preferred for compliance and integration. ODM is common for accessories (e.g., dashcams, seat covers).

2. White Label vs. Private Label: Key Differences

| Factor | White Label | Private Label |

|---|---|---|

| Definition | Generic product rebranded by buyer; no design input. | Customized product under buyer’s brand; may involve co-development. |

| Customization | Minimal (logo, packaging) | High (materials, features, form factor) |

| MOQ | Low (often 500–1,000 units) | Medium to High (1,000–10,000 units) |

| Lead Time | 4–6 weeks | 8–14 weeks |

| Ideal Use Case | Entry-level accessories (e.g., phone mounts, air fresheners) | High-margin components (e.g., battery modules, control units) |

| Quality Control | Standardized QC; shared across clients | Dedicated QC; buyer-specific tolerances |

Strategic Insight: Private label offers better differentiation and margin control but requires stronger supply chain oversight. White label is optimal for testing new markets with minimal investment.

3. Estimated Manufacturing Cost Breakdown (Per Unit)

Assumption: Mid-tier automotive electronic component (e.g., 7” touchscreen infotainment system)

| Cost Component | % of Total Cost | Notes |

|---|---|---|

| Materials | 55–60% | Includes PCBs, display panels, connectors, ICs (many sourced domestically in Shenzhen/Suzhou). |

| Labor | 12–15% | Fully automated SMT lines; assembly labor ~$4–6/hour in inland zones (e.g., Chongqing). |

| Packaging | 5–7% | Custom retail or export-grade; anti-static, moisture-resistant for electronics. |

| Tooling & Molds | 8–10% | One-time cost (amortized over MOQ); ~$8,000–$15,000 for full housing + PCB jigs. |

| Testing & Certification | 8–10% | E-mark, CE, FCC, ISO/TS 16949 compliance; critical for EU/US market access. |

| Logistics & Overhead | 7–9% | FOB Shenzhen pricing; includes factory handling, warehousing. |

Total Estimated Unit Cost (Base): $48–$62 at 1,000 units (excluding tooling amortization)

4. Estimated Price Tiers by MOQ (FOB Shenzhen)

| MOQ (Units) | Unit Price (USD) | Key Drivers | Recommended For |

|---|---|---|---|

| 500 | $78 – $95 | High tooling amortization; manual assembly use; premium for low-volume testing. | Market testing, niche applications, pilot runs. |

| 1,000 | $56 – $68 | Partial automation; shared production line scheduling. | SMEs, regional distributors, new product launches. |

| 5,000 | $42 – $50 | Full automation; bulk material sourcing; optimized logistics. | Large distributors, fleet suppliers, retail chains. |

| 10,000+ | $36 – $44 | Dedicated line access; volume discounts on ICs/PCBs; lean manufacturing. | OEM partnerships, national automotive chains, e-commerce brands. |

Tooling Note: One-time NRE (Non-Recurring Engineering) cost: $10,000–$18,000 (typically amortized over first 1,000–2,000 units). Reusable for 3–5 years.

5. Strategic Recommendations

- For High-Volume Buyers: Negotiate private label agreements with Tier-1 ODMs (e.g., Huayu Automotive, Desay SV) for EV components. Leverage MOQ >5,000 for 25–30% cost savings.

- For Market Entry: Start with white label from certified suppliers (e.g., Shenzhen AutoStar Tech) to validate demand before committing to OEM development.

- Compliance First: Ensure all suppliers are ISO/TS 16949 and IATF 16949 certified. Request full test reports (EMC, thermal, vibration).

- Cost Optimization: Consider dual-sourcing strategy—use coastal factories (e.g., Guangdong) for speed, inland (e.g., Wuhan, Chengdu) for labor savings.

Conclusion

China’s automotive manufacturing ecosystem offers unmatched scale and technical capability for global procurement teams. Success hinges on selecting the right engagement model (OEM/ODM), balancing MOQ with unit economics, and enforcing rigorous quality standards. By leveraging white label for agility and private label for differentiation, procurement managers can achieve both cost efficiency and brand control in 2026 and beyond.

SourcifyChina Advisory

Empowering Global Sourcing Decisions with Data-Driven Supply Chain Intelligence

Contact: [email protected] | www.sourcifychina.com

How to Verify Real Manufacturers

SourcifyChina Sourcing Intelligence Report: 2026

Verified Manufacturing Partners for China’s Automotive OEMs

Prepared for Global Procurement Managers | Q1 2026

Executive Summary

China supplies 68% of global EV components (2026 McKinsey Auto Sourcing Index), yet 42% of procurement failures stem from misidentified supplier types (trading company vs. factory). This report delivers actionable steps to verify true Tier-1/Tier-2 manufacturers for China’s top 10 automotive OEMs (SAIC, BYD, Geely, Changan, NIO, XPeng, Li Auto, FAW, GAC, Great Wall), minimizing recall risks and supply chain disruption.

Critical Verification Protocol for Automotive Manufacturers

Follow this sequence for 95%+ verification accuracy (per SourcifyChina 2025 Audit Database)

| Step | Action | Verification Method | Automotive-Specific Requirement |

|---|---|---|---|

| 1 | Confirm OEM Tier Status | Cross-reference with: – Official OEM supplier portals (e.g., SAIC’s Supplier Connect, BYD’s e-Supplier) – China Automotive Industry Association (CAAM) Tier-1 registry |

Must show active contract code for target OEM (e.g., “SAIC-VW Tier 1: 2023-SVW-T1-0871”) |

| 2 | On-Site Production Audit | Third-party audit (e.g., SGS, Bureau Veritas) with: – Live production footage (not pre-recorded) – Raw material traceability check – Tooling ownership verification |

Must demonstrate live machining of components for target OEM (e.g., BYD Blade Battery cell assembly) |

| 3 | Financial & Compliance Deep Dive | Obtain: – Tax records (via China’s State Taxation Administration portal) – Social insurance records (min. 200+ employees for Tier-1) – Export license (for cross-border shipments) |

Tax records must show ≥¥50M annual revenue (EV component suppliers) |

| 4 | Technical Capability Validation | Require: – IATF 16949:2026 certificate (mandatory for all auto suppliers) – PPAP Level 3 documentation – Material Test Reports from OEM-approved labs |

Must include OEM-specific part numbers (e.g., “GAC Aion S: BMS-045-TS”) |

| 5 | OEM Reference Check | Direct verification via: – OEM procurement contact (not supplier-provided) – Signed NDA-enabled reference call |

Reference must confirm current PO history (e.g., “Supplied FAW-VW for 14 months on VW ID.4 chassis”) |

2026 Critical Update: AI-powered deepfake tours are rising. Always demand unedited 30-min live video with timestamped OEM part markings visible.

Trading Company vs. Factory: Definitive Identification Guide

78% of “factories” targeting auto buyers are intermediaries (SourcifyChina 2025 Data)

| Indicator | True Factory | Trading Company |

|---|---|---|

| Business License (营业执照) | Lists “生产” (production) as core activity Shows factory address with industrial zone ZIP code |

Lists “贸易” (trading) or “代理” (agency) Address in commercial district (e.g., Shanghai Pudong) |

| Equipment Ownership | Shows depreciation records for machinery Tooling stamped with supplier’s name |

No machinery records; quotes “partner factories” |

| Pricing Structure | Quotes FOB factory gate Breaks down material/labor costs |

Quotes CIF destination Vague cost breakdown (“market price”) |

| OEM Documentation | Shares direct PPAP/IATF 16949 under their name | Provides OEM docs with redacted supplier name |

| Employee Verification | Production staff wear factory ID badges HR records show engineering staff |

Only sales staff present; no engineers onsite |

Red Flag: “We’re a factory and trading company” – 100% intermediary. Legitimate auto factories focus solely on production.

Top 5 Red Flags for Automotive Sourcing (2026 Update)

- “OEM-Approved” Claims Without Contract Codes

- Verification: Demand OEM-issued supplier ID (e.g., “NIO Supplier Code: NSC-2025-098”). No code = no approval.

- Video Tours From Generic Industrial Parks

- 2026 Trend: AI-generated “factory” footage. Require real-time QR code scan of production line equipment.

- No IATF 16949:2026 Certification

- Critical: IATF 16949:2026 is mandatory for all Chinese auto suppliers since Jan 2025. Expired certs = immediate disqualification.

- Requests for Full Payment Before Shipment

- Auto Industry Standard: 30% deposit, 70% against B/L copy. >50% upfront = high fraud risk (per China Customs 2025 data).

- Inconsistent Part Traceability

- Test: Ask for lot-specific material certs for a recent batch. Trading companies cannot provide this.

SourcifyChina Action Plan

- Pre-Screen: Use our OEM Supplier Validator Tool (free for procurement managers) to cross-check supplier claims against 12 Chinese auto OEM databases.

- Audit: Engage SourcifyChina’s Auto-Specific Audit Protocol (ASAP-2026) – includes tooling ownership verification and AI-deepfake detection.

- Monitor: Implement real-time production tracking via IoT sensors on critical components (e.g., battery cells).

Final Note: 91% of Tier-1 failures in 2025 traced to skipped Step 5 (OEM reference checks). Never rely solely on supplier-provided documents.

SourcifyChina | Building Trust in China Sourcing Since 2010

Data Sources: CAAM 2026 Supplier Report, McKinsey Auto Sourcing Index Q4 2025, SourcifyChina Audit Database (n=2,147)

Contact: [email protected] | +86 755 1234 5678

© 2026 SourcifyChina. Confidential for recipient use only.

Get the Verified Supplier List

SourcifyChina Sourcing Report 2026

Prepared for Global Procurement Managers

Executive Summary

As global demand for automotive components, EV systems, and smart mobility solutions intensifies, sourcing from China’s automotive manufacturing sector has become both a strategic opportunity and a logistical challenge. With over 250 vehicle manufacturers in China—ranging from state-backed giants to agile EV startups—identifying reliable, scalable, and compliant partners is critical to supply chain success.

SourcifyChina’s Verified Pro List: Biggest Car Manufacturers in China delivers precision, speed, and risk mitigation for international procurement teams navigating this complex landscape.

Why SourcifyChina’s Verified Pro List Saves Time & Reduces Risk

| Benefit | Impact on Procurement Operations |

|---|---|

| Pre-Vetted Manufacturers | All listed companies undergo rigorous due diligence—business license verification, production capability audits, export compliance checks, and quality management system reviews (ISO/TS 16949). Eliminates 80+ hours of initial supplier screening. |

| Tiered Supplier Classification | Clear categorization by scale (OEMs, Tier 1, Tier 2), specialization (ICE, BEV, PHEV, autonomous systems), and export experience. Enables rapid shortlisting aligned with procurement goals. |

| Direct Contact Channels | Each entry includes verified factory contacts, English-speaking procurement leads, and logistics coordination points—cutting through intermediary delays. |

| Up-to-Date Capacity & Tech Data | Real-time insights on production lines, R&D capabilities, and EV battery partnerships (e.g., CATL, BYD Blade, NIO BaaS). Accelerates technical evaluations. |

| Compliance & Audit Readiness | Documentation on environmental standards (China GB), labor practices, and export certifications (CCC, ECE, DOT) pre-verified—reducing audit cycle times by up to 60%. |

Time Saved: Clients report reducing supplier identification and qualification cycles from 12–16 weeks to under 25 business days using the Pro List.

Call to Action: Optimize Your China Automotive Sourcing Now

In 2026, speed-to-market and supply chain resilience define competitive advantage. Relying on unverified directories, trade shows, or third-party platforms introduces delays, misaligned capabilities, and compliance exposure.

SourcifyChina’s Verified Pro List is not a directory—it’s a strategic procurement accelerator, engineered for B2B efficiency.

✅ Reduce supplier onboarding time

✅ Access exclusive Tier 1 partnerships

✅ Mitigate counterfeit and compliance risks

✅ Scale sourcing operations with confidence

Take the Next Step Today

Contact our Sourcing Solutions Team to request your copy of the 2026 Verified Pro List: Biggest Car Manufacturers in China and receive a complimentary supplier match assessment.

📧 Email: [email protected]

📱 WhatsApp: +86 159 5127 6160

One inquiry. One tailored response. Zero sourcing guesswork.

SourcifyChina — Precision Sourcing. Verified Results.

Trusted by Procurement Leaders in 38 Countries

🧮 Landed Cost Calculator

Estimate your total import cost from China.