The global bentonite market is experiencing steady expansion, driven by rising demand across industries such as foundry, drilling, cat litter, and environmental engineering. According to a report by Mordor Intelligence, the global bentonite market was valued at USD 2.45 billion in 2023 and is projected to grow at a CAGR of over 4.5% from 2024 to 2029. This growth is largely fueled by the increasing use of bentonite granules in pet care products—particularly clumping cat litter—alongside their critical role in oil & gas drilling operations and waste containment systems. As demand for high-quality, consistent granular bentonite rises, a select group of manufacturers have emerged as leaders in production capacity, technological innovation, and global distribution. These top eight companies are shaping the industry through advanced processing techniques, sustainable sourcing, and strategic partnerships, positioning themselves at the forefront of a tightening supply chain landscape.

Top 8 Bentonite Granules Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 Wyo-Ben

Domain Est. 1996 | Founded: 1951

Website: wyoben.com

Key Highlights: Wyo-Ben has been in business since 1951, and is a leading producer of Wyoming Bentonite Clay based products. Our materials are used globally….

#2 Products

Domain Est. 1998

Website: bhbentonite.com

Key Highlights: Black Hills Bentonite has processed high-quality Wyoming Sodium Bentonite for a diverse range of industrial and commercial applications….

#3 Bentonite Manufacturer, Bentonite Exporter & Bentonite Supplier …

Domain Est. 2018

Website: kutchbentoclay.com

Key Highlights: Discover high-quality Bentonite products with A Trusted and Globally recognised company – Kutch Bentoclay, Bentonite manufacturer, Bentonite Exporter ……

#4 Bentonite Performance Minerals

Domain Est. 1996

Website: bentonite.com

Key Highlights: An integrated Wyoming sodium bentonite company. Collaborating with our customers for over 90 years. Leave it better than we find it….

#5 Bentonite

Domain Est. 1999

Website: imerys.com

Key Highlights: Bentonite is a highly absorbent, viscous plastic clay which is a valuable binding, sealing, absorbing and lubricating agent in a huge variety of industries ……

#6 Texas Sodium Bentonite

Domain Est. 2000

Website: texassodiumbentonite.com

Key Highlights: We are a sodium bentonite supplier providing premium materials for a variety of industries. Buy our sodium bentonite in bulk at competitive prices….

#7 Bentonite

Domain Est. 2008 | Founded: 1971

Website: teaguemineralproducts.com

Key Highlights: Teague Mineral Products has specialized in producing premium sealant grade sodium bentonite for a variety of projects requiring impermeable barriers since 1971….

#8 Lonestar Minerals

Domain Est. 2012

Website: lonestarbarite.com

Key Highlights: We supply high quality bentonite for Pond sealing, wastewater treatment, cat litter and drilling mud wherever you need it in the United States….

Expert Sourcing Insights for Bentonite Granules

H2: 2026 Market Trends for Bentonite Granules

The global bentonite granules market is poised for steady growth by 2026, driven by increasing demand across key industrial sectors and technological advancements in processing and application methods. Below are the major trends shaping the bentonite granules market in 2026:

-

Rising Demand in Foundry and Metallurgy Applications

Bentonite granules remain a critical binder in green sand molding processes within the foundry industry. As global manufacturing and automotive production rebound, especially in Asia-Pacific and emerging economies, demand for high-performance bentonite granules is expected to rise. Foundries are increasingly prioritizing consistent quality and thermal stability, favoring premium-grade sodium bentonite granules. -

Growth in Environmental and Waste Management Uses

Environmental regulations are driving the use of bentonite granules in landfill liners, containment systems, and slurry walls due to their exceptional swelling and impermeability properties. With heightened focus on sustainable waste management and groundwater protection, bentonite granules are being adopted in engineered barrier systems, supporting market expansion in North America and Europe. -

Expansion in Construction and Civil Engineering

The construction sector is increasingly utilizing bentonite granules for trench sealing, tunneling, and soil stabilization. Major infrastructure projects, especially in India, China, and the Middle East, are contributing to higher consumption. Innovations in bentonite-based geosynthetic clay liners (GCLs) are further boosting adoption in civil engineering applications. -

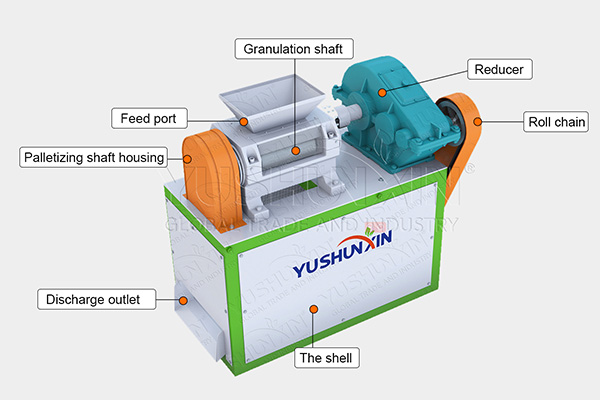

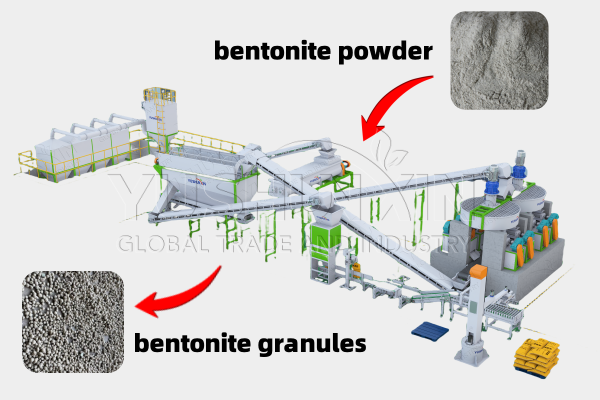

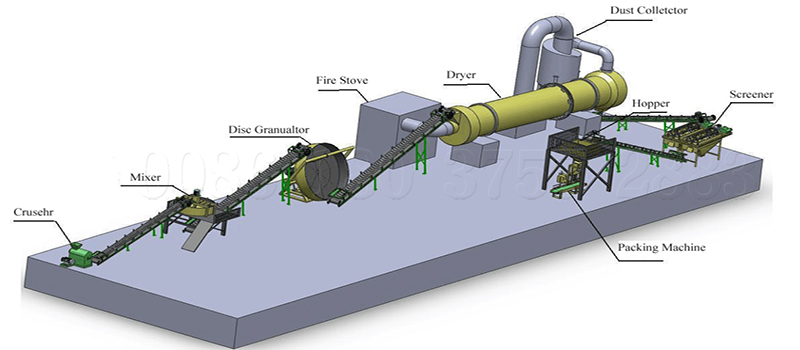

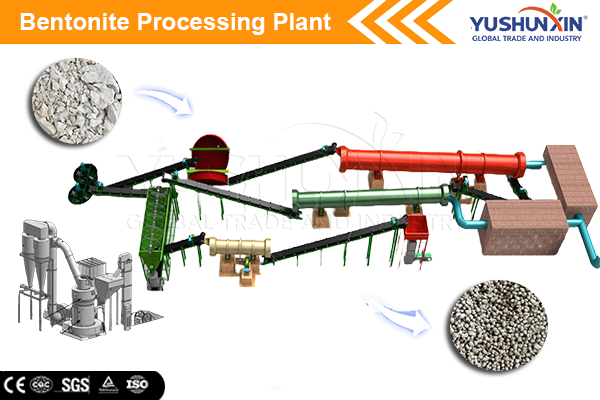

Advancements in Pelletizing and Granulation Technology

Manufacturers are investing in advanced granulation techniques to improve the handling, flowability, and performance of bentonite granules. Improved dust control and consistent granule size enhance usability in automated industrial processes, making the product more attractive to large-scale end users. -

Sustainability and Circular Economy Initiatives

There is a growing trend toward sustainable sourcing and processing of bentonite. Producers are adopting eco-friendly mining practices and exploring recycling of spent foundry sand containing bentonite. These initiatives align with corporate sustainability goals and regulatory frameworks, enhancing the long-term viability of bentonite granule applications. -

Regional Market Shifts

Asia-Pacific remains the largest and fastest-growing market due to strong industrial activity in China, India, and Southeast Asia. Meanwhile, North America and Europe are focusing on high-value specialty grades for environmental and petrochemical applications. Latin America and Africa show emerging potential, driven by infrastructure development and mining activities. -

Price Volatility and Supply Chain Resilience

Geopolitical factors, energy costs, and transportation logistics continue to influence bentonite pricing. Leading suppliers are diversifying mining operations and enhancing supply chain resilience to mitigate disruptions, ensuring consistent supply to key markets.

In conclusion, the 2026 bentonite granules market reflects a convergence of industrial demand, environmental compliance, and technological innovation. Companies that invest in product quality, sustainability, and application-specific formulations are likely to gain a competitive edge in this evolving landscape.

Common Pitfalls When Sourcing Bentonite Granules (Quality, IP)

Sourcing high-quality bentonite granules while protecting intellectual property (IP) involves navigating several potential pitfalls. Being aware of these challenges is crucial for ensuring product performance, regulatory compliance, and safeguarding proprietary formulations or processes.

Inadequate Quality Control and Specification Misalignment

One of the most frequent issues is sourcing bentonite granules that fail to meet the required technical specifications. Buyers may assume all bentonite granules are equivalent, but performance varies significantly based on the bentonite source (sodium vs. calcium montmorillonite), granule size distribution, moisture content, swelling capacity, viscosity, and purity. Suppliers may provide generic or outdated certificates of analysis (CoA), or worse—falsify documentation. Without rigorous incoming quality testing or clear, enforceable specifications in contracts, companies risk receiving substandard material that underperforms in applications such as foundry molds, cat litter, or drilling fluids.

Lack of Supply Chain Transparency and Raw Material Traceability

Many suppliers source bentonite from multiple mines or blend materials inconsistently, leading to batch-to-batch variability. Without transparent supply chains and verifiable traceability, it becomes difficult to ensure consistent quality or meet regulatory requirements (e.g., REACH, FDA). This opacity also increases the risk of unintentional contamination or sourcing from environmentally or ethically questionable operations, which can damage brand reputation.

Intellectual Property Exposure During Supplier Qualification

During the sourcing process—especially in technical evaluations, sampling, or joint development—buyers may inadvertently disclose proprietary formulations, application methods, or performance requirements. Suppliers could misuse this information to reverse-engineer products or offer similar solutions to competitors. Without robust non-disclosure agreements (NDAs) and controlled communication protocols, companies risk significant IP leakage.

Inadequate IP Clauses in Supply Agreements

Standard procurement contracts often lack specific clauses to protect IP related to custom formulations or co-developed products. For instance, ownership of improvements, limitations on supplier use of buyer data, and restrictions on reverse engineering may not be clearly defined. This ambiguity can lead to disputes over IP rights, especially if the supplier begins marketing a similar product.

Counterfeit or Adulterated Materials

The bentonite market is susceptible to adulteration, where lower-grade materials or fillers are mixed with genuine bentonite to cut costs. Without independent third-party testing or supplier audits, buyers may receive granules with diluted active content, impacting functionality and reliability. This is particularly problematic in industries where performance consistency is critical.

Overlooking Regulatory and Compliance Risks

Bentonite granules used in food-contact, pharmaceutical, or cosmetic applications must comply with strict regulatory standards. Sourcing from suppliers lacking proper certifications (e.g., ISO, FDA registration, FSSC 22000) or who cannot provide full material disclosures increases compliance risk. This may result in product recalls, legal liabilities, or market access issues.

Insufficient Due Diligence on Supplier Capabilities

Companies may select suppliers based solely on price or availability, neglecting to assess their manufacturing capabilities, quality management systems, or scalability. A supplier unable to maintain consistent granulation processes or scale production may cause supply disruptions or quality drift, especially under increased demand.

Conclusion

To mitigate these pitfalls, buyers should implement a structured sourcing strategy that includes detailed technical specifications, robust supplier audits, enforceable IP protections, and ongoing quality monitoring. Prioritizing partnerships with transparent, certified suppliers and maintaining strong contractual safeguards ensures both material performance and IP security.

Logistics & Compliance Guide for Bentonite Granules

Overview of Bentonite Granules

Bentonite granules are a processed form of natural clay, primarily composed of montmorillonite, used across various industries including foundry operations, pet care (cat litter), drilling, construction, and environmental remediation. Due to their absorbent properties and regulatory implications, proper logistics and compliance measures are essential for safe and legal transportation and handling.

Classification & Regulatory Status

Bentonite granules are generally considered non-hazardous under international and national transport regulations. According to the UN Model Regulations (UN 3082, ENVIRONMENTALLY HAZARDOUS SUBSTANCE, SOLID, N.O.S., Class 9 – only if it meets criteria), bentonite typically does not require hazardous classification unless contaminated or specifically formulated with regulated additives. Always verify with a Safety Data Sheet (SDS) to confirm classification.

Packaging Requirements

Bentonite granules are commonly shipped in:

– Multi-wall paper bags (e.g., 25 kg or 50 lb)

– Flexible intermediate bulk containers (FIBCs or “big bags”) – typically 500–1000 kg

– Bulk tankers or railcars for large-volume shipments

Packaging must be moisture-resistant to prevent caking and maintain granule integrity. Closure mechanisms must ensure dust containment during transit. Export shipments must comply with ISPM 15 standards if wooden pallets are used.

Transportation & Shipping

- Domestic (e.g., U.S. DOT): Regulated under 49 CFR; generally exempt from hazardous material requirements when classified as non-hazardous. Proper labeling with product name, net weight, and handling instructions (e.g., “Keep Dry”) is recommended.

- International (IMDG, IATA, ADR): When shipped by sea, air, or road, ensure compliance with mode-specific regulations. Non-hazardous bentonite granules usually do not require dangerous goods declarations, but documentation such as commercial invoices, packing lists, and SDS must accompany shipments.

- Bulk Transport: Use covered hopper trucks, railcars, or containerized bulk systems to prevent moisture ingress and dust emission.

Storage & Handling

- Store in a dry, well-ventilated area away from moisture and direct weather exposure.

- Elevate bags or FIBCs off the ground using pallets to prevent water absorption.

- Minimize dust generation during handling; use local exhaust ventilation if processing in enclosed areas.

- Follow OSHA (or equivalent) guidelines regarding respirable dust exposure limits.

Environmental & Safety Compliance

- SDS Compliance: Maintain a current Safety Data Sheet compliant with GHS (Globally Harmonized System) and regional regulations (e.g., OSHA HazCom 2012 in the U.S., CLP in the EU).

- REACH (EU): Bentonite is listed in the EINECS inventory (215-907-7). No registration obligation for natural, unprocessed bentonite; granulated forms may require evaluation depending on additives.

- TSCA (U.S.): Bentonite is listed on the TSCA Inventory and generally compliant when used as intended.

- Environmental Disposal: Non-hazardous waste classification typically applies; dispose of per local solid waste regulations. Avoid releasing large quantities into waterways due to sedimentation concerns.

Import/Export Documentation

Key documents for international trade include:

– Commercial Invoice

– Packing List

– Bill of Lading or Air Waybill

– Certificate of Origin (if required for tariff eligibility)

– Safety Data Sheet (SDS)

– Phytosanitary Certificate (only if required by destination country, though rare for bentonite)

Verify import requirements with the destination country, as some may impose additional restrictions or labeling rules.

Quality Assurance & Traceability

Maintain batch records and quality test reports (e.g., moisture content, granule size, swelling capacity). Implement traceability systems to support compliance with customer specifications and regulatory audits.

Summary & Best Practices

- Confirm non-hazardous status with up-to-date SDS.

- Use sealed, moisture-resistant packaging suitable for transport mode.

- Comply with transport regulations (DOT, IMDG, IATA, ADR) based on shipment type.

- Store in dry conditions; control dust during handling.

- Maintain complete documentation for customs and compliance audits.

- Monitor regulatory updates in target markets, especially for environmental or industrial use restrictions.

Adhering to this guide ensures safe, efficient, and compliant logistics management of bentonite granules across global supply chains.

Conclusion for Sourcing Bentonite Granules:

In conclusion, sourcing bentonite granules requires a strategic approach that balances quality, cost, reliability, and sustainability. After evaluating various suppliers, conducting technical assessments, and considering logistical factors, it is evident that selecting the right supplier involves more than just competitive pricing. Critical factors such as consistent product quality (including swelling capacity, purity, and granule size), regulatory compliance, supply chain reliability, and strong environmental and ethical practices play a vital role in long-term success.

Establishing partnerships with reputable suppliers—preferably those with certifications, proven track records, and technical support—ensures the consistent performance of bentonite granules in intended applications, whether in drilling, foundry, construction, or environmental projects. Additionally, building strong supplier relationships, considering geographic proximity to reduce lead times and transportation costs, and maintaining a contingency plan for supply chain disruptions can enhance operational resilience.

Ultimately, a well-structured sourcing strategy for bentonite granules not only supports operational efficiency and product performance but also contributes to overall cost savings and sustainability goals. Continuous monitoring, periodic supplier reassessments, and staying informed about market trends will further optimize procurement outcomes in the evolving industrial landscape.