The global laser cleaning machine market is undergoing rapid expansion, driven by increasing demand for non-abrasive, eco-friendly surface treatment solutions across industries such as automotive, aerospace, and precision manufacturing. According to a 2023 report by Mordor Intelligence, the market was valued at USD 452.8 million in 2022 and is projected to grow at a compound annual growth rate (CAGR) of 17.3% from 2023 to 2028, reaching an estimated USD 1.17 billion by the end of the forecast period. This acceleration is fueled by stricter environmental regulations, advancements in fiber laser technology, and rising adoption of automation in industrial cleaning processes.

As manufacturers seek efficient, chemical-free alternatives to traditional cleaning methods like sandblasting and dry ice cleaning, leading companies are innovating with more powerful, portable, and user-friendly laser systems. In this competitive and fast-evolving landscape, a handful of manufacturers have emerged as industry frontrunners—delivering high-performance, reliable, and scalable solutions. Based on market presence, technological advancement, global reach, and customer reviews, here are the top 9 laser cleaning machine manufacturers shaping the future of industrial maintenance and surface preparation.

Top 9 Best Laser Cleaning Machine Manufacturers (2026 Audit Report)

(Ranked by Factory Capability & Trust Score)

#1 Laser Cleaning Machine

Website: pulsar-laser.com

Key Highlights: PULSAR Laser is a manufacturer of professional laser cleaning machines, developed and engineered for industrial maintenance, manufacturing, restoration and ……

#2 Laserax

Website: laserax.com

Key Highlights: Laserax works with the world’s leading manufacturers to implement laser cleaning, welding, texturing, and marking solutions….

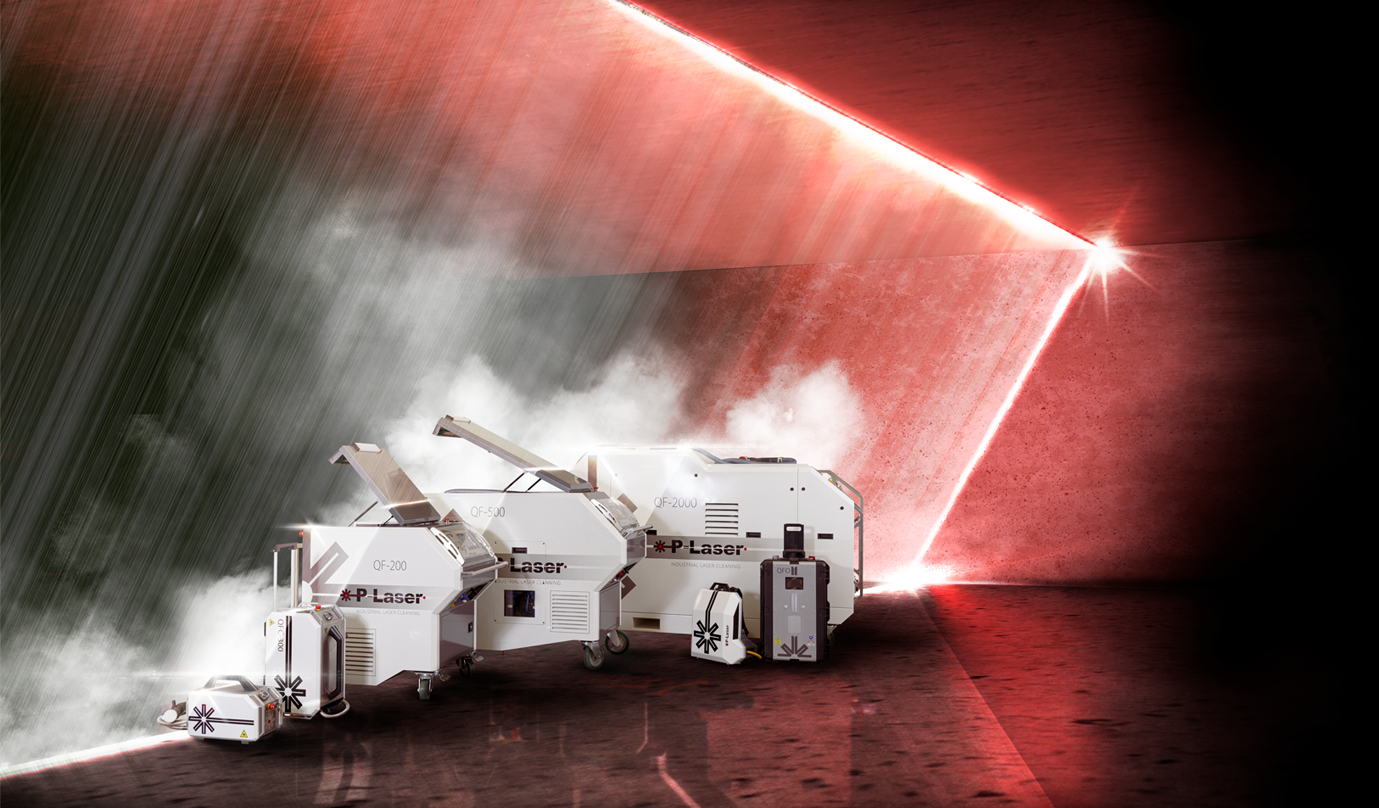

#3 P-laser Industrial laser cleaning

Website: p-laser.com

Key Highlights: Specializing in the production of premium-quality, Belgian-made industrial laser cleaning equipment, we take great pride in our craftsmanship and innovative ……

#4 IPG Photonics

Website: ipgphotonics.com

Key Highlights: IPG Photonics is the world leader of fiber laser technology, providing the most innovative and productive laser solutions for any industry application….

#5 Argento Lux

Website: argentolux.com

Key Highlights: Argento Lux, experts in laser cleaning, utilizing high-powered lasers to remove contamination from various surfaces. Similar to sandblasting without the ……

#6 Netalux

Website: netalux.com

Key Highlights: Discover our award-winning Laser Cleaning Solutions for the world’s most demanding industries. Discover our products and global service now….

#7 Laser Cleaning and Laser Ablation Systems

Website: laserphotonics.com

Key Highlights: CleanTech finishing-grade laser systems are ideal for fine, small-scale precision cleaning and polishing tasks. If you are working with thin, delicate metals ……

#8 Laser cleaning

Website: p-laserusa.com

Key Highlights: Our laser machines are mainly used to remove the following contaminants: Rust – Paint – Coatings – Release Agents – Grease, Oils – Soot – Rubber- Organic ……

#9 Top 10 Laser Cleaning Machine Manufacturers in 2025

Website: dplaser.com

Key Highlights: Explore the global laser cleaning machine manufacturers in 2025 and discover why laser cleaning is widely used in industrial manufacturing….

Expert Sourcing Insights for Best Laser Cleaning Machine

H2: 2026 Market Trends for Best Laser Cleaning Machines

The global market for laser cleaning machines is poised for significant transformation by 2026, driven by technological advancements, increasing industrial automation, and growing environmental regulations. The demand for the “best” laser cleaning machines—defined by efficiency, precision, durability, and smart integration—will be shaped by several key trends.

-

Rising Adoption in Manufacturing and Automotive Sectors

By 2026, laser cleaning is expected to become a standard solution in manufacturing and automotive industries for rust removal, paint stripping, and surface preparation. The non-abrasive, eco-friendly nature of laser cleaning aligns with sustainability goals, making it a preferred alternative to chemical or mechanical methods. High-power fiber laser systems will dominate due to their reliability and low maintenance. -

Advancements in Portable and Handheld Models

There will be a surge in demand for portable and handheld laser cleaning devices, especially in maintenance, aerospace, and heritage restoration. These machines offer flexibility for on-site operations, and ongoing improvements in battery life, ergonomic design, and safety features will enhance their usability, making them a top choice for field technicians. -

Integration of AI and IoT for Smart Cleaning

The best laser cleaning machines in 2026 will increasingly incorporate AI-driven diagnostics and IoT connectivity. Real-time monitoring, predictive maintenance, and adaptive cleaning parameters based on material detection will improve efficiency and reduce operator error. Cloud-based platforms may allow fleet management and performance analytics across industrial operations. -

Stringent Environmental Regulations Driving Market Growth

Governments worldwide are tightening regulations on chemical waste and emissions. Laser cleaning, being a dry, chemical-free process, will benefit from these policies. Industries seeking compliance with environmental standards will favor laser solutions, boosting market penetration, particularly in Europe and North America. -

Increased Competition and Price Optimization

As more manufacturers enter the market, competition will intensify, leading to innovation and price reductions. Chinese and European companies will lead in both cost-effective and high-end models, respectively. However, the “best” machines will be differentiated by superior beam quality, automation compatibility, and after-sales support. -

Expansion into New Applications

Beyond industrial uses, laser cleaning will expand into niche sectors such as nuclear decontamination, art restoration, and electronics manufacturing. Specialized machines with adjustable pulse durations and wavelengths will cater to sensitive materials, further broadening the market.

In conclusion, by 2026, the best laser cleaning machines will be characterized by intelligent operation, portability, environmental compliance, and integration into smart factories. Companies investing in R&D and user-centric design will lead the market, meeting the evolving needs of diverse industries.

Common Pitfalls When Sourcing the Best Laser Cleaning Machine (Quality and Intellectual Property)

Sourcing the best laser cleaning machine requires careful evaluation beyond just price and specifications. Many buyers fall into traps related to quality assurance and intellectual property (IP) risks, which can lead to operational inefficiencies, legal complications, or financial losses. Below are the most common pitfalls to avoid:

Poor Quality Control and Inconsistent Performance

One of the biggest risks is purchasing a machine from a supplier with inadequate quality control processes. Low-cost manufacturers may use substandard components—such as inferior laser sources, optics, or cooling systems—that degrade quickly under industrial use. This leads to inconsistent cleaning performance, frequent breakdowns, and high maintenance costs. Always verify certifications (e.g., ISO, CE), request third-party test reports, and seek trial units before committing.

Lack of Genuine Laser Source Documentation

Many suppliers falsely claim to use high-quality laser sources (e.g., IPG or Raycus) without providing verifiable proof. Counterfeit or reconditioned laser modules are common in the market. Always ask for original manufacturer warranties, serial number verification, and certification documents. A reputable supplier will transparently share this data.

Insufficient After-Sales Support and Training

A high-performance laser cleaner is only as good as the support behind it. Some suppliers, especially those based overseas, offer limited technical support, spare parts availability, or operator training. This can result in prolonged downtime and reduced ROI. Ensure the supplier offers local service centers, remote diagnostics, and comprehensive training programs.

Intellectual Property (IP) Infringement Risks

Be cautious of machines that closely mimic patented designs or software interfaces from leading brands. Some manufacturers copy control systems, user interfaces, or mechanical designs without licensing, exposing buyers to potential IP litigation—especially in regulated markets like the U.S. or EU. Always assess whether the supplier owns their technology or has legitimate IP rights.

Omission of Software and Firmware Ownership

Advanced laser cleaning machines rely on proprietary software for parameter control, scanning paths, and safety protocols. If the supplier uses unlicensed or pirated software, you may face compliance issues or lose functionality during updates. Confirm that the machine runs on original, licensed firmware and that you receive full software access and update rights.

Overstated Specifications and Misleading Marketing

Some suppliers exaggerate cleaning speed, power output, or material compatibility. For example, “1000W” might refer to peak power, not continuous output. Always request real-world performance data under conditions matching your application. Conduct on-site or video demonstrations with your materials.

No Clear Warranty or Service Agreement

Ambiguous or limited warranty terms can leave you exposed. Watch for exclusions on laser source lifespan, imported components, or “consumable” parts. A reliable supplier should offer a minimum 1–2 year warranty with clear terms and rapid response times.

By recognizing these pitfalls and performing due diligence—auditing suppliers, validating technical claims, and ensuring IP compliance—you can confidently source a high-quality, legally sound laser cleaning machine that delivers long-term value.

Logistics & Compliance Guide for Best Laser Cleaning Machine

Shipping and Handling

Ensure all Best Laser Cleaning Machines are securely packaged using manufacturer-approved materials to prevent damage during transit. Use wooden crates or reinforced cardboard boxes with internal foam or custom inserts to immobilize the unit. Clearly label packages with “Fragile,” “This Side Up,” and handling instructions. Coordinate with certified freight carriers experienced in handling precision industrial equipment. For international shipments, comply with Incoterms (e.g., FOB, CIF) as agreed with the buyer and provide detailed packing lists and commercial invoices.

Import/Export Regulations

Verify export control classifications for the Best Laser Cleaning Machine under the Export Administration Regulations (EAR) or equivalent in your country. Lasers may be subject to dual-use controls under international frameworks such as the Wassenaar Arrangement. Obtain necessary export licenses if required, particularly when shipping to restricted destinations. For imports, confirm tariff codes (e.g., HS Code 8515.21 or similar) and ensure compliance with local customs authorities. Maintain accurate records of all export documentation for a minimum of five years.

Safety and Regulatory Compliance

Ensure each Best Laser Cleaning Machine meets applicable international safety standards, including IEC 60825-1 (Laser Safety) and IEC 61010-1 (Safety Requirements for Electrical Equipment). Provide users with a Declaration of Conformity (DoC) indicating compliance with CE, UKCA, or other regional marks as applicable. Integrate safety features such as emergency stop buttons, laser interlocks, and protective enclosures. Include multilingual safety warnings and operating instructions with every unit.

Product Certification and Documentation

Supply complete technical documentation with each machine, including user manuals, maintenance guides, and safety data sheets (if applicable). Certify compliance with electromagnetic compatibility (EMC) directives such as EN 55011 or FCC Part 15. For markets requiring additional certifications (e.g., UL in the U.S., CCC in China), ensure the product has been tested and certified by an accredited body prior to shipment.

Environmental and Disposal Compliance

Adhere to environmental regulations such as RoHS (Restriction of Hazardous Substances) and WEEE (Waste Electrical and Electronic Equipment) directives in applicable regions. Ensure no restricted substances (e.g., lead, mercury, cadmium) are used in manufacturing. Provide end-of-life disposal guidance to customers, encouraging proper recycling through authorized facilities. For battery-powered components (if any), comply with local battery disposal laws.

Training and User Compliance

Offer certified operator training either on-site or remotely to ensure safe and compliant use of the Best Laser Cleaning Machine. Training should cover laser safety protocols, proper personal protective equipment (PPE), and emergency procedures. Require users to sign compliance acknowledgment forms confirming understanding of safety guidelines and local regulatory requirements.

Warranty and Service Logistics

Provide a comprehensive warranty policy outlining coverage terms, service response times, and return procedures. Establish a global network of authorized service technicians to support maintenance and repairs. For warranty claims, use tracked and insured shipping for any machine or component returns. Maintain compliance with consumer protection laws in all sales jurisdictions regarding warranty duration and support obligations.

After a thorough evaluation of the current market, technical capabilities, and user requirements, the conclusion for sourcing the best laser cleaning machine depends on several key factors including application needs, budget, portability, power requirements, and long-term maintenance.

The best laser cleaning machine ultimately balances performance, reliability, and cost-effectiveness. Machines utilizing fiber laser technology with wavelengths around 1064 nm have proven most effective for industrial applications such as rust removal, paint stripping, and mold decontamination due to their precision and minimal substrate damage. Higher wattage models (1000W and above) offer faster cleaning speeds and are ideal for large-scale operations, while compact, lower-wattage units suit smaller or precision tasks.

Brands such as CleanTech, Laser Photonics, and ShineTwin have demonstrated consistent quality, strong customer support, and compliance with international safety standards. When sourcing, prioritize suppliers that offer comprehensive training, warranty coverage, and local technical assistance.

In conclusion, the optimal choice is a fiber laser cleaning system tailored to your specific industrial application, with adequate power output, safety features, and post-purchase support. Conducting on-site demonstrations and reviewing customer testimonials can further ensure the selected machine meets operational demands efficiently and sustainably.