The global laser marking technology market is experiencing robust growth, driven by increasing demand for permanent, high-precision marking across industrial sectors such as automotive, aerospace, medical devices, and electronics. According to a report by Mordor Intelligence, the laser marking systems market was valued at USD 1.26 billion in 2023 and is projected to grow at a CAGR of over 6.8% from 2024 to 2029. This expansion is fueled by the rising need for traceability, anti-counterfeiting measures, and compliance with regulatory standards in manufacturing. As industrial materials manufacturers seek greater efficiency and durability in product identification, the adoption of advanced laser marking technologies has become a strategic imperative. With a wide array of laser types—ranging from fiber and CO₂ to UV and green lasers—each offering distinct advantages for different materials and applications, selecting the optimal solution is critical. Below, we present the top 10 best laser marking technologies tailored to meet the evolving demands of modern industrial material manufacturing.

Top 10 Best Laser Marking Technologies For Industrial Materials Manufacturers (2026 Audit Report)

(Ranked by Factory Capability & Trust Score)

#1 Industrial Laser Marking & Dot Peen Marking Solutions

Website: telesis.com

Key Highlights: The biggest advancement in laser marking technology from the industry leader: XpressMark™ fiber laser marking systems deliver the ultimate power and meet the ……

#2 Laser Marking for All Industries

Website: lasermarktech.com

Key Highlights: Discover innovative laser marking solutions tailored for various industries. Explore our cutting-edge technology as leaders in laser marking and engraving….

#3 Laserax

Website: laserax.com

Key Highlights: Laserax works with the world’s leading manufacturers to implement laser cleaning, welding, texturing, and marking solutions….

#4 Laser Photonics

Website: laserphotonics.com

Key Highlights: Laser Photonics manufactures reliable, safe, and eco-friendly Laser Cleaning, Laser Cutting, Laser Engraving, Laser Marking, and Laser Welding solutions….

#5 LaserStar Technologies

Website: laserstar.net

Key Highlights: LaserStar Technologies designs and manufactures high-performance laser welding, marking, and cutting systems for industrial, jewelry, ……

#6 MECCO

Website: mecco.com

Key Highlights: Manufacturers rely on MECCO engraving and marking systems to help problem-solve and ensure part traceability. Learn about our products for laser and pin ……

#7 Laser Marking

Website: cermarkusa.com

Key Highlights: Laser marking is a cost-effective and reliable way to mark parts and components with information such as serial numbers, barcodes, logos, and text….

#8 Laser Marking Systems

Website: datalogic.com

Key Highlights: Depending on the materials to mark, there is a wide range of Laser Marking technologies to use: Fiber, DPSS, CO2, UV, Green, among many others….

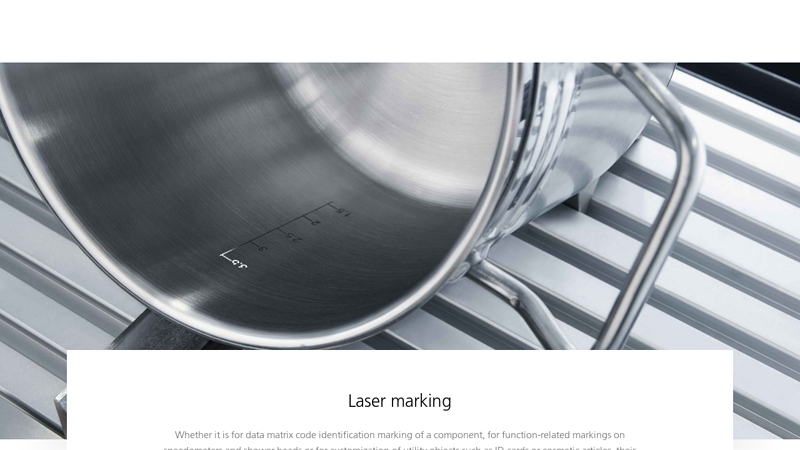

#9 Laser marking

Website: trumpf.com

Key Highlights: Laser marking is a collective term for several marking procedures: ablation, engraving, annealing, black marking, colour change and foaming….

#10 Gravotech

Website: gravotech.us

Key Highlights: Gravotech designs, manufactures, and distributes innovative engraving, marking, and cutting solutions….

Expert Sourcing Insights for Best Laser Marking Technologies For Industrial Materials

H2: Best Laser Marking Technologies for Industrial Materials: 2026 Market Trends

As we approach 2026, the global market for laser marking technologies in industrial applications is undergoing a transformative evolution, driven by advances in manufacturing precision, demand for traceability, and the integration of Industry 4.0 initiatives. The convergence of technological innovation and sustainability goals is reshaping the landscape, favoring high-performance, energy-efficient, and intelligent laser marking systems. Below are the key trends shaping the best laser marking technologies for industrial materials in 2026:

-

Dominance of Fiber Lasers in Industrial Applications

Fiber laser marking systems continue to lead the market, particularly for metals and engineered plastics. Their reliability, low maintenance, and exceptional beam quality make them ideal for high-speed, permanent marking on materials such as stainless steel, aluminum, and titanium. By 2026, fiber lasers are expected to hold over 60% of the industrial laser marking market due to their superior efficiency and adaptability in automated production lines. -

Rise of Ultrafast (Picosecond and Femtosecond) Lasers

Ultrafast lasers are gaining traction in high-precision industries such as aerospace, medical devices, and electronics. These lasers deliver minimal heat-affected zones, enabling clean, micro-scale marking on sensitive or heat-conductive materials. In 2026, adoption is accelerating due to falling costs and improved system integration, making ultrafast lasers more accessible for niche industrial applications requiring micron-level accuracy. -

Integration with Smart Manufacturing and IoT

Laser marking systems are increasingly embedded with IoT capabilities, allowing real-time monitoring, predictive maintenance, and seamless data exchange with MES (Manufacturing Execution Systems) and ERP platforms. Smart laser markers can now automatically adjust parameters based on material type and production conditions, enhancing consistency and reducing waste—key factors in Industry 4.0 environments. -

Growth in Green and UV Lasers for Plastics and Sensitive Materials

For non-metallic industrial materials—including polycarbonates, ABS, and composites—green (532 nm) and UV (355 nm) lasers offer superior contrast and reduced thermal damage. In 2026, demand is rising in the automotive, consumer electronics, and healthcare sectors, where aesthetic quality and regulatory compliance (e.g., UDI marking) are critical. These lasers also support eco-friendly, solvent-free marking processes. -

Advancements in 3D and Dynamic Marking Technologies

Innovations in galvanometer scanning and beam shaping now enable 3D surface marking and real-time variable data engraving (e.g., QR codes, serial numbers). This is particularly valuable in mass customization and traceability applications. By 2026, 3D laser marking will be standard in high-mix manufacturing environments, supported by AI-driven path optimization. -

Sustainability and Energy Efficiency as Market Drivers

With stricter environmental regulations and corporate ESG commitments, manufacturers are prioritizing energy-efficient laser systems. Modern fiber and diode-pumped lasers consume up to 30% less power than older models while maintaining high throughput. Additionally, the elimination of inks and chemicals in laser marking supports sustainable production goals. -

Regional Market Expansion and Automation Demand

Asia-Pacific, particularly China and India, will remain the fastest-growing market due to expanding manufacturing sectors and investments in automation. North America and Europe are focusing on high-value applications in aerospace and medical devices, driving demand for premium laser marking solutions with certification compliance (e.g., FDA, ISO).

Conclusion:

By 2026, the best laser marking technologies for industrial materials will be characterized by precision, intelligence, and sustainability. Fiber lasers will dominate general industrial use, while ultrafast, green, and UV lasers will serve specialized niches. Integration with digital manufacturing ecosystems and adherence to green production standards will define competitive advantage, positioning advanced laser marking as a cornerstone of modern industrial operations.

Common Pitfalls When Sourcing Best Laser Marking Technologies for Industrial Materials (Quality and IP Considerations)

When sourcing laser marking technologies for industrial applications, companies often focus on performance and cost but overlook critical quality and intellectual property (IP) aspects. These oversights can lead to long-term operational inefficiencies, legal risks, and compromised product integrity. Below are common pitfalls to avoid during the sourcing process.

Overlooking Material Compatibility and Marking Quality

One of the most frequent mistakes is assuming that a single laser marking system can handle diverse industrial materials effectively. Different materials—such as metals, plastics, ceramics, and composites—require specific laser wavelengths (fiber, CO₂, UV, etc.) and power settings. Sourcing a system without thorough material testing can result in poor mark contrast, surface damage, or non-permanent markings that fail regulatory or traceability standards.

Ignoring Regulatory and Industry Compliance

Industrial sectors like aerospace, medical devices, and automotive have strict traceability requirements (e.g., UDI, AS9100, ISO 13485). A common pitfall is selecting a laser system that doesn’t support compliant marking formats (e.g., Data Matrix codes with required readability grades). Failing to verify compliance upfront can lead to rejected parts, audit failures, or recalls.

Underestimating System Integration Challenges

Many buyers focus on the laser marker in isolation, neglecting how it integrates into existing production lines. Issues such as communication protocols (EtherNet/IP, PROFINET), automation interfaces, and software compatibility can delay deployment and increase integration costs. Ensuring the laser system supports seamless integration with PLCs and MES platforms is crucial.

Overlooking Software Capabilities and IP Protection

The software controlling the laser marking process often holds proprietary algorithms and user-defined marking templates. A key pitfall is failing to address intellectual property ownership and licensing terms. Some suppliers retain full IP rights over custom-developed marking software, limiting your ability to modify, transfer, or replicate solutions across facilities. Always clarify IP rights in contracts.

Falling for Inadequate Service and Support Structures

High-performance laser systems require routine maintenance, calibration, and technical support. Relying on suppliers with limited local service networks or poor response times can result in extended downtime. Additionally, some vendors restrict access to technical documentation or firmware updates, creating vendor lock-in and compromising long-term operational control.

Neglecting Data Security and Traceability Features

Modern laser marking systems often connect to factory networks, raising cybersecurity concerns. A common oversight is not verifying whether the system supports secure data logging, user authentication, and encrypted communication. Without these, marked data can be tampered with, jeopardizing product traceability and audit readiness.

Assuming All Lasers Offer Equal Longevity and Uptime

Not all laser sources are created equal. Lower-cost systems may use components with shorter lifespans or inconsistent beam quality, leading to frequent downtime and higher total cost of ownership. It’s essential to evaluate Mean Time Between Failures (MTBF), warranty terms, and availability of replacement parts before procurement.

By recognizing and addressing these pitfalls, companies can ensure they select a laser marking solution that delivers consistent quality, complies with industry standards, and protects their intellectual property and operational continuity.

Logistics & Compliance Guide for Best Laser Marking Technologies for Industrial Materials

Selecting the best laser marking technology for industrial materials involves more than just performance—it requires careful consideration of logistics and compliance to ensure safe, efficient, and legally sound operations. This guide outlines key aspects to assess before implementation.

Equipment Sourcing and Supply Chain Logistics

When procuring laser marking systems, evaluate the reliability and location of suppliers. Prioritize vendors with a strong global service network to minimize downtime. Ensure lead times align with production schedules, and confirm whether equipment can be shipped pre-calibrated. Consider modular designs that simplify installation and relocation across facilities. Also, plan for spare parts inventory, especially for optical components and cooling systems, to reduce maintenance delays.

Installation and Facility Requirements

Laser marking systems have specific infrastructure needs. Verify power supply compatibility (voltage, phase, amperage), especially for high-power fiber or CO₂ lasers. Ensure adequate ventilation or extraction systems are in place to manage fumes generated during marking—this is critical for compliance with indoor air quality standards. Allocate sufficient floor space with vibration-free surfaces, and confirm environmental conditions (temperature, humidity) meet manufacturer specifications to maintain marking precision.

Safety Compliance and Regulatory Standards

Laser systems are classified under international safety standards (e.g., IEC 60825-1). Ensure the equipment carries appropriate laser safety classifications (typically Class 1 when enclosed). Implement engineering controls such as interlocks, emergency stop buttons, and protective enclosures. Provide proper training for operators on laser safety (ANSI Z136.1 in the U.S.) and adhere to local occupational health regulations. Use appropriate personal protective equipment (PPE), such as laser safety goggles when maintenance requires exposure to open beams.

Environmental and Waste Management Compliance

Laser marking may produce particulate matter or gaseous byproducts, especially when marking plastics or coated metals. Install certified fume extraction and filtration systems compliant with EPA (U.S.), REACH (EU), or other regional environmental regulations. Properly dispose of filtered residues as hazardous waste if required. Monitor emissions to ensure compliance with permissible exposure limits (PELs) for airborne contaminants.

Industry-Specific Regulatory Alignment

Different industries impose strict traceability and permanency requirements. For example:

– Medical Devices: Must comply with UDI (Unique Device Identification) per FDA 21 CFR Part 801 and EU MDR, requiring permanent, machine-readable marks.

– Aerospace: Adheres to AS9100 and NADCAP standards, where marking depth, contrast, and material integrity are rigorously inspected.

– Automotive: Requires compliance with AIAG standards for part traceability; laser marks must withstand harsh environments without degradation.

Ensure the selected laser technology (fiber, UV, green, or pulsed YAG) produces marks that meet these industry-specific durability and readability benchmarks.

Documentation and Traceability

Maintain detailed records of laser system calibration, maintenance logs, operator training, and compliance certifications. Implement integrated software that supports audit trails and digital traceability (e.g., marking QR codes linked to production databases). This supports ISO 9001, IATF 16949, and other quality management system requirements.

International Shipping and Import Regulations

When deploying laser systems across borders, verify compliance with international shipping regulations for electronic and laser equipment. Some countries require import permits or certifications (e.g., CE, FCC, RoHS). Be aware that high-powered lasers may be subject to export controls under regimes like the Wassenaar Arrangement.

By addressing these logistics and compliance factors early, manufacturers can ensure seamless integration of laser marking technologies while maintaining safety, regulatory adherence, and operational efficiency across global industrial applications.

Conclusion: Sourcing the Best Laser Marking Technologies for Industrial Materials

Selecting the best laser marking technology for industrial materials requires a strategic evaluation of material type, application requirements, production environment, and long-term operational goals. Fiber lasers remain the dominant choice for marking metals and certain engineered plastics due to their durability, precision, low maintenance, and excellent contrast marking capabilities. For organic materials, such as wood, leather, and some plastics, CO₂ lasers offer superior performance and cost-efficiency. UV lasers are ideal for high-precision, non-thermal marking on sensitive or reflective materials, including medical devices and electronics, where minimal heat impact is critical.

When sourcing laser marking systems, key factors to consider include laser wavelength, power output, marking speed, system integration capabilities, software compatibility, and compliance with industry regulations (e.g., UDI in healthcare or traceability standards in aerospace). Additionally, scalability, service support, and total cost of ownership should guide decision-making to ensure long-term reliability and return on investment.

Ultimately, the optimal laser marking solution is one that aligns with specific material and production needs while offering flexibility for future advancements. Partnering with reputable suppliers who provide technical expertise, customization options, and ongoing support will ensure successful implementation and sustained performance in demanding industrial environments. As manufacturing continues to evolve with Industry 4.0 and digital traceability demands, investing in the right laser marking technology today positions businesses for greater efficiency, compliance, and competitiveness tomorrow.